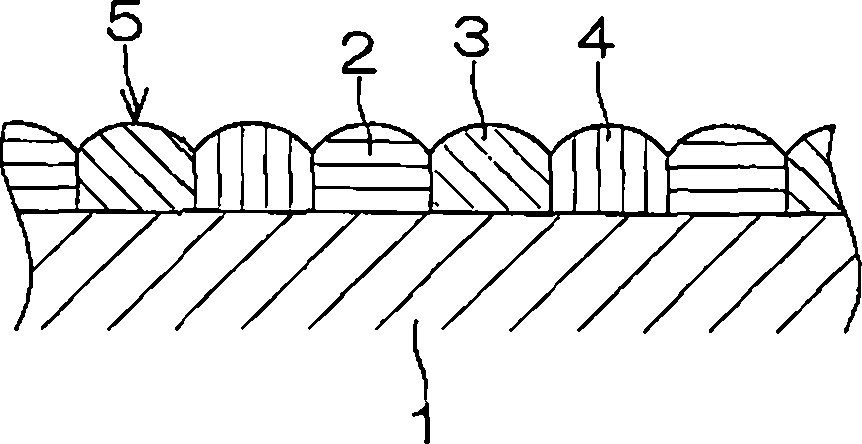

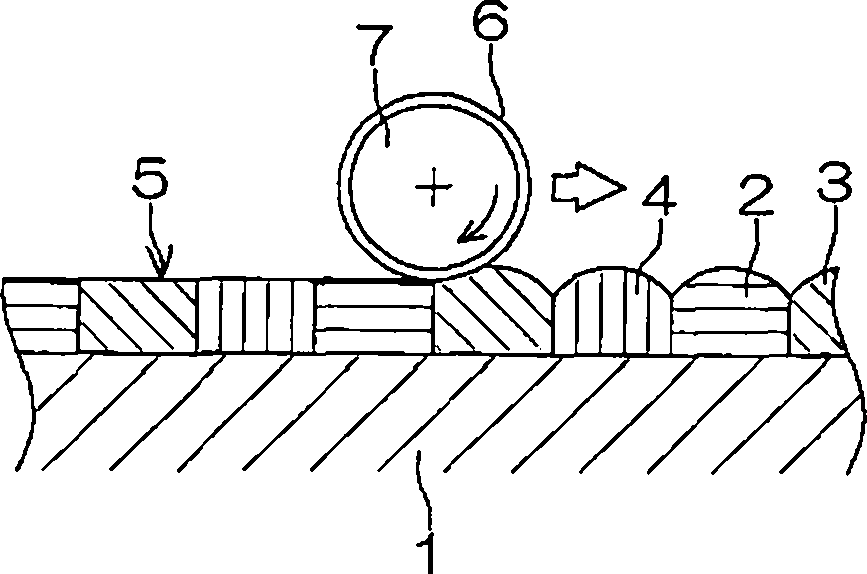

Planarizing sheet and process for preparation of color filter using the same

A flattening and color filter technology, used in applications, instruments, filters, etc., can solve problems such as excessively hard metal rollers, reduced contrast, and uniform overall flattening of difficult-to-transparent resin layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

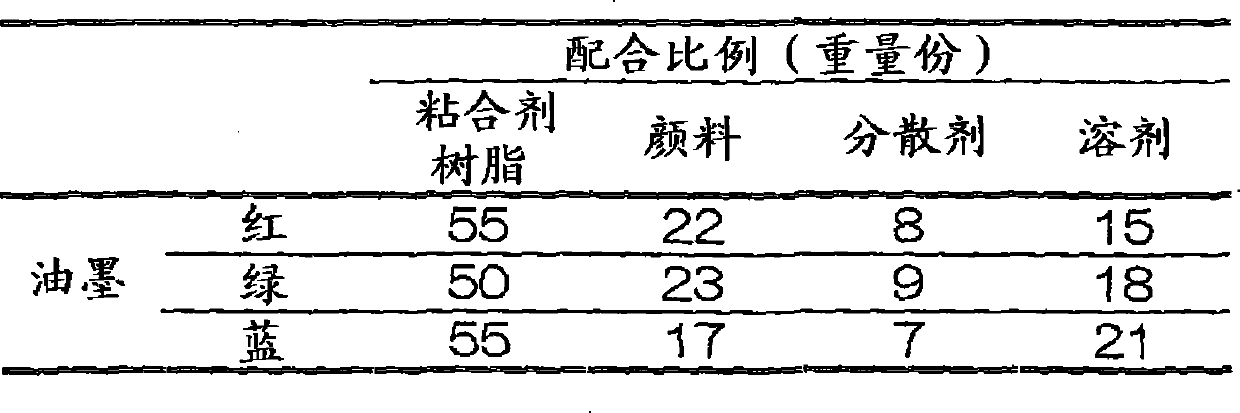

Examples

Embodiment 1

[0059] As the substrate layer, a PET film [T60 manufactured by Toray Co., Ltd.] having a thickness of 100 μm, having an arithmetic mean roughness Ra of 11.5 nm of roughness curves on both sides, a tensile modulus (23° C.) of 210 MPa, and a thickness of 100 μm was prepared. Then, cut the above-mentioned PET film into a rectangular shape of 300 mm in length and 400 mm in width, and stick mending tape on the edges of the two long sides of the rectangle on one side, and fix it with the above-mentioned one side of the PET film facing upwards. In the state on the flat disk, the above-mentioned sewing tape was used as a thickness guide (guide), and a coating rod made of stainless steel with a diameter of 12 mm and whose outer peripheral surface was ground and finished was applied to the above-mentioned single side by the bar coating method. After coating the silicone resin-based coating liquid [SEPA-COAT, a registered trademark manufactured by Shin-Etsu Chemical Co., Ltd., the surface...

Embodiment 2

[0062] In addition to using the registered trademark SEPA-COAT manufactured by Shin-Etsu Chemical Co., Ltd. and KS-830 manufactured by the same company in a weight ratio of 40:60 [surface tension of a single cured product (23°C): 38mN / m] as a mold release A flattened sheet of Example 2 was produced in the same manner as in Example 1 except for the silicone resin-based coating liquid used as a raw material for the layer. The surface tension (23° C.) of the surface of the release layer was 28 mN / m, the arithmetic mean roughness Ra of the roughness curve was 8.7 nm, and the thickness was 1 μm.

Embodiment 3

[0068] In addition to using the registered trademark SEPA-COAT manufactured by Shin-Etsu Chemical Co., Ltd. and KS-837 manufactured by the same company in a weight ratio of 80:20 [surface tension of a single cured product (23°C): 16mN / m] as a mold release A flattened sheet of Example 3 was produced in the same manner as in Example 1 except for the silicone resin-based coating liquid as the raw material of the layer. The surface tension (23° C.) of the surface of the release layer was 16 mN / m, the arithmetic mean roughness Ra of the roughness curve was 18 nm, and the thickness was 1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com