Patents

Literature

80results about How to "Conveniently placed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

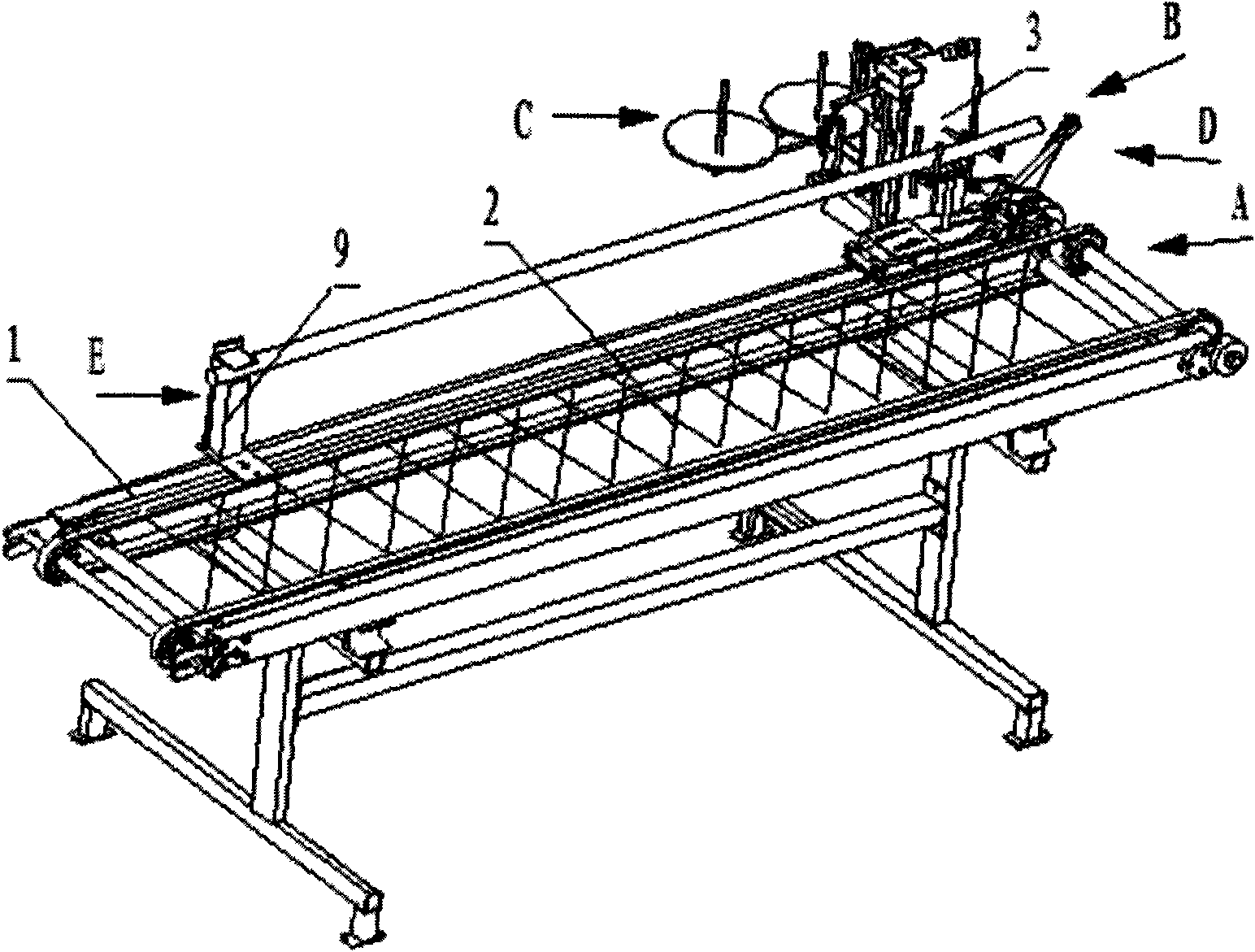

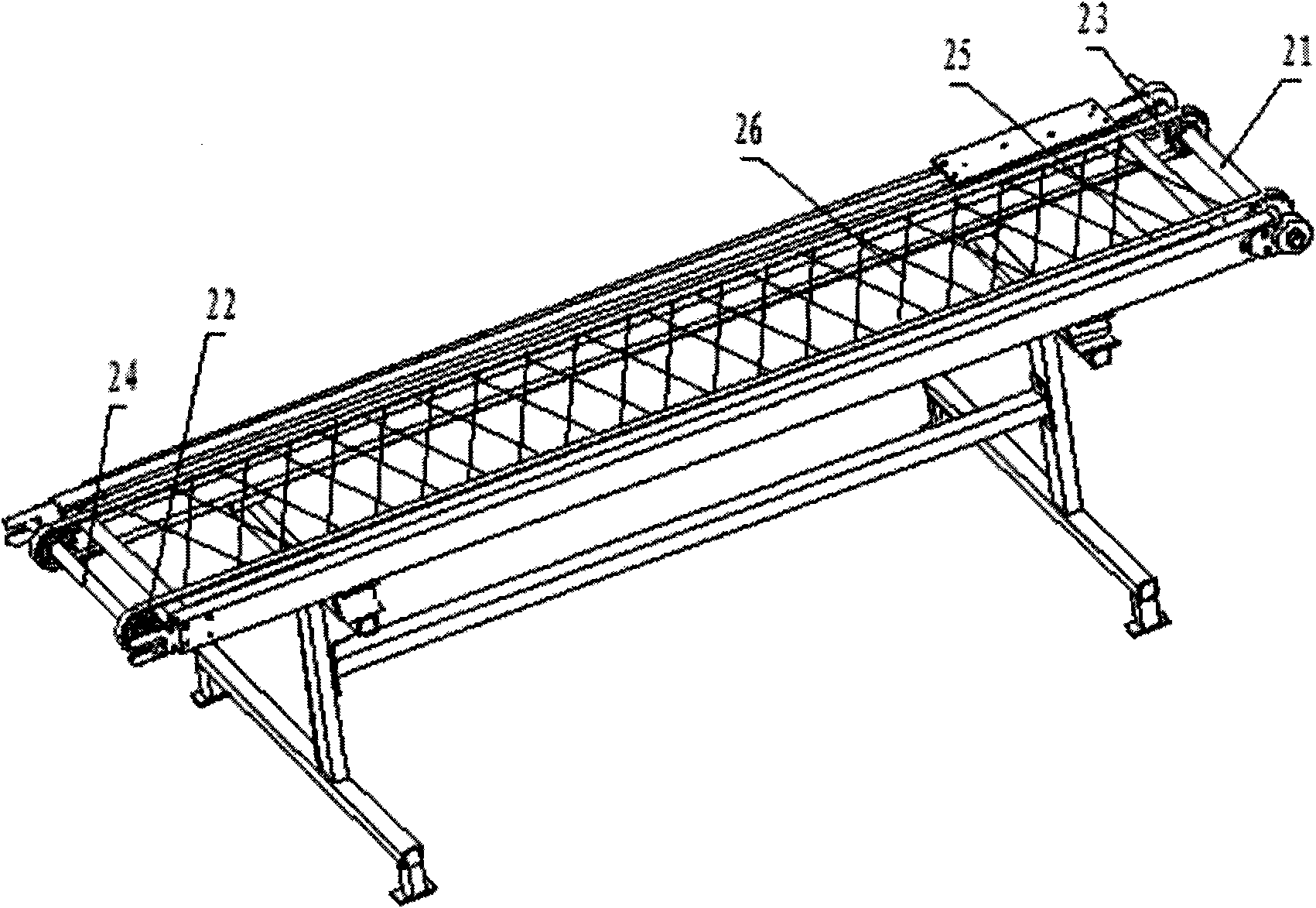

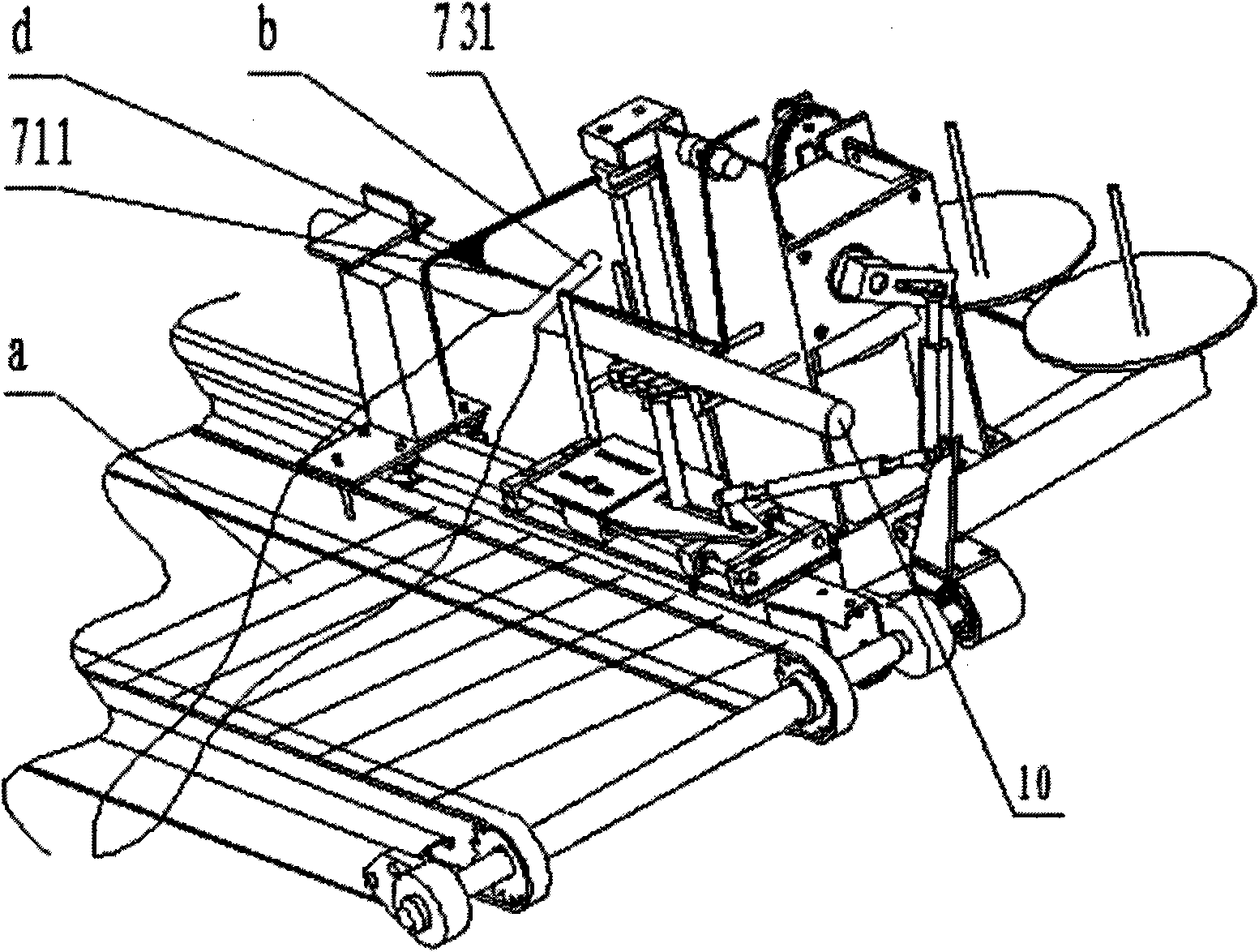

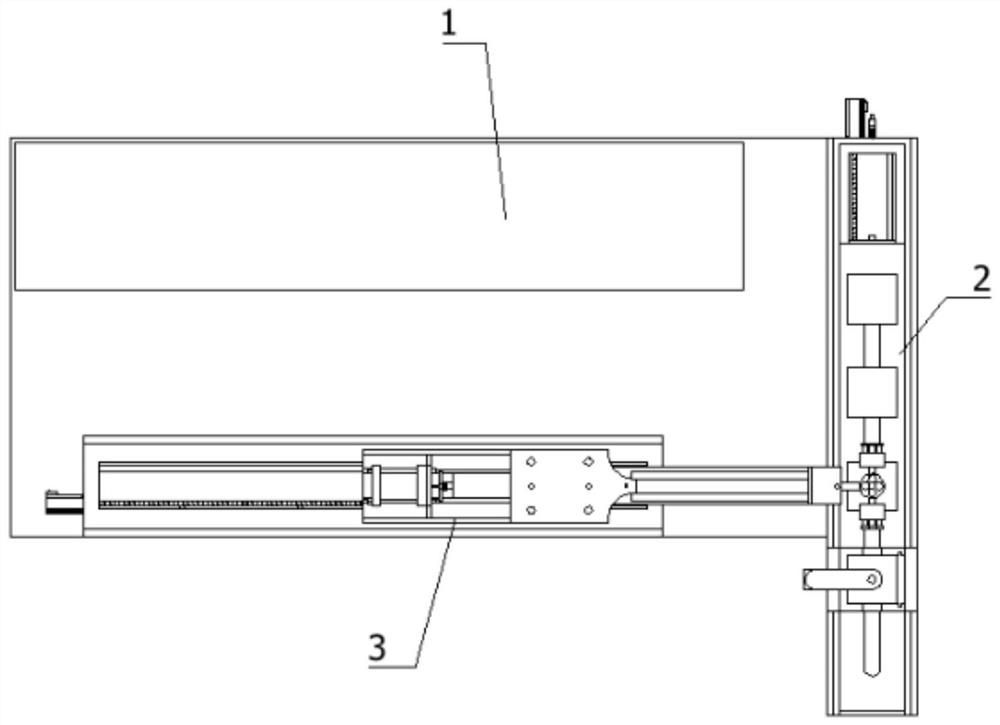

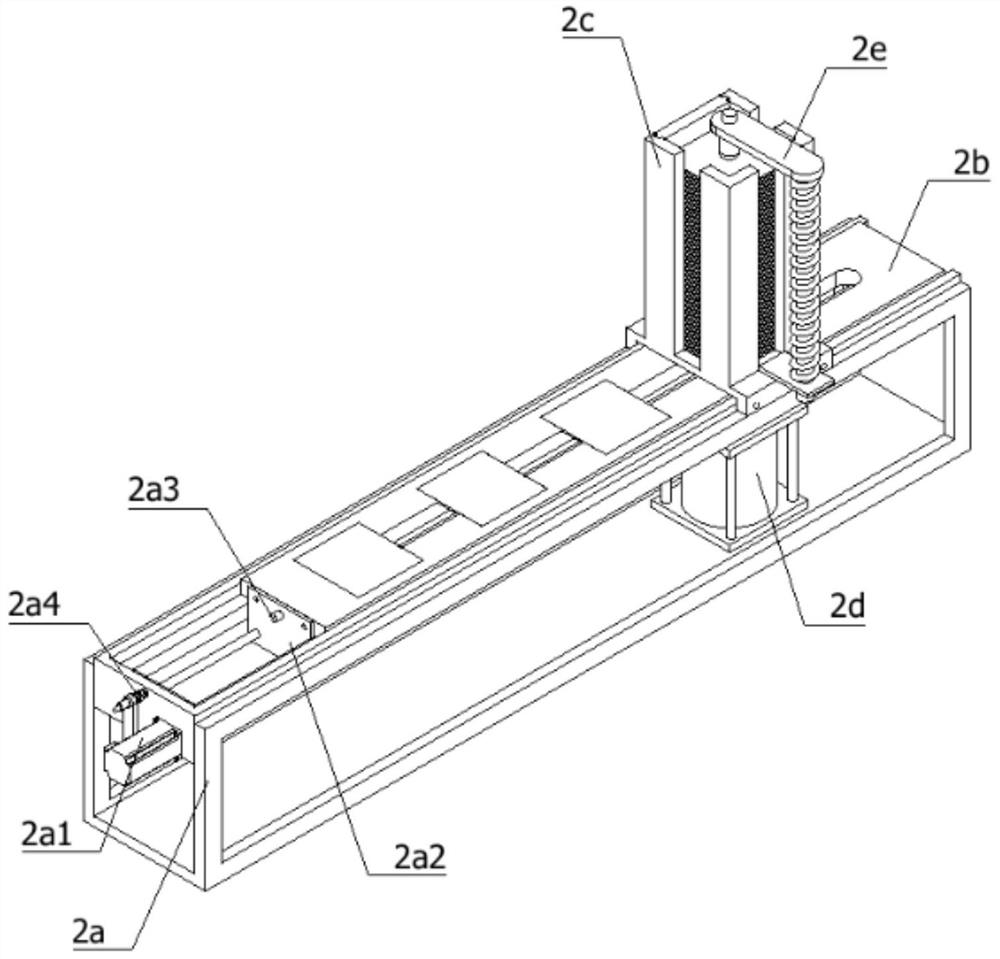

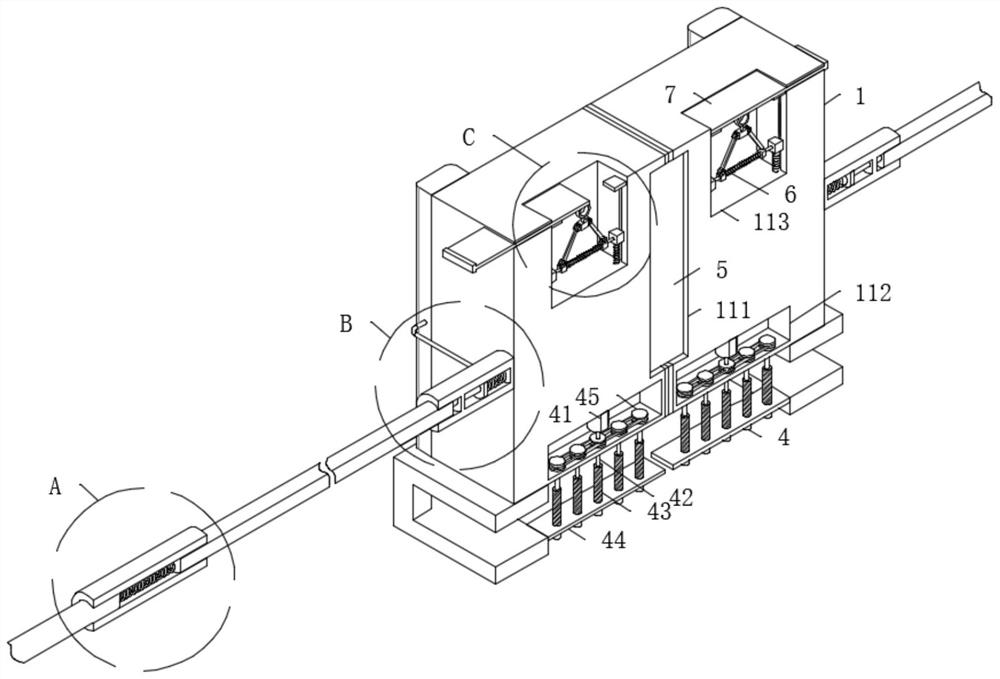

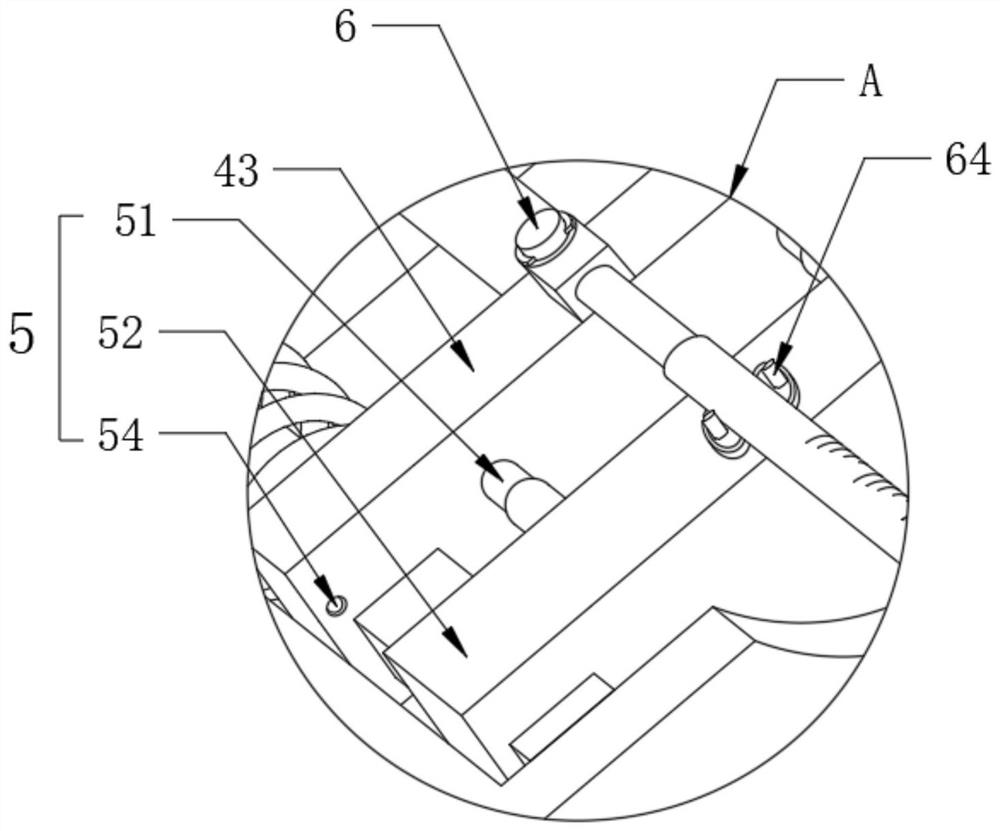

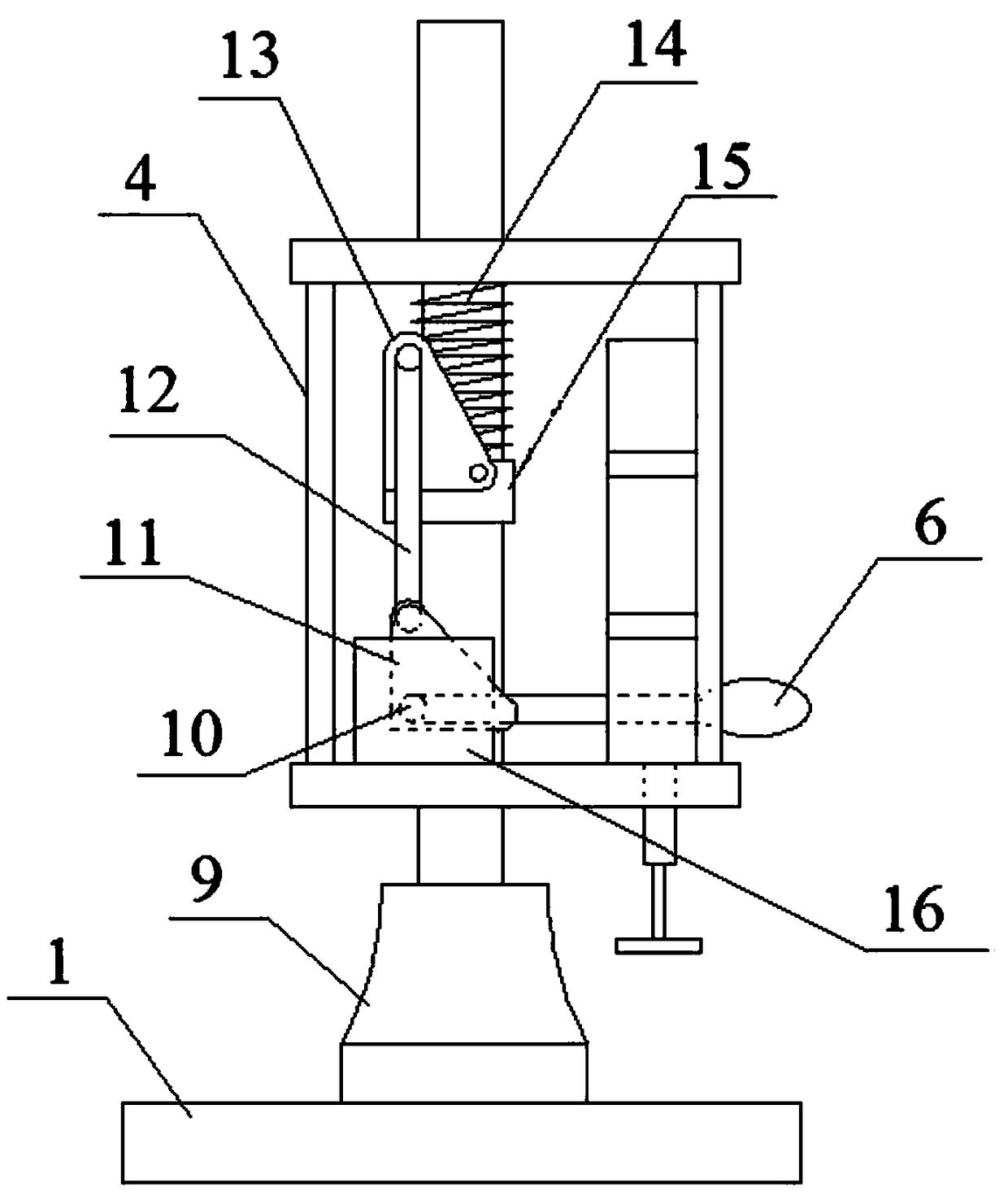

Semiautomatic tobacco-weaving machine

The invention provides a semiautomatic tobacco-weaving machine which comprises a frame, a tobacco delivering mechanism arranged on the frame, a tobacco rod supporting mechanism, and a tobacco-weaving mechanism provided with a shell and a power machine. The tobacco-weaving machine is characterized by comprising a spatial crank-rocker mechanism connected with an output shaft of the power machine, a crank-slider mechanism connected with the spatial crank-rocker mechanism, a tobacco stalk hold-down mechanism connected with the crank-slider mechanism, and a winding mechanism connected with the output shaft of the power machine, wherein the spatial crank-rocker mechanism is also connected with the delivering mechanism and a tobacco stalk supporting and dragging mechanism. The problems of low working efficiency and strong labour intensity which are caused by manual tobacco weaving are solved fundamentally; in addition, the actions of the delivering mechanism, the tobacco rod supporting and dragging mechanism, the tobacco stalk hold-down mechanism and the winding machine are completed by only one power source, thereby not only reducing cost and simplifying structure, but also leading tobacco growers to finish weaving tobacco when sorting tobacco leaves.

