Patents

Literature

95results about How to "Interconnected firmly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

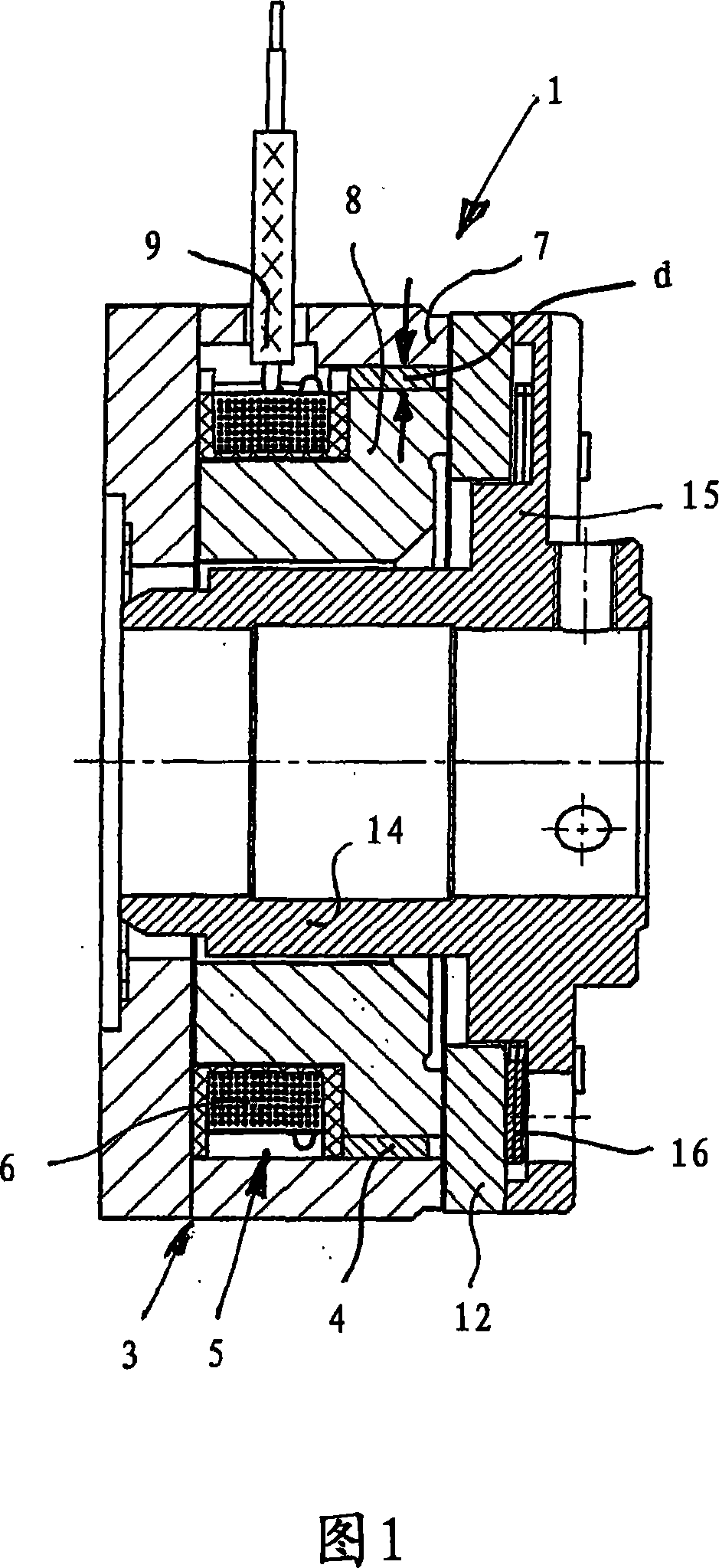

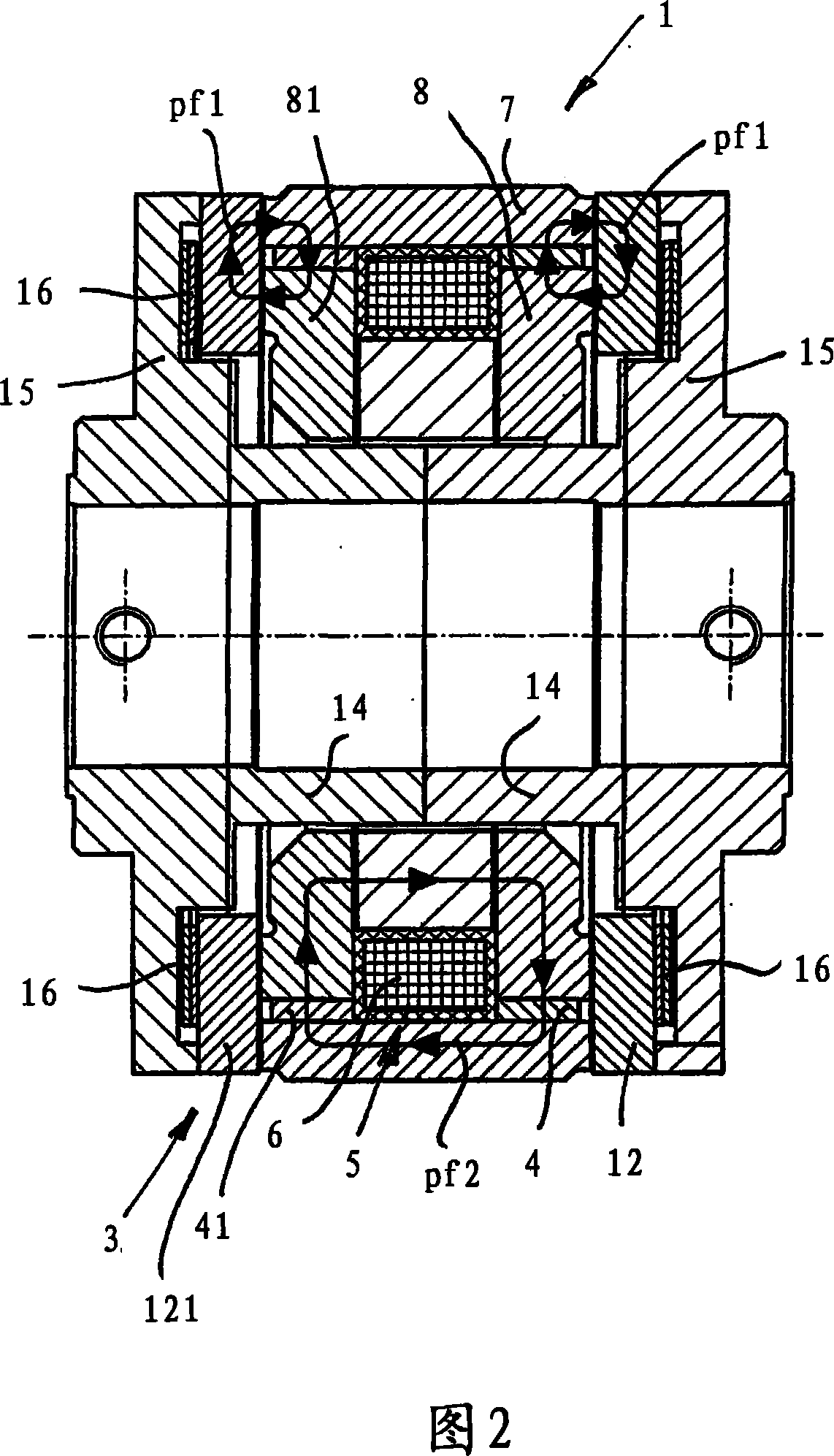

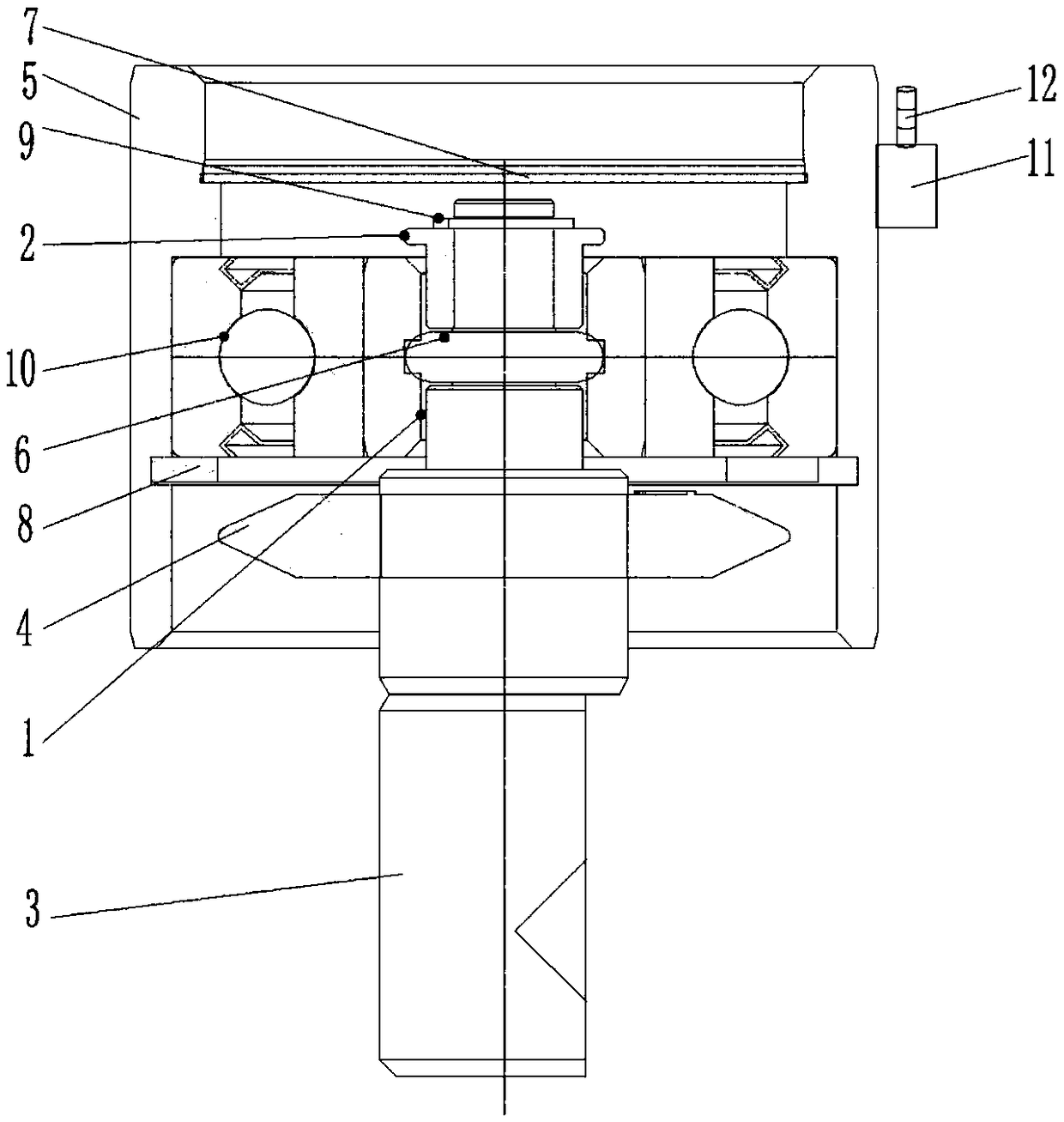

