Device for detecting concrete permeability on surface layer

A detection device and permeability technology, applied in the direction of measurement device, permeability/surface area analysis, suspension and porous material analysis, etc., to achieve the effects of easy production and processing, improved service life, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

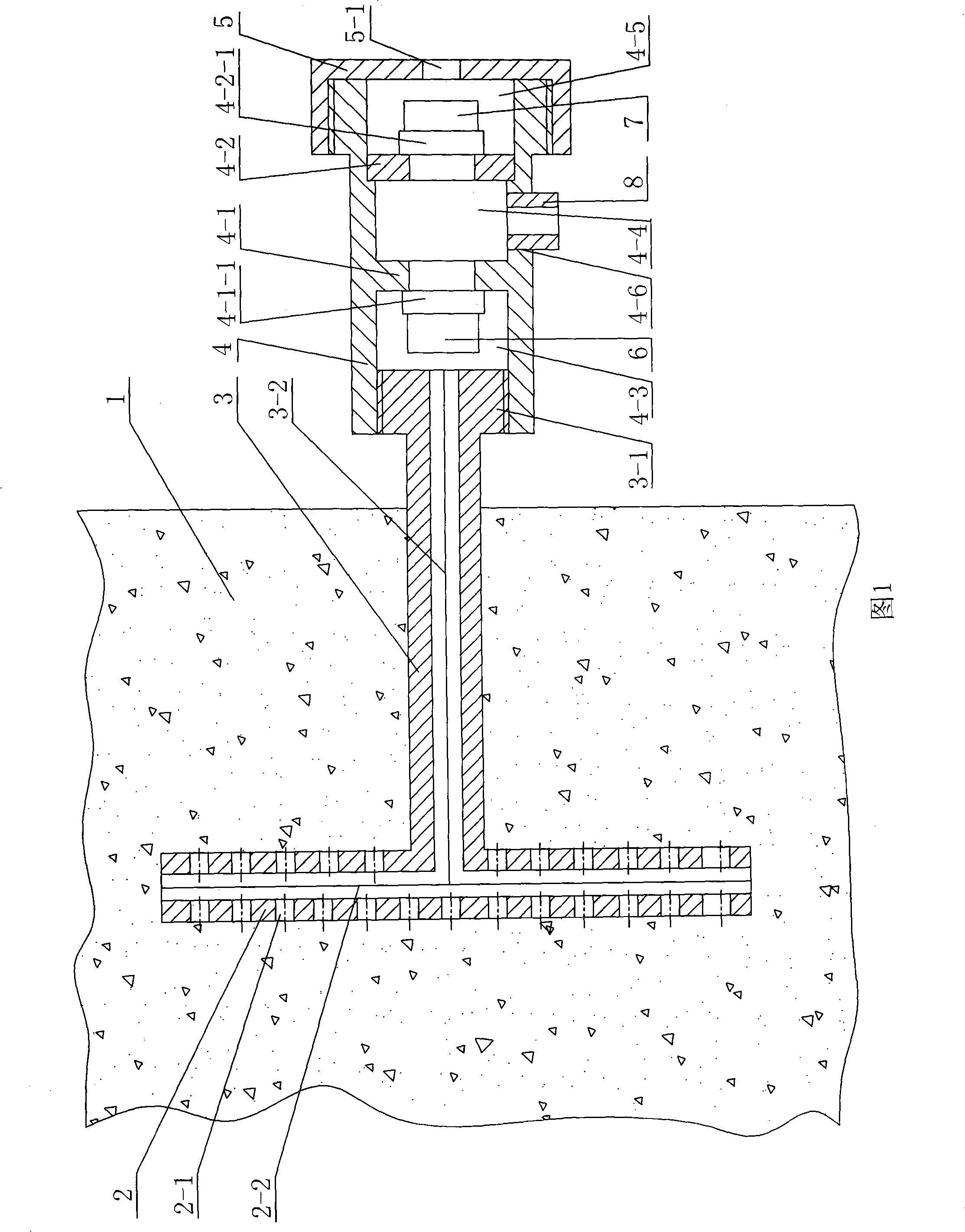

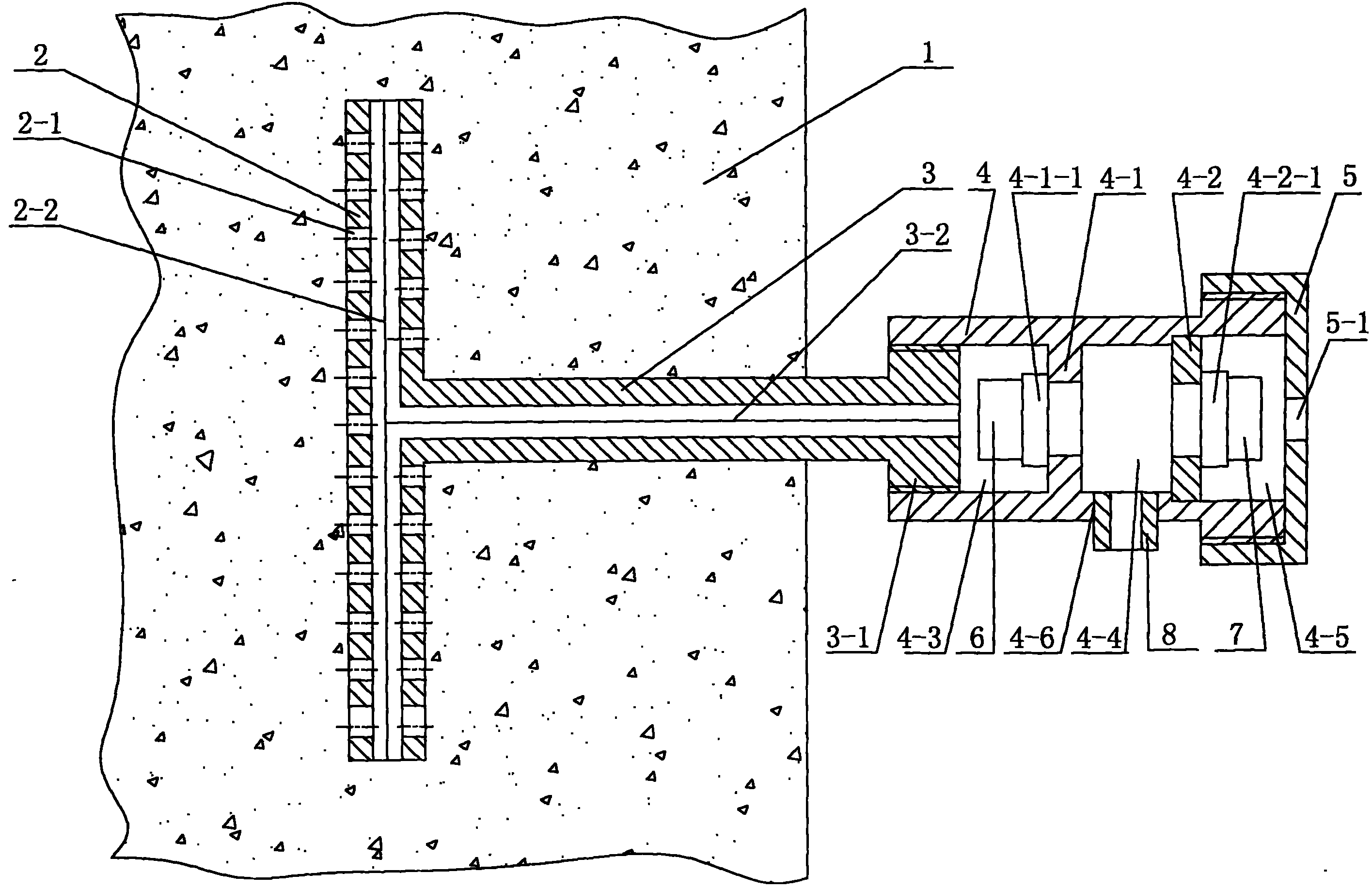

[0009] Embodiment 1: As shown in Figure 1, the detection device for detecting the permeability of the concrete surface described in this embodiment includes a pre-embedded pipe 2, a semi-embedded pipe 3, a short pipe 4, a nut 5, a first humidity Sensor 6, the second humidity sensor 7, the first partition 4-1 with through holes and the second partition 4-2 with through holes; the side wall of the embedded pipe 2 is evenly opened with several through holes 2-1, there is a hole 5-1 on the top of the nut 5, the middle side wall of the embedded pipe 2 and one end of the half-embedded pipe 3 are vertically fixed together to form a T-shape, the embedded pipe 2 and the half-embedded pipe The buried pipe 3 is connected, and the side wall of the other end of the semi-embedded pipe 3 is provided with an external thread 3-1 and is threadedly connected with one end of the short pipe 4. The other end of the short pipe 4 is screwed into the nut 5, and the short pipe 4 A first partition 4-1 w...

specific Embodiment approach 2

[0010] Embodiment 2: The pre-embedded pipe 2 and semi-embedded pipe 3 in this embodiment are all stainless steel pipes. Stainless steel pipes are not easily oxidized. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0011] Specific embodiment three: As shown in Figure 1, the detection device described in this embodiment also includes a pre-embedded column core 2-2 and a half-embedded column core 3-2, and a pre-embedded column core 2-2 and a half-embedded column core 3-2 are vertically connected, the pre-embedded column core 2-2 is arranged in the pre-embedded pipe 2, and the half-embedded column core 3-2 is arranged in the half-embedded pipe 3. The purpose of setting the embedded column core 2-2 and the semi-embedded column core 3-2 is to reduce the space volume of the embedded tube 2 and the semi-embedded tube 3, thereby reducing the gas space and improving the accuracy of humidity measurement . Other compositions and connections are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com