Owner:KUNMING UNIV OF SCI & TECH

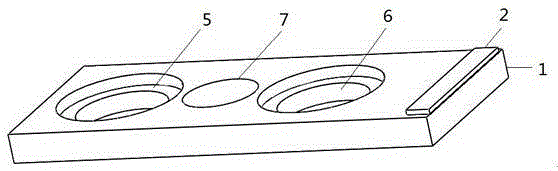

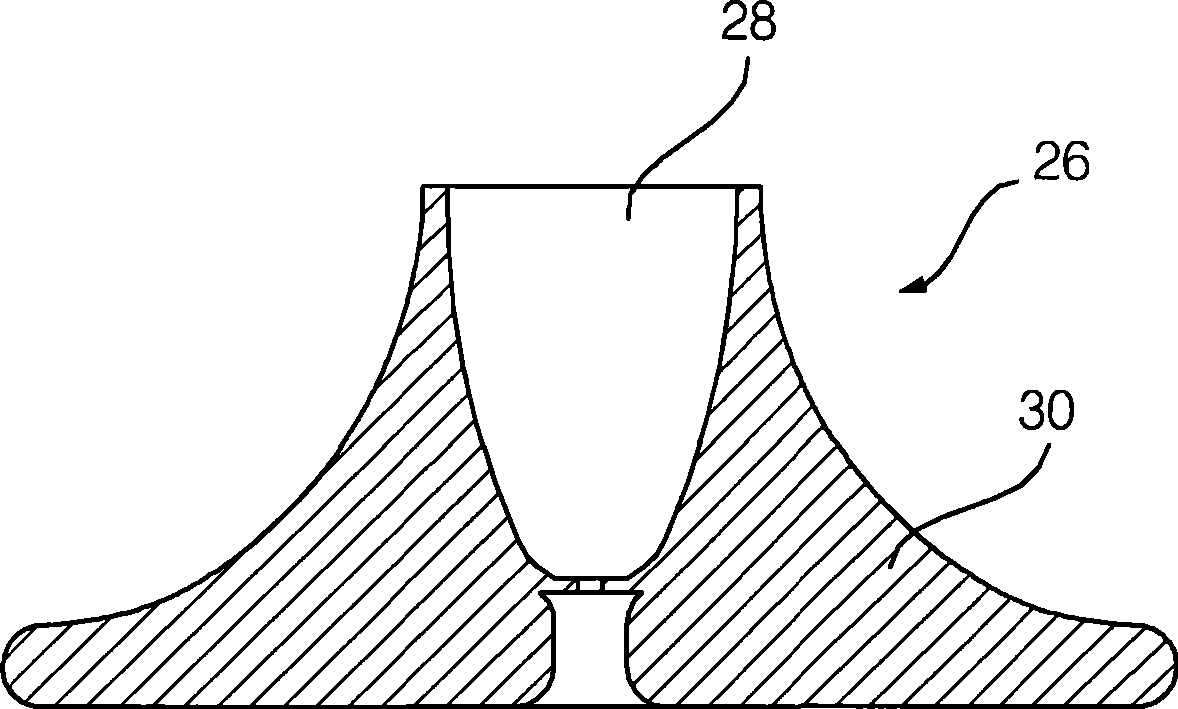

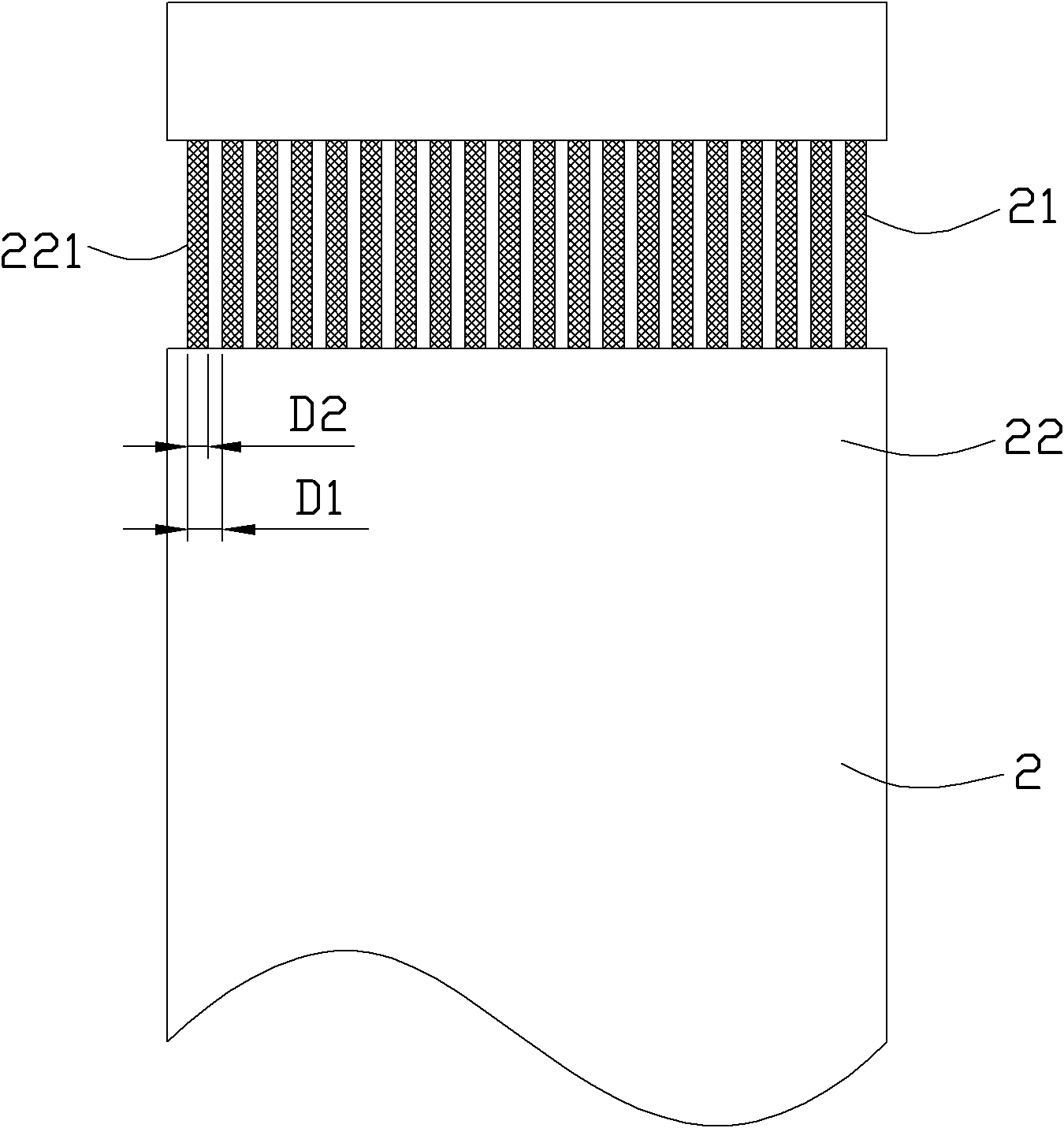

Sintering fixture for micro channel semiconductor laser and sintering method thereof

The invention discloses a sintering fixture for a micro channel semiconductor laser and a sintering method thereof. The sintering fixture comprises a positioning base and an adjustable cover plate, wherein the adjustable cover plate is connected onto the positioning base; a concave surface is arranged on the positioning base; two sides of the concave surface are bosses; the adjustable cover plate comprises a main body, a pressing block and a pressing block adjustment mechanism, the main body is provided with a pressing block groove, and the pressing block is arranged inside the pressing block groove via the pressing block adjustment mechanism. The micro channel semiconductor laser sintering method by the above device comprises steps: a micro channel heat sink sintered with a semiconductor laser bar chip, an insulated sheet and the adjustable cover plate are sequentially connected onto the positioning base from bottom to top and fixed by using bolts, and the above well-fixed entire fixture is sealed in a protection cover shell with nitrogen and is placed on a heating table for sintering. According to the sintering fixture for the micro-channel semiconductor laser and the sintering method thereof, the structure is simple, the cost is low, the operation is simple, convenient and reliable, and through one-time sintering, quick and accurate fixed connection among the bar chip of the micro-channel semiconductor laser, the micro-channel heat sink, the insulated sheet and a negative electrode sheet can be realized.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

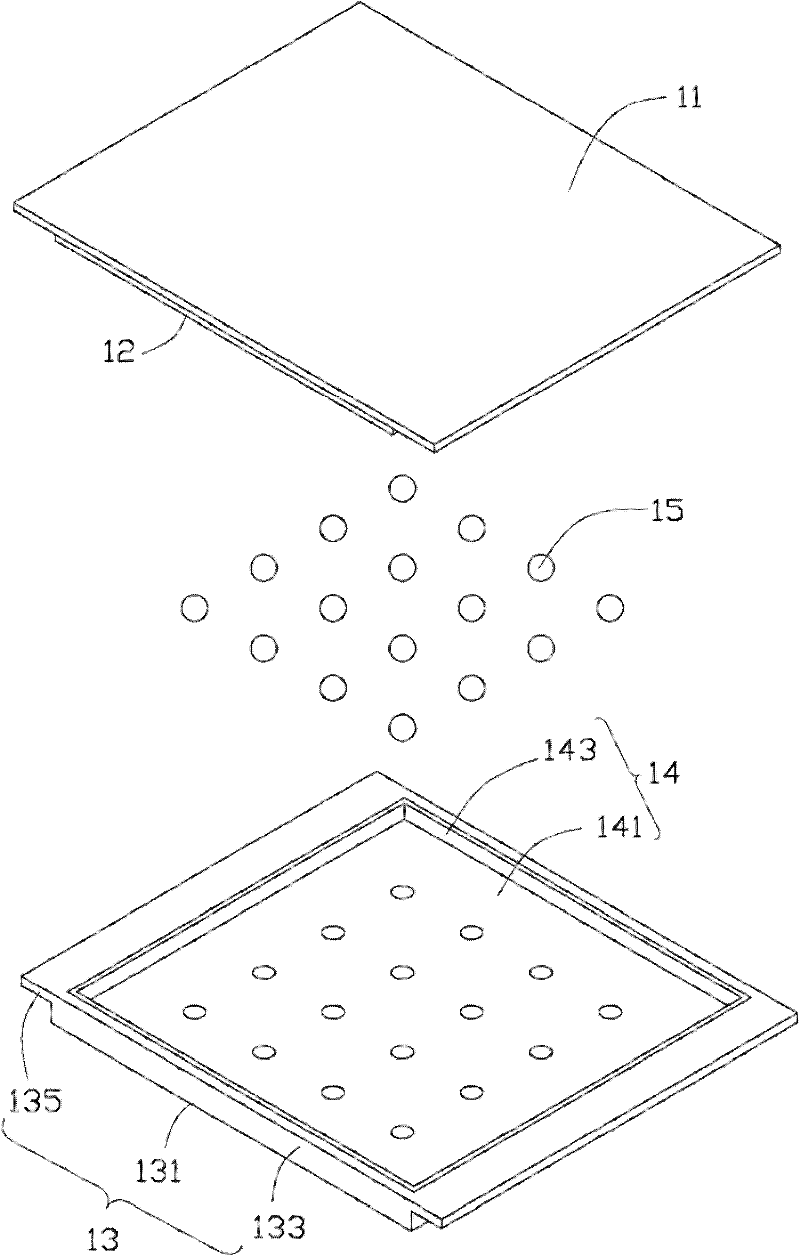

Flat plate heat pipe and manufacturing method thereof

InactiveCN102205485AImprove performanceEasy to manufactureReinforcing meansIndirect heat exchangersEngineeringMetal sheet

The invention relates to a manufacturing method of a flat plate heat pipe. The manufacturing method comprises the following steps of: providing a first metal sheet body; providing a plurality of spherical supporting bodies and a second metal sheet body, wherein the second metal sheet body comprises a base plate and a side plate extending from the base plate; arranging the spherical supporting bodies on the base plate of the second metal sheet; and folding the first metal sheet body and the second metal sheet body, and performing diffusion welding on the first metal sheet body and the second metal sheet body so that the first metal sheet body and the second metal sheet body are in sealing connection with each other, and the spherical supporting bodies are clamped between the first metal sheet body and the base plate of the second metal sheet body and directly pressed against the first metal sheet body and the base plate of the second metal sheet body. The flat plate heat pipe comprises a flat plate shell which comprises a base plate and a top plate opposite to the base plate; and at least one spherical supporting body is clamped between the base plate and the top plate. The supporting bodies in the invention are spherical, easy to manufacture and free of direction, can be conveniently arranged in the shell and easily combined with the shell without falling, so the flat plate heat pipe has stable performance.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

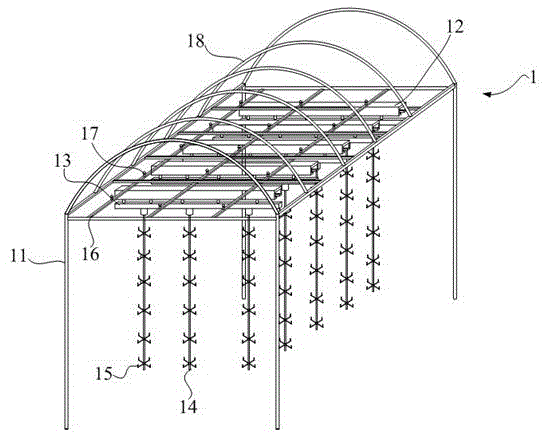

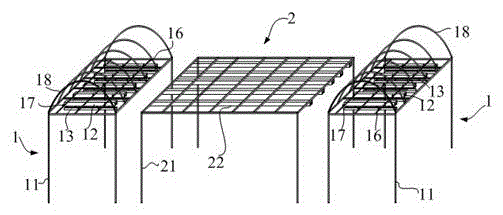

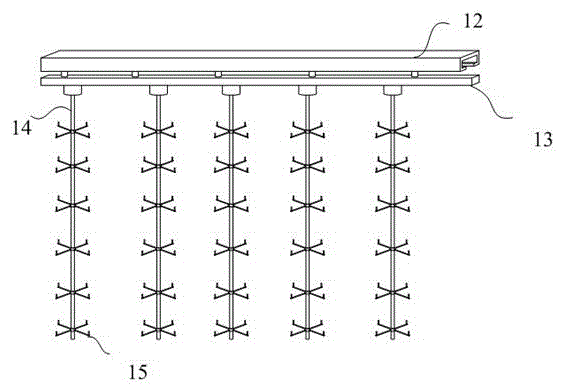

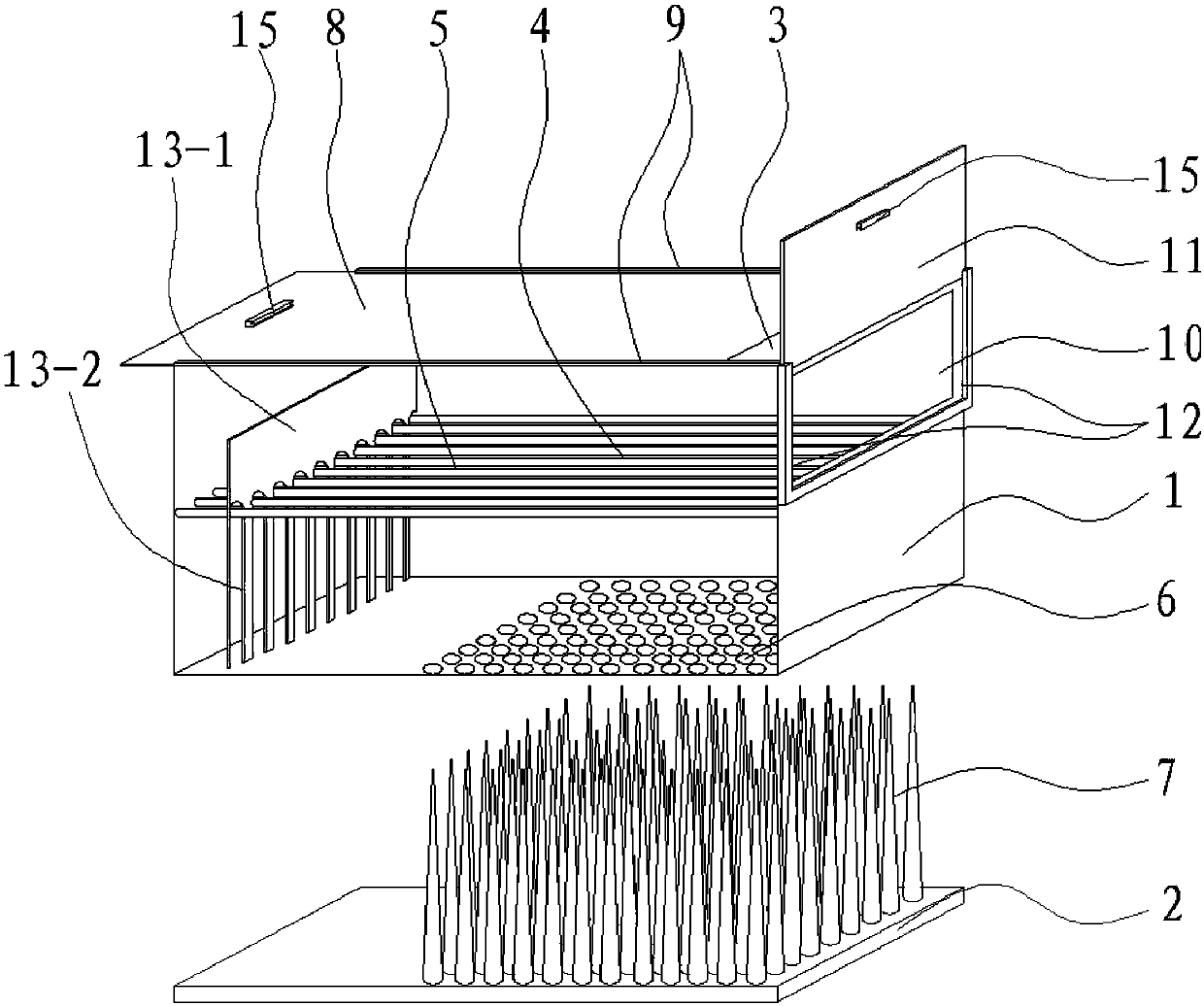

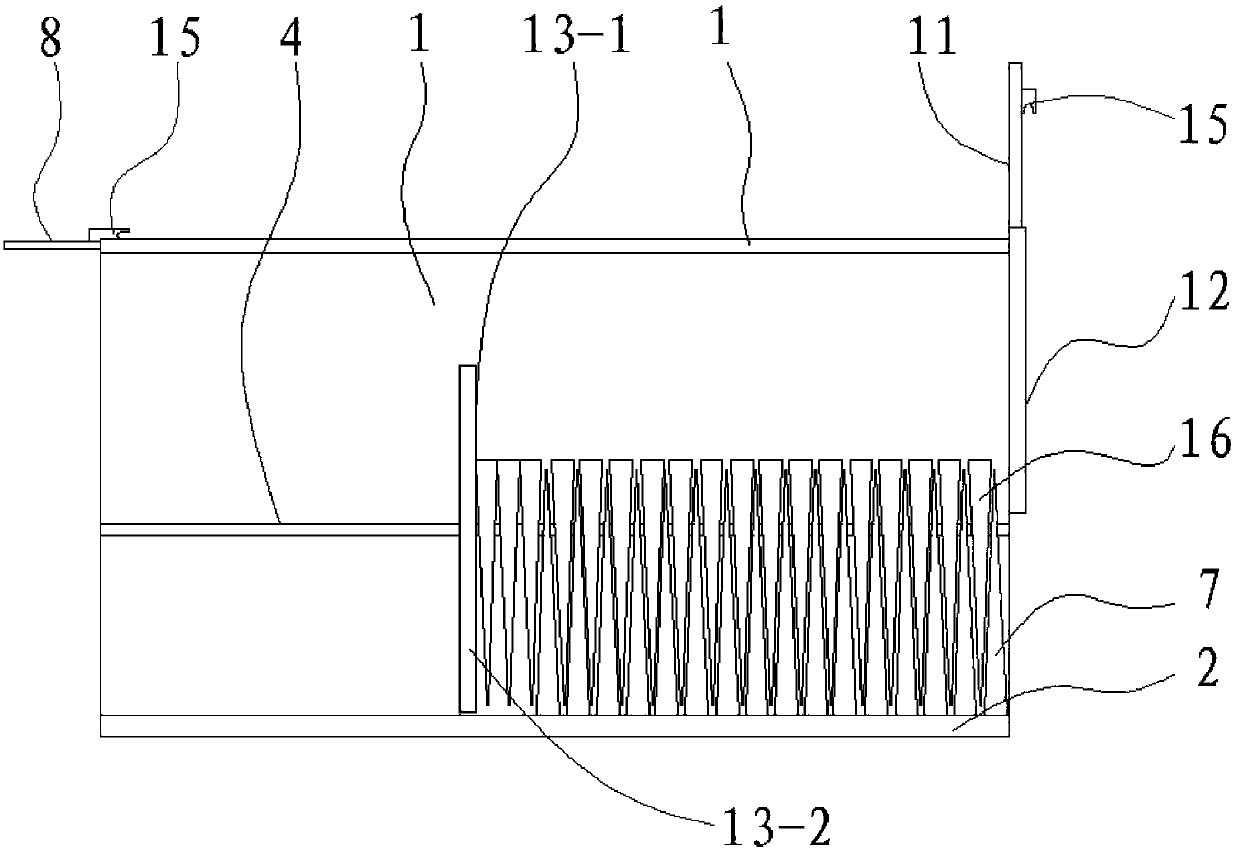

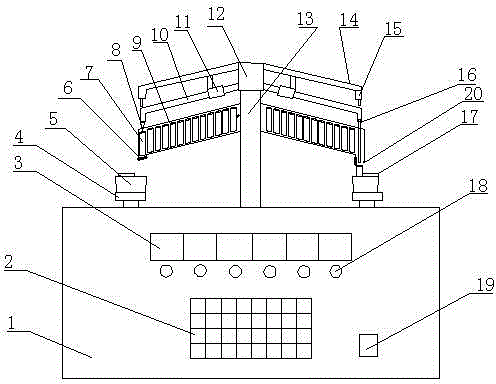

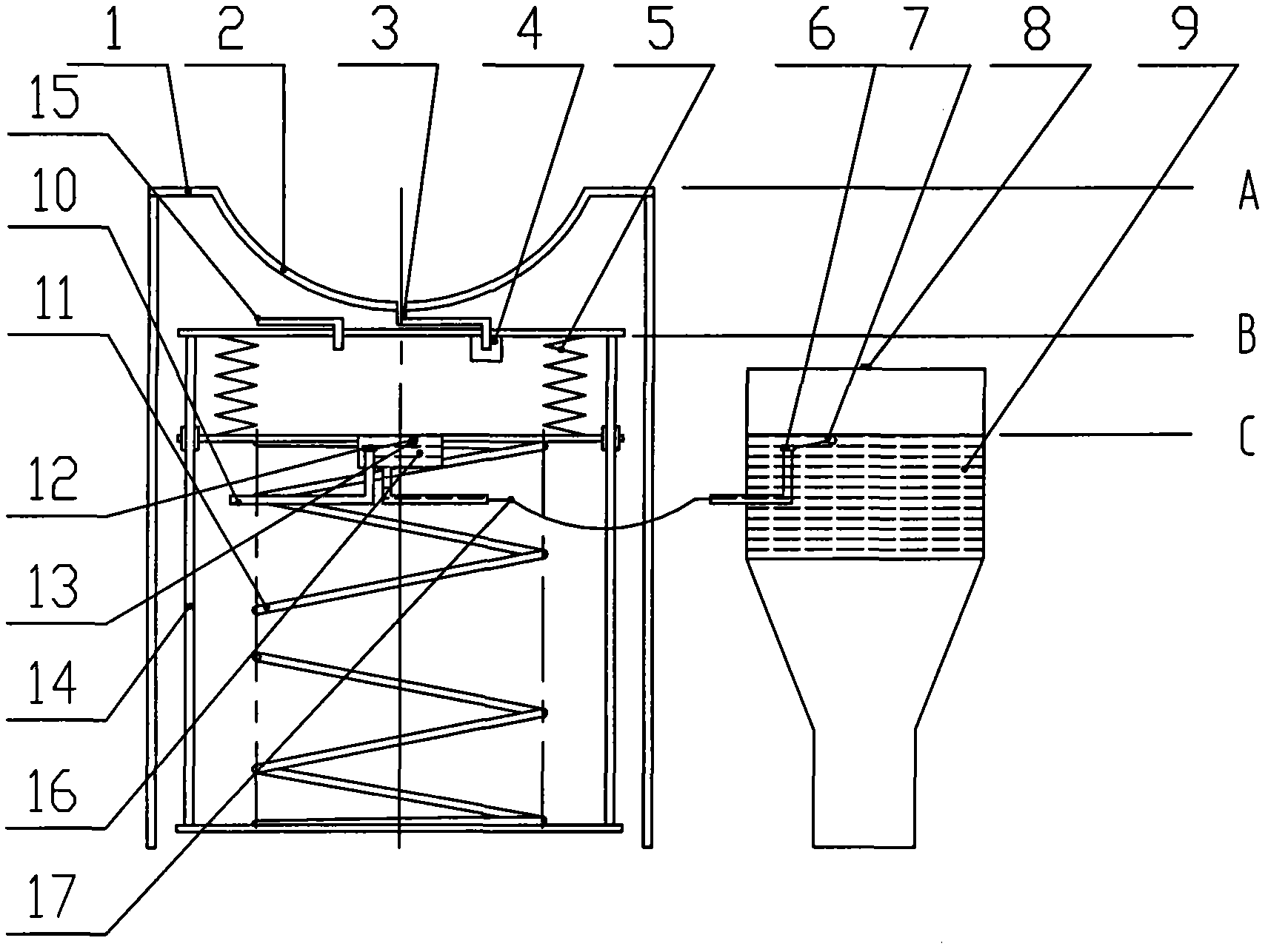

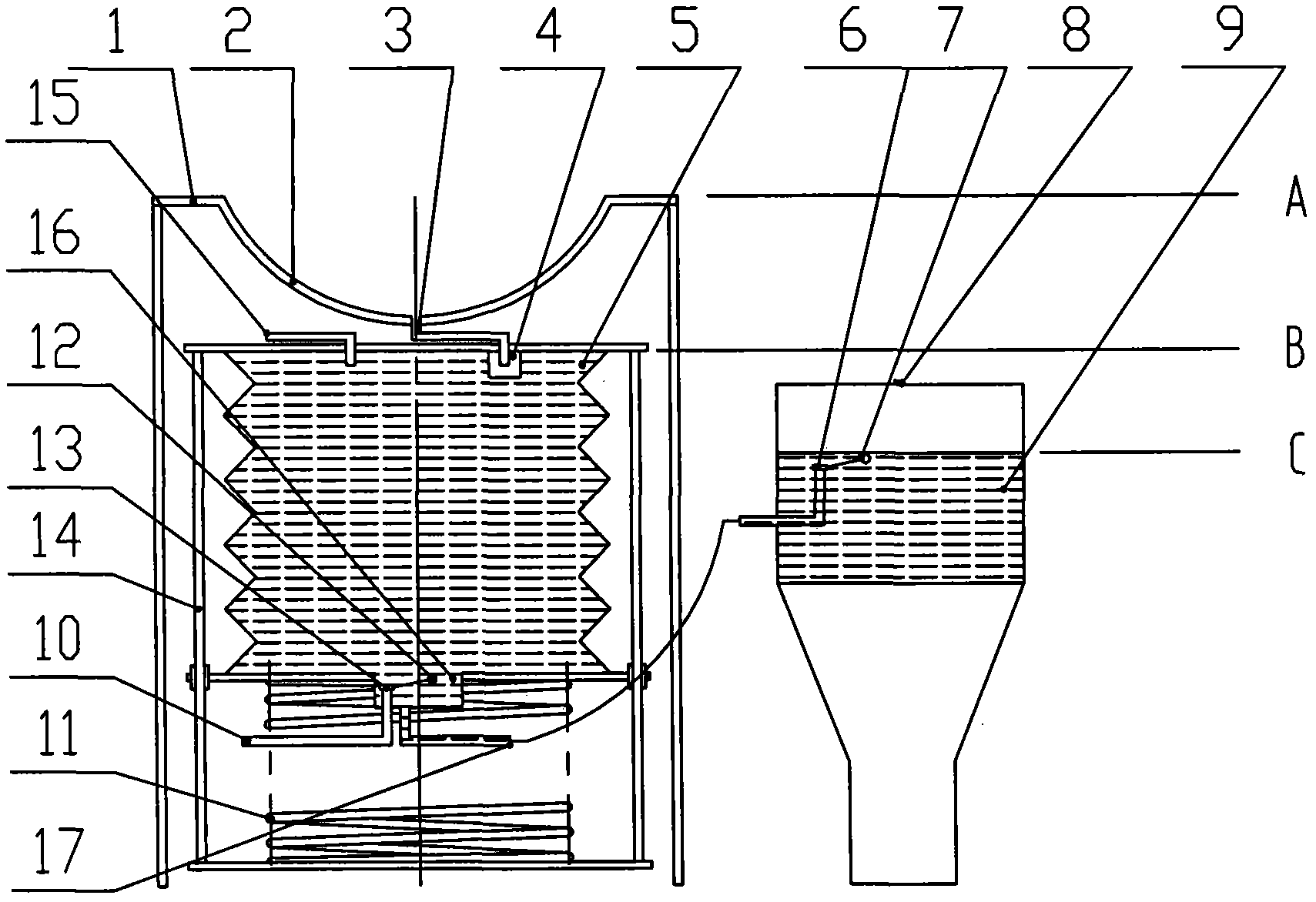

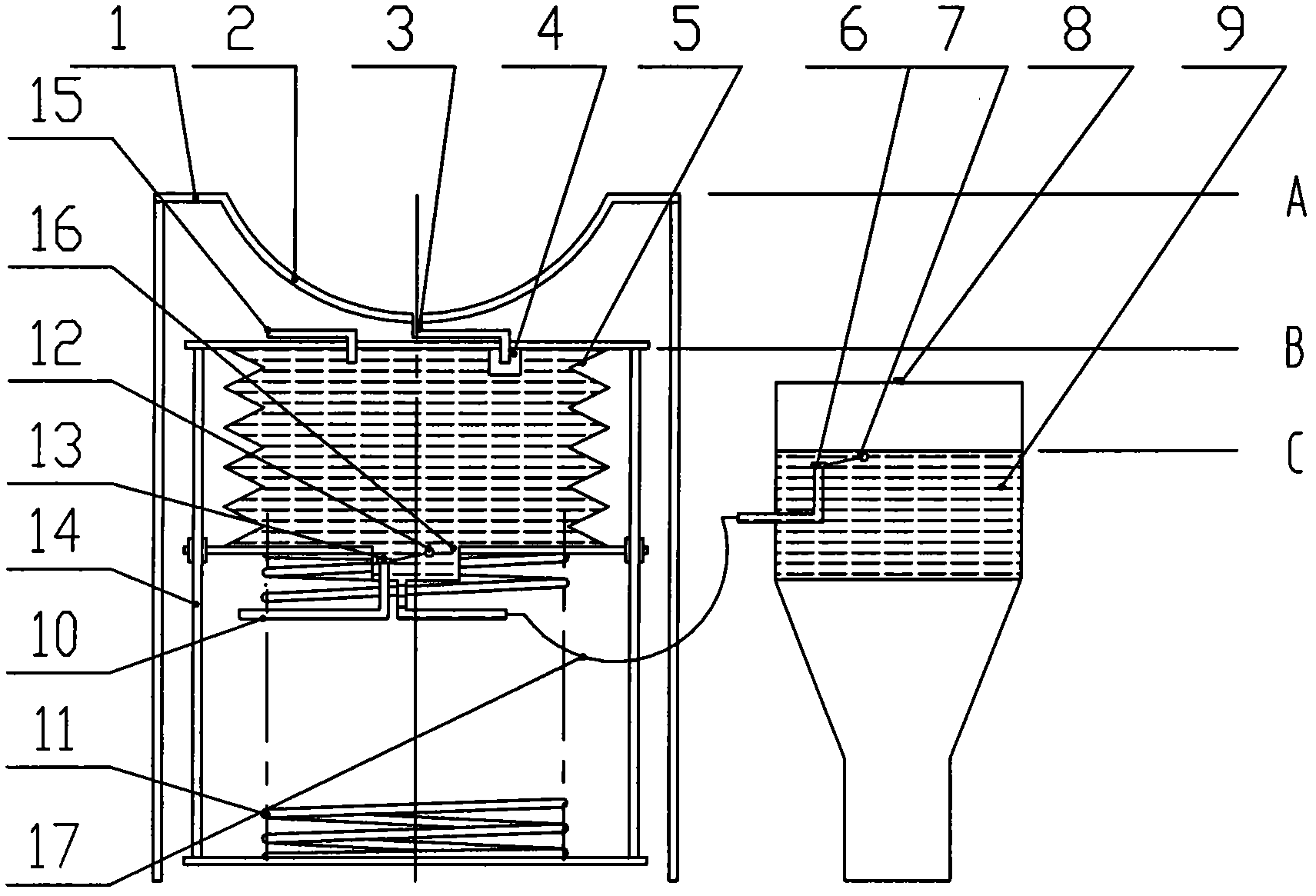

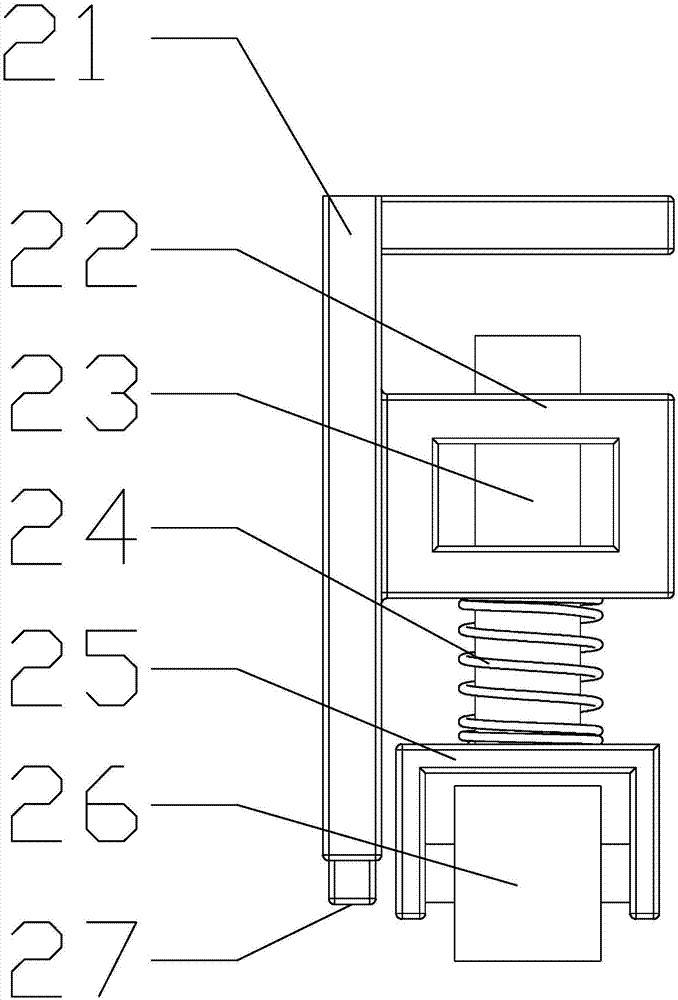

Drawing type three-dimensional planting greenhouse set for edible mushrooms and using method thereof

InactiveCN105027973AConveniently placedSave landCultivating equipmentsMushroom cultivationGreenhouseLife habit

The invention belongs to the field of agricultural planting facilities, and relates to a greenhouse, in particular to a drawing type three-dimensional planting greenhouse set for edible mushrooms and a using method thereof. The drawing type three-dimensional planting greenhouse set for the edible mushrooms comprises two dank greenhouses and a drying platform, wherein the dank greenhouses are used for supplying a shading and moisturizing environment for the edible mushrooms, and the drying platform is used for supplying a ventilating and drying environment for the edible mushrooms. Compared with the prior art, the drawing type three-dimensional planting greenhouse set for the edible mushrooms and the using method thereof have the advantages that traditional ground planting of the edible mushrooms is designed into three-dimensional planting, and the greenhouse set formed by combining the two opposite dank greenhouses and the shared drying platform is designed according to the life habits of the edible mushrooms; coordination of track racks and walking tracks is utilized, the walking tracks with the edible mushrooms on hanging pieces can be conveniently placed in the dank greenhouses and on the drying platform through drawing, so that the dank or drying conditions needed by the growth of the edible mushrooms can be met, therefore, land is saved, and the yield and quality are improved.

