Testing and venting pipe annulus

An annular, flexible tube technology, used in fluid tightness testing, testing of pipes, machinery/structural components, etc., to solve problems such as failure to successfully test the integrity of the inner annular area, time consuming, and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

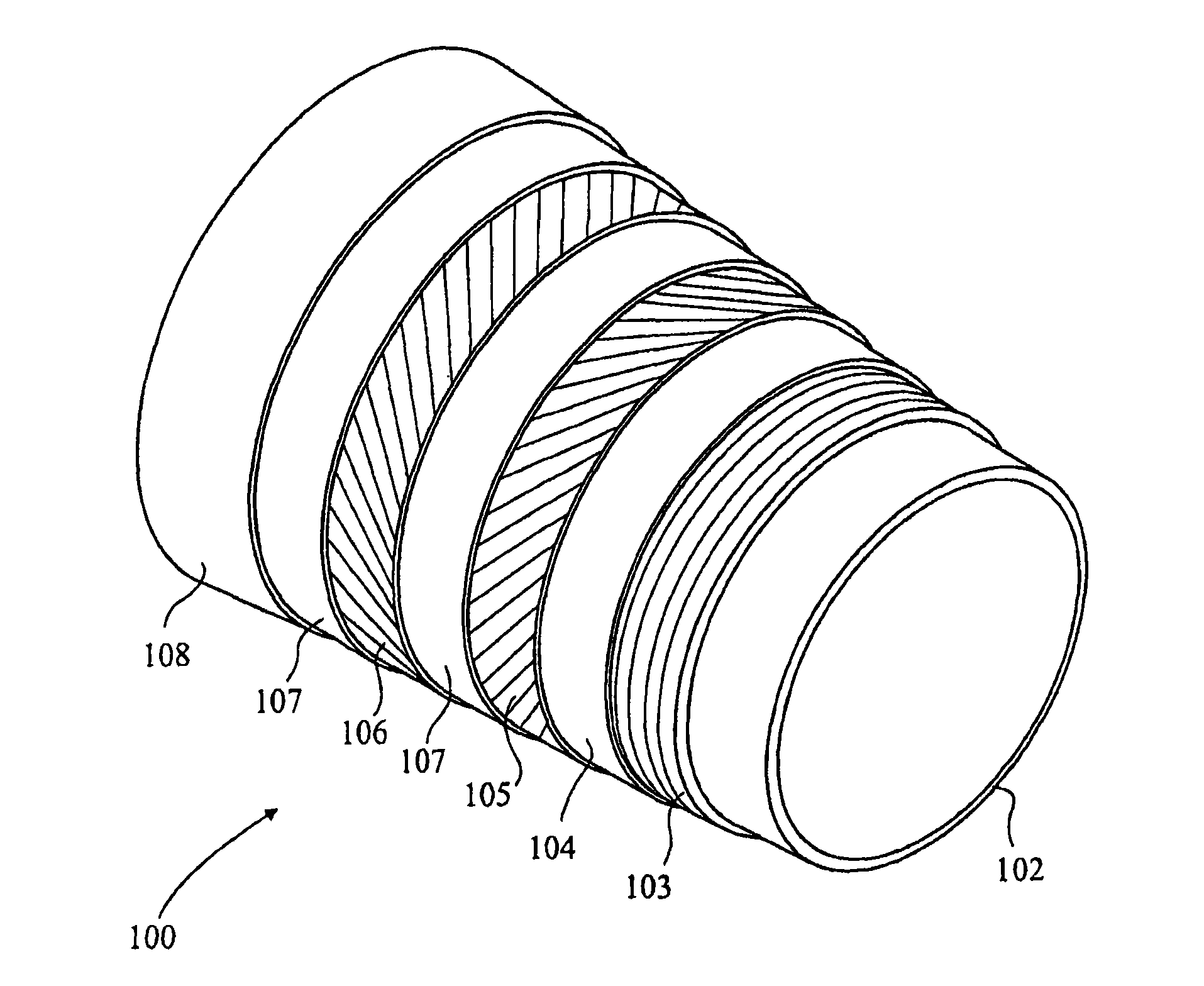

[0032] Throughout this specification reference will be made to flexible pipe. It should be understood that a flexible pipe is an assembly of a pipe body and one or more end fittings in which the ends of the pipe body are terminated. figure 1 It is shown how the pipe body 100 is formed from a composite of layered materials forming a pressure-containing conduit. although figure 1 A number of specific pipe layers are shown, but it should be understood that the invention is broadly applicable to composite pipe structures comprising two or more layers.

[0033] Such as figure 1 As shown in , the tubular body generally includes an innermost pressure sleeve 102 . Internal pressure sleeve 102 typically includes a polymer layer that ensures internal fluid integrity. It should be understood that the barrier layer itself may comprise many sub-layers. It should also be noted that it is preferred to refer to as figure 1 Embodiments of the present invention are utilized with the "smoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com