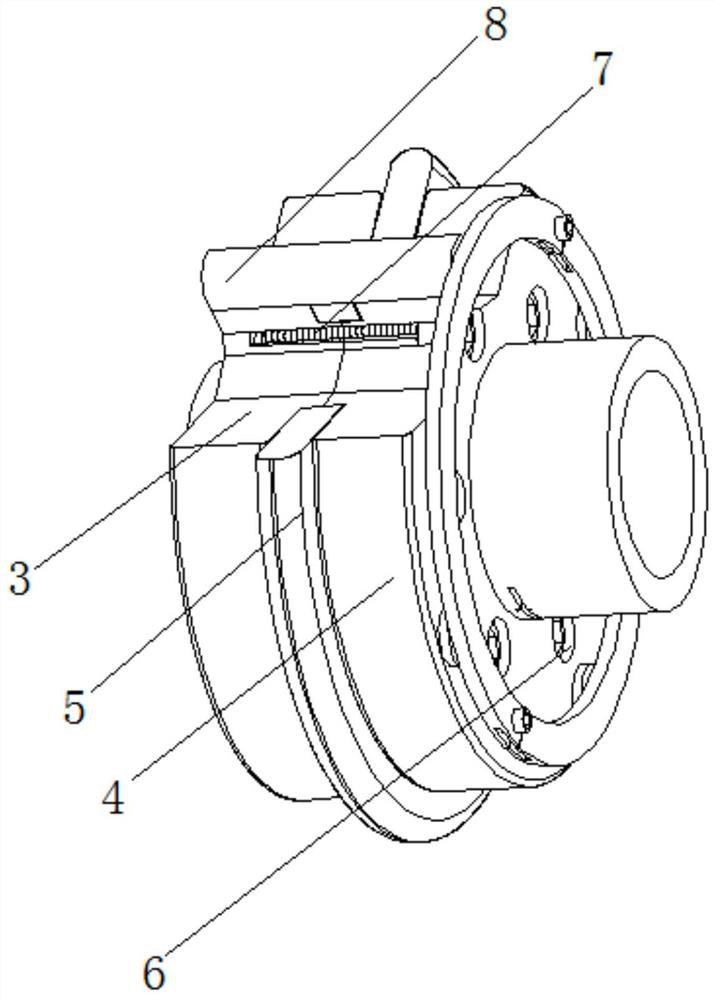

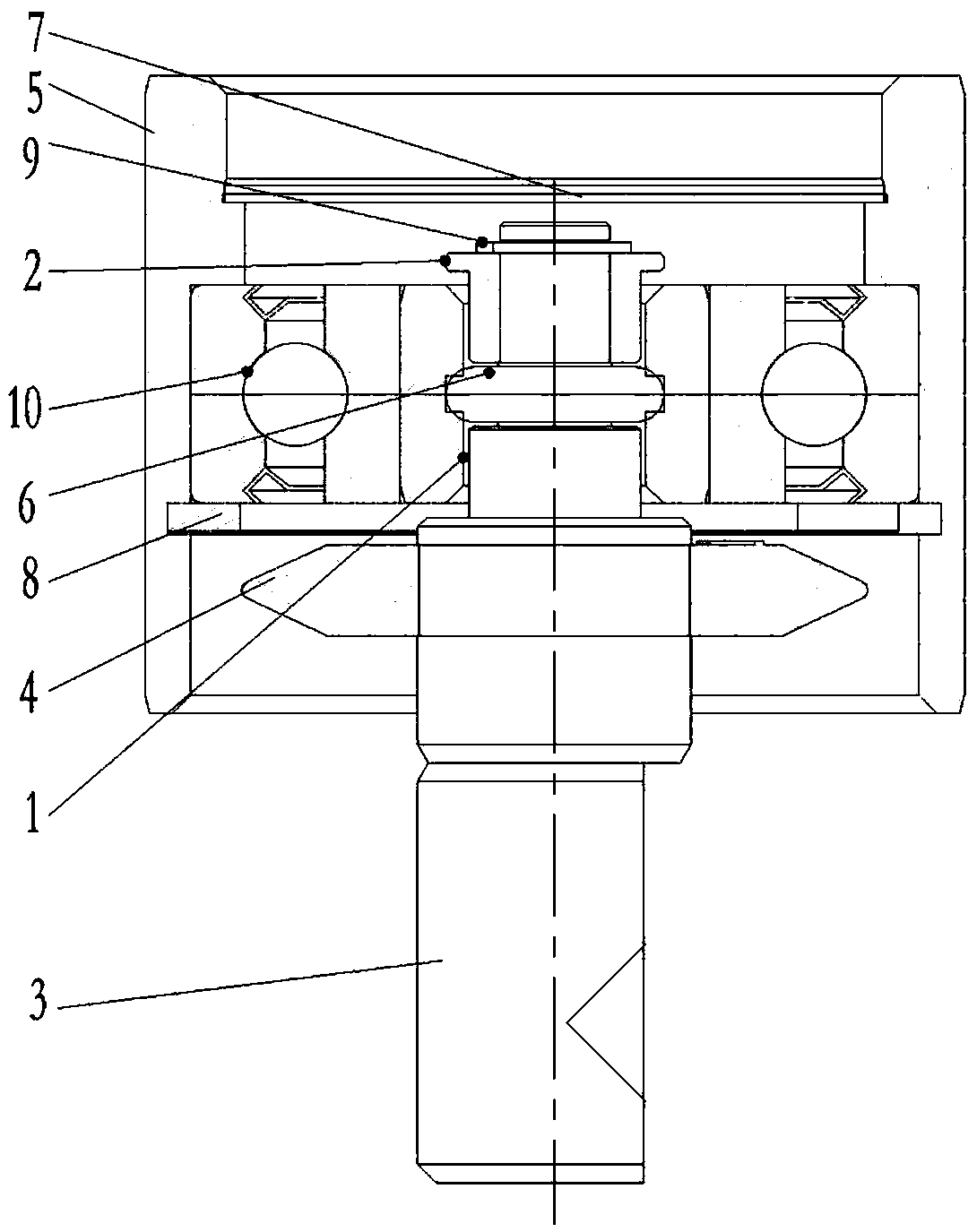

Electromagnetic permanent magnet brake

ActiveCN101115937AConstant torqueRaise or enlarge the magnet surfaceAxially engaging brakesBrake actuating mechanismsMagnetic tension forceSpring force