Owner:LINYI LANSHAN DISTRICT JINQIAO EDIBLE MUSHROOMS GROWING FARMERS SPECIALIZED COOP

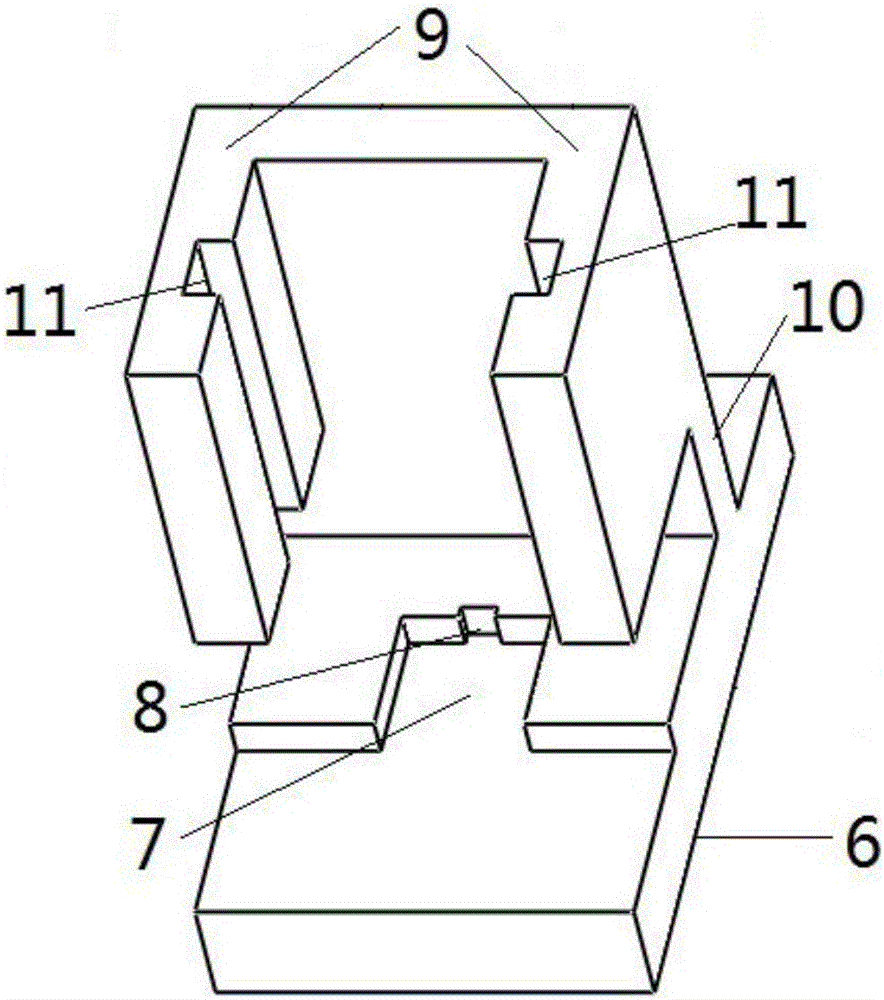

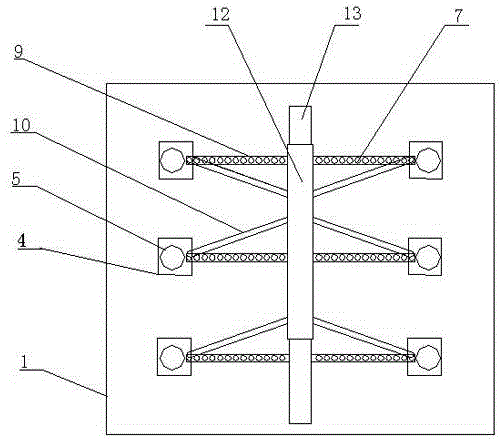

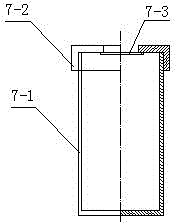

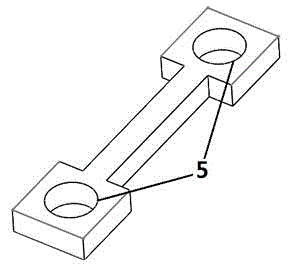

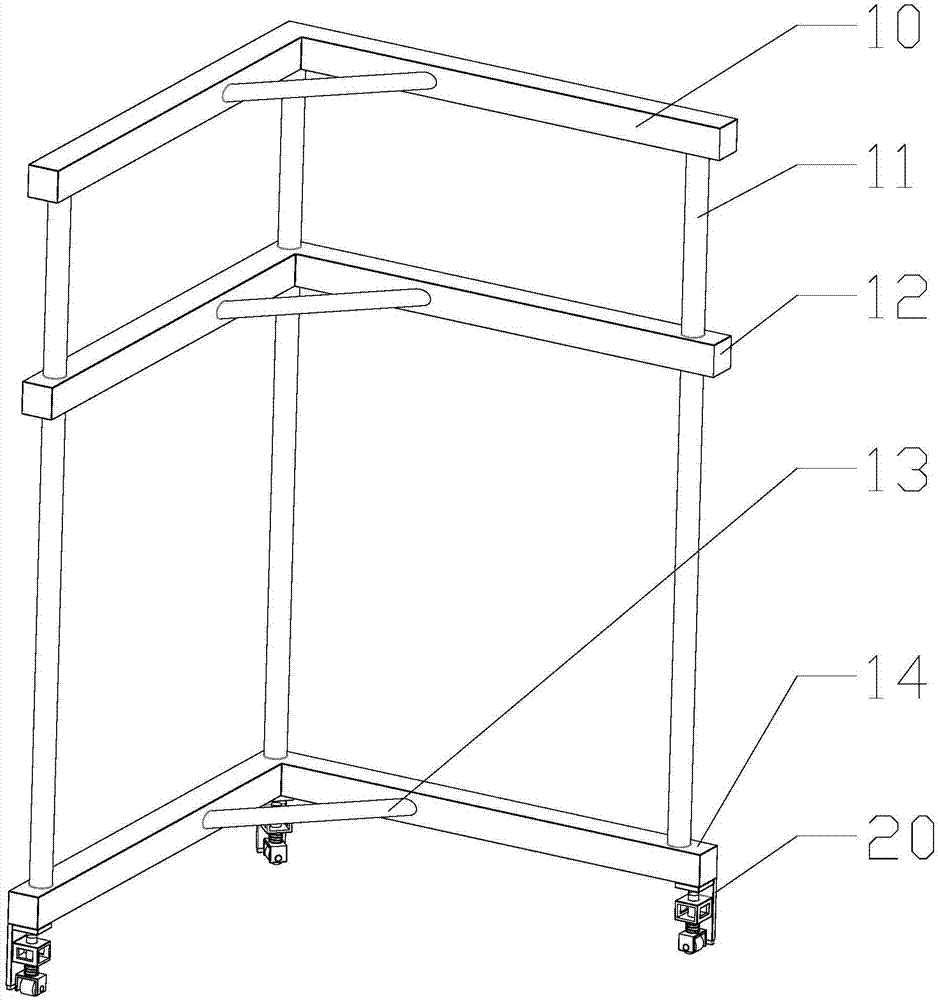

Self-aligning sintering clamp and method for semiconductor laser chip

ActiveCN105896307ASimple structureLow costLaser detailsSemiconductor lasersSemiconductor chipEngineering

The invention relates to a self-aligning sintering clamp and method for a semiconductor laser chip. The clamp comprises a pedestal, a guide rail support, and a press block. The pedestal is provided with a positioning card slot matched with a heat sink. Two sides of the press block are provided with symmetric positioning racks. The guide rail support is vertically disposed on the pedestal, and is provided with symmetric suspension arms. The interior of each suspension arm is provided with a positioning guide rail. The positioning racks of the press block can be sleeved by the positioning guide rails, and move up and down in the positioning guide rails. The bottom end of the press block is provided with a press column. When the press block moves downwards, the press column compresses a chip on the heat sink. The invention also provides the method for sintering the semiconductor laser chip through the above clamp. The clamp is simple in structure, is low in cost, can achieve the self-aligning, and is convenient for operation and observation. The method can achieve the quick batch sintering of the semiconductor laser chips and heat sinks, and remarkably improves the sintering yield of the clamp.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

Portable device box capable of rapidly introducing gun head

ActiveCN107837832ADress up quicklySave time at workSupporting apparatusElectrical and Electronics engineering

Owner:贵州金域医学检验中心有限公司

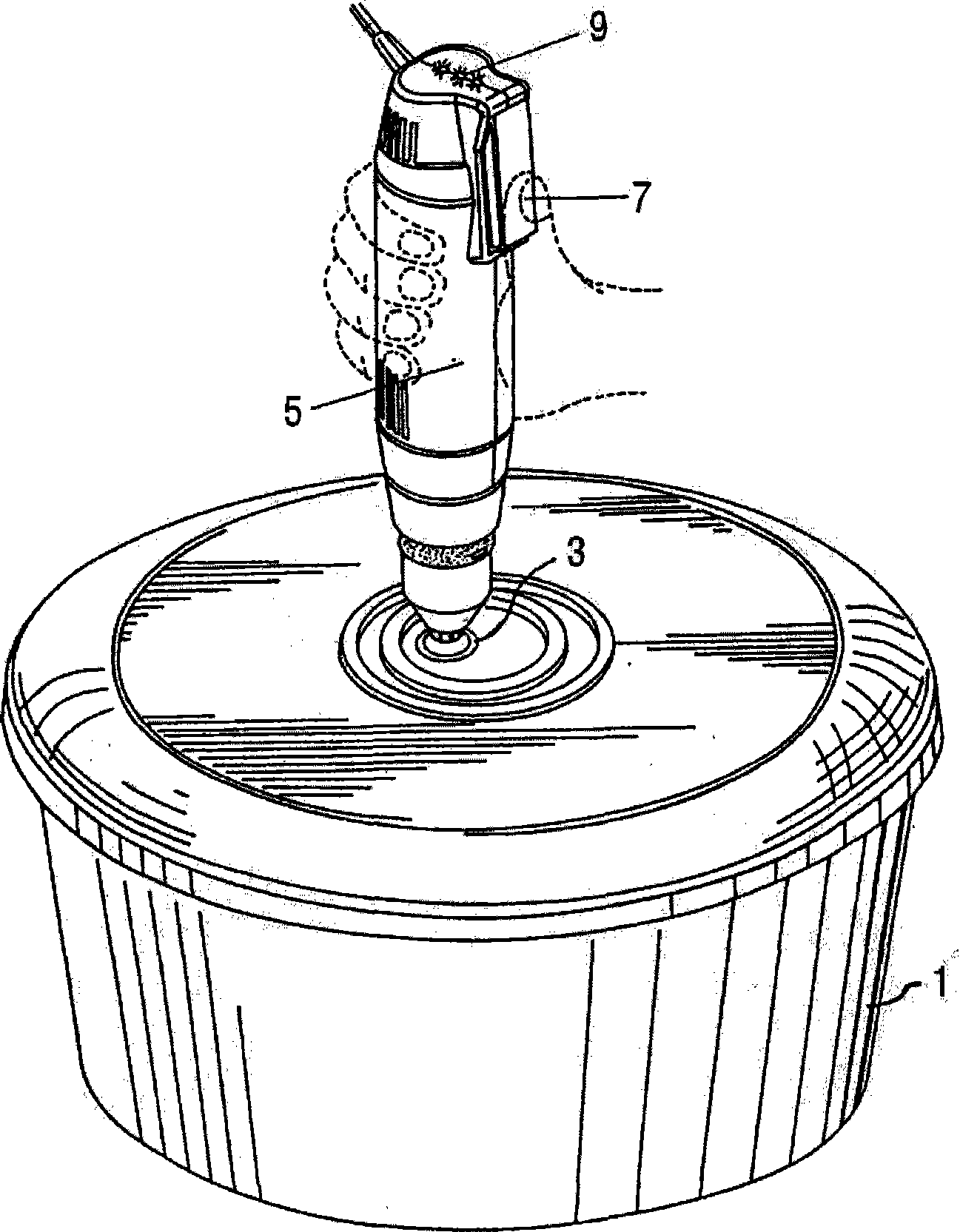

Handheld vacuum suction device

InactiveCN101387287AIncreased durabilitySimple internal structurePositive displacement pump componentsFlexible member pumpsElectricityDecreased pressure

Provided is a handy type vacuum suction device compactly constructed including a suction nozzle for minimizing the flow of water into a vacuum pump to improve the durability of a pressure switch which measures a degree of vacuum, and a diaphragm type vacuum pump. The handy type vacuum suction device comprises an external case, a cap including the suction nozzle and detachably mounted at the lower end of the external case, a pressure switch part mounted in the external case and including the pressure switch for cutting off power supply with a sliding body to be moved down while overcoming the elastic force of a spring when pressure in the cap falls down to predetermined pressure or lower, and a suction pipe formed passing though the inside to the outside, the vacuum pump having a suction port connected to the suction pipe for sucking air in a diaphragm system, and a control part having an operating switch and electrically connected to the vacuum pump and the pressure switch for controlling the operation of the vacuum pump.

Owner:HANA COBI PLASTIC

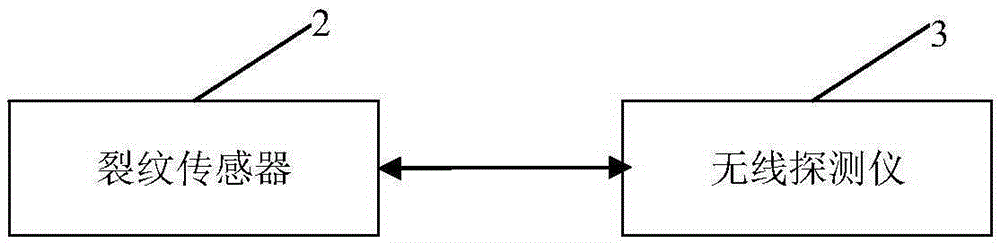

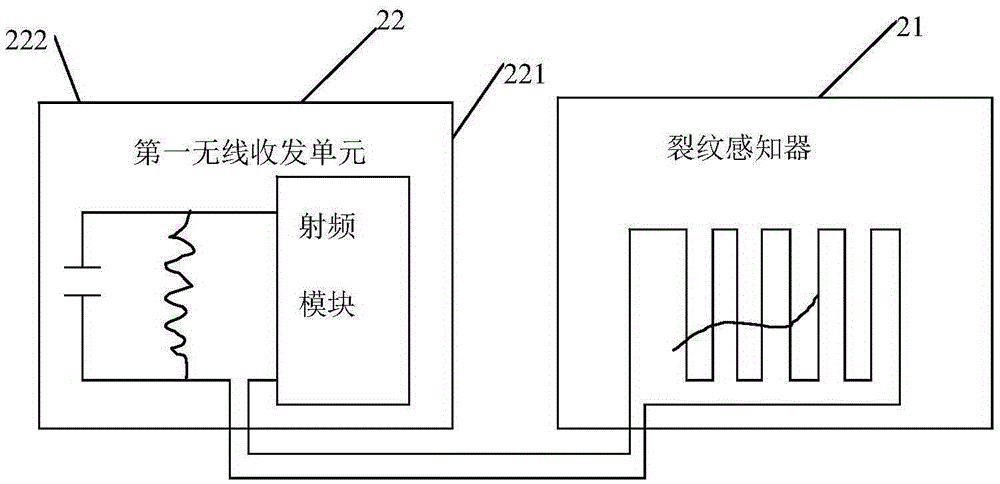

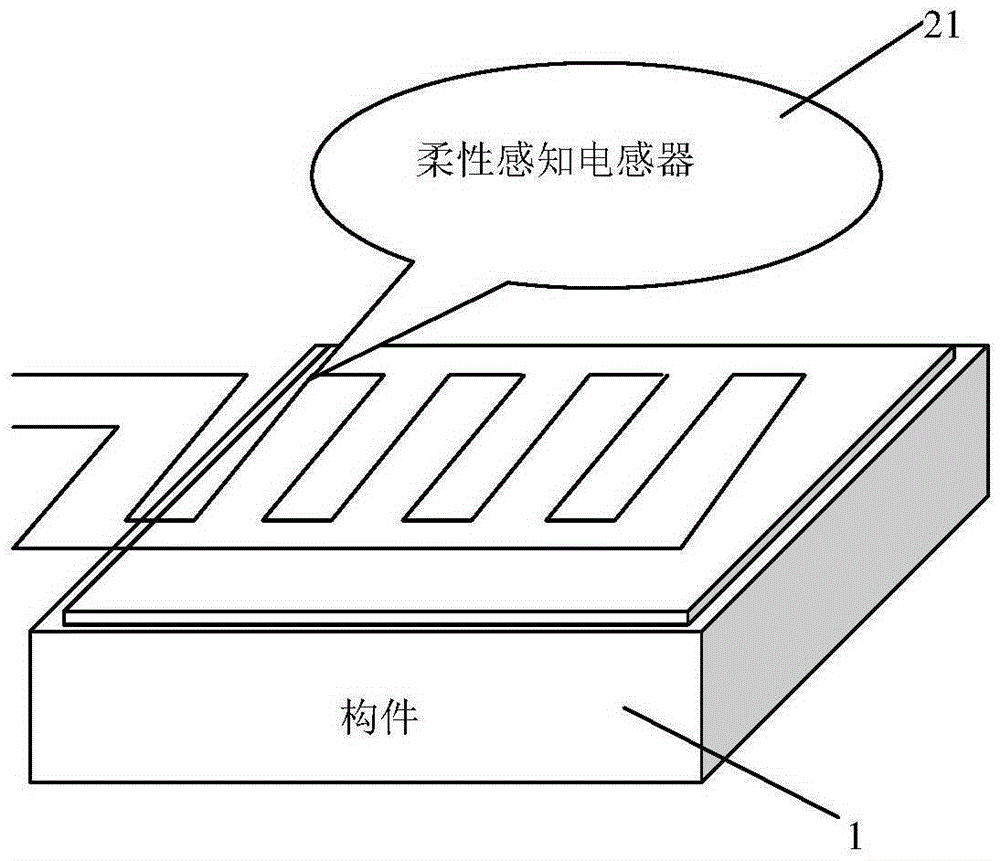

Crack detecting system and detecting method thereof

ActiveCN105334235ASimple and efficient operationEasy to readMaterial analysis using wave/particle radiationElectric energyComputer science

The invention discloses a crack detecting system which comprises a crack sensor installed on a component to be detected, and a wireless detecting instrument in communication connection with the crack sensor. The wireless detecting instrument is configured to send electromagnetic waves to the crack sensor so as to send inquiring signals and electric energy to the crack sensor, and whether cracks exist or not is judged according to whether the wireless detecting instrument receives response signals corresponding to the inquiring signals or not. The crack sensor is configured to detect whether cracks exist on the component or not, and when it is detected that no crack exists on the component, the response signals corresponding to the inquiring signals are sent to the wireless detecting instrument. When it is detected that the cracks exist on the component, no signal is sent to the wireless detecting instrument. The crack detecting system has the advantages of being convenient to install and high in detecting precision and needing no external power source.

Owner:兰毓华

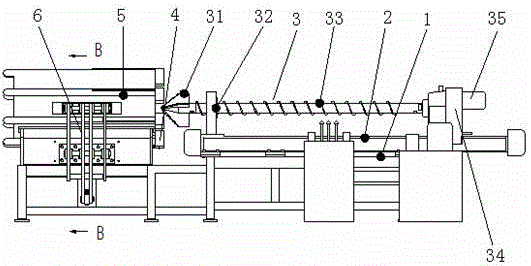

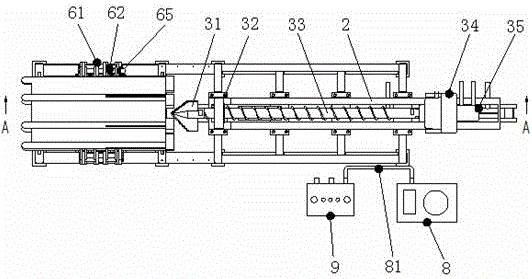

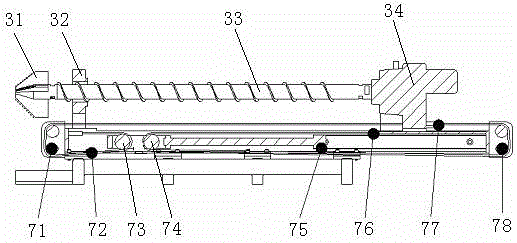

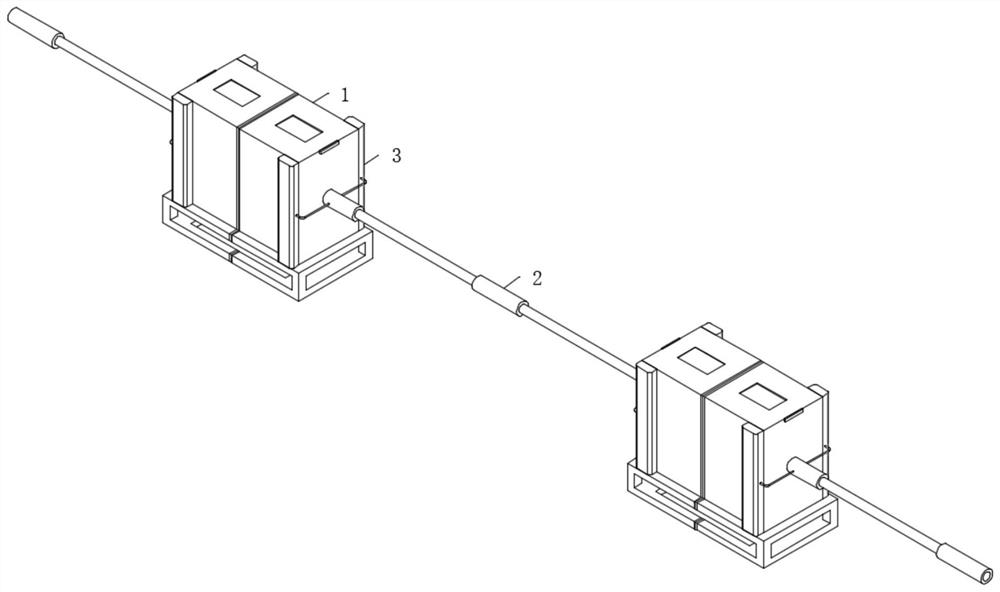

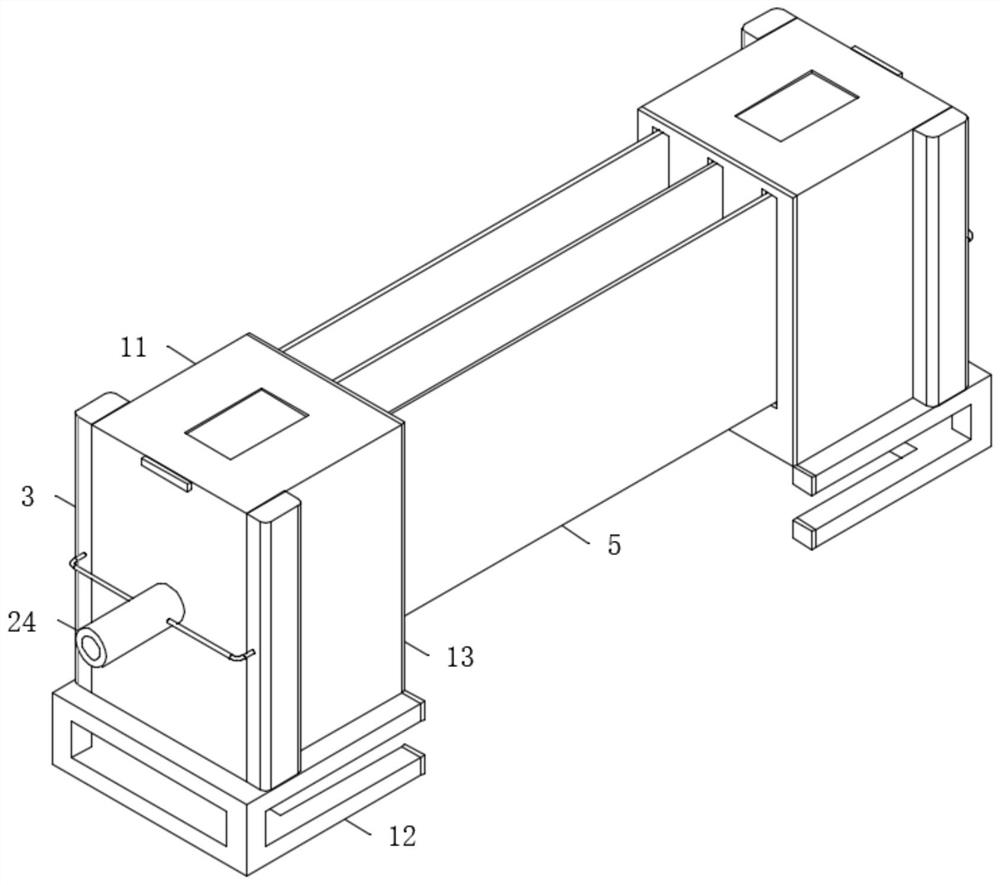

Cast workpiece inner cavity automatic sand cleaning machine

The invention provides a cast workpiece inner cavity automatic sand cleaning machine. The machine comprises a frame, and is characterized in that a guide rail is arranged at one end of the frame; the guide rail is provided with a spiral feeding drill bit mechanism; and front and back clamping mechanisms are oppositely arranged at the other end of the frame. The machine can conveniently place cast workpieces on the frame, clamps the cast workpieces through the clamping mechanisms, can push into cavities of the cast workpieces to automatically loosen sand through the spiral feeding drill bit mechanism, cleans out the sand in the cavities of the cast workpieces through spiral rotation, discharges the sand into sand bags or sand baskets by a sand discharge groove, is high in working efficiency and fast and convenient to clean the sand, largely reduces the labor intensity of workers, can once remove and load the sand into the bags or baskets, realizes clean production, and guarantees the product quality.

Owner:KUNMING SHIPBUILDING EQUIP

Intelligent blood centrifugation balancing instrument and balancing method

InactiveCN104061988ARealize automatic trimTrim is simpleMaterial check-weighingSolenoid valveCentrifugation

The invention provides an intelligent blood centrifugation balancing instrument and a balancing method. The intelligent blood centrifugation balancing instrument is characterized in that the adopted balancing object comprises plastic cement balancing rods and liquid filler, wherein each of the plastic cement balancing rods is a hollow rod with one end open, and a plug or an elastic closing cover is arranged at the open end. On the basis of the intelligent balancing instrument, a balancing filler chamber is arranged in a case, six feeding tubes independent to each other are connected to a discharging port in the balancing filler chamber, and solenoid valves are arranged on the feeding tubes. A magnetic core push rod of a push electromagnet drives feeding ports of the feeding tubes to move to be in butt joint with the corresponding plastic cement balancing rods in centrifugation lining buckets on trays of electronic balances, the feeding tubes return to the original places after feeding, and the push electromagnet, the solenoid valves and weighing sensors are connected with a board of a single-chip microcomputer. The intelligent blood centrifugation balancing instrument is capable of performing balancing simply, conveniently and accurately and high in automation degree. The balancing object is reasonable in structure and capable of being filled conveniently, formation of centrifugal dead space is prevented effectively, and risk of centrifugal breakage is reduced.

