Metal cable combined pipe

A cable and pipeline technology, applied in the field of metal cable combined pipeline, can solve the problems of corrosion of the external structure of the cable, easy damage to the cable support structure, affecting the service life, etc., and achieves convenient transportation and storage, good strength, and convenience. The effect of combing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

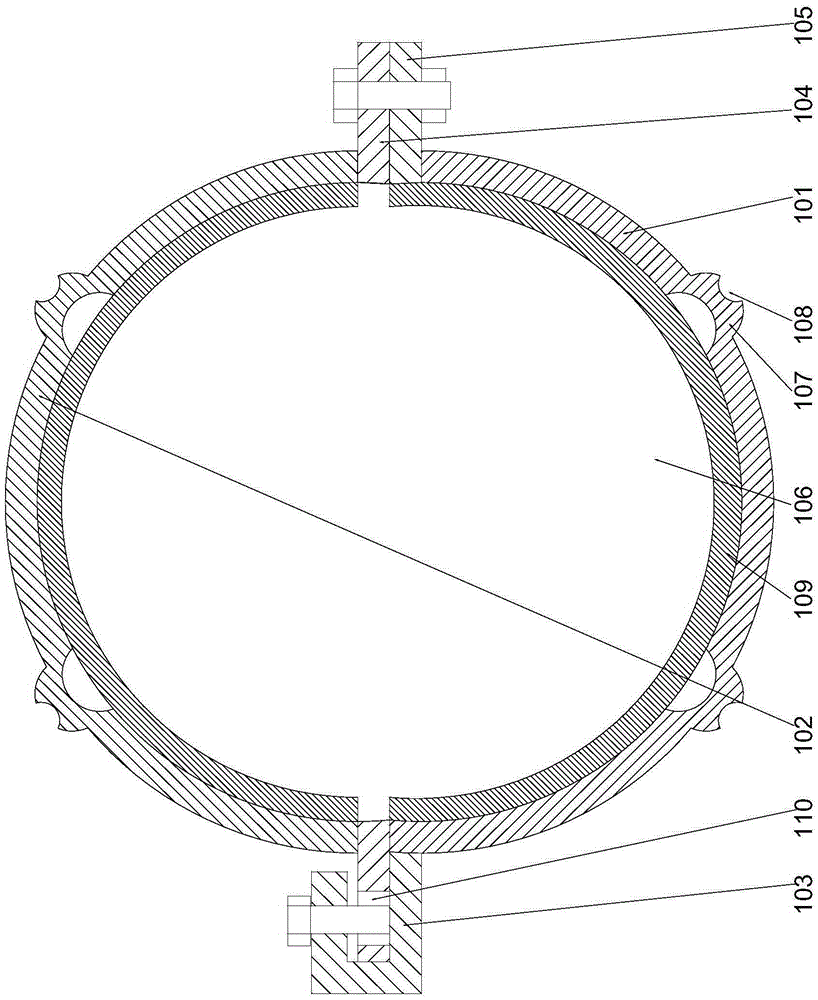

[0020] like figure 1 As shown, a metal cable combined pipe includes an upper connecting section 101 and a lower connecting section 102. The cross-sections of the upper connecting section 101 and the lower connecting section 102 are both semicircular. One end of the connecting section 101 is provided with a clamping slot 103 , the opening direction of the clamping slot 103 faces the axial direction of the upper connecting section 101 , and the two ends of the lower connecting section 102 are respectively provided with fixing plates 104, the fixing plate 104 on one side of the lower connecting section 102 is clamped in the clamping slot 103, and an extension plate 105 is provided at the end of the upper connecting section 101 away from the clamping slot 103, A through hole is provided on the fixing plate 104 at one end of the lower connecting section 102 away from the clamping slot 103, and a bolt is arranged in the through hole, and the bolt penetrates the through hole and is t...

Embodiment 2

[0023] In this embodiment, on the basis of Embodiment 1, in order to improve the elasticity of the eave structure and make it have better impact resistance, in this embodiment, preferably, the end of the eave structure 107 is provided with a directional Inside recessed groove 108. By arranging the groove structure, the eave structure is less likely to be damaged under external force extrusion, and at the same time, the eave structure can have better elasticity and is less likely to be damaged when the eave structure is extruded from the outside.

[0024] When installing the cable in the hollow cable channel, in order to avoid the potential short circuit caused by the surface damage of the cable caused by the extrusion of the upper connecting section and the lower connecting section under the action of external force, in this embodiment, preferably, the upper The inner end surfaces of the connecting section 101 and the lower connecting section 102 are provided with an anti-skid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com