Food processor

A food processing machine and food technology, applied in the direction of household machinery for filtering food, beverage preparation devices, household appliances, etc., can solve the problems of increased volume, increased cost, and inconvenient collection, etc., to achieve convenient transportation and increased volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

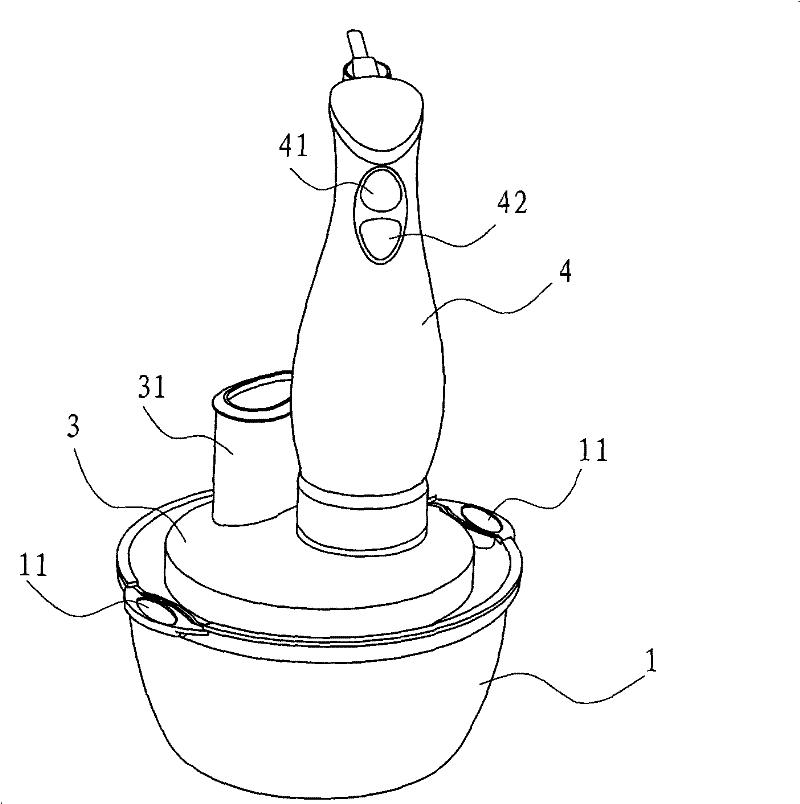

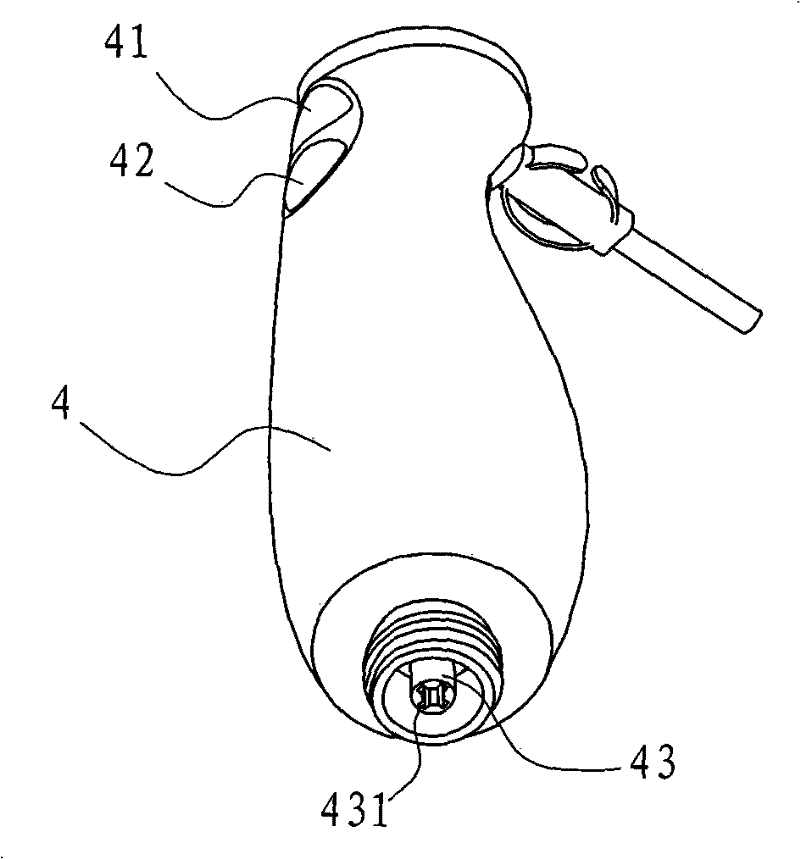

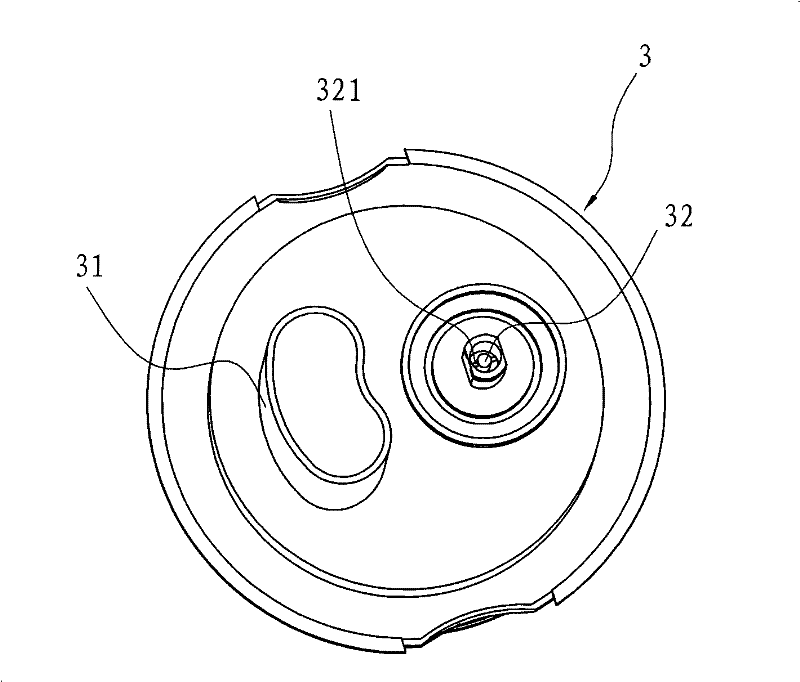

[0033] like Figure 1~1 The food processor shown in 2 includes an outer cup body 1 with an opening at the top, an inner cup body 2 with an opening at the top arranged inside the outer cup body 1, and a cup cover 3 that can be buckled and mounted on the mouth of the outer cup body 1 , the handle 4 of the built-in motor, and the food feed pipe 31 that is arranged on the cup cover 3, the bottom of the food feed pipe 31 is the food feed port 37 that is opened on the cup cover 3, and the food feed pipe 31 is provided with a food propelling member 38, which is used to mash the inner cutter head 5 and the outer cutter head 6 of the food. The outer cup body 1 and the inner cup body 2 are both made of transparent material into a conventional barrel shape, and of course other materials can also be used to make other shapes. In order to facilitate holdi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com