Rotary cleaning mechanism and pipeline surface cleaning mechanism

A technology for cleaning machines and pipes, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., and can solve the problems of low cleaning efficiency and difficulty in cleaning pipe surface cleaning machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with the drawings and embodiments.

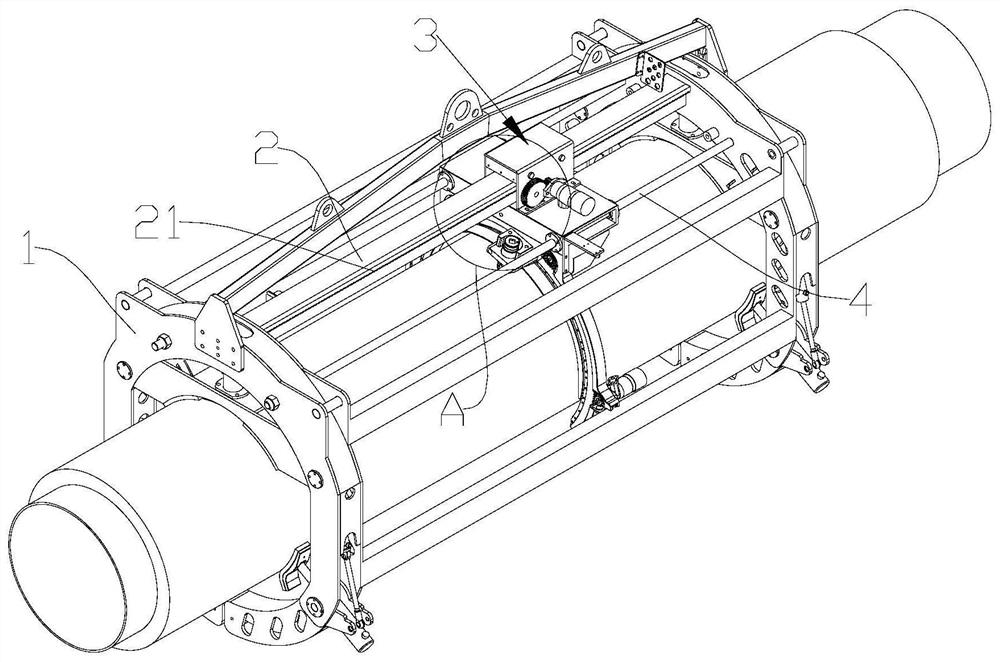

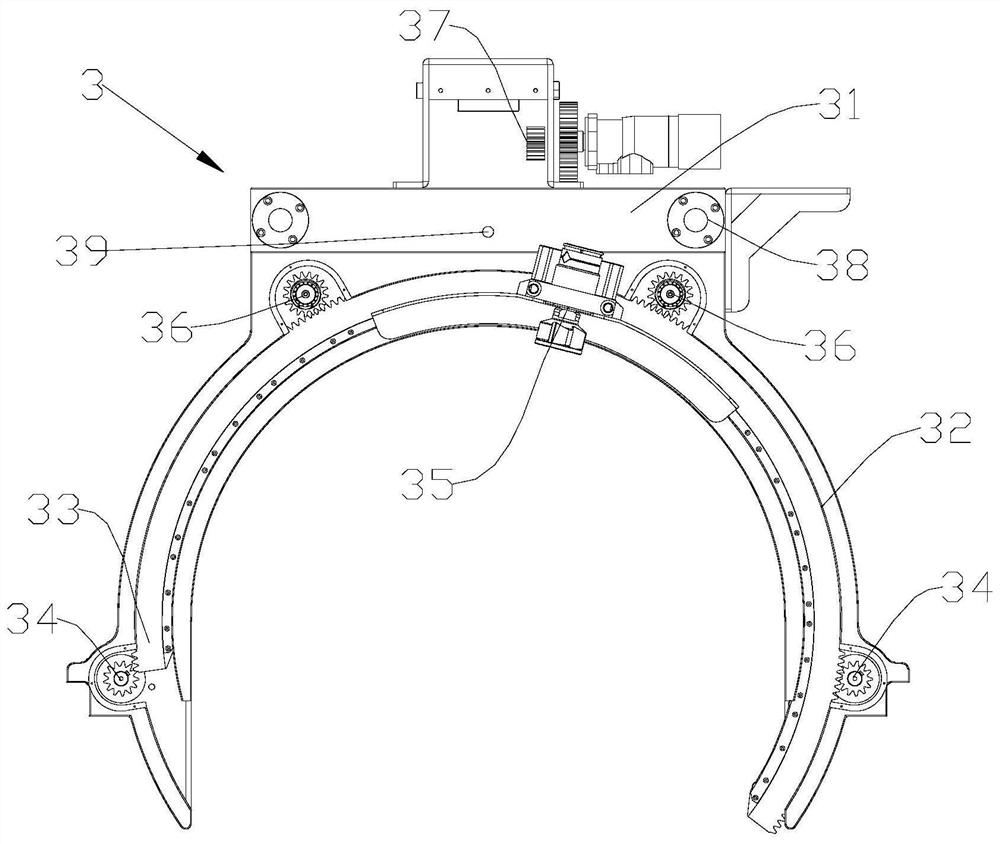

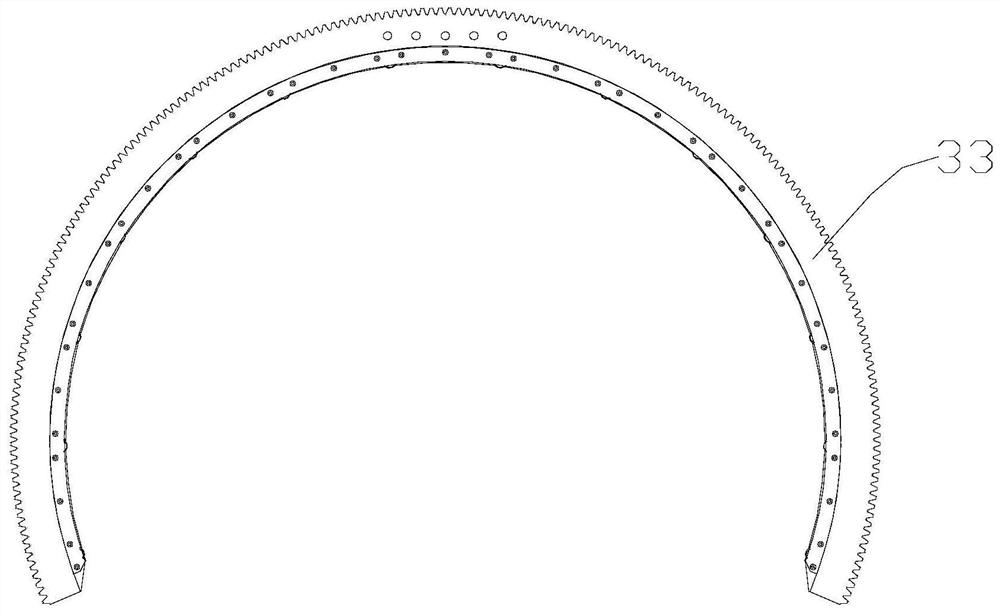

[0018] The embodiment of the present invention proposes a rotating cleaning mechanism 3, such as figure 2 As shown, a rack 31 is included. The lower part of the rack 31 is fixedly connected with a slide rail 32. The structure of the slide rail 32 is as Figure 4 , The shape of the slide rail 32 is a circular ring with a gap, the gap is downward, the inner diameter of the circular ring should be greater than the outer diameter of the pipe to be cleaned, the slide rail 32 is slidably provided with a ring gear 33, the ring gear 33 Should coincide with the axis of the slide rail 32, the ring gear 33 can rotate in the slide rail 32. The structure of the ring gear 33 is as follows image 3 , The ring gear 33 has a downward gap, the outer ring of the ring gear 33 is provided with a number of external teeth, the slide rail 32 is provided with a first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com