An electromagnetic brake (20), in particular for an electric drive is provided, having a brake body (3), which is provided with a sleeve-shaped permanent magnet (4), an electromagnet (5) with an exciting coil (6), an external ring in the form of an external pole and an internal ring (8) in the form of an internal pole, wherein an armature disc (12) rotatably connected to a shaft is attractable against the brake body (3) or the external or internal ring surfaces by the permanent magnet (4) force acting against a return spring force. When the exciting coil is powered, the permanent magnet (4) magnetic field is compensated in such a way that the armature disc (12) is lifted up from the brake body (3) by the spring force, thereby allowing the brake to be released. A radial cross-sectional dimension or cross-sectional thickness d of the permanent magnet (4) is smaller than the axial dimension thereof and a spatial arrangement, viewed in the axial direction, is provided between the armature disc (12) and the exciting coil (6) in the area radially external with respect to the exciting coil (6) or the housing thereof.

Owner:KENDRION VILLINGEN GMBH

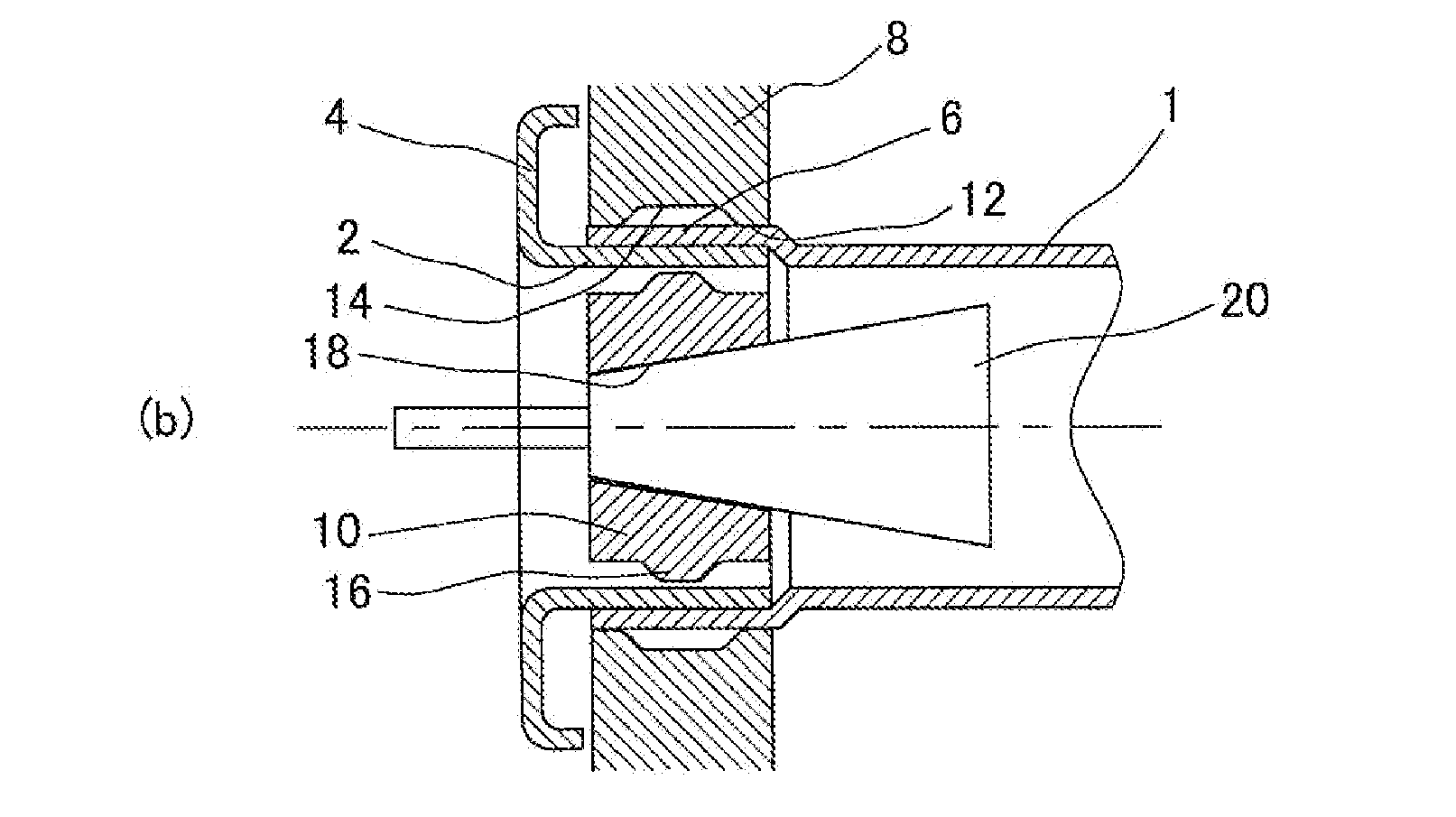

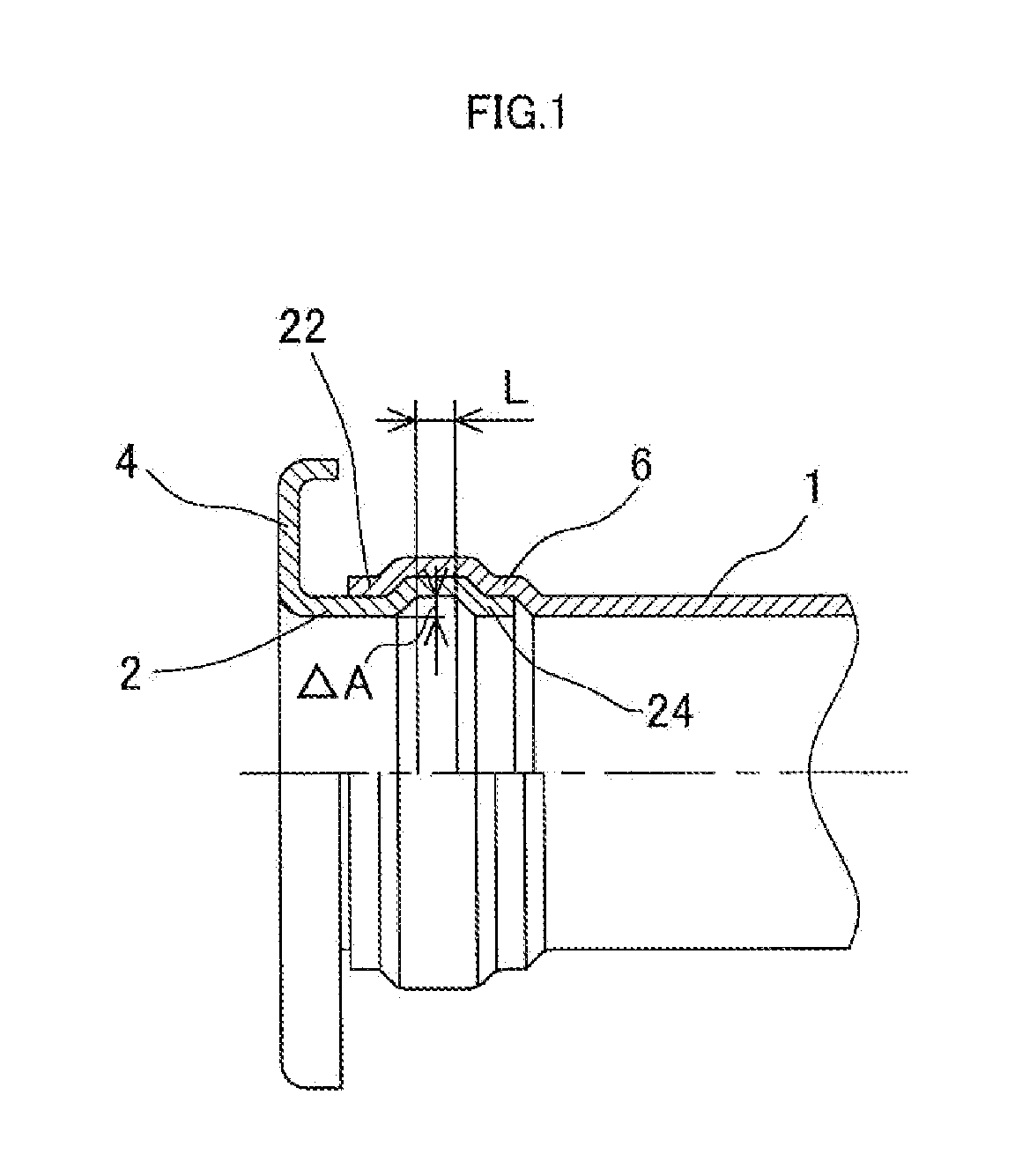

