Semiautomatic tobacco-weaving machine

A tobacco knitting machine, semi-automatic technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of high labor intensity, affecting the quality of flue-cured tobacco, and poor quality of knitting tobacco, so as to simplify the structure, reduce costs, and solve the problems of low work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiments given in the drawings.

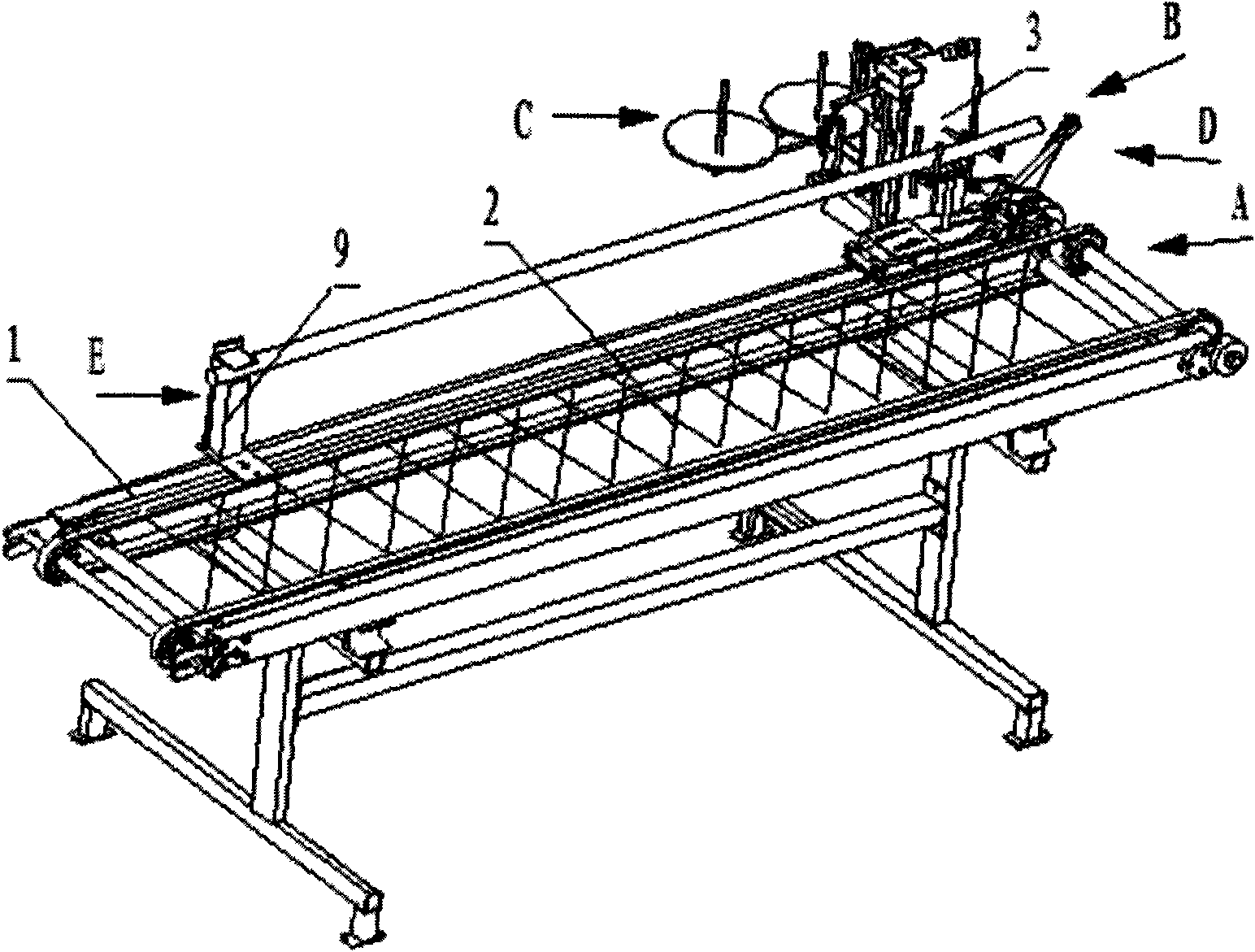

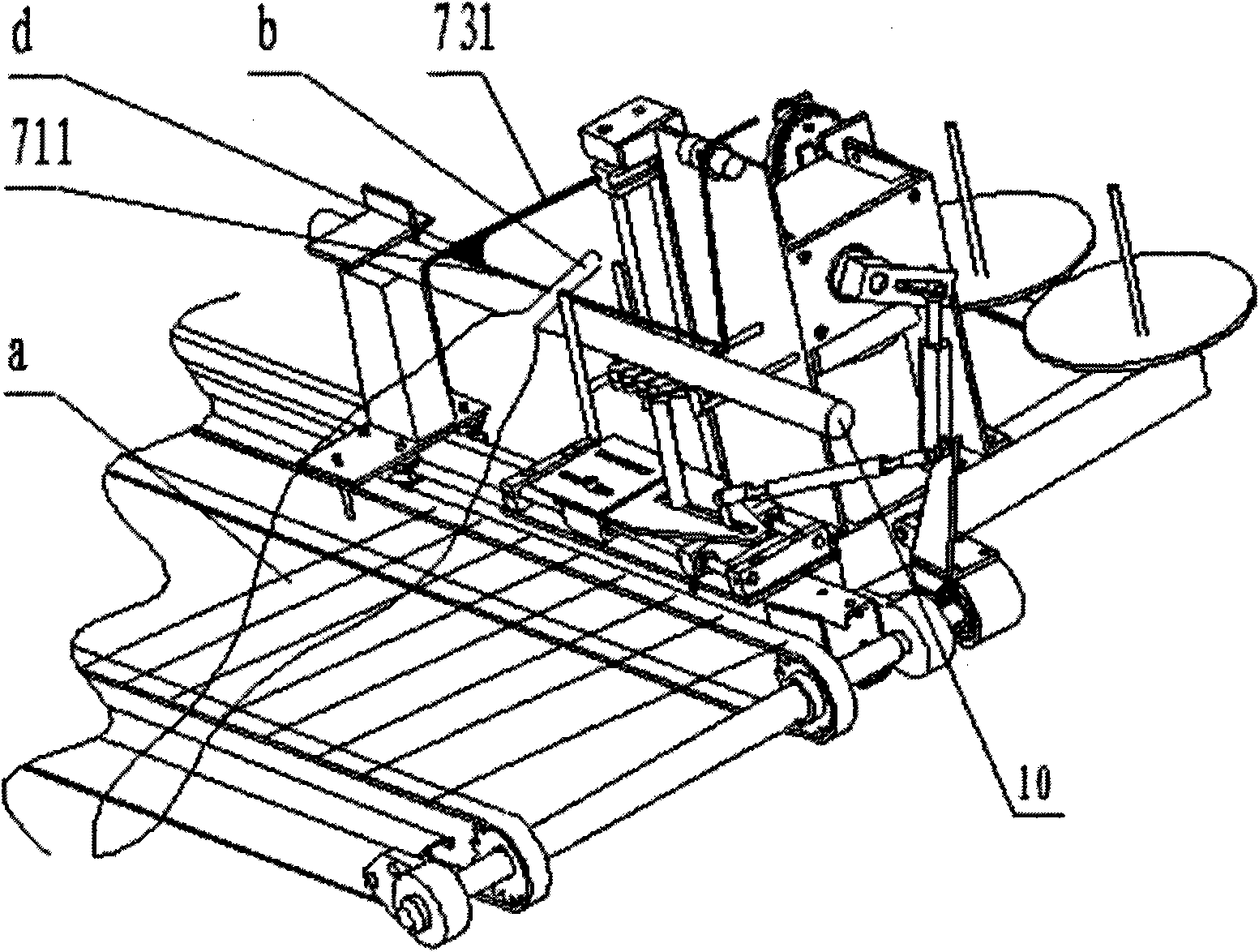

[0024] The semi-automatic tobacco weaving machine provided by the present invention includes a frame 1, a tobacco leaf conveying mechanism 2 arranged on the frame 1, a tobacco rod supporting and dragging mechanism 9 and a tobacco weaving mechanism 3 with a casing and a power machine, in which:

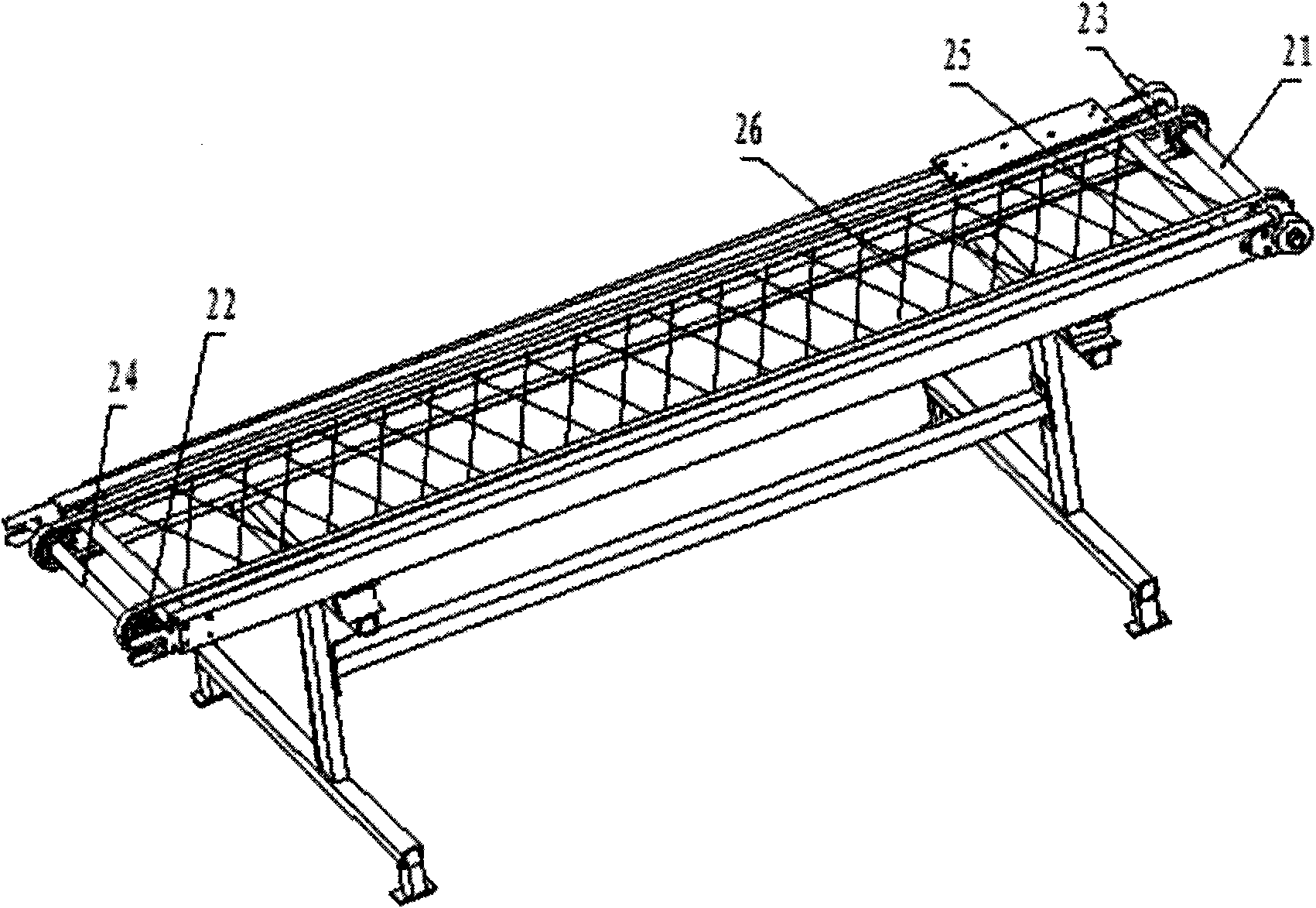

[0025] The conveying mechanism 2 on the frame 1 includes a driving shaft 21 and a driven shaft 24 respectively fixed at both ends of the frame 1. The driving shaft 21 is connected with the one-way overrunning clutch 46 on the rocker of the crank and rocker mechanism. Two driving sprockets 22 and driven sprockets 23 are respectively provided on the shafts 21 and 24. The two conveying chains 25 are respectively placed on the corresponding sprockets 22 and 23 of the two shafts. A wire mesh 26 is fixed on the two conveying chains 25, To form a conveyor network chain, such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com