Wood grain bamboo floor and preparing method thereof

A technology of bamboo flooring and wood grain, applied in the direction of manufacturing tools, wood processing equipment, floors, etc., can solve the problems of single color, inability to meet the needs of diversity of bamboo flooring products, obvious bamboo joints, etc., and achieve the goal of satisfying diversity desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

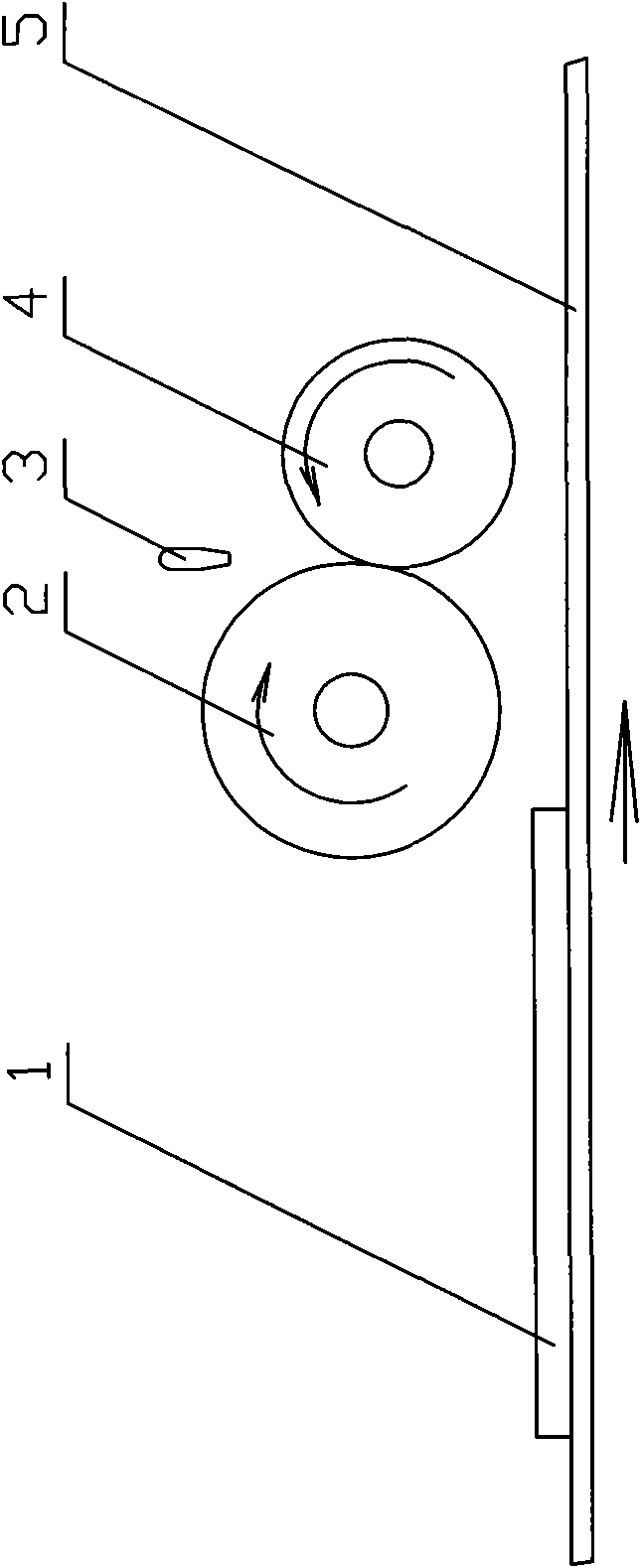

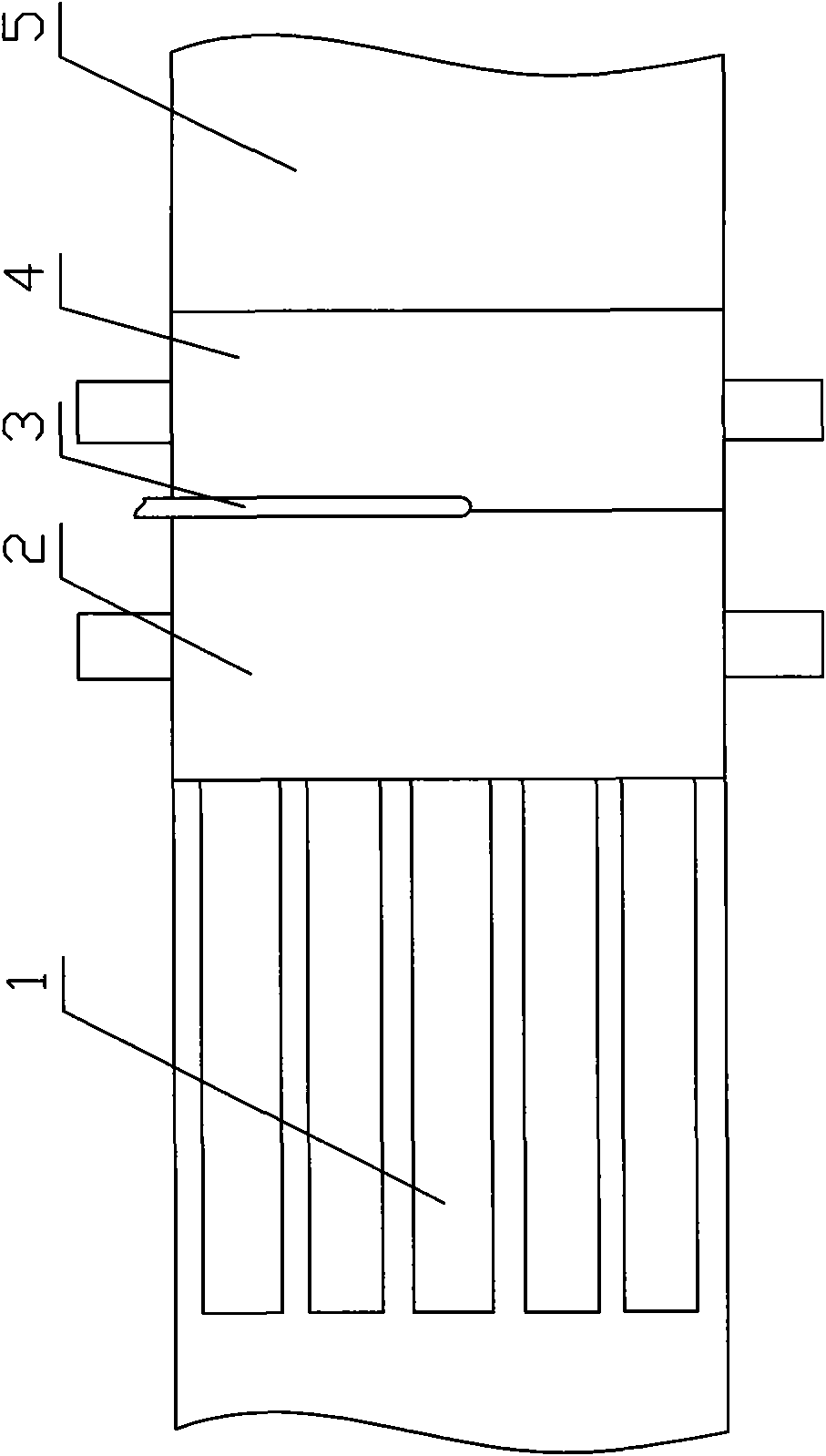

[0029] Follow these steps:

[0030] ① Sanding the upper surface of the bamboo floor body 1;

[0031] ②The roller is coated with transparent putty, heated to a semi-cured state, and sanded;

[0032] ③Coat the base color of the wood texture on the roller, and bake it until the water content is 10% to 15%;

[0033] ④Automatically correct the wood texture, apply the color of the wood texture on the roller, and bake until the water content is 10% to 15%;

[0034] ⑤ Roller coated with wear-resistant primer, heat baked to semi-cured state;

[0035] ⑥ Coat the elastic primer on the roller and heat it to a semi-cured state; coat the elastic primer on the roller and bake it to a semi-cured state;

[0036] ⑦Coat the hard primer on the roller, heat it to the semi-cured state, apply the hard primer on the roller, heat it to the semi-cured state, and sand it;

[0037] ⑧The roller is coated with an elastic topcoat, heated to a semi-cured state, the roller is coated with an elastic topcoa...

no. 2 example

[0039] ① Sanding the upper surface of the bamboo floor body 1;

[0040] ②The roller is coated with transparent putty, heated to a semi-cured state, and sanded;

[0041] ③Coat the base color of the wood texture on the roller, and bake it until the water content is 10% to 15%;

[0042] ④Automatically correct the wood texture, apply the color of the wood texture on the roller, and bake until the water content is 10% to 15%;

[0043] ⑤ Roller coated with wear-resistant primer, heat baked to semi-cured state;

[0044] ⑥ Coat the elastic primer on the roller and heat it to a semi-cured state; coat the elastic primer on the roller and bake it to a semi-cured state;

[0045] ⑦Coat the hard primer on the roller, heat it to the semi-cured state, apply the hard primer on the roller, heat it to the semi-cured state, and sand it;

[0046] ⑧The roller is coated with an elastic topcoat, heated to a semi-cured state, the roller is coated with an elastic topcoat, heated to a fully cured sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com