Sliding contact arrangement with wear elimination

A sliding contact, component technology for applications in the field of systems with particles and abrasive substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

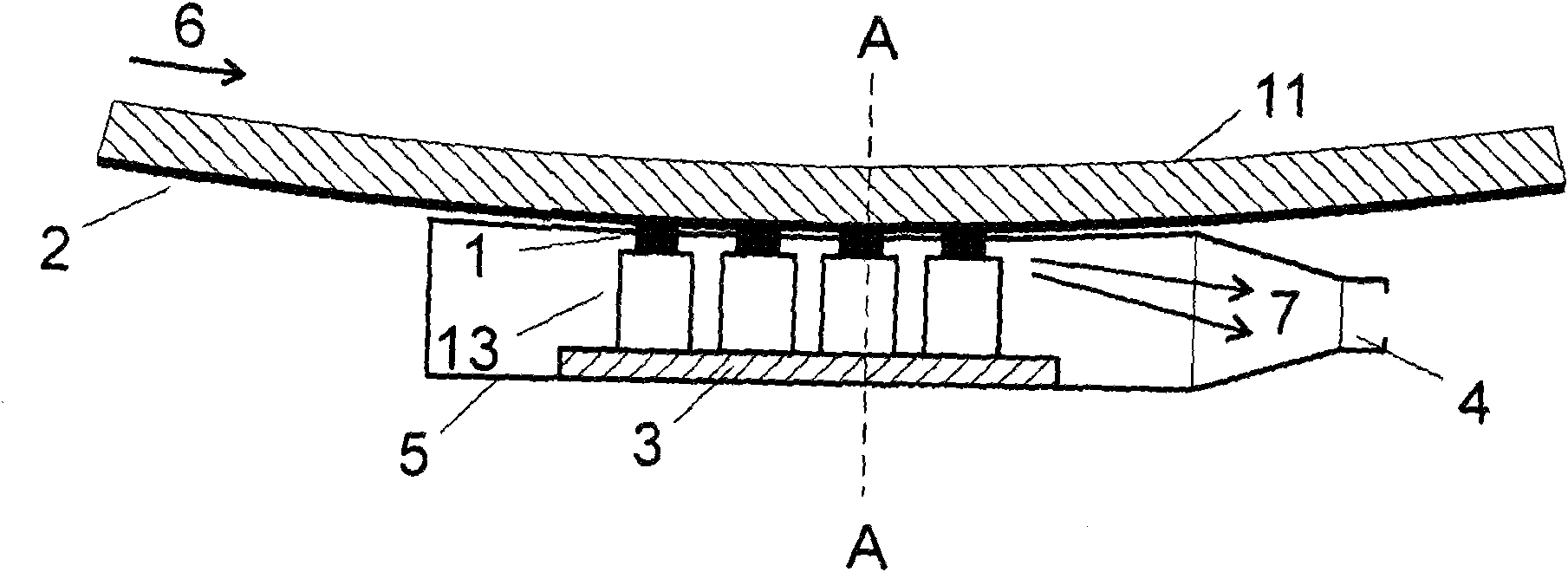

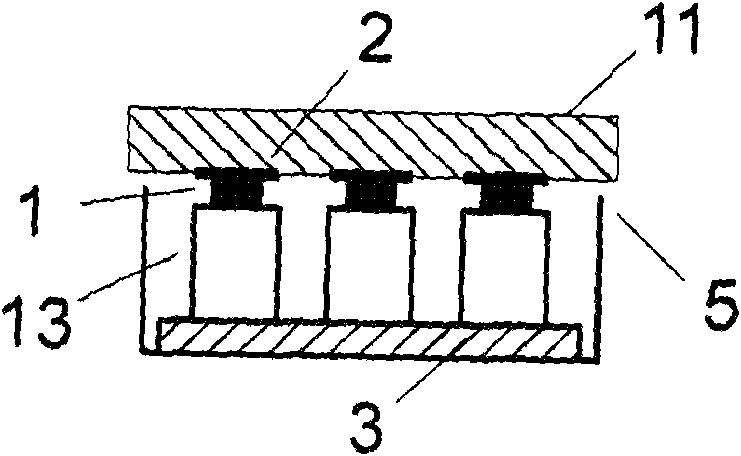

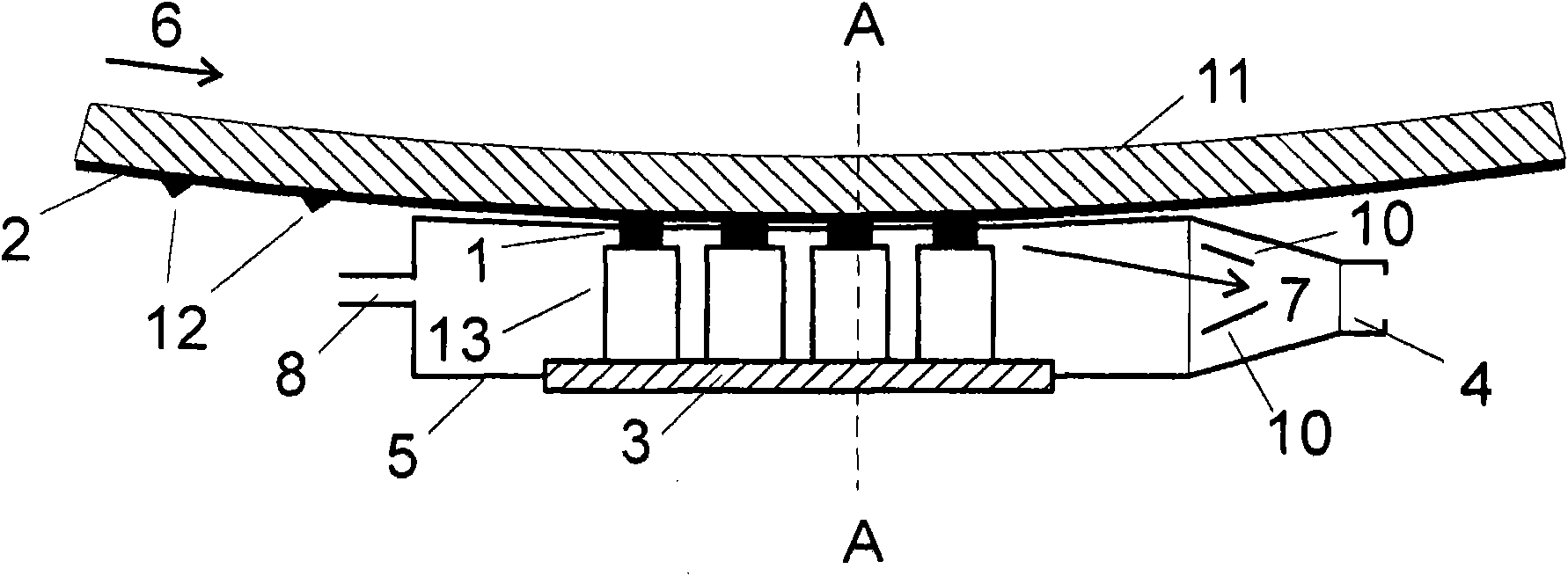

[0020] figure 1 A partial view showing the device of the present invention. Here, for example, four brushes are provided, each of which is accommodated in the stem 13 . The sliding contact assembly includes at least one brush. However, depending on the current to be carried, the sliding contact assembly may also comprise a large number of brushes, eg 20 brushes. If several current paths or also signal paths are provided at the same time, a suitable number of brushes is provided individually for each path and runs along the relevant rails. A typical sliding contact assembly for a computerized tomograph may include 50 or more brushes. The brushes are grouped together in the brush block 3 . The brush blocks generally accommodate the sockets of the brushes and make contact with these sockets. There is a special construction in which multiple brush blocks are also provided. Such a configuration may be necessary, for example, to increase insulation. The brushes are in sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com