Sieve plate convenient for ventilation

A technology of sieve plate and plate, applied in the field of improvement of sieve plate structure, can solve the problems of flatness error, affecting the effect of returning material, etc., and achieve the effect of restoring flatness, improving processing quality, and being beneficial to returning material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

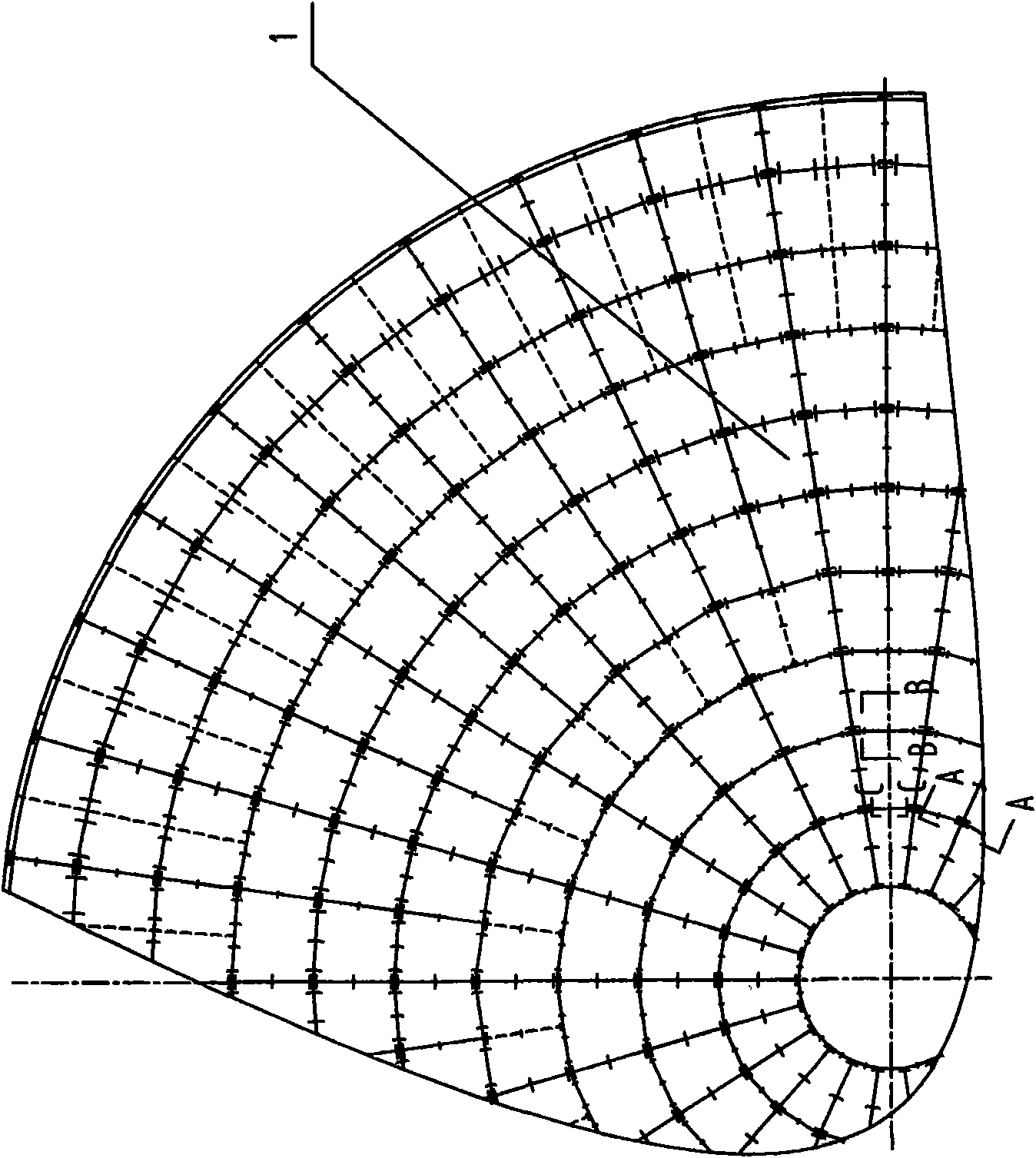

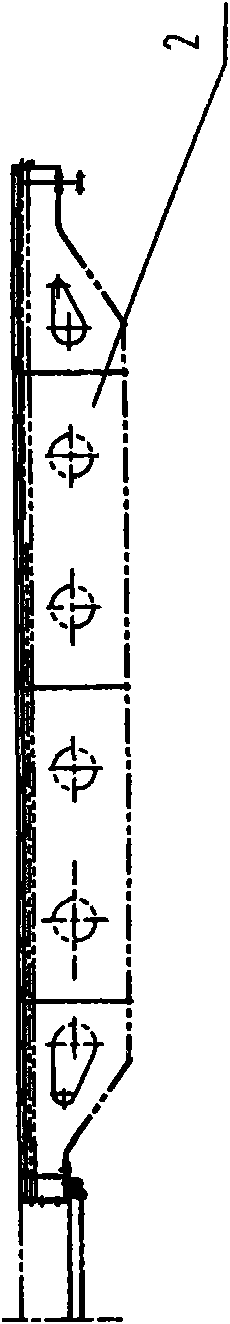

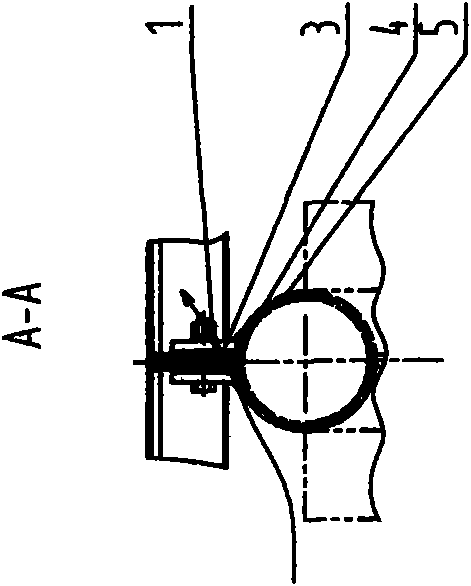

[0017] Such as Figure 1~5 As shown, the present invention includes a support beam 2, a number of sieve plates 1 connected to the support beam 2, a wing tube 5 is provided on the support beam 2, a connecting ear plate 3 is provided on the wing tube 5, and the connecting ear plate 3 is provided with a waist-shaped hole 7, and the adjacent sieve plate 1 is fixedly connected with the waist-shaped hole 4 on the connecting ear plate 3.

[0018] Ear plate 3 and wing tube 5 are as image 3 The portrait setting form in and such as Figure 5 In the horizontal setting form, the connecting ear plates 3 are arranged in pairs, and each pair of ear plates 3 is arranged at intervals in the axial direction of the wing tube 5 to form a certain wind passing width. The height of the wind passing gap is determined by the bottom surface of the screen plate 1 and the wing. The gap on the upper edge of the round pipe 5 determines. In order to ensure that after installation, the gap will not decre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com