Owner:QINGDAO BLOOD CENT

Multifunctional culture device for parasitic plant and application method thereof

PendingCN109392685AEasy to joinPromote emptyingAgriculture gas emission reductionCultivating equipmentsGerminationEngineering

The invention provides a multifunctional culture device for a parasitic plant and an application method thereof. The multifunctional culture device is used for conveniently culture the parasitic plant. According to the invention, a magnifying glass is arranged on a drum cover; a fixed block is fixedly arranged on the inner wall of a drum body; a transition pipe is fixedly arranged on the fixed block; a water inlet pipe and a water outlet pipe communicating with the chamber of the transition pipe are arranged on the transition pipe; a first one-way valve is arranged in the water inlet pipe; a second one-way valve is arranged in the water outlet pipe; a rotating shaft is rotatably arranged at the upper part of the fixed block; a locking block is arranged on the rotating shaft; an inoculationsupport is detachably arranged on the locking block; a germination box is detachably arranged on the inoculation support; the opened end of the germination box is provided with a box cover; a partition plate is fixedly arranged in the inner chamber of the germination box; a cloth pad is placed on the partition plate; the bottom part of the cloth pad is provided with cloth whiskers which penetratethrough water through holes arranged on the partition plate to extend downward; a plurality of clips are hinged on the outer wall of the germination box; and a bearing mechanism is arranged at the bottom part of the inner chamber of the drum body. The multifunctional culture device provided by the invention can facilitate culture research on the parasitic plant.

Owner:HANGZHOU NORMAL UNIVERSITY

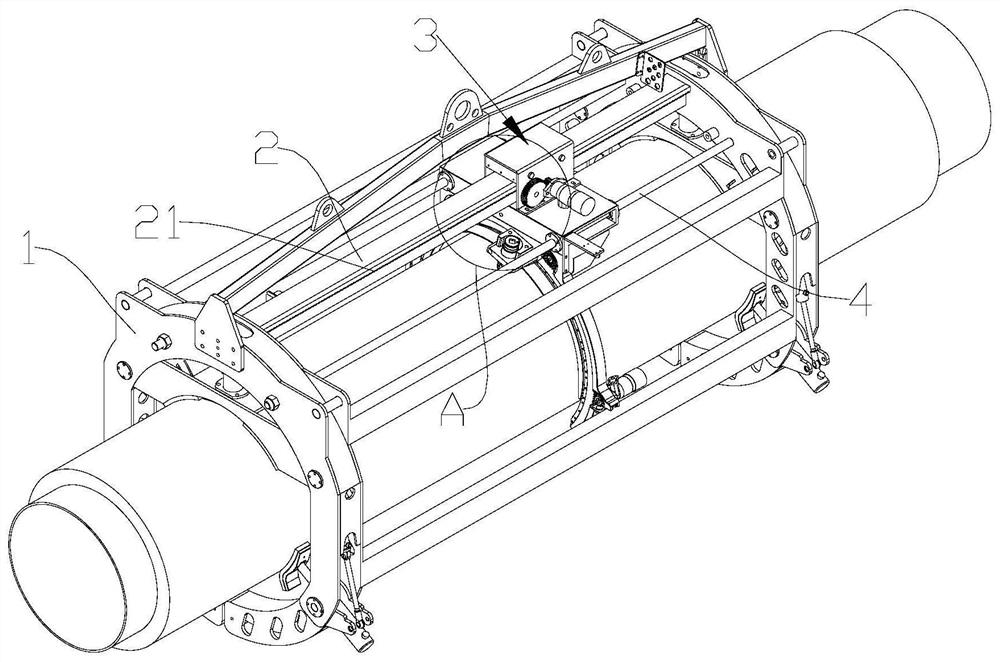

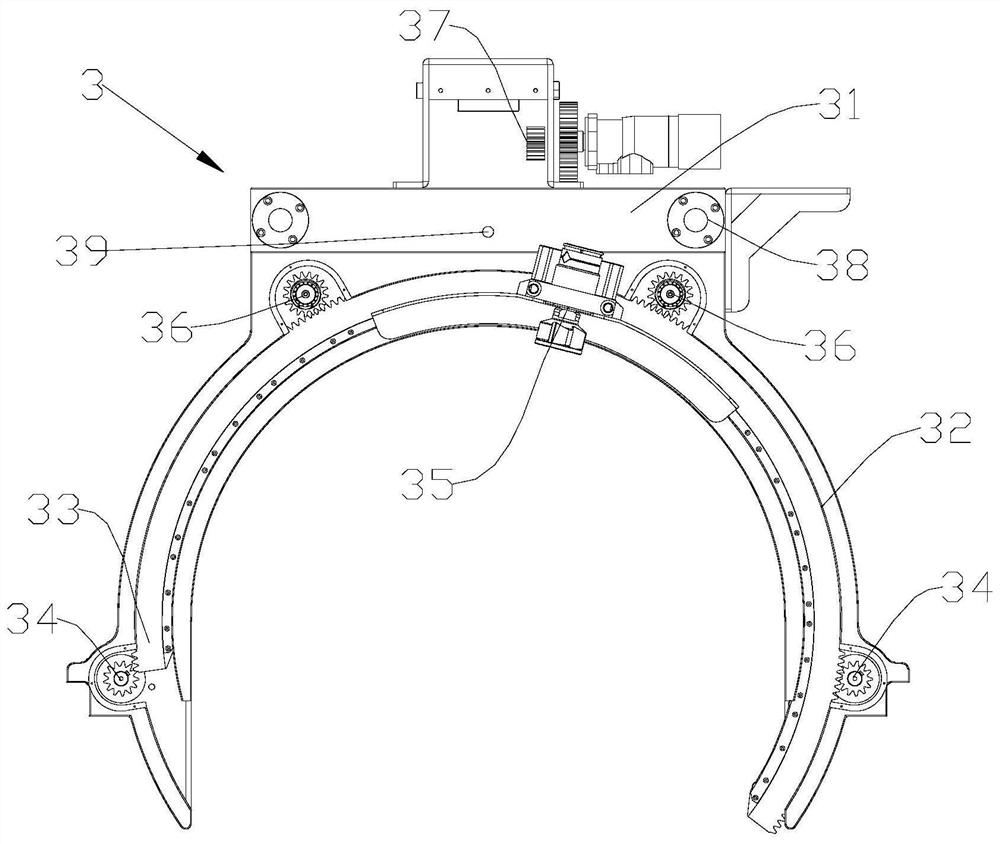

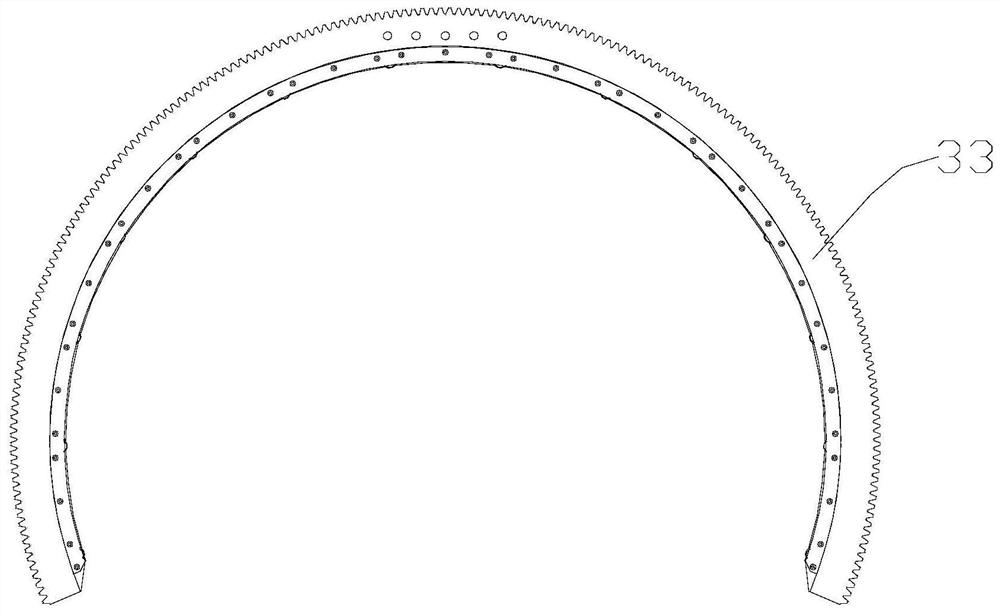

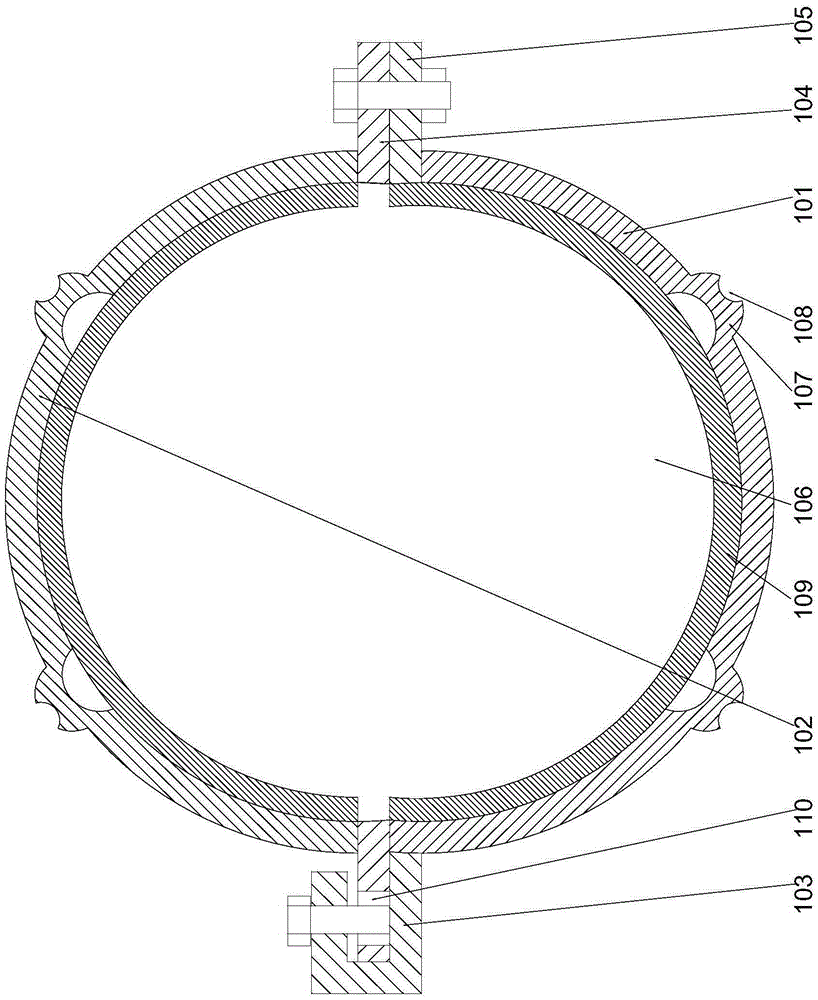

Rotary cleaning mechanism and pipeline surface cleaning mechanism

PendingCN111842351AImprove cleaning efficiencyConveniently placedHollow article cleaningSurface cleaningGear wheel

The invention provides a rotary cleaning mechanism and a pipeline surface cleaning mechanism, and particularly relates to the field of water bottom pipeline surface cleaning equipment. The rotary cleaning mechanism capable of sliding back and forth in the pipeline direction is installed on a pipeline surface cleaning machine, a notch is formed in the rotary cleaning mechanism, and a pipeline is conveniently arranged at the rotary center of the rotary cleaning mechanism. According to the rotary cleaning mechanism, through the transmission of a gear and a gear ring, a spray nozzle is driven to rotate by 360 degrees, that is the outer surface of the pipeline can be cleaned by 360 degrees, after the rotary cleaning mechanism is installed on the pipeline surface cleaning machine, the pipeline can be conveniently clamped, under the driving of the gear, the rotary cleaning mechanism is driven to operate back and forth on a connecting column, the rotary cleaning mechanism can axially move along the pipeline within the cleaning range of the pipeline and rotates by 360 degrees around the pipeline, cleaning dead angles are completely eradicated, and the cleaning efficiency of the pipeline surface cleaning machine is improved.

Owner:重庆洁盟环保科技有限公司

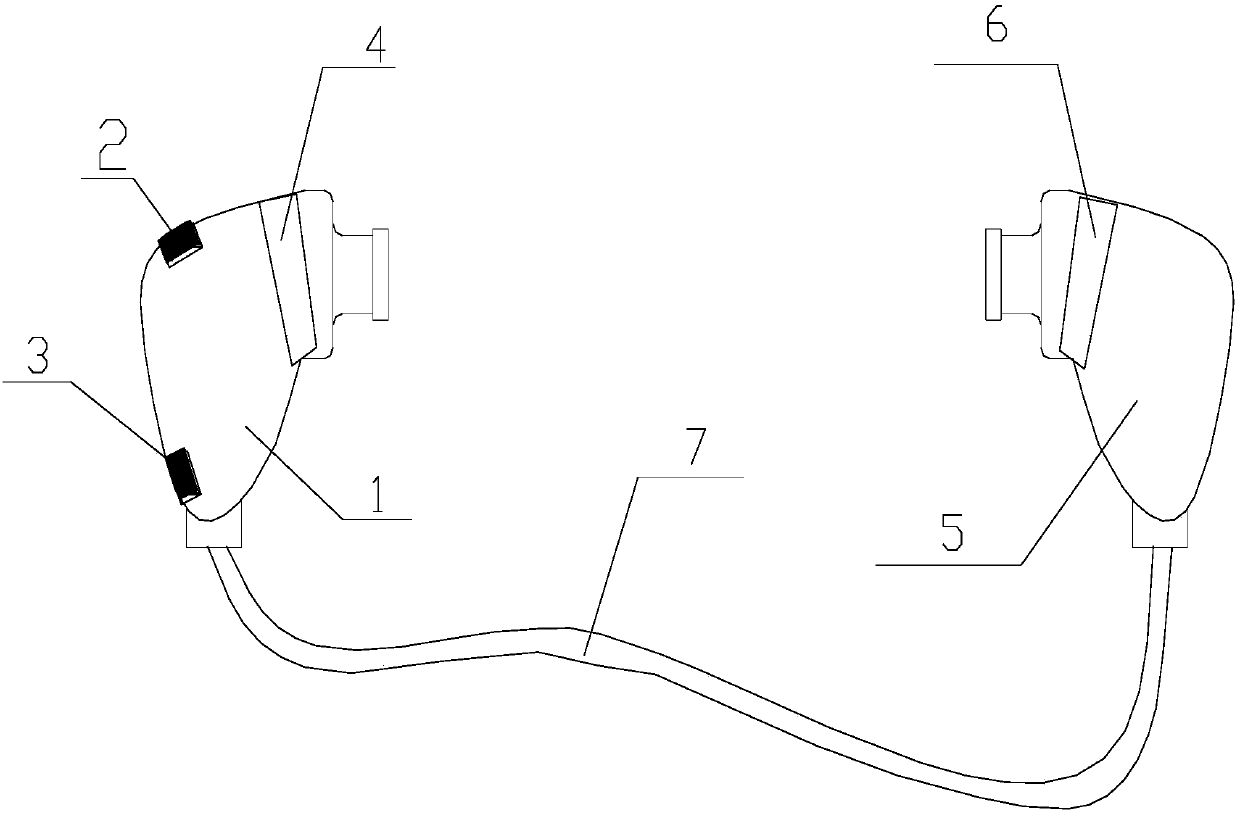

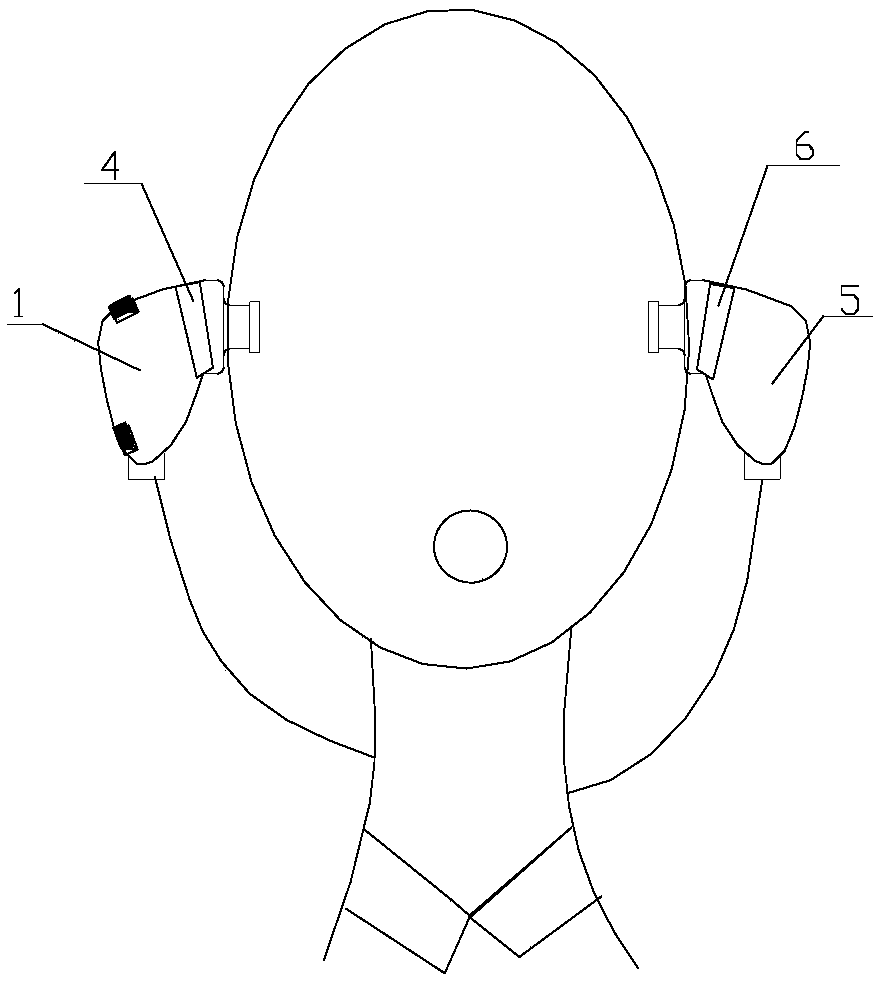

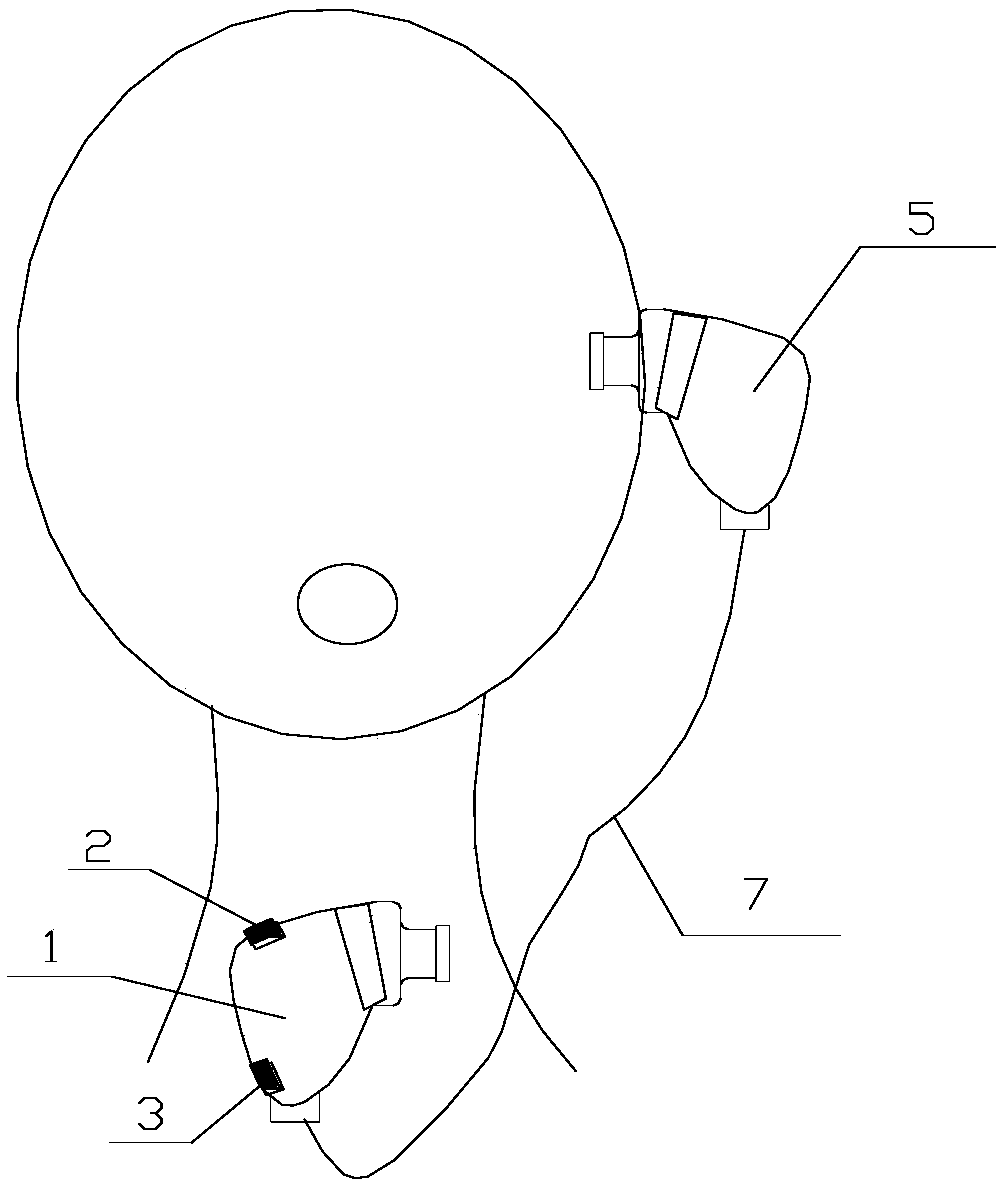

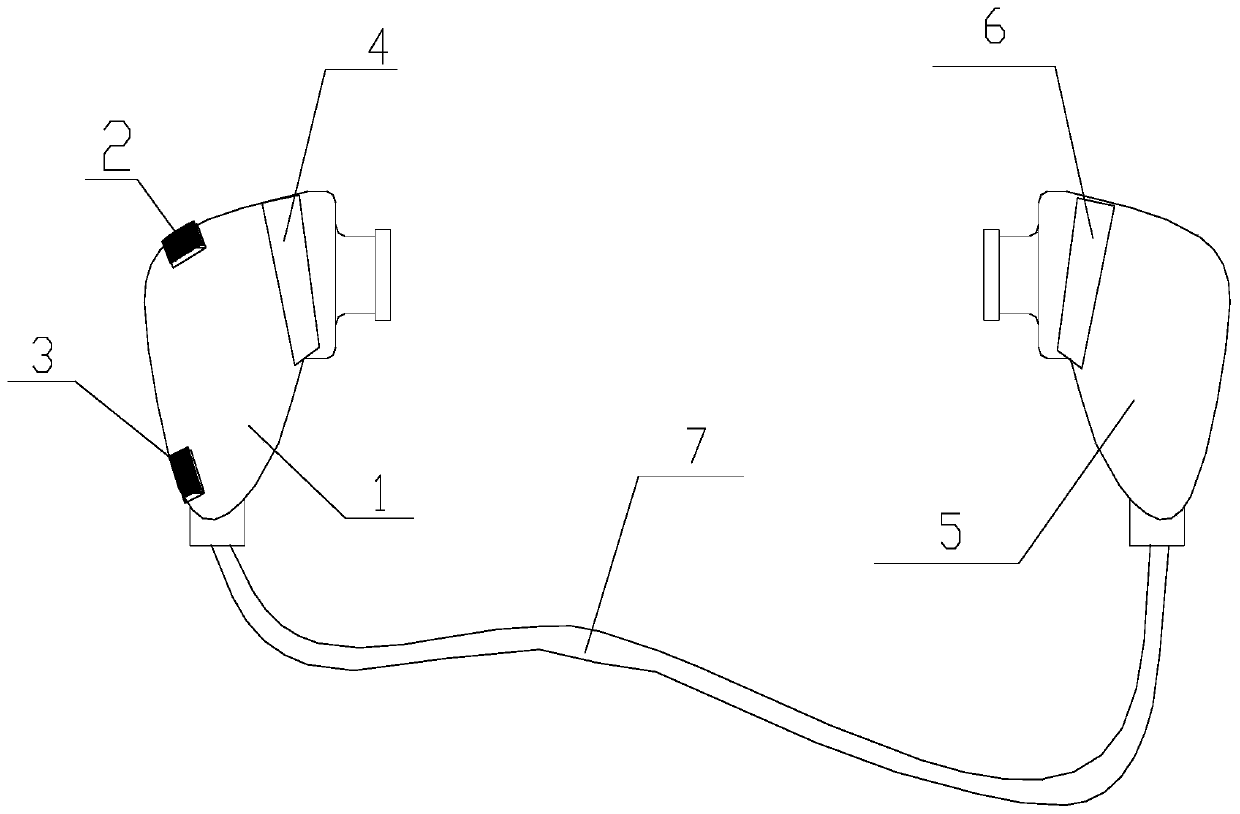

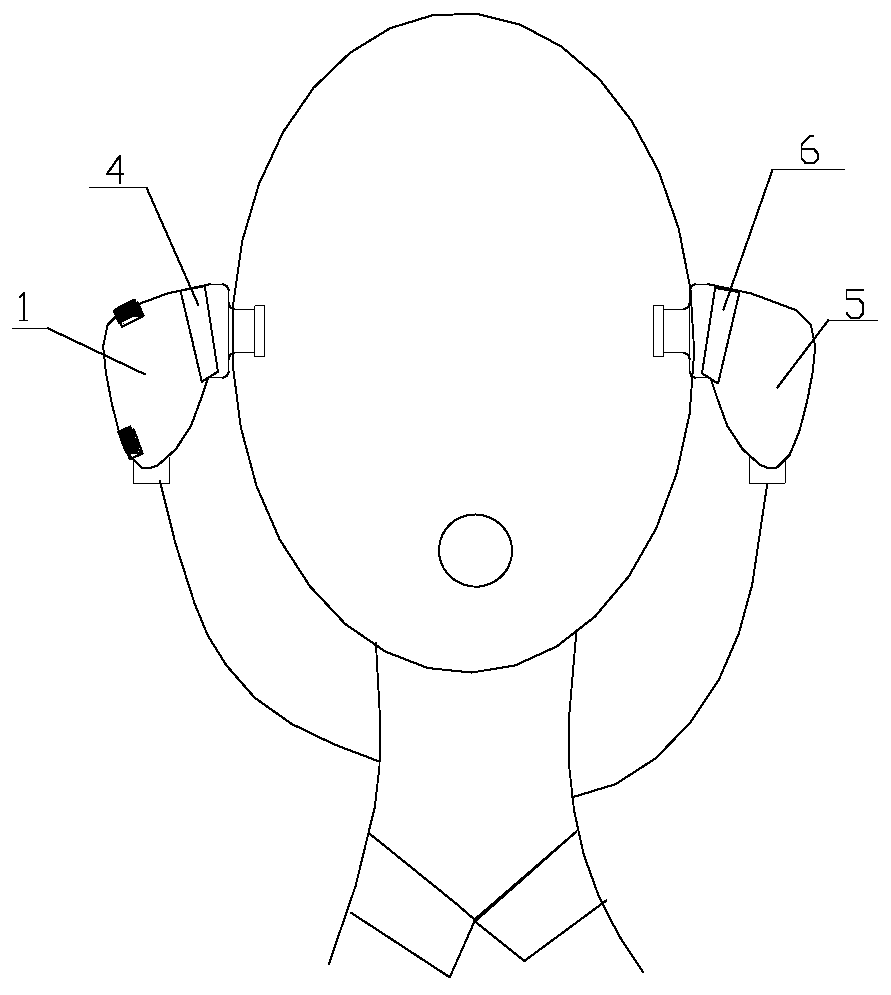

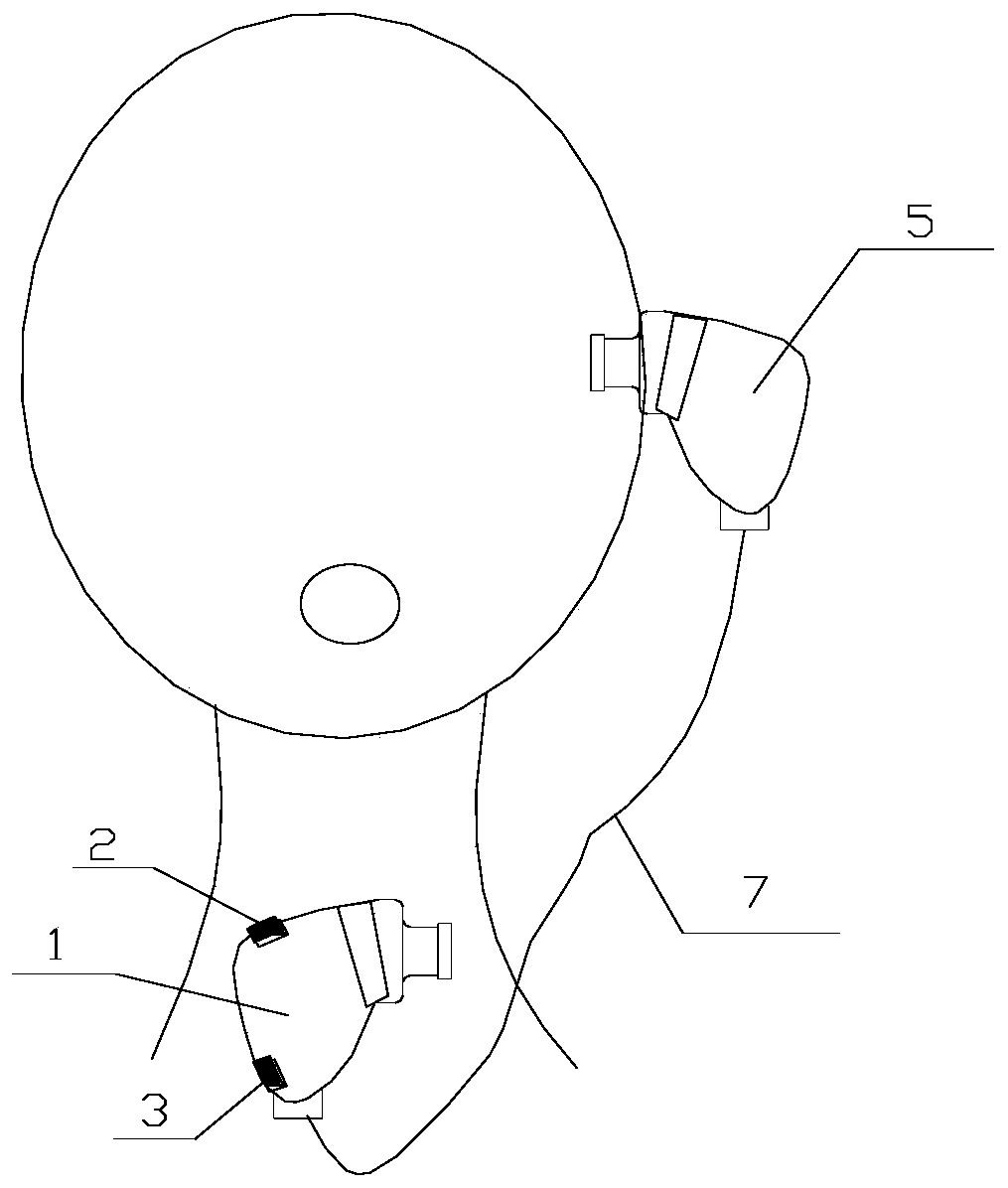

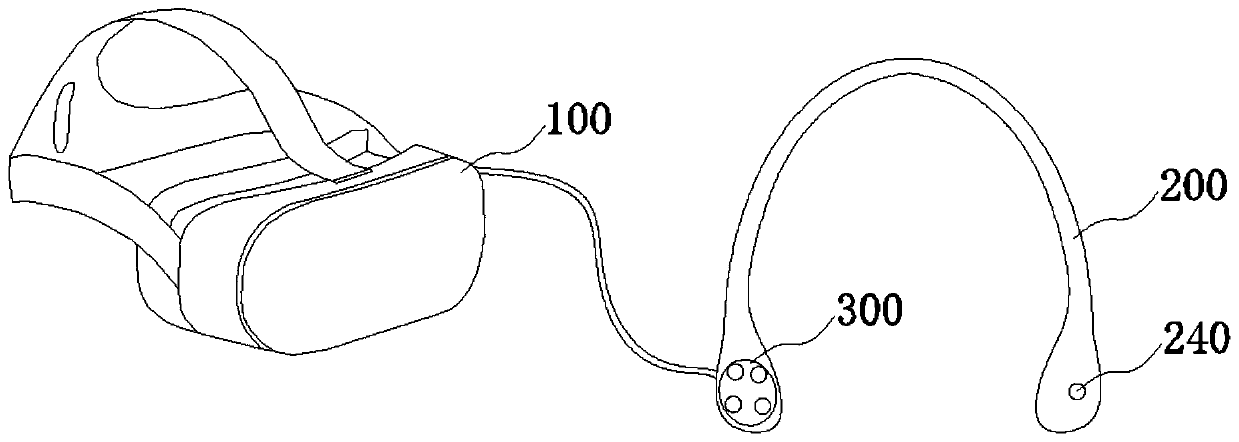

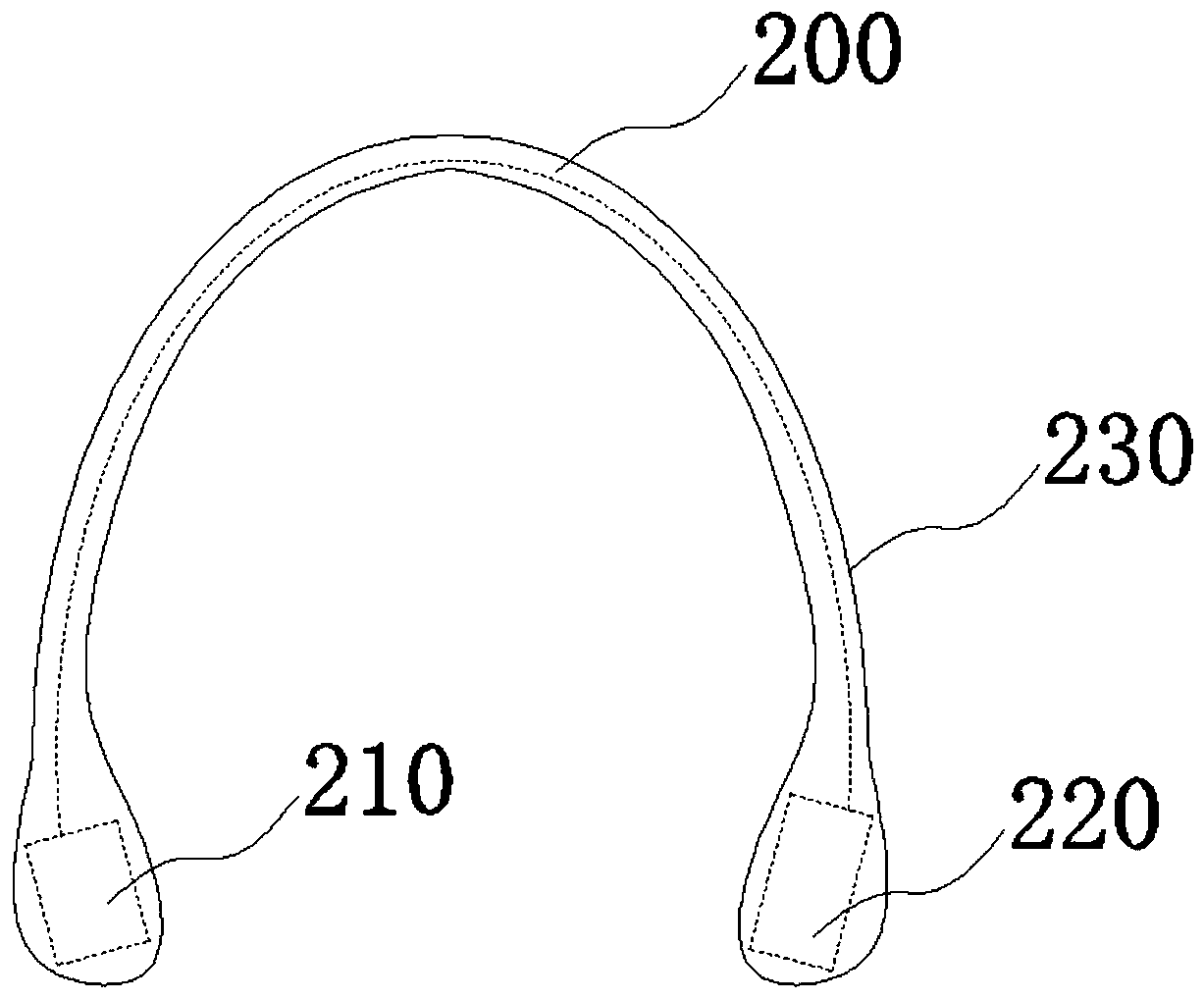

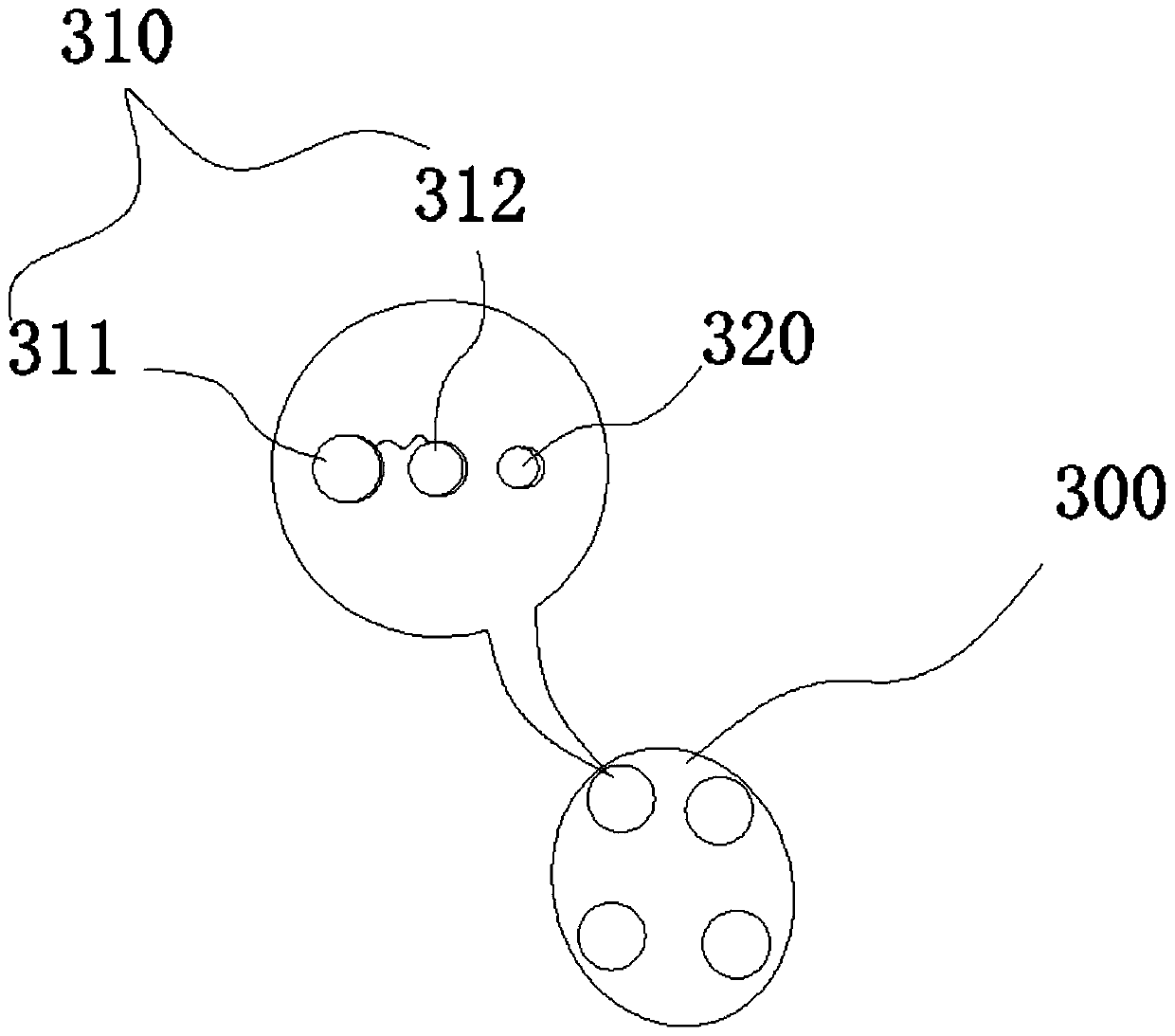

Neck-line bluetooth earphone and application method thereof

ActiveCN108055605AGood noise reductionNearbySupra/circum aural earpiecesMouthpiece/microphone attachmentsEngineeringNoise detection

The invention provides a neck-line bluetooth earphone and an application method thereof, wherein the neck-line bluetooth earphone comprises two earphone shells and an earphone wire used for being connected with the two earphone shells; a microphone array is arranged on one of the earphone shells; the neck-line bluetooth earphone further comprises a noise detection sensor arranged on the two earphone shells or the earphone wires, and the noise detection sensor is used for detecting the noise of the environment where the neck-line bluetooth earphone is located; a metal tube is arranged on the earphone wire in a sleeved mode, and the metal tube is used for fixing the shape of the earphone wire. By means of the earphone and the method in the invention, the problem that the noise reduction effect is poor due to the fact that the microphone of the existing bluetooth earphone is far away from the sound source can be solved.

Owner:GOERTEK INC

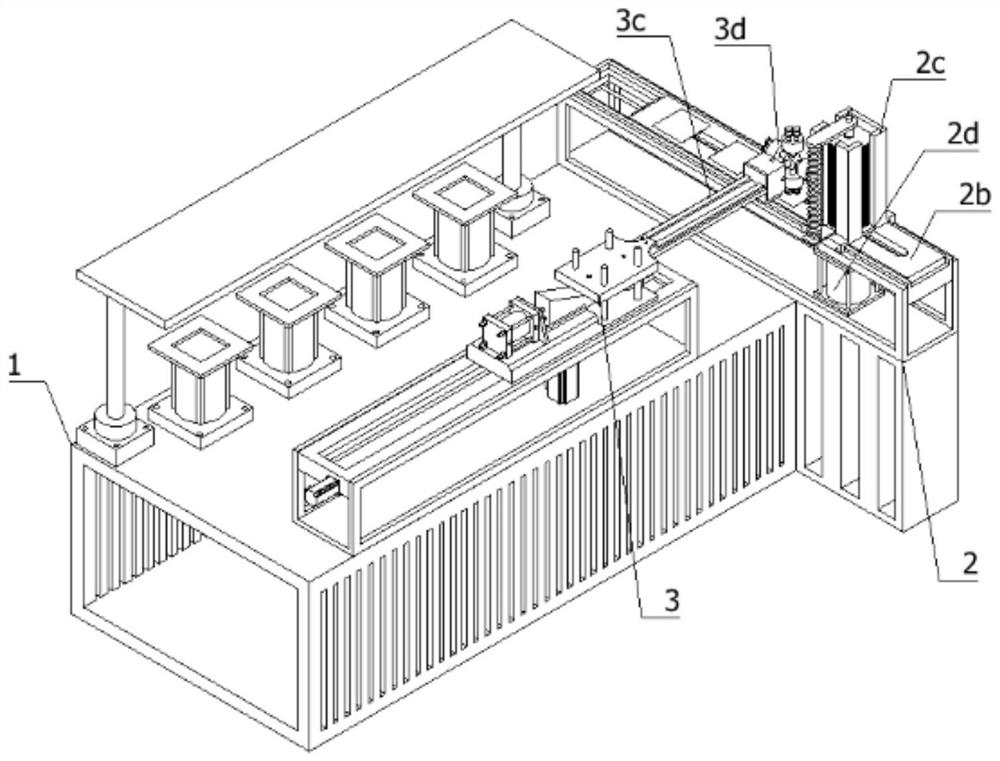

Multi-station high-speed carrying device for press line

ActiveCN113714411AImprove processing efficiencyReduce labor intensityMetal-working feeding devicesPositioning devicesStampingPhysics

The invention relates to the field of multi-station stamping dies, in particular to a multi-station high-speed carrying device for a press line. The multi-station high-speed carrying device comprises a multi-station stamping table, and further comprises a material distributing device and a material sucking device which are arranged on the multi-station stamping table, wherein the material distributing device is used for separating plate-shaped parts to be adsorbed from plate-shaped parts which are not adsorbed according to the number of the plate-shaped parts adsorbed by the material sucking device; and the material distributing device comprises a conveying frame, a material distributing plate arranged at the top of the conveying frame, a material stacking frame and a jacking air cylinder which is arranged on the conveying frame and is positioned under the material stacking frame. According to the multi-station high-speed carrying device, the material distributing device and the material sucking device are matched with each other, thus, the circumstance that numbers of the absorbed plate-shaped parts in different times are different in the process of carrying the plate-shaped parts at the same time is avoided, the processing efficiency of the plate-shaped parts in batches is improved, and the labor intensity of workers is reduced.

Owner:江苏兴锻智能装备科技有限公司

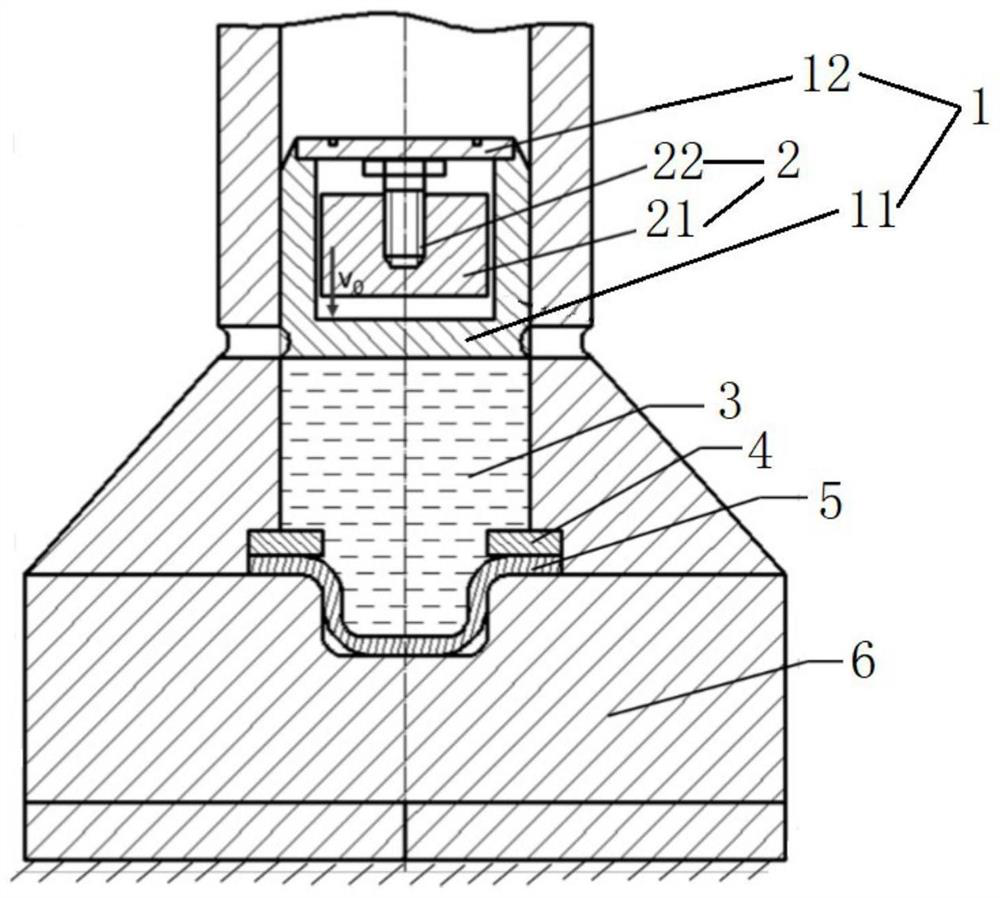

Compound impact body, impact hydraulic formation equipment and impact hydraulic formation method

ActiveCN113290107ATake advantage ofReduce lossShaping toolsMetal working apparatusImpact loadingImpact

The invention discloses a compound impact body, impact hydraulic formation equipment and an impact hydraulic formation method. The mainly adopted technical scheme is characterized in that the compound impact body comprises a primary impact structure and a secondary impact structure, wherein the primary impact structure is provided with an enclosed chamber body; the secondary impact structure is positioned in the enclosed chamber body of the primary impact structure and can be moved in the enclosed chamber body in the impact direction; in an impact hydraulic formation process, after one-time energy is released, the compound impact body is moved, the secondary impact structure can continuously move in the enclosed chamber body in the impact direction when the primary impact structure contacts the liquid level of a liquid chamber and then stops moving, the primary impact structure is stroke after the secondary impact structure is moved at a set distance, so that secondary impact loading of blanks under single-time energy release is realized, the energy is fully utilized and energy loss in the impact hydraulic formation process is reduced, and more importantly, the formation performance of materials can be improved under the effect of the compound impact body.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

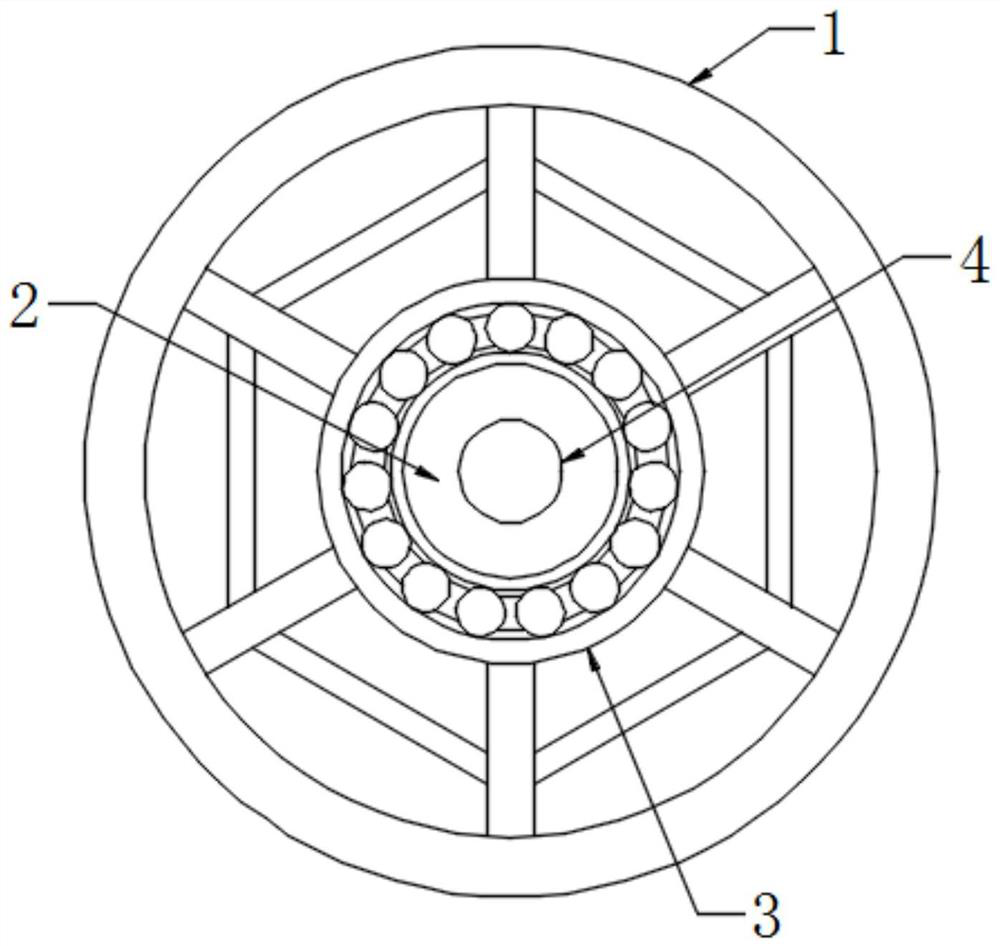

Permanent magnet motor rotor protection device

PendingCN112821641AAddressing Insufficient ProtectionImprove protectionSupports/enclosures/casingsElectric machineryMagneto

The present invention provides a permanent magnet motor rotor protection device which comprises a connecting rod, an outer ring, an outer sliding groove, a ball, an inner sliding groove, a protection ring and a stabilizer bar, the protection ring is mounted on the annular side surface of a rotor main body, the inner sliding groove is formed in the annular side surface of the protection ring, the ball is embedded in the inner sliding groove, and the outer ring is mounted on the outer side of the ball. The inner annular side face of the outer ring is provided with an outer sliding groove, the balls are embedded into the outer sliding groove, the connecting rods are installed between the motor shell and the outer ring, and the stabilizing rod is installed between the connecting rods, the problem that an original permanent magnet motor rotor lacks protection measures is solved through the design, the permanent magnet motor rotor protection device is reasonable in structure, protection is provided for the permanent magnet motor rotor, and abrasion is avoided.

Owner:环一军

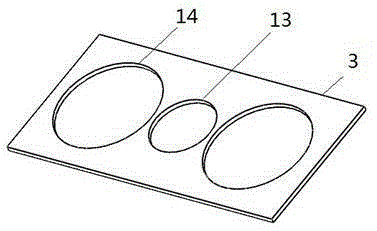

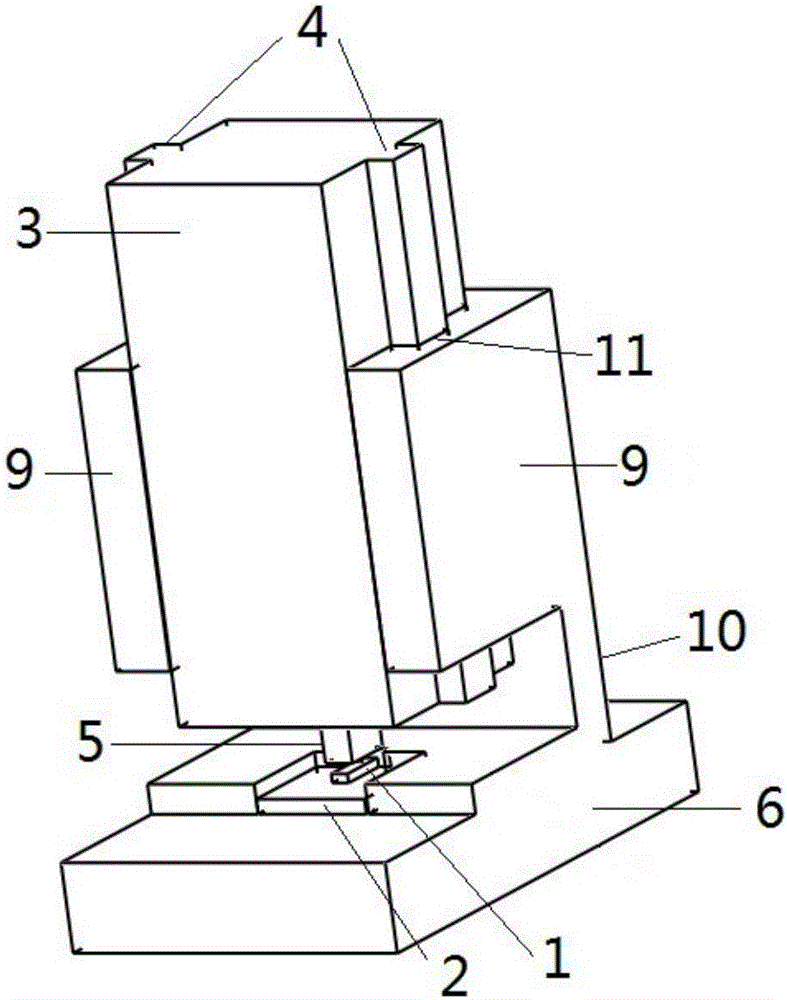

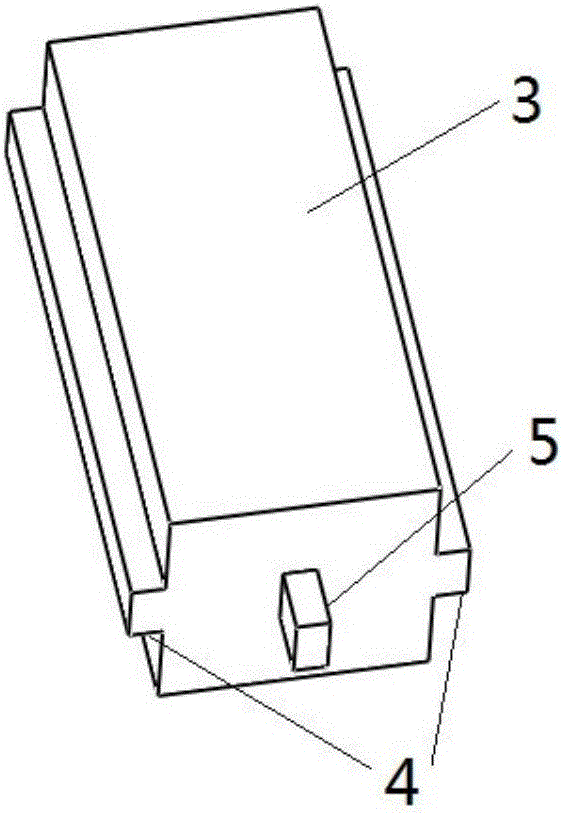

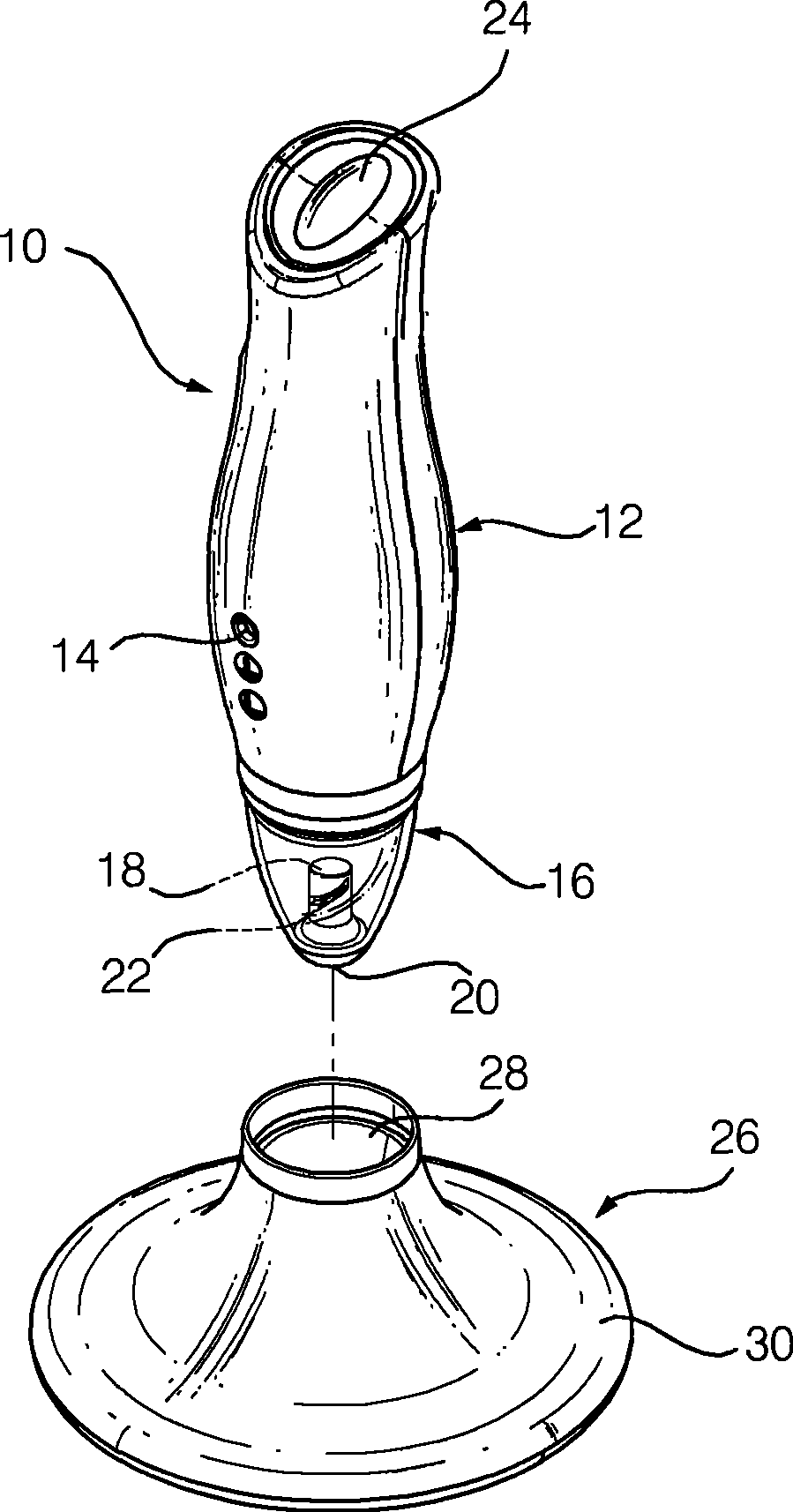

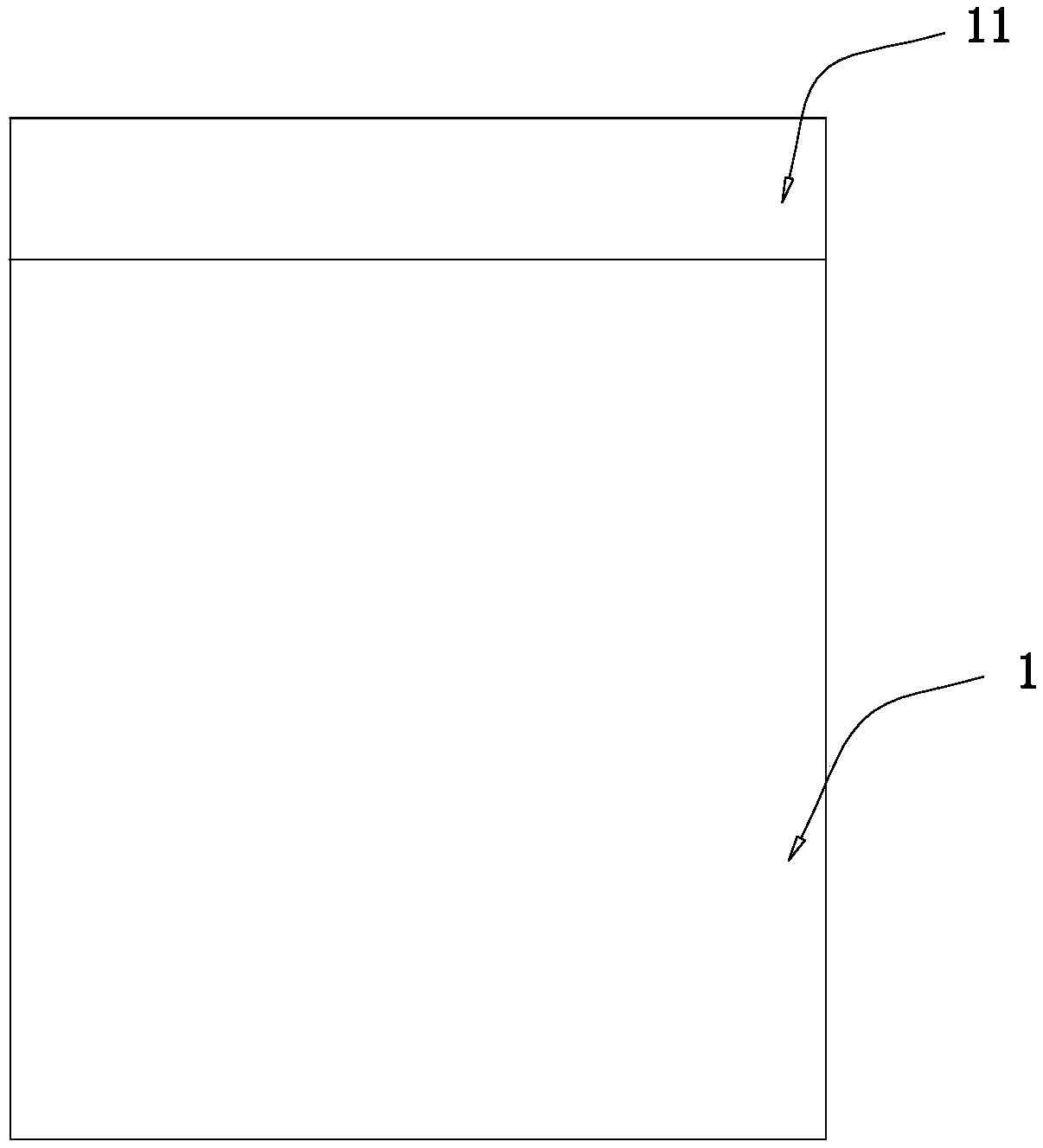

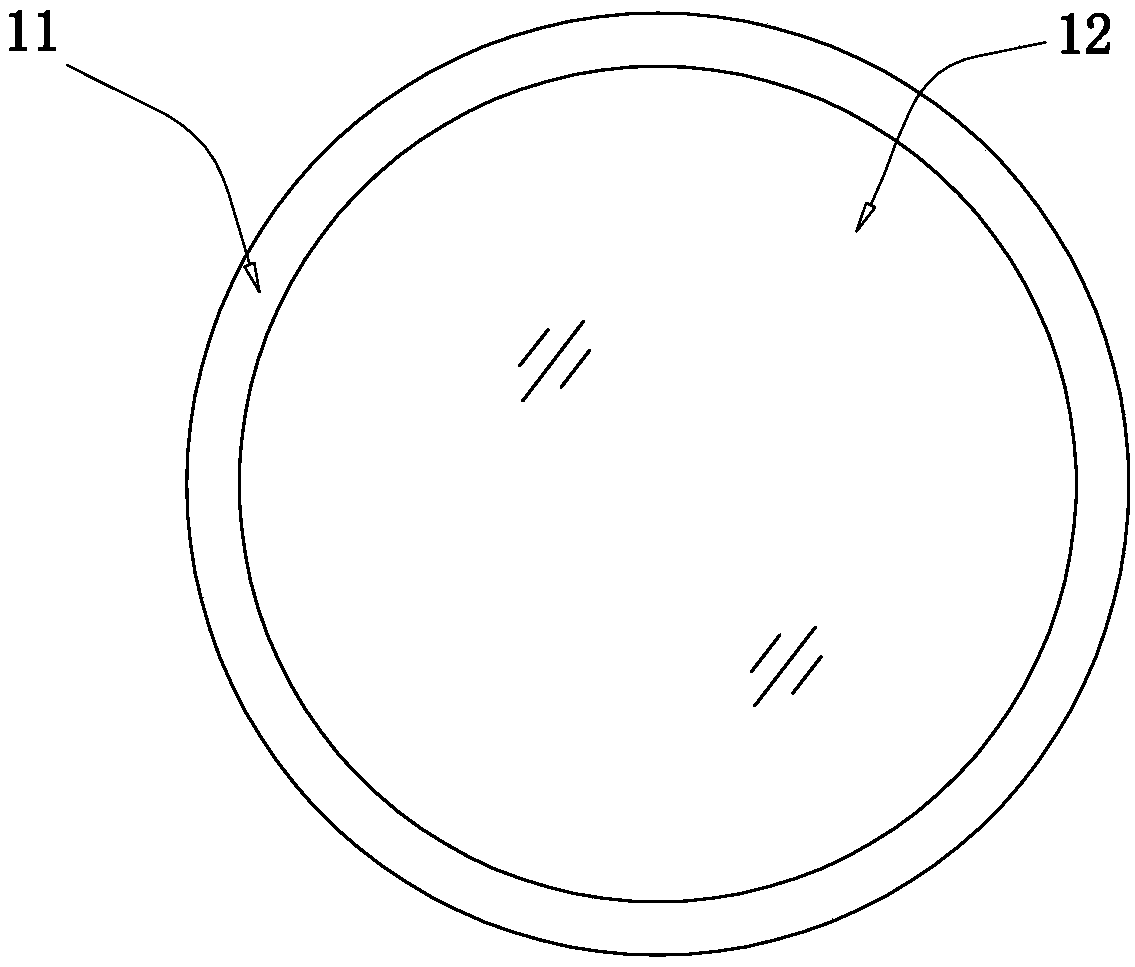

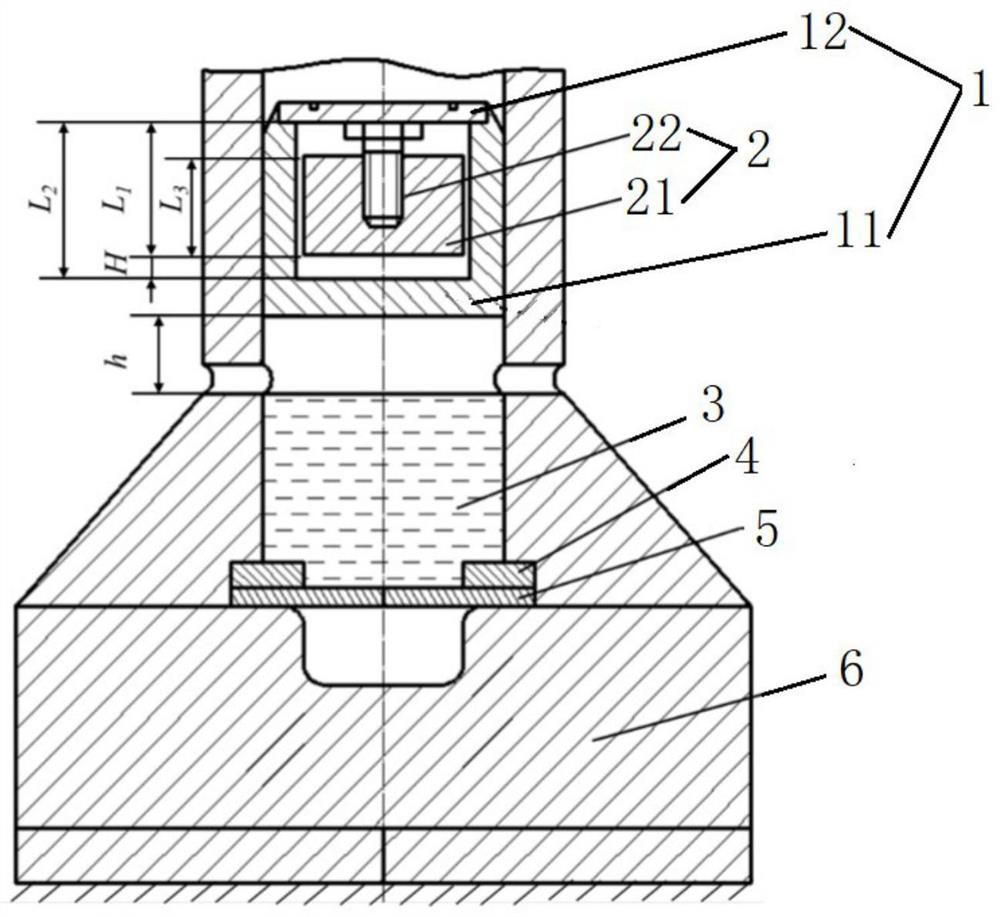

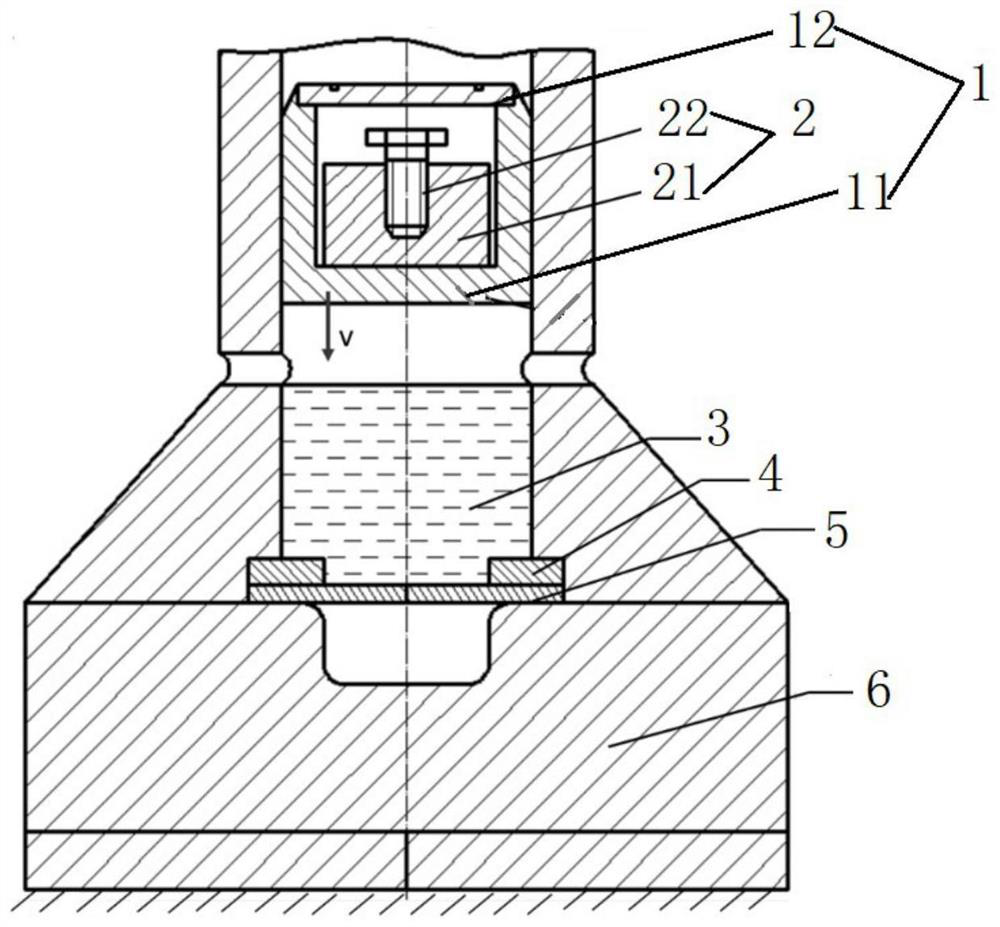

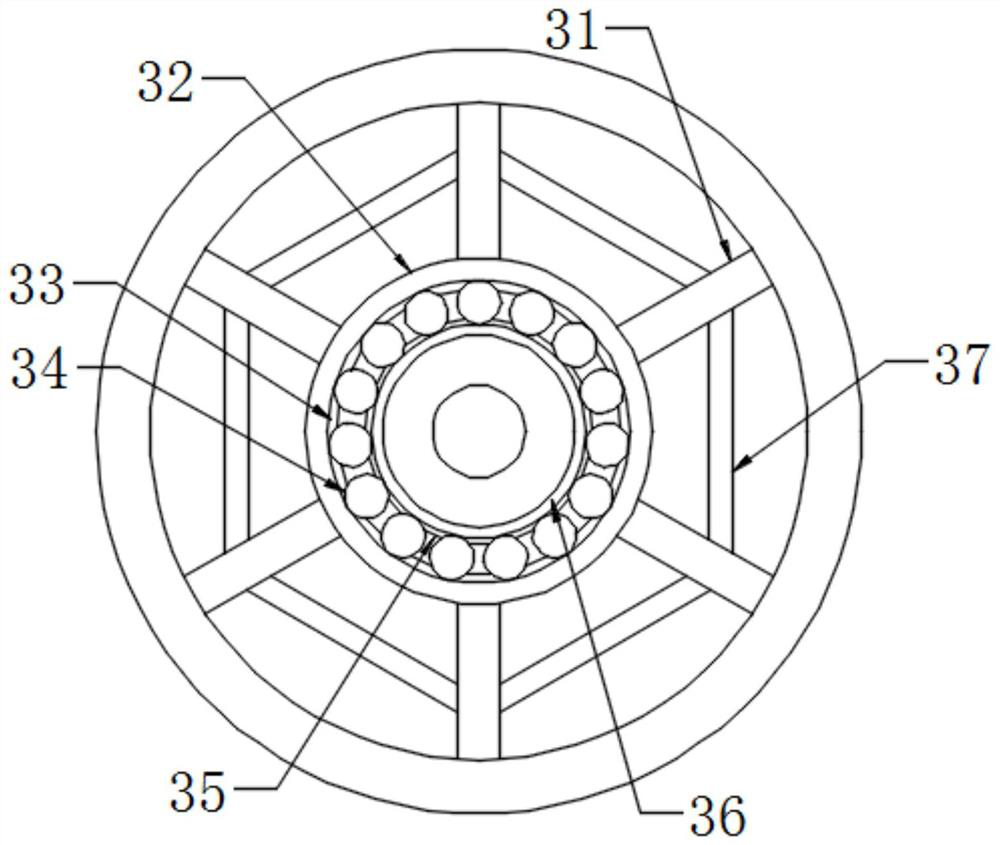

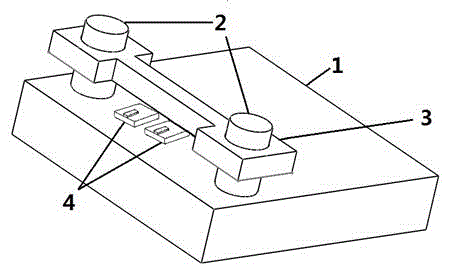

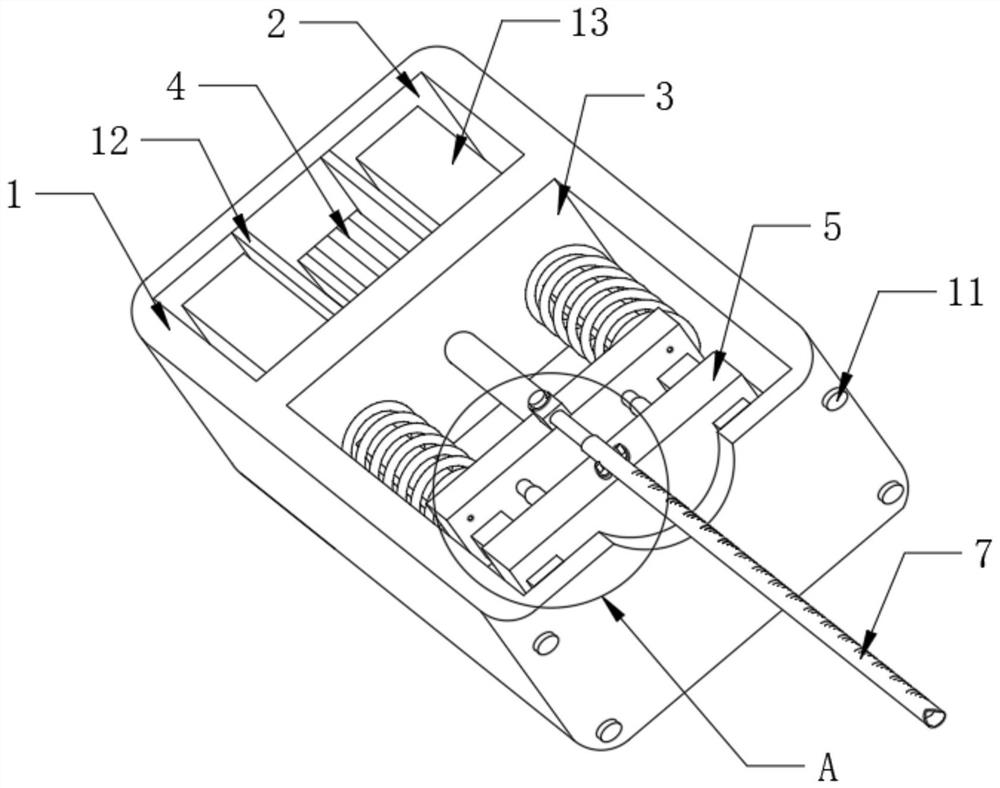

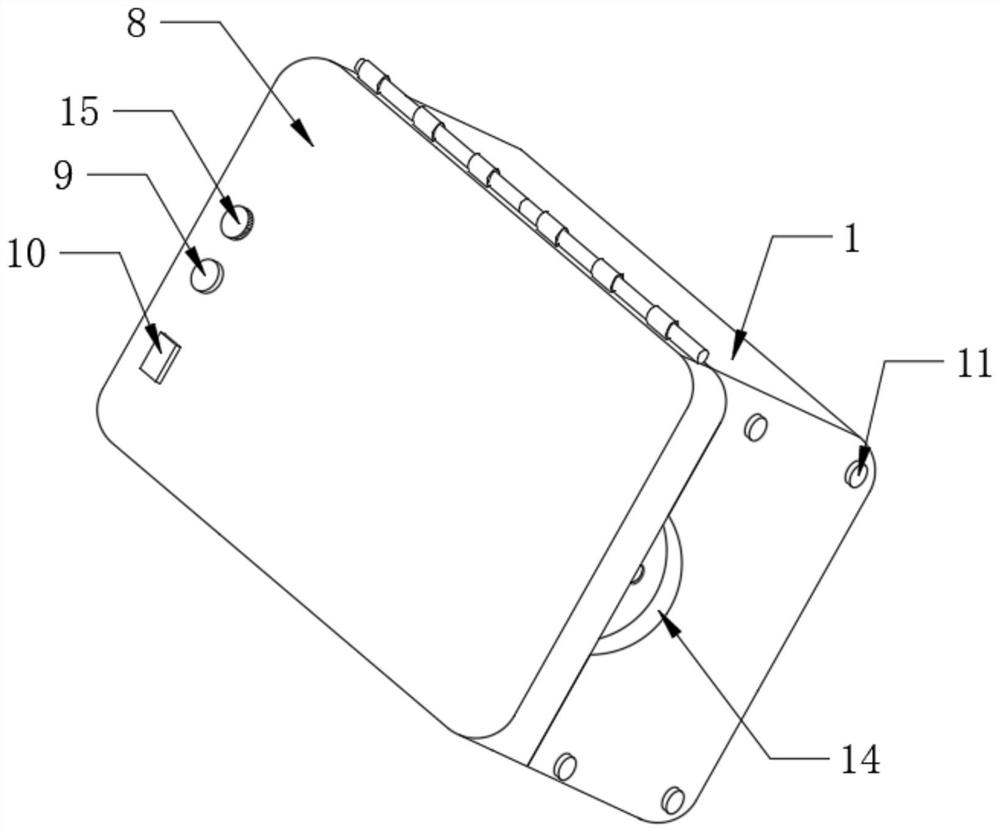

Semiconductor laser tube core sintering clamp and sintering method thereof

InactiveCN104882781ASimple structureLow costLaser detailsSemiconductor lasersHeat sinkSemiconductor laser theory

The invention discloses a semiconductor laser tube core sintering clamp and a sintering method thereof. The clamp comprises a base, fixation columns and a pressure block. The fixation columns are fixed on the base, the base is at least provided with a group of fixation columns, each group comprises two fixation columns, the two fixation columns of each group are provided with the pressure block, and the pressure block is provided with two guide holes and are sleeved on the fixation columns through the two guide holes. The sintering method comprises the following steps: (1), arranging laser tube cores and heat sinks on the two fixation columns of each group of the fixation columns; (2), placing the pressure block on the two fixation columns of each group, enabling the pressure block to apply pressure on the tube cores, and enabling the pressure block to be compacted right opposite to laser tube cores; and (3), carrying out sintering. The semiconductor laser tube core sintering clamp is simple in structure, low in cost and simple to operate, can be conveniently placed in a nitrogen protective cover casing, effectively prevents a solder from oxidation in high-temperature sintering, can realize rapid batch sintering of the tube cores and the heat sinks of semiconductor lasers, and is high in production efficiency.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

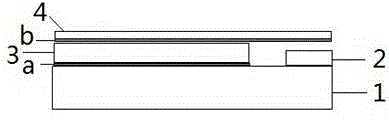

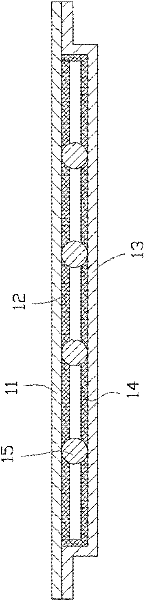

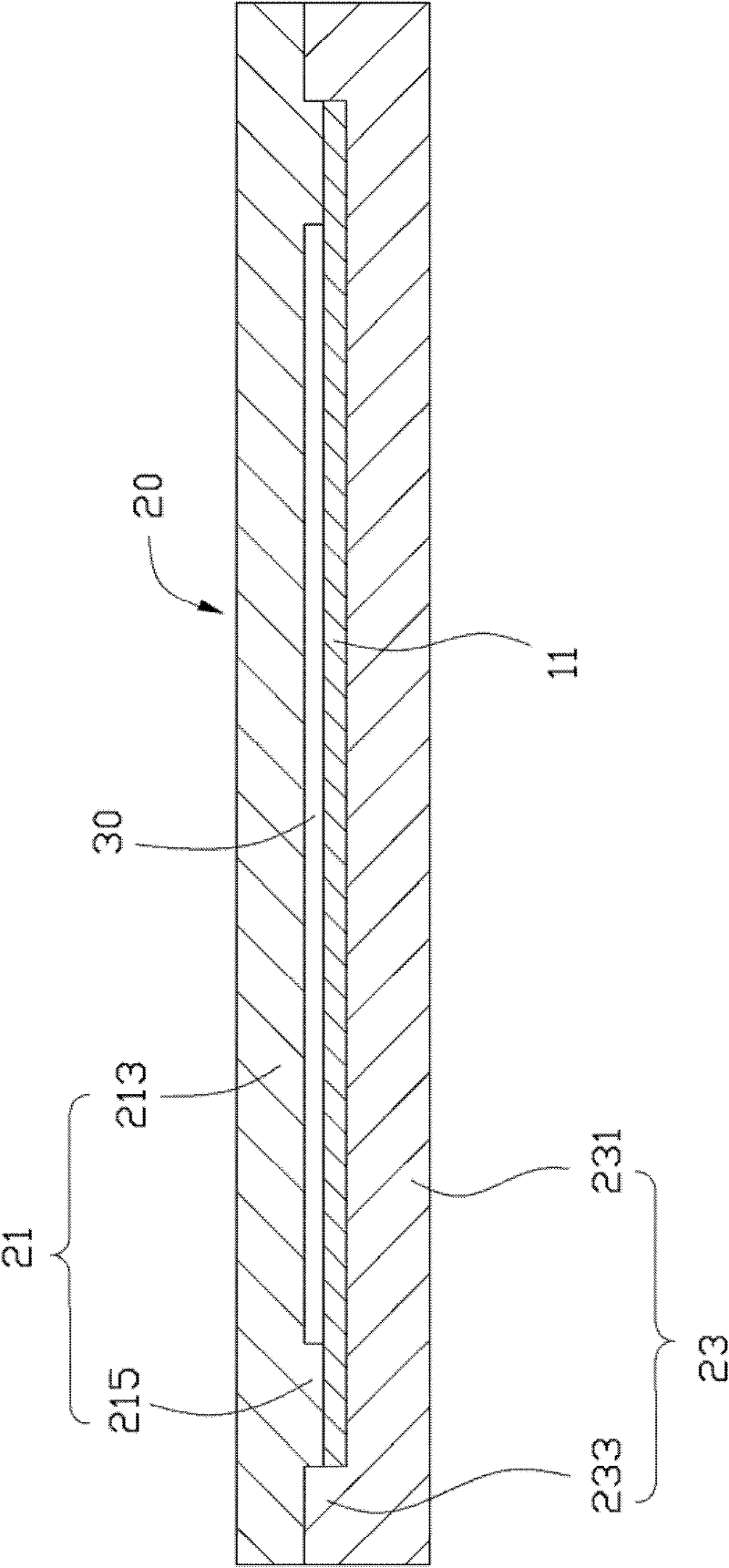

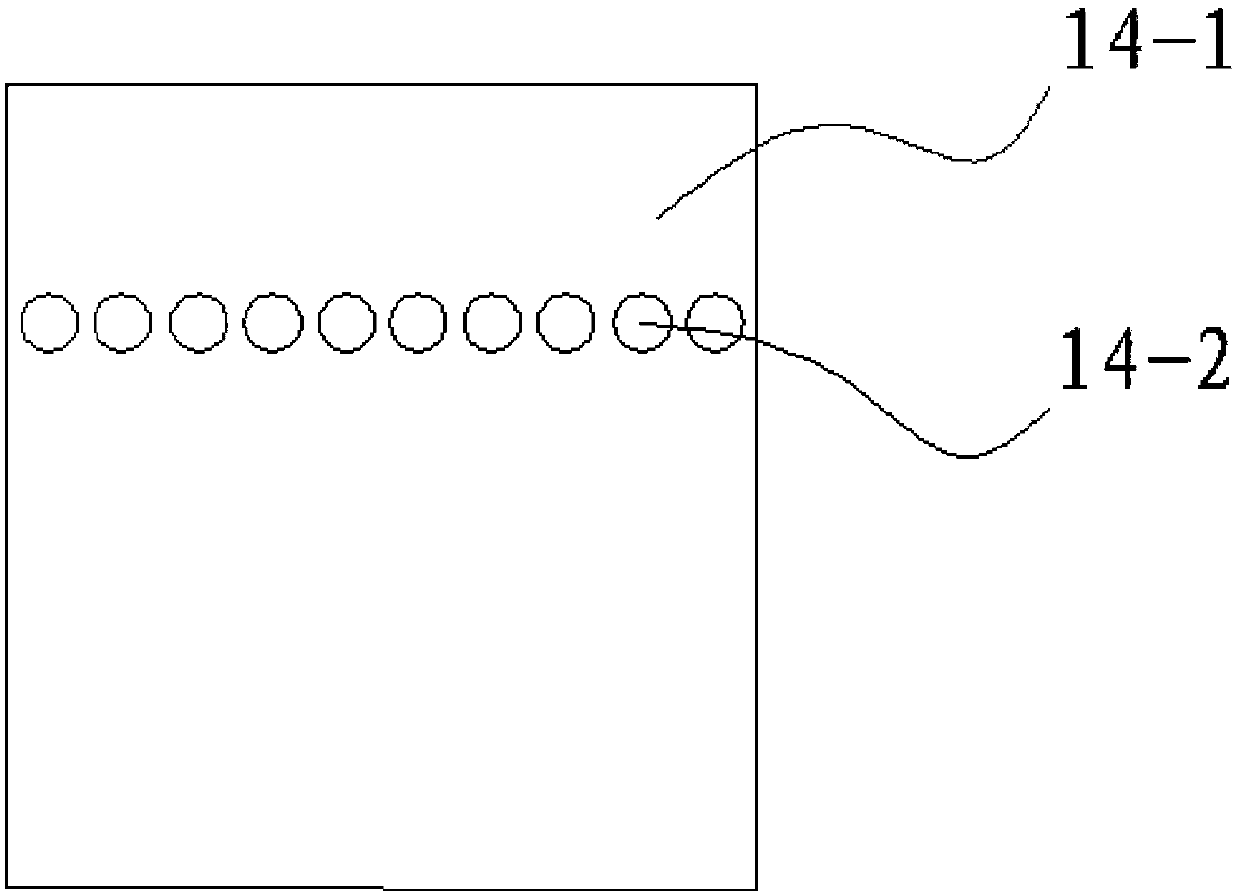

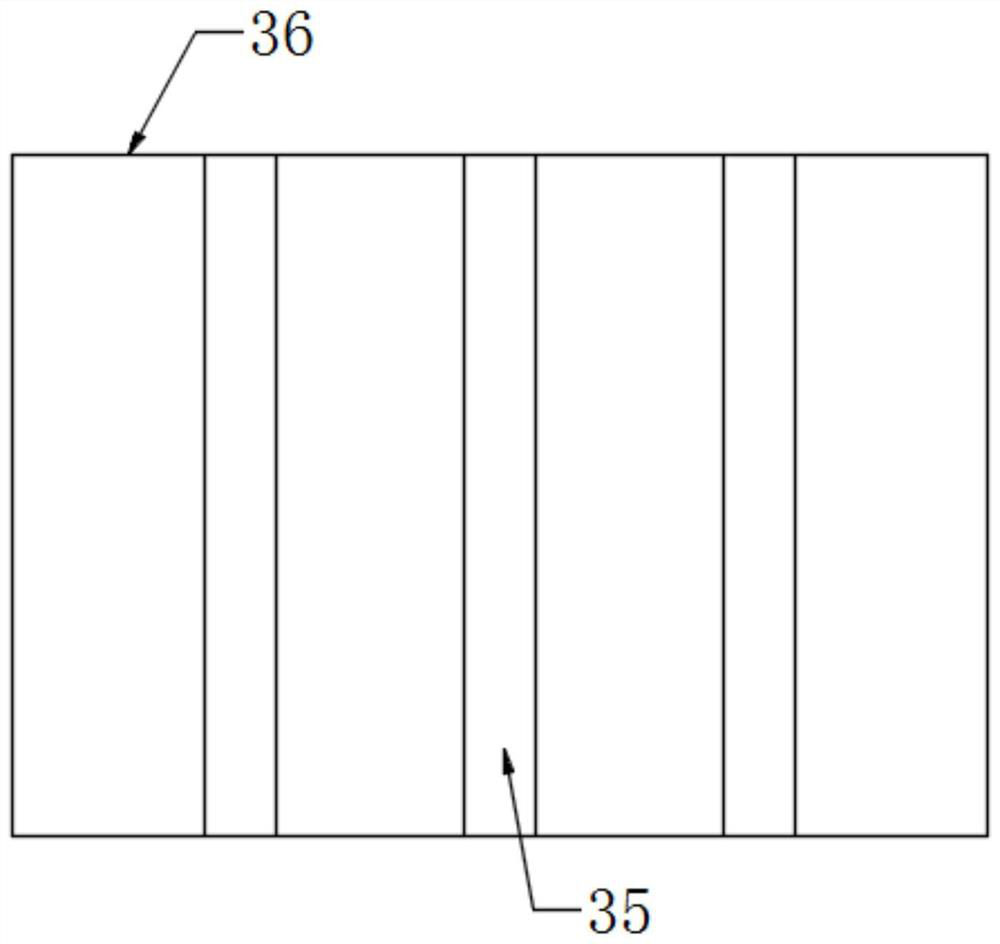

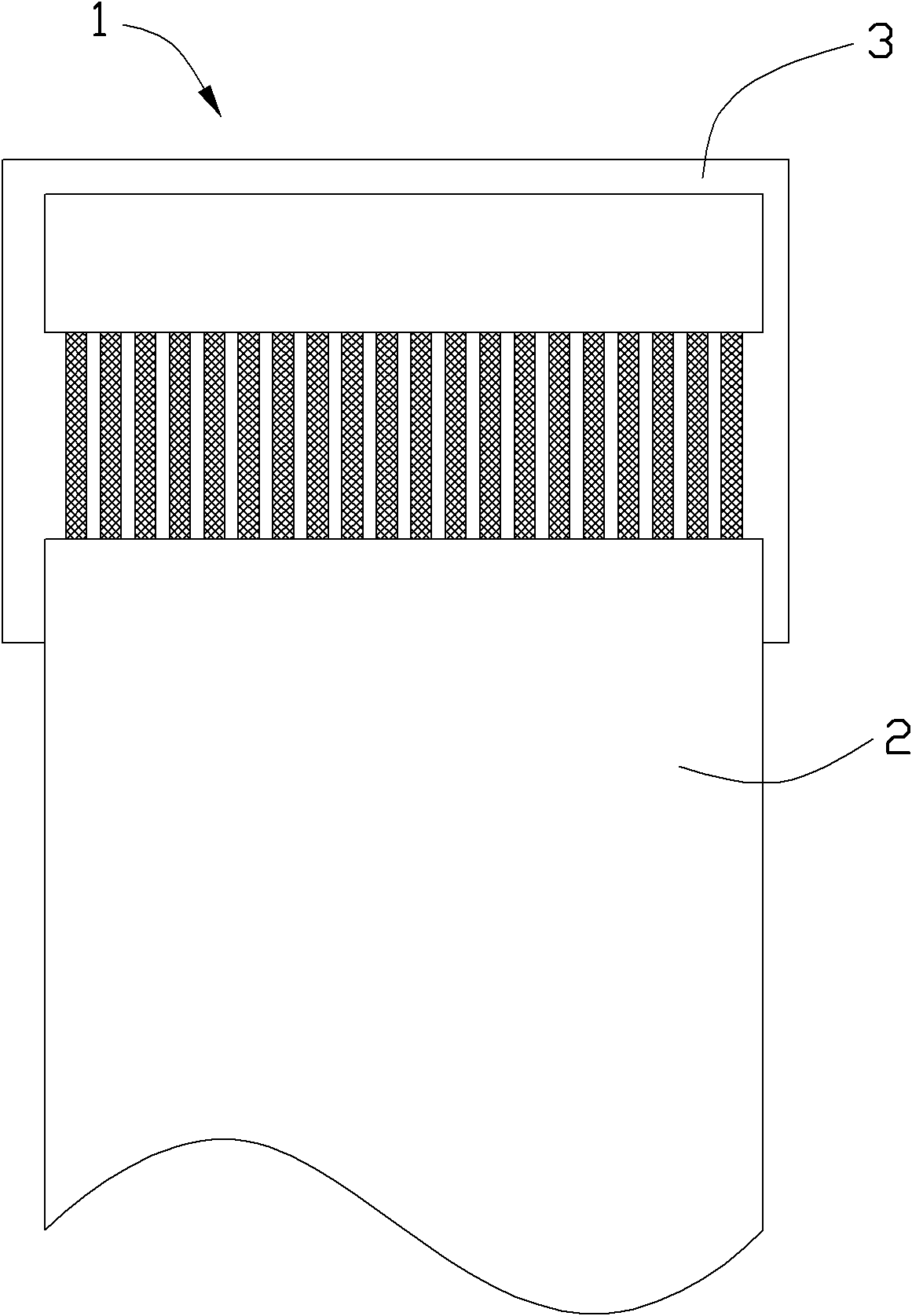

Flexible flat cable assembly and assembling method thereof

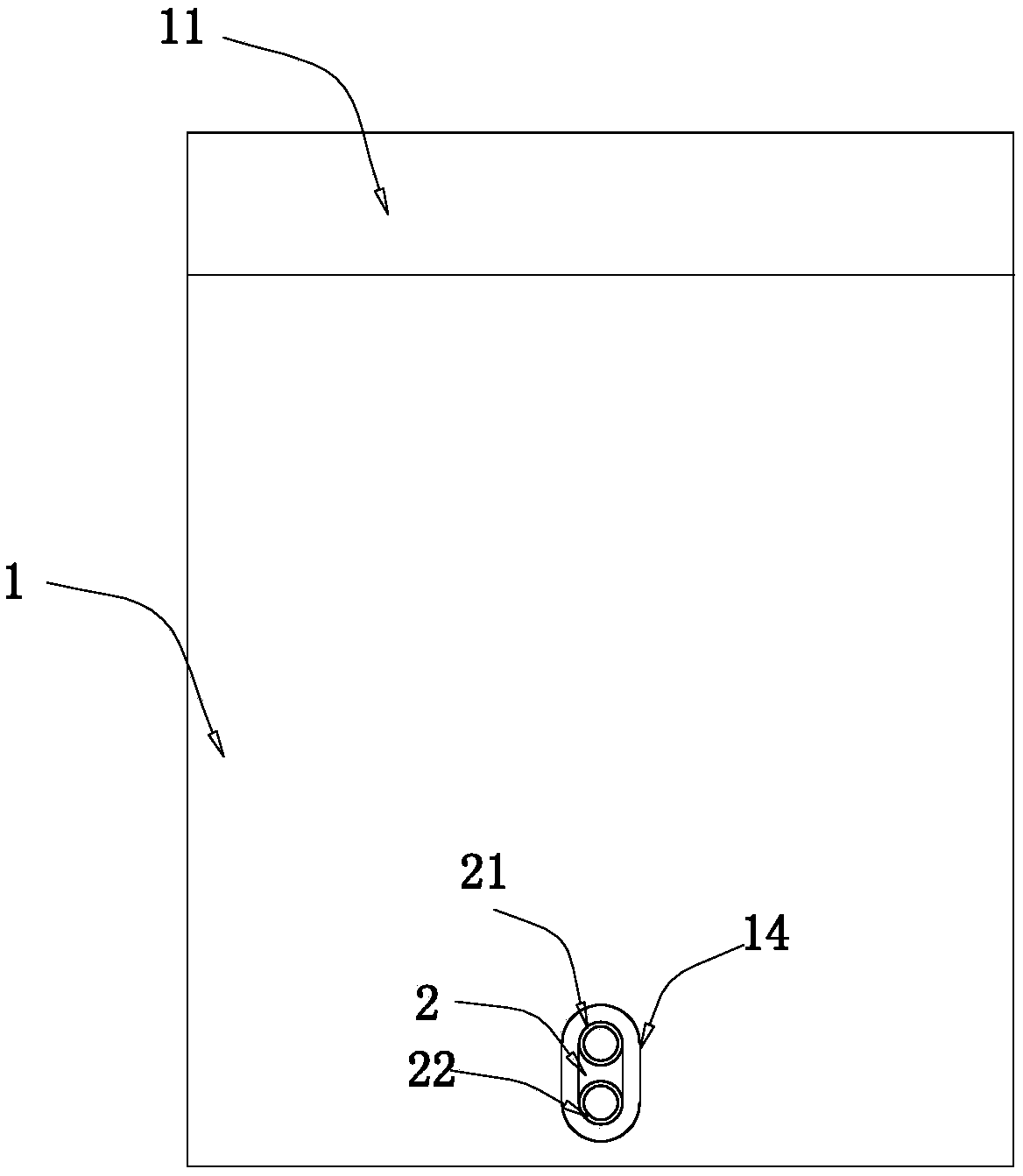

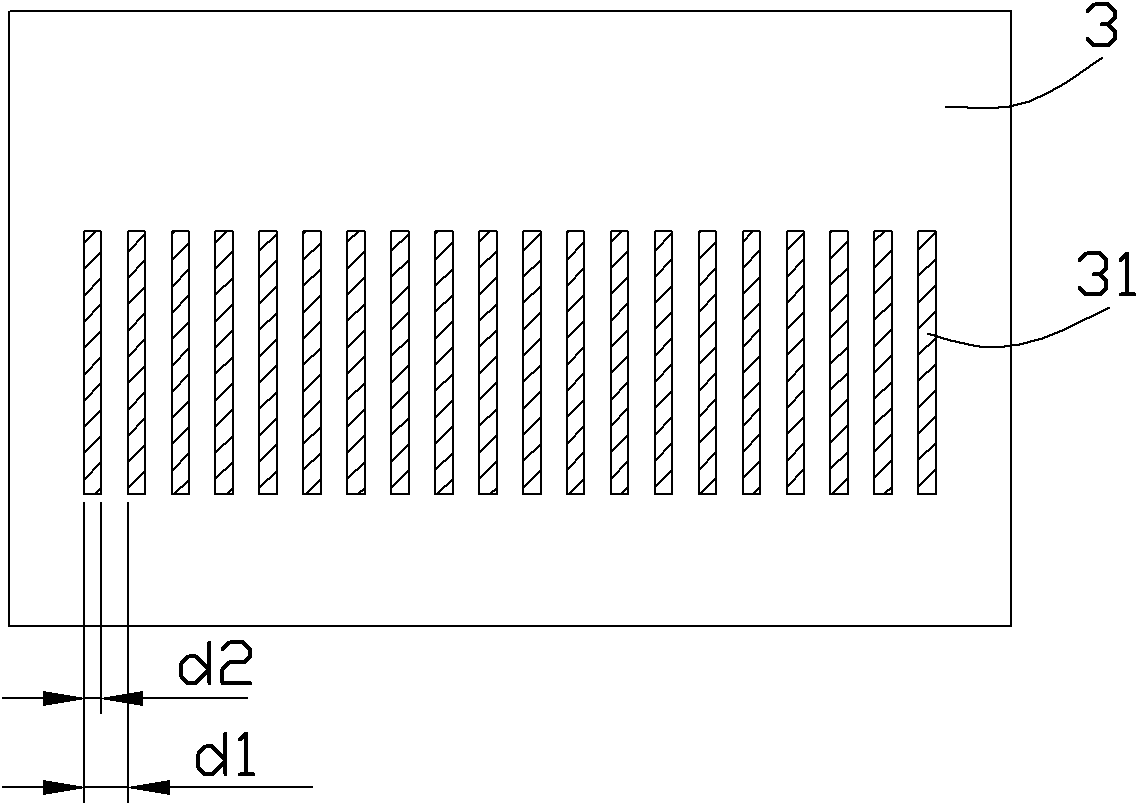

InactiveCN102593626AConveniently placedReliable electrical connectionFixed connectionsElectrical conductorEngineering

The invention discloses a flexible flat cable assembly (1), which comprises a flexible flat cable (2) and a printed circuit board (3) electrically connected with the flexible flat cable. The flexible flat cable comprises a plurality of conductors (21) which are transversely arranged in parallel and an insulator (22) coated outside the plurality of conductors; the insulator is provided with a notch section (221), so that the conductors in the flexible flat cable are exposed outside the insulator in a vertical direction; the printed circuit board is provided with a plurality of conducting strips (3) electrically connected with the conductors respectively; a distance between two adjacent conductors is the same as a distance between two adjacent conducting strips; and the width of each conductor is larger than that of each conducting strip.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

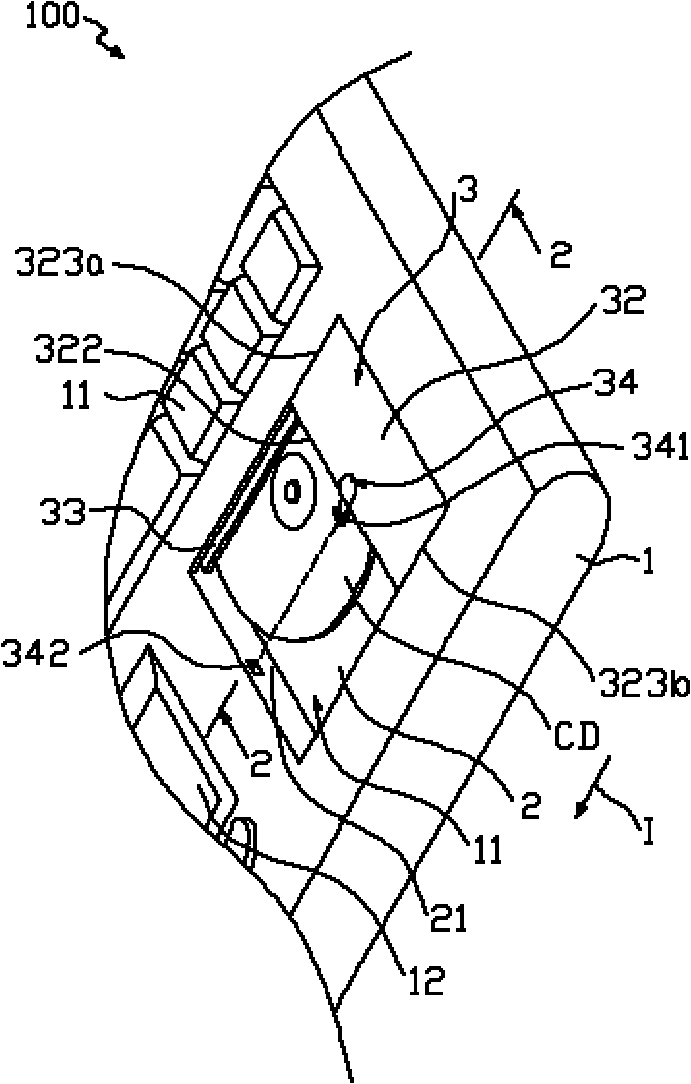

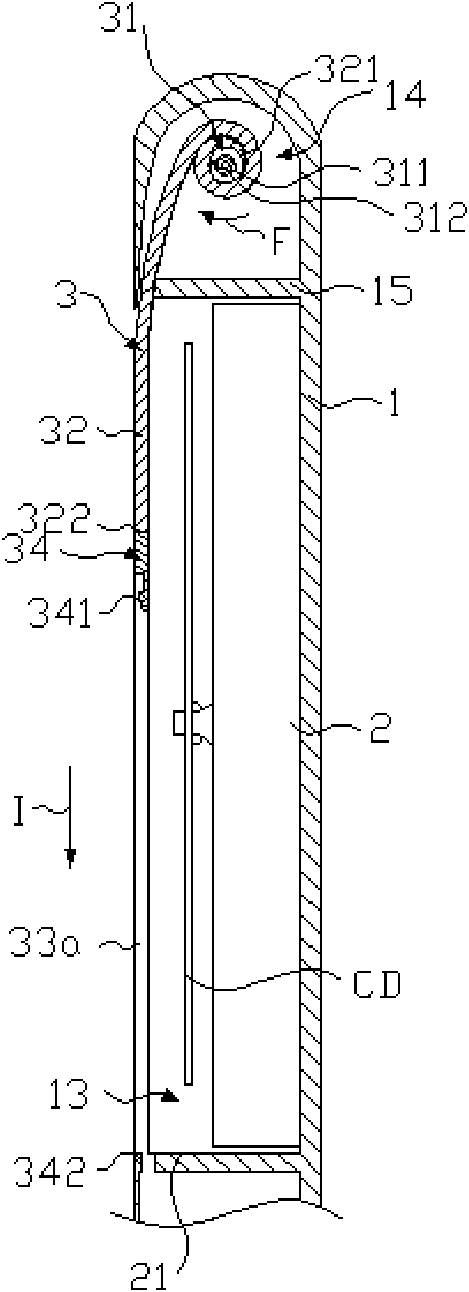

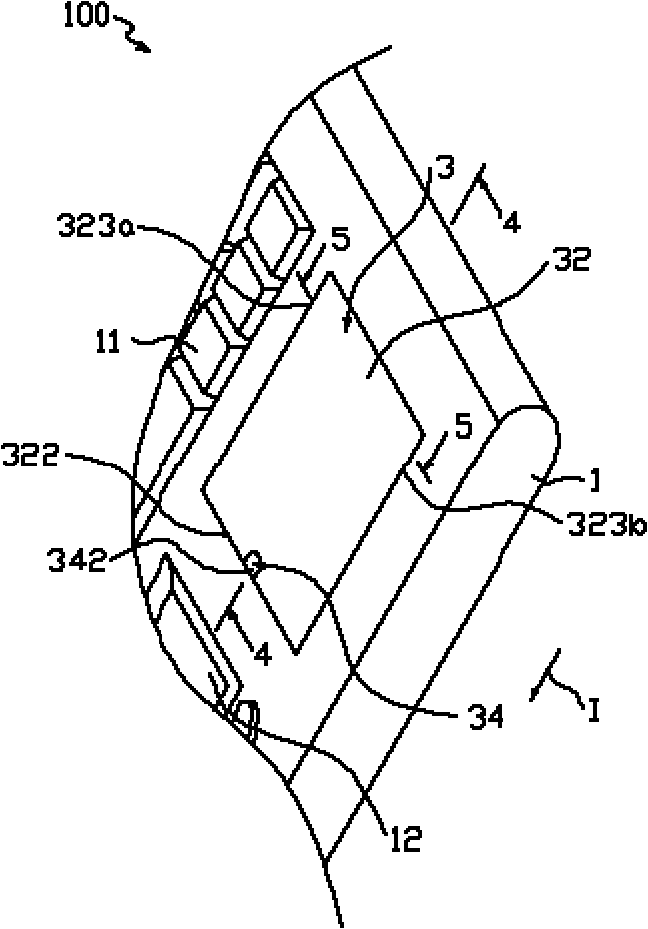

Electronic data processing device with rolling door covering type compact disc driver and rolling door covering structure

InactiveCN102043441ADoes not increase structural thicknessKeep it thin and shortCarrier constructional parts dispositionShutters/ movable grillesEngineeringMechanical engineering

The invention discloses an electronic data processing device with a rolling door covering type compact disc driver. The electronic data processing device comprises an electronic data processing device shell, a compact disc driver and a rolling door covering structure, wherein the compact disc driver is arranged in a compact disc driver accommodating space of the electronic data processing device shell and provided with a compact disc gate; the rolling door covering structure comprises a scroll bar mechanism which is arranged on one side of the compact disc gate of the compact disc driver and a roller shutter which is connected with the scroll bar mechanism; and the roller shutter is wound and received in the scroll bar mechanism during winding operation, is slidably stretched along a predetermined stretching direction during stretching operation, is positioned at a covering position and covers the compact disc gate of the compact disc driver.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

Metal cable combined pipe

InactiveCN105375412AConveniently placedEasy to installElectrical apparatusElectrical and Electronics engineeringMetal

The invention discloses a metal cable combined pipe. The metal cable combined pipe includes an upper connection section and a lower connecting section; the cross sections of the upper connection section and the lower connecting section are both semicircle-shaped; one end portion of the upper connection section is provided with a clamping groove; the direction of the opening of the clamping groove faces the direction of the axis of the upper connection section; two ends of the lower connecting section are respectively provided with a fixing plate; the fixing plate at one side of the lower connection section is clamped into the clamping groove; one end of the upper connection section, which is far away from the clamping groove, is provided with an extension board; a through hole is formed in the fixing plate at one end of the lower connecting section which is far away from the clamping groove; a bolt is arranged in the through hole; and the bolt passes through the through hole and is in threaded connection with the upper extension plate. According to the metal cable combined pipe of the invention, the upper connection section and the lower connecting section are connected in a dismountable manner, so that the laying of cables can be facilitated. The metal cable combined pipe has the advantages of excellent compression resistant performance, simple structure, convenient installation and higher structural reliability and durability.

Owner:CHONGQING TUOZHUO METAL MATERIALS CO LTD

Anti-collision pier for highway construction

PendingCN114411591AQuick assemblyConveniently placedFencingTraffic restrictionsArchitectural engineeringFriction force

The invention relates to the technical field of highway construction, in particular to an anti-collision pier for highway construction. The anti-collision pier for highway construction comprises a plurality of pier body assemblies, connecting rod assemblies, positioning assemblies and hanging assemblies, the pier body assemblies are used for protecting a construction site, and the connecting rod assemblies used for connecting the pier body assemblies are installed between every two adjacent pier body assemblies. The positioning assembly for improving the ground friction force of the pier body assembly is installed at the bottom of the pier body assembly, and the hanging assembly facilitating stable transfer of the pier body assembly is installed in the pier body assembly. The anti-collision pier for highway construction has the advantages that the anti-collision pier can be automatically separated when being impacted by large force, all the anti-collision piers are prevented from being turned over together, and the anti-collision piers can be stably lifted and transferred.

Owner:张虎

Full-automatic waste water utilization flush toilet

ActiveCN102561469BImplement automatic conversionPerformance is not affectedFlushing devicesDomestic plumbingWater savingTap water

The invention discloses a full-automatic waste water utilization water-saving device. A telescopic waste water storage tank (5) is positioned below a wash basin (2); wash waste water enters the telescopic waste water storage tank (5) through a waste water pipe (3) and a filter net (4); a balance region (16) for accommodating a waste water tank floater (12) and a waste water tank floater switch (13) is formed on the lower part of the water storage tank; and the balance region can accommodate the waste water tank floater (12) and the waste water tank floater switch (13); a running water inlet pipe (10) and a toilet water inlet pipe (17) are arranged below the balance region; and the level of the floated waste water tank floater (12) is equal to or a little higher than that of a floated toilet floater (7). According to the design, a large amount of waste water can be stored automatically, and automatic switching between the waste water and running water is realized.

Owner:山西霖之源科技有限公司

Endoscope puncture tool for digestive endoscopic surgery

ActiveCN112137657AAdjust insertion depthAdjustable lengthSurgical needlesVaccination/ovulation diagnosticsPuncture BiopsyEndoscopic surgery

The invention discloses an endoscope puncture tool for a digestive endoscopic surgery. The endoscope puncture tool comprises a handle; the handle is provided with a power cavity and a mounting cavity;a percussion device is installed in the mounting cavity; the percussion device is connected with a length adjusting mechanism; the upper portion of the length adjusting mechanism is connected with amounting mechanism; the mounting mechanism is connected with a puncture device; the percussion device drives the puncture device to conduct biopsy sampling; the length adjusting mechanism is used foradjusting the placement depth of the puncture device; the mounting mechanism is used for being rapidly connected with the puncture device; the puncture device is used for conducting puncture biopsy sampling on a patient; and the percussion device comprises a hydraulic cylinder, an ejector rod, a push plate, a sliding block and a reset spring. According to the endoscope puncture tool, the placementdepth of the puncture device can be adjusted, the length of a biopsy needle sampling groove can be adjusted, automatic percussion sampling is achieved, and whether the puncture device is placed in place or not can be judged.

