Semiconductor laser tube core sintering clamp and sintering method thereof

A laser and semiconductor technology, applied in the direction of semiconductor lasers, lasers, laser parts, etc., can solve the problems of difficult processing and assembly of precision parts, easy deformation of parts, unusable fixtures, etc., to reduce sintering voids, high production efficiency, Easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

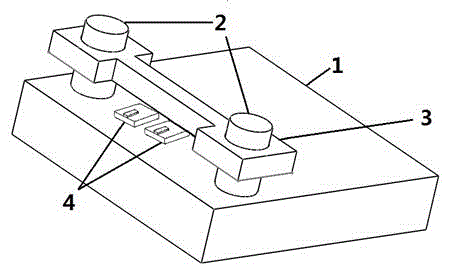

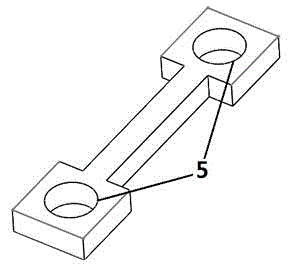

[0020] Such as figure 1 As shown, the semiconductor laser die sintering jig of the present invention includes a base 1 , a fixing column 2 and a pressing block 3 . The base 1 can be a cuboid, a cube, a cylinder or other shapes, preferably a cuboid. The fixed column 2 is fixed on the base 1 by screw connection or welding, and there is at least one set of fixed columns on the base 1, each group is two fixed columns, and 2-20 can be placed within the distance between the two fixed columns Laser die and heat sink 4 (Use an adsorption machine under a microscope to place the semiconductor laser die on the heat sink with solder to form the laser die and heat sink 4, the heat sink refers to the packaging and cooling of the laser die used heat sink), it is advisable to place 2-5 laser dies and heat sinks, so that batch sintering can be performed. A briquetting block 3 is arranged on the two fixed columns of each group. Such as figure 2 , The pressing block 3 is provided with two g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com