Pre-articulated handsaw with screw-and-nut fastening structure

A tie-rod nut and articulation technology, applied in hacksaws, step-down saws, sawing machines, etc., can solve the problems of complex structure and inability to tension the saw blade, and achieve the effect of maintaining elastic tension, convenient loading and unloading, and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

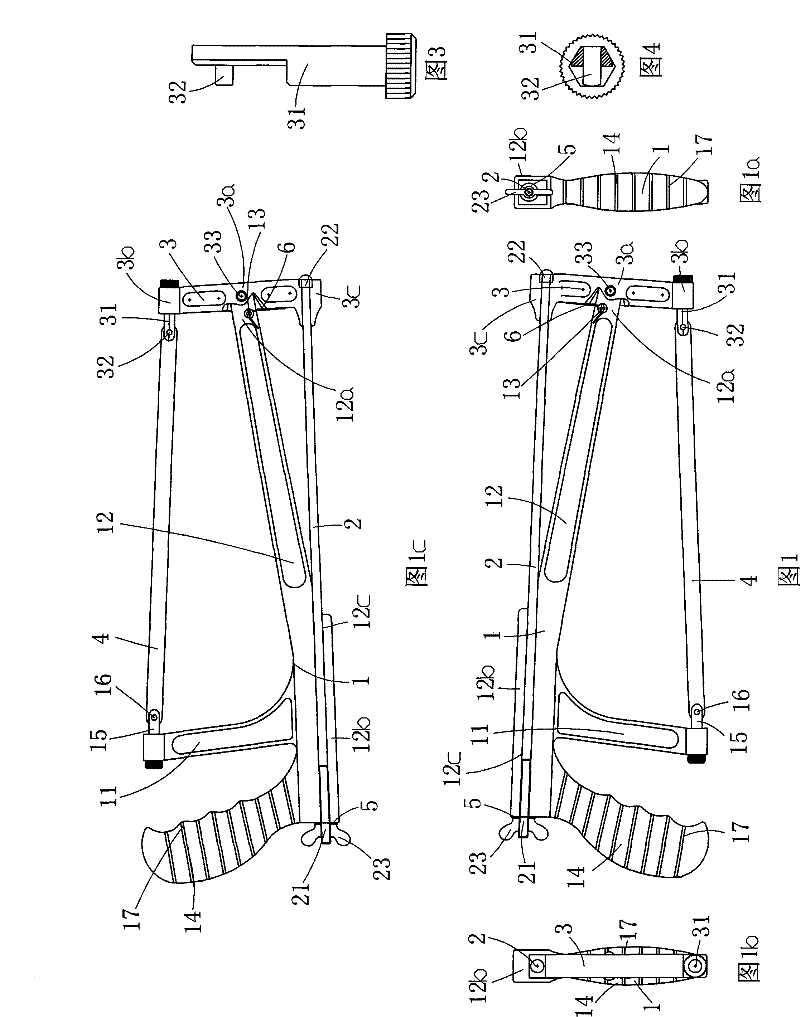

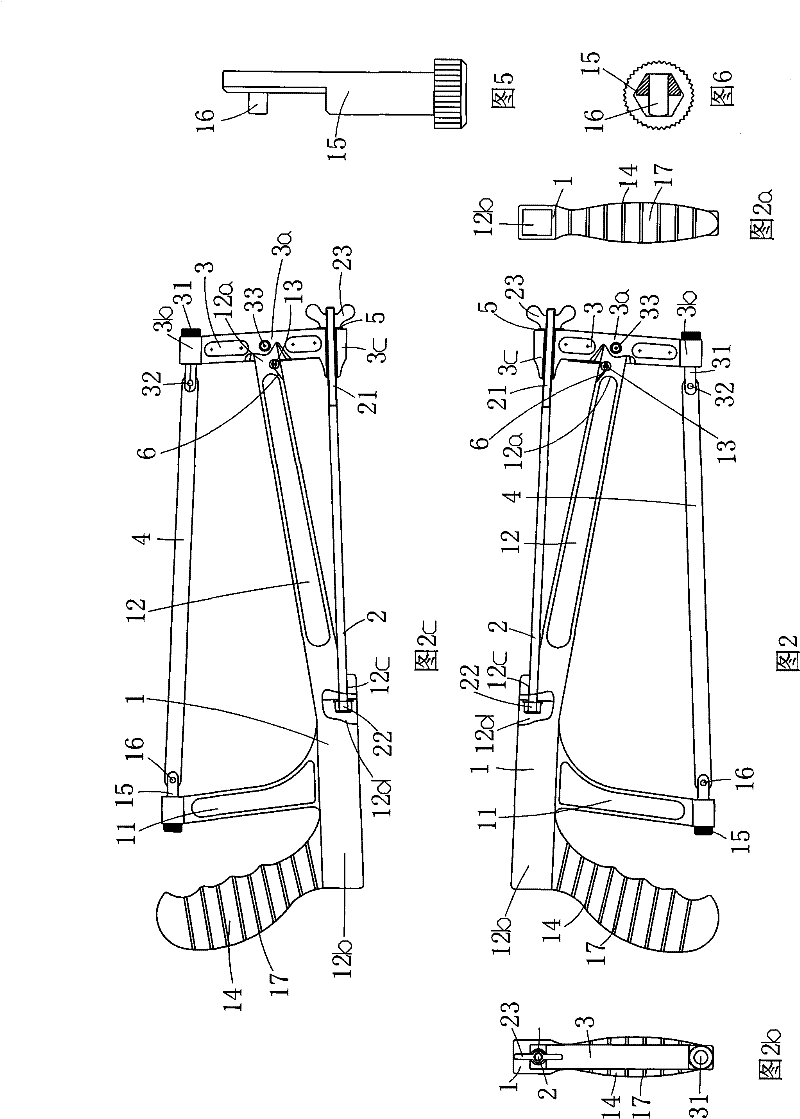

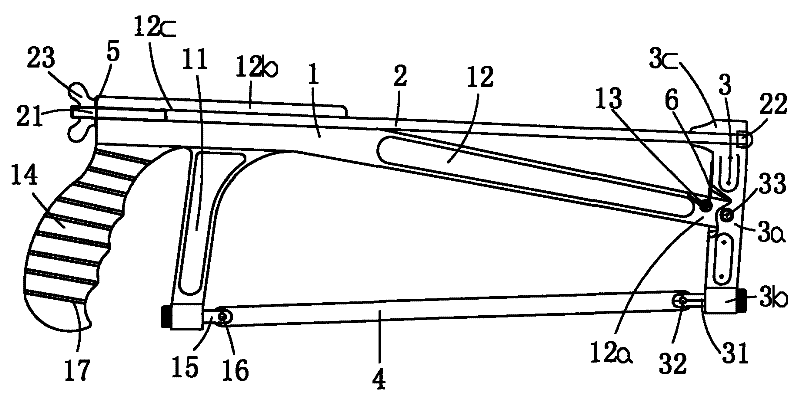

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] Such as Figure 1 to Figure 6 As shown, the icon numbers are as follows: saw frame body 1, saw blade connecting body 11, saw blade connecting back body 12, support end 12a, fixed end 12b, middle rod hole 12c, notch groove 12d, screw body 13, handle body 14 , the second movable part 15, the second positioning pin 16, the sheath body 17, the adjusting screw 2, the threaded adjusting end 21, the fixed end 22 of the rod, the nut 23, the movable adjusting part 3, the connecting end 3a, the saw blade fitting end 3b, the tension end 3c, the first movable part 31, the first positioning pin 32, the guide combination stud 33, the saw blade 4, the gasket 5, and the torsion spring body 6.

[0034] Embodiment 1 of the present invention, such as figure 1 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, the front hinged hand saw with p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com