Owner:SUZHOU FRANKENMAN MEDICAL EQUIP

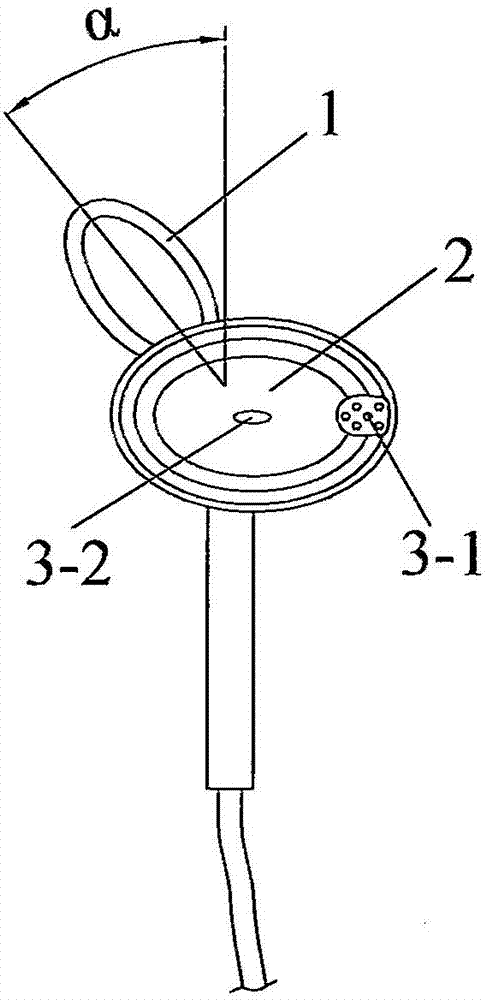

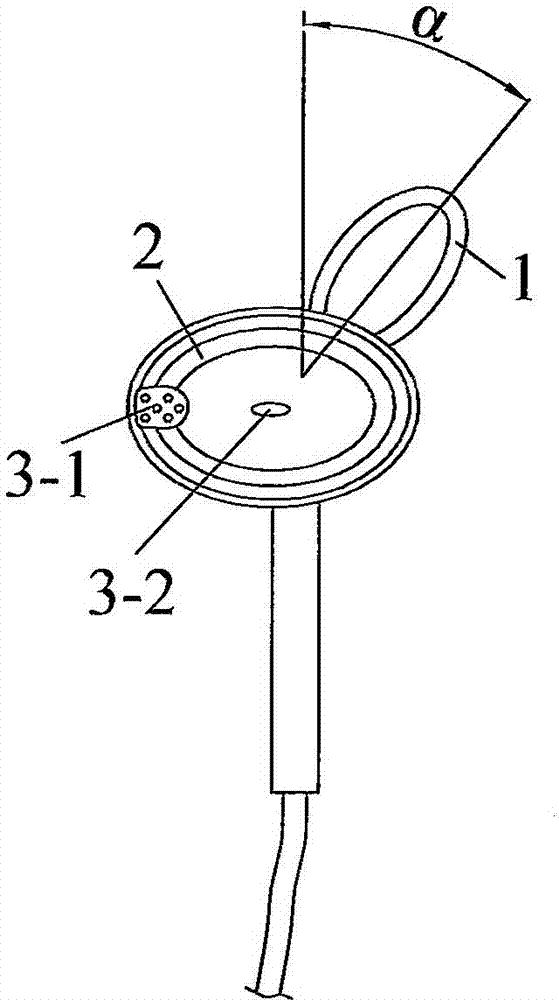

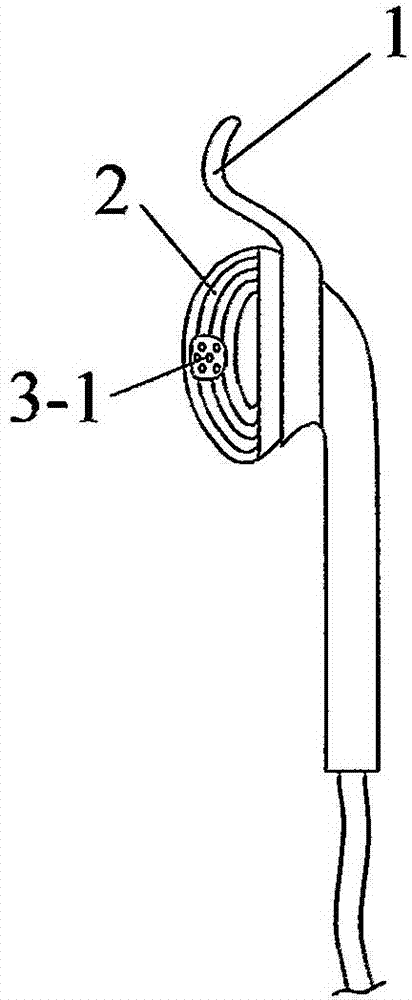

Earplug type earphone

InactiveCN103096205ANot easy to dropWear firmlyEarpiece/earphone attachmentsAssistive device/technologyEngineering

The invention relates to an earphone, in particular to a common earplug type earphone with a transmission wire. The invention belongs to the technical field of audition equipment and audition auxiliary equipment. The technical scheme includes that the earplug type earphone comprises an earphone head (2) and a main sound output hole (3-1) which is formed in the earphone head. An annular ring (1) is arranged on the back upper portion of the earphone head (2), the angle of the annular ring (1) and a perpendicular line is alpha , and 20 degrees < = alpha < = 50 degrees. The main sound output hole (3-1) is formed in the edge of the earphone head, and a second sound output hole (3-2) is formed in the middle of the end face of the earphone head (2). Due to the adoption of the technical scheme, the earplug type earphone is firm and comfortable in wearing.

Owner:蒋云

Neckline bluetooth headset and its application method

ActiveCN108055605BNearbyMeet needsSupra/circum aural earpiecesMouthpiece/microphone attachmentsSound sourcesNoise detection

Owner:GOERTEK INC

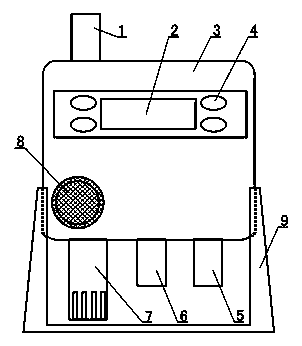

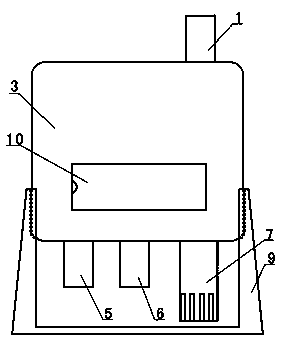

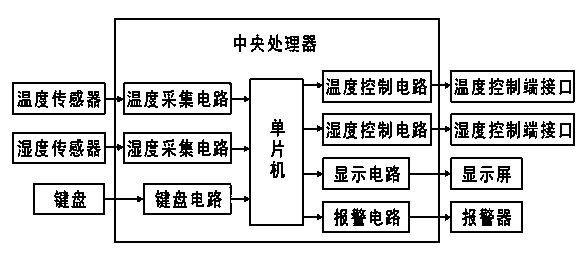

Floor type fully digital humiture monitoring meter

InactiveCN103425156AConveniently placedEasy to place directlySimultaneous control of multiple variablesTemperature controlEngineering

The invention discloses a floor type fully digital humiture monitoring meter which comprises a casing, a display screen, a keyboard, a data exchange port, a temperature sensor, a humidity sensor, a temperature control end port, a humidity control end port and a central processor arranged in the casing. The floor type fully digital humiture monitoring meter further comprises an alarm and an installation base, a signal input end of the alarm is connected with an alarm signal output end of the central processor, the alarm is arranged in the casing and arranged at the position close to the front face of the casing, and a sound conducting opening is arranged at the position, corresponding to the alarm, of the front face of the casing. The installation base is in a U shape, supporting grooves are formed in the inner sides of two supporting arms of the installation base, and the lower portions of the two sides of the casing are arranged in the supporting grooves. The U-shaped installation base is arranged, so that the casing of the monitoring meter can be conveniently arranged in the installation base, and direct placement and movement of the monitoring meter are facilitated. A manager conveniently knows whether the humiture is out of scope in time.

Owner:CHENGDU BINGUO TECH

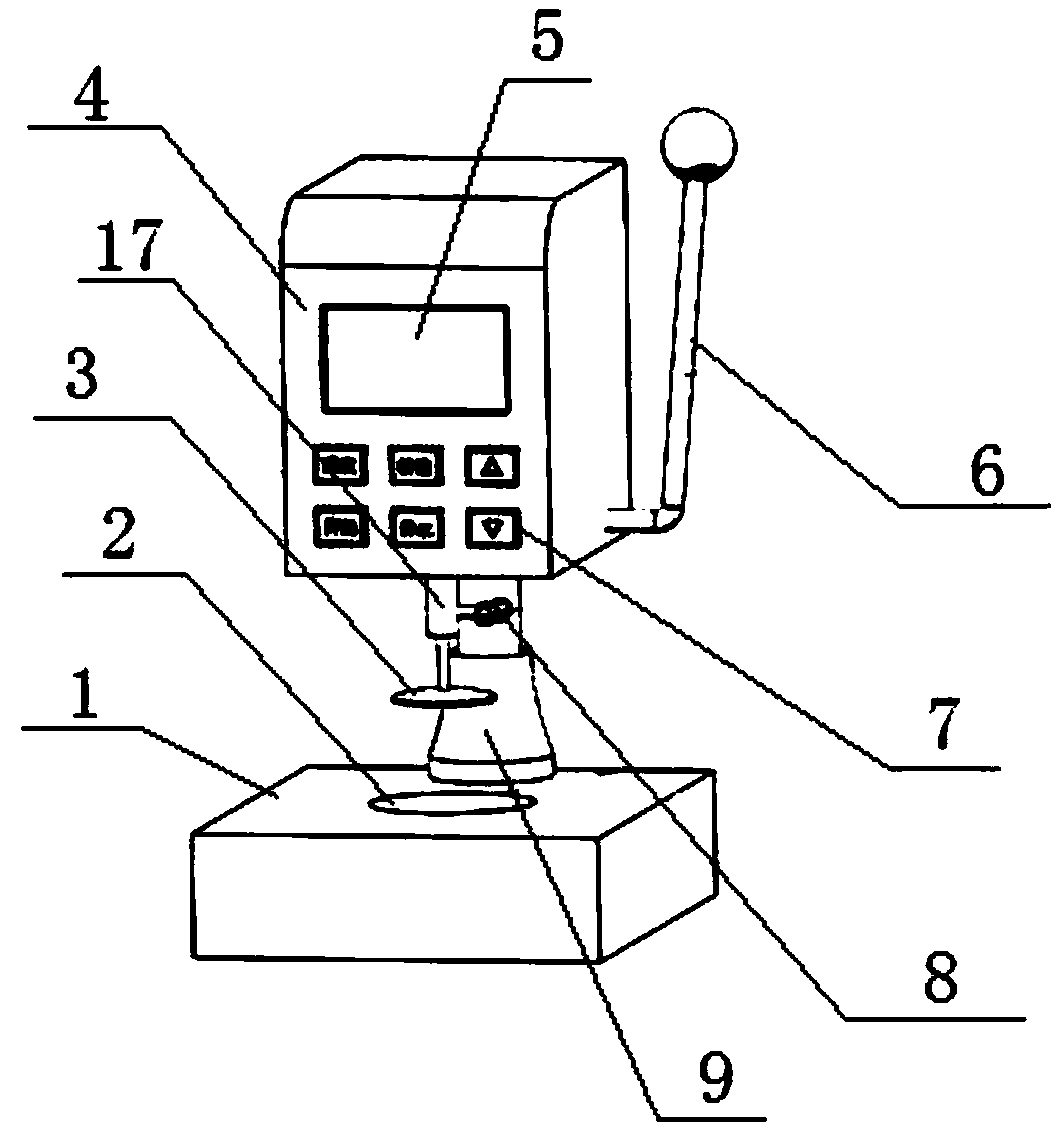

Gelation time measuring device and testing method

PendingCN109342490AConveniently placedHigh measurement accuracyInvestigating phase/state changeElectric machineryEngineering

The invention discloses a gelation time measuring device and a testing method. The gelation time measuring device comprises a base and a testing machine head, wherein a vertical column is arranged behind the base; a lifting mechanism for controlling the testing machine head to move up and down is arranged on the vertical column; the testing machine head comprises a casing and a testing head; a main motor for driving the testing head to rotate is arranged in the casing; a heating plate matched with the testing head is arranged on the base; a control module for detecting the solidification degree of a sample by detecting a rotating torque change of the main motor. By arranging the testing machine head provided with the control module, the gelation time measuring device improves the measuringprecision of the gelation time; by arranging the heating plate and the rotatable testing head, the sample is reacted to be solidified to a gel state step by step, the interference of manmade factorson a testing result is reduced, and the accuracy and the reliability of data are improved; by arranging the lifting mechanism, a height between the testing head and the heating plate can be adjusted,so that the sample can be placed on the heating plate conveniently, and the measuring efficiency is improved.

Owner:JIANGSU HHCK NEW MATERIAL CO LTD

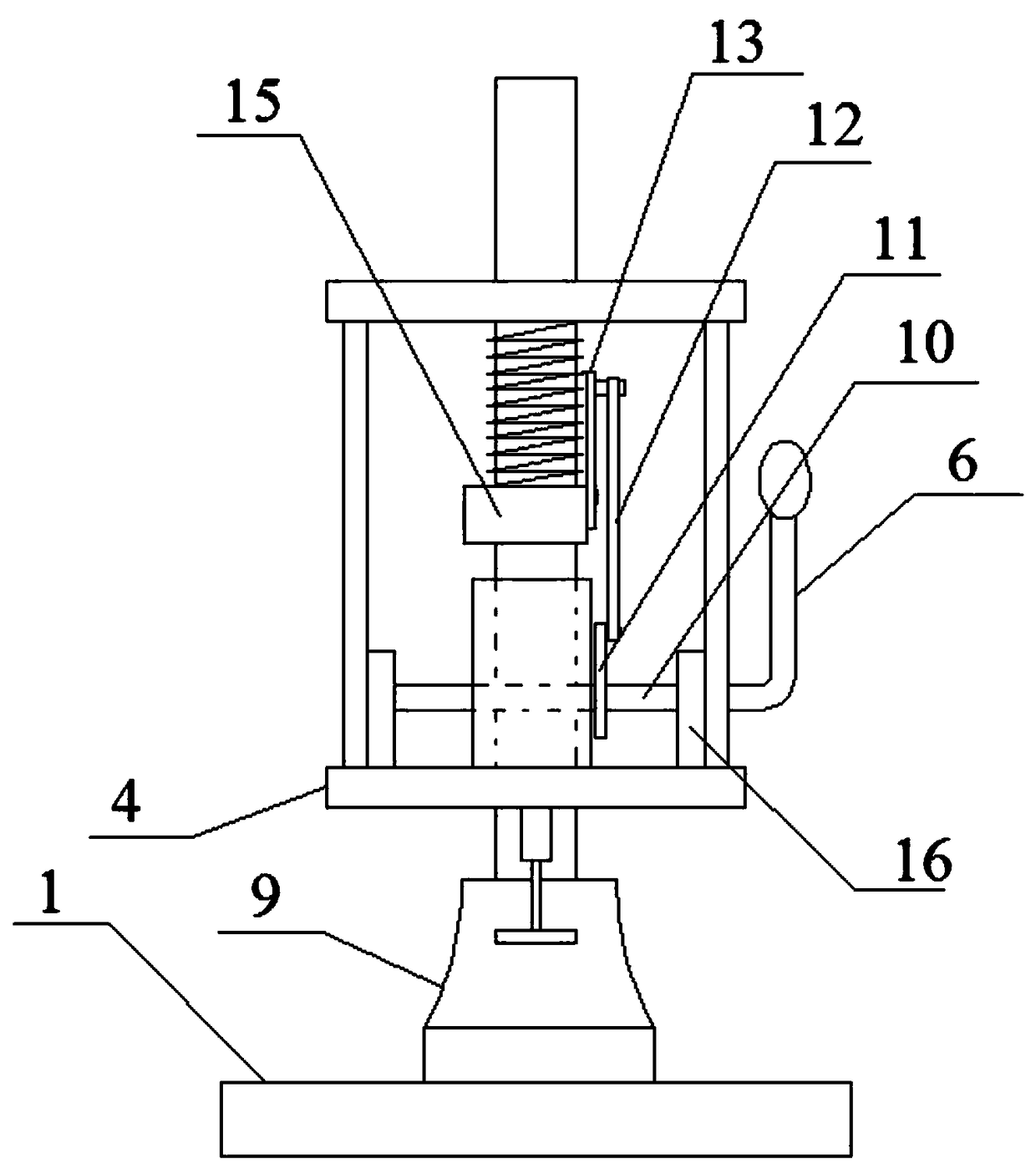

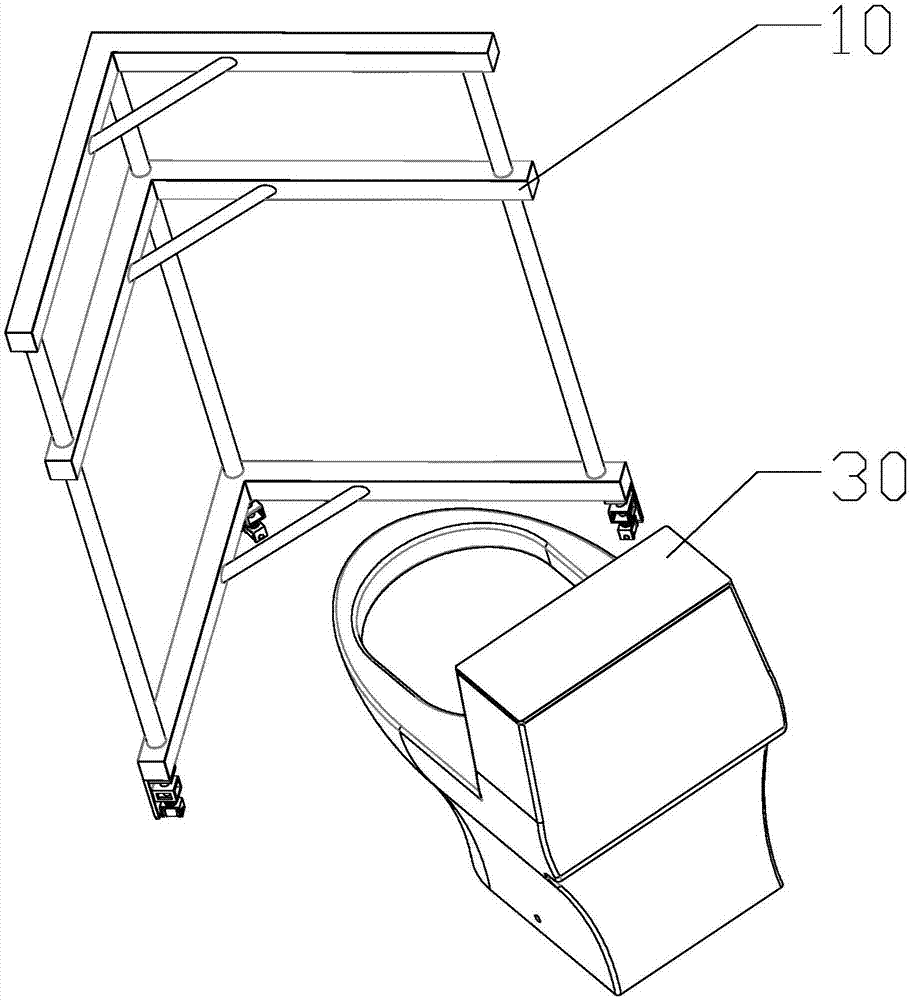

Defecation bracket

InactiveCN107997667AAchieve fixationEasy to pushBathroom accessoriesEngineeringPulp and paper industry

The invention relates to a defecation bracket, and belongs to the relevant technical field of medical apparatus and instruments. The defecation bracket mainly comprises an upper-layer framework. The upper-layer framework is connected with a middle-layer framework by connecting rods; the middle-layer framework is connected with a lower-layer framework by connecting rods; universal wheels are mounted on the lower portion of the lower-layer framework; the universal wheels comprise main brackets, limit frames are connected with the inner sides of the main brackets, steering shafts are inserted inside the limit frames, roller carriers are fixedly connected with the lower ends of the steering shafts, and rollers are mounted on the roller carriers; springs sleeve the steering shafts and are positioned between the limit frames and the roller carriers. The defecation bracket has the advantages that novel structures are designed, and accordingly patients can independently carry out actions for squatting and getting up on toilet bowls and can independently defecate without assistance of other people.

Owner:陶金

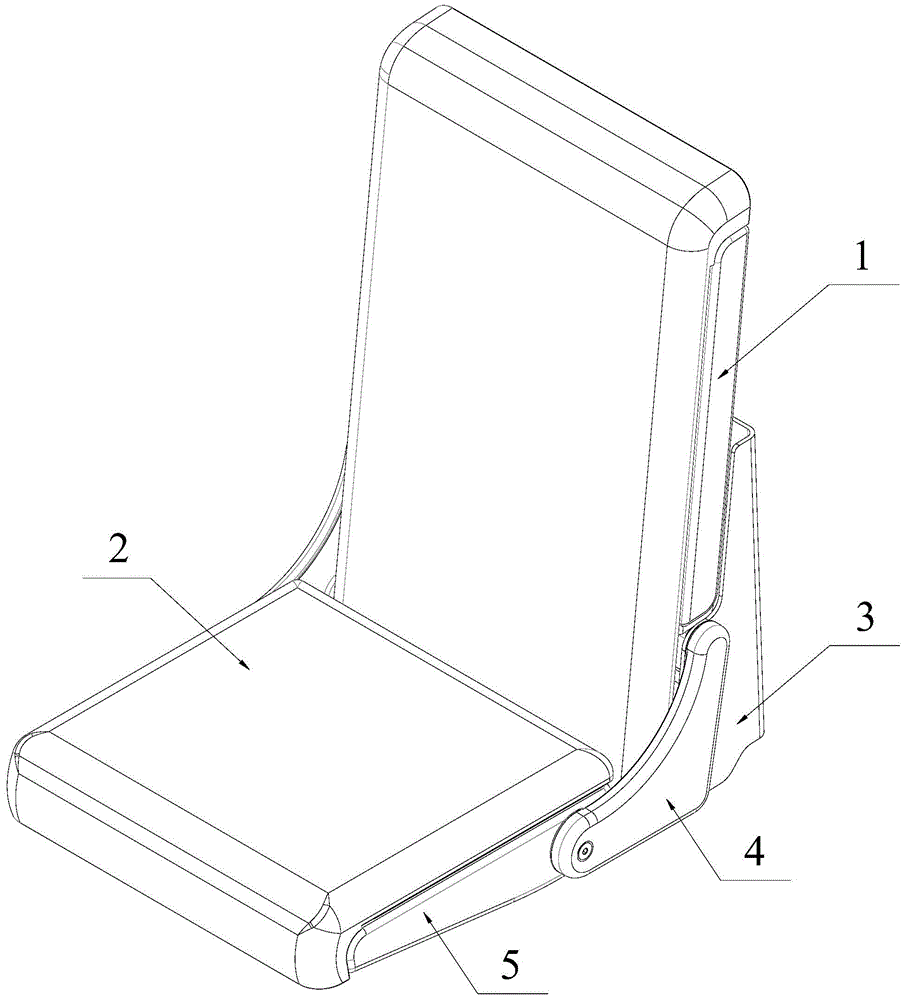

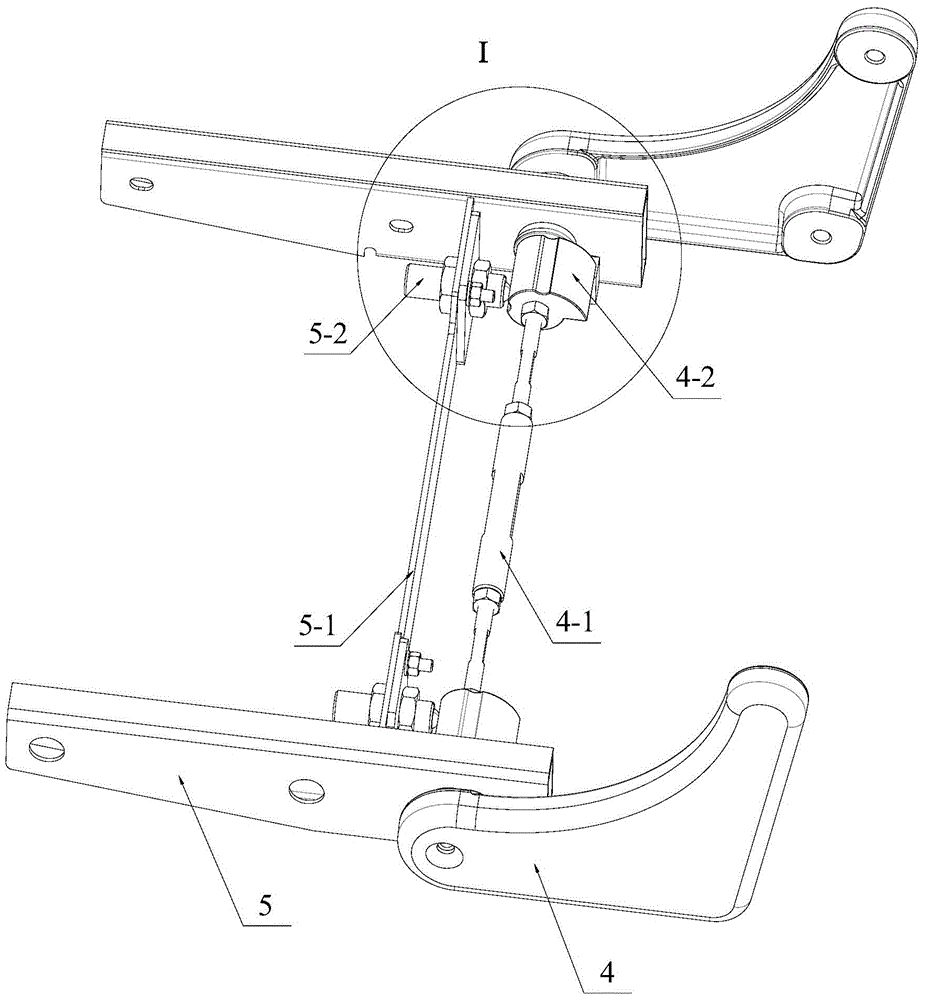

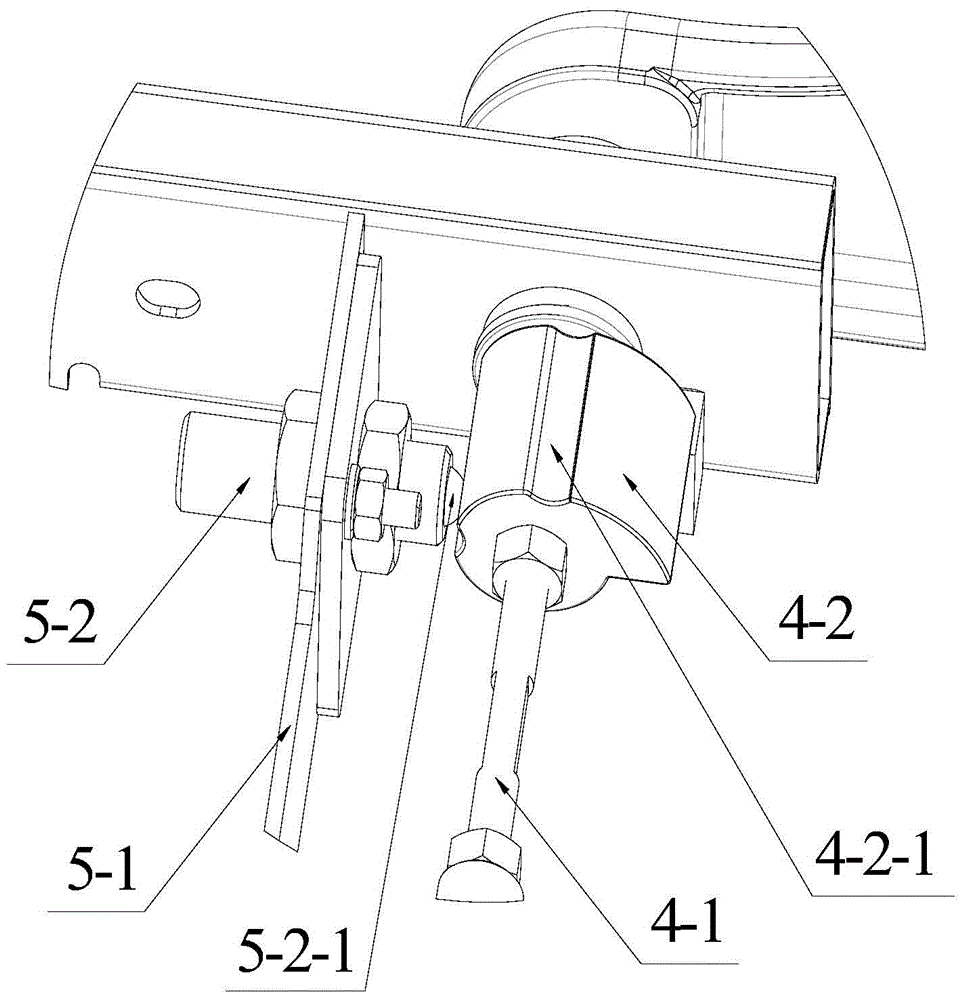

Foldable single seat for urban railway vehicles

The invention discloses a foldable individual seat for a city railway vehicle, and belongs to the field of railway vehicle foldable seats. The foldable individual seat comprises a backrest frame, a seat cushion, a seat installation base, a seat supporting base and a seat cushion frame. The backrest frame is hung on hanging holes in the seat installation base. The seat supporting base comprises two limiting blocks, and each limiting block is provided with two top bead clamping grooves. A beam is fixed at the back ends of two end plates of the seat cushion frame, the two ends of the beam are fixedly and vertically connected with two top bead structures respectively, a top bead is arranged on the top of each top bead structure, and the top bead structures are matched with the limiting blocks to form a top bead self-locking mechanism. According to the foldable individual seat, the top bead self-locking mechanism is adopted, the seat cushion can be limited and fixed through the top bead self-locking mechanism when unfolded or folded, and operation is easy and convenient. The seat is installed in sliding grooves in the side walls of a vehicle body through sliding blocks, the installation method is simple and efficient, and later period repairing and maintaining are convenient. After being folded, the seat is self-locked, the physically challenged can place a wheelchair at the position of the seat, and space is saved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Vibration type data processing device

InactiveCN109765965ASolving inconveniences and distressConveniently placedInput/output for user-computer interactionDigital data processing detailsData informationData processing

The invention relates to a vibration type data processing device. The device comprises a display part, an information processing unit and a control unit, the display part is a display device that displays an image, The information processing unit is an information processing device with the data information processing capability, and the control unit is a control device by which the users can sendout the control instructions or signals. The spatial distance and the relative position of the display part and the information processing part are not fixed, the display part and the information processing part are electrically connected through a cable or in the wireless manner, and the control part and the information processing part are electrically connected through the cable or in the wireless manner. The device has the advantages of portability and flexibility.

Owner:VR TECH (SHENZHEN) LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com