Flat plate heat pipe and manufacturing method thereof

A flat-plate heat pipe and manufacturing method technology, applied in heat exchange equipment, indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as easy to fall off, difficult to control the height of the support body, and difficult to assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

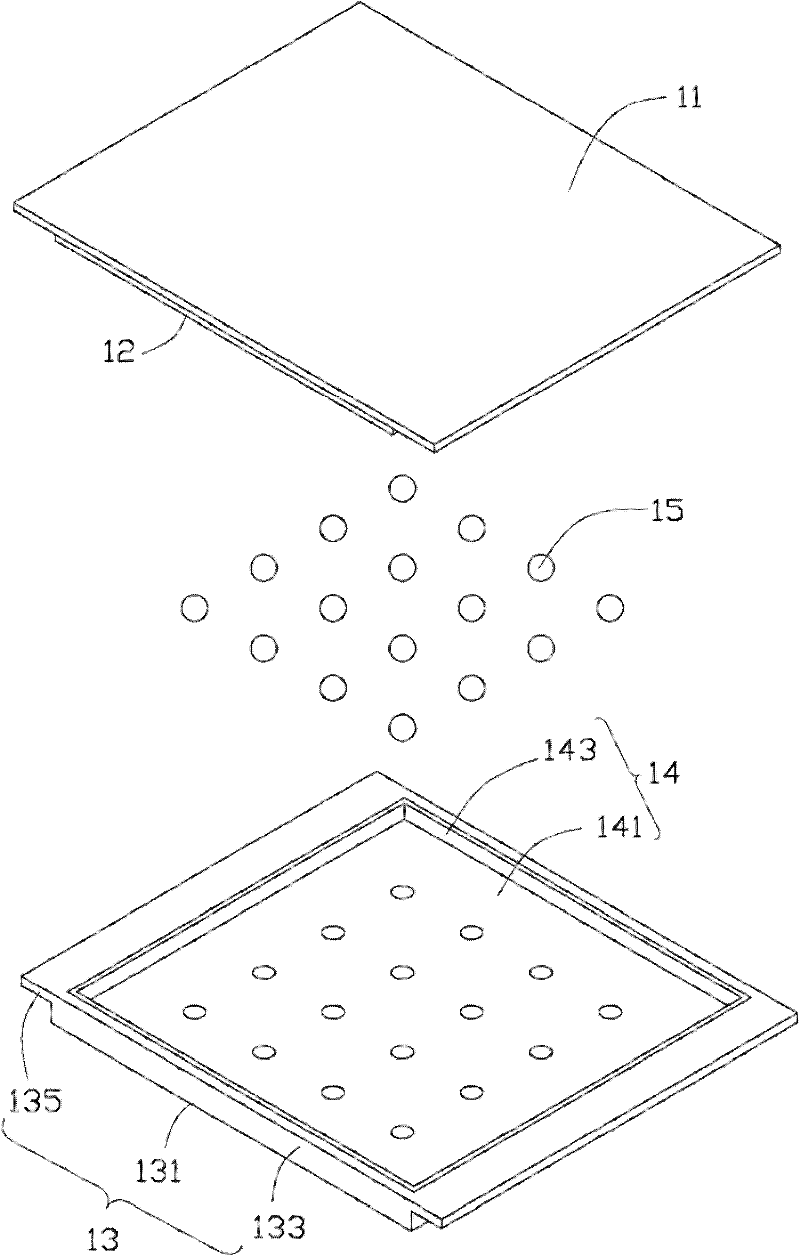

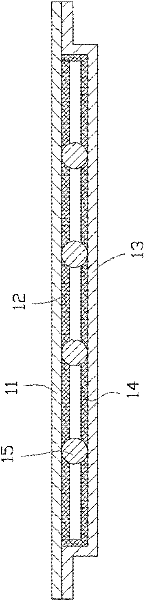

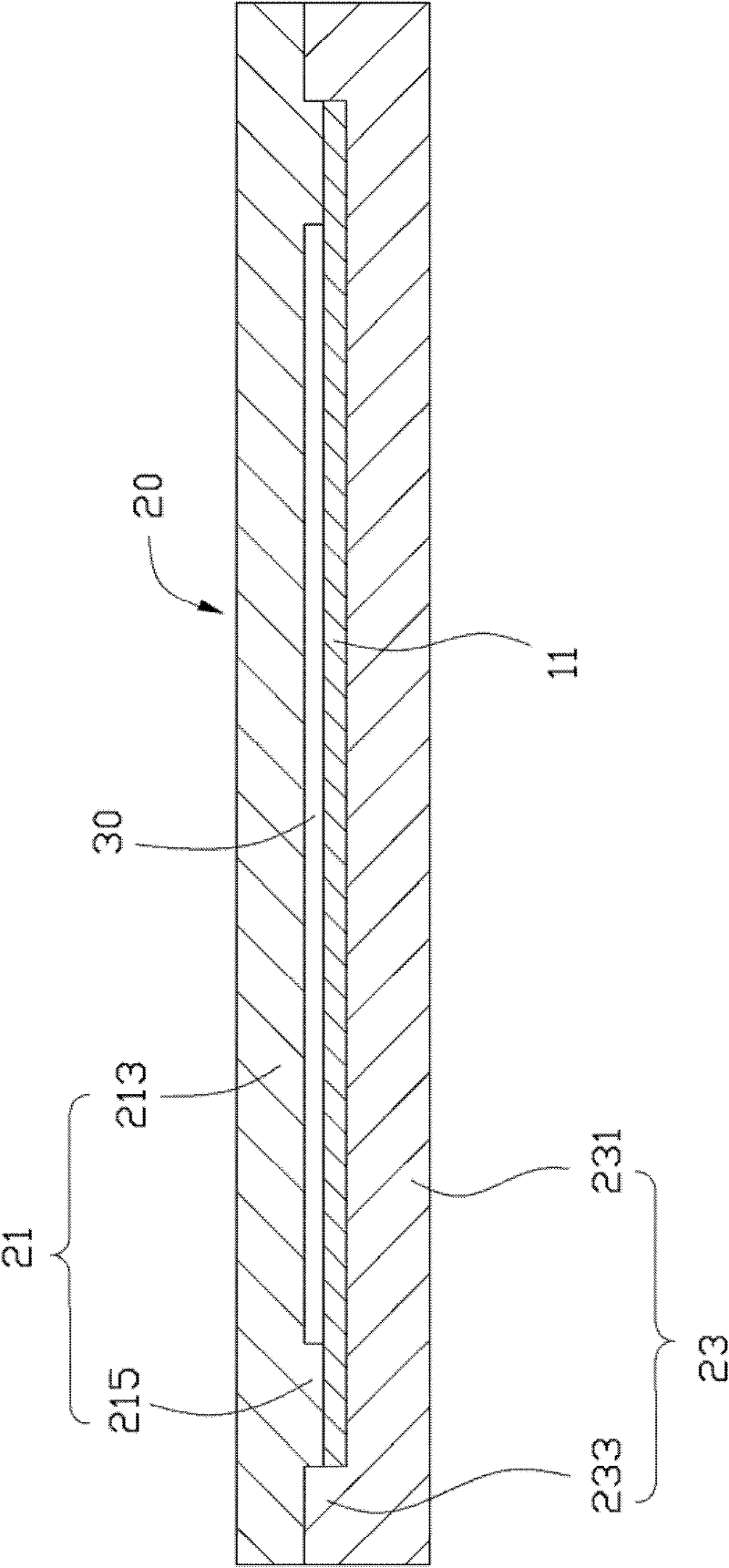

[0015] The manufacturing method of the flat heat pipe in one embodiment of the present invention includes the following steps: providing a first metal sheet body; providing several spherical supports and a second metal sheet body, the second metal sheet body includes a bottom plate and a The side plate extending from the bottom plate; placing the spherical support on the bottom plate of the second metal sheet; closing the first and second metal sheets, and performing diffusion welding on them, so that the first and second metal sheets are sealed and connected , and make the spherical support body sandwiched between the bottom plates of the first metal sheet body and the second metal sheet body and directly abut against the bottom plates of the first metal sheet body and the second metal sheet body.

[0016] see figure 1 and figure 2 , the manufacturing method of the above-mentioned heat pipe will now be described in detail by taking the manufacturing process of a flat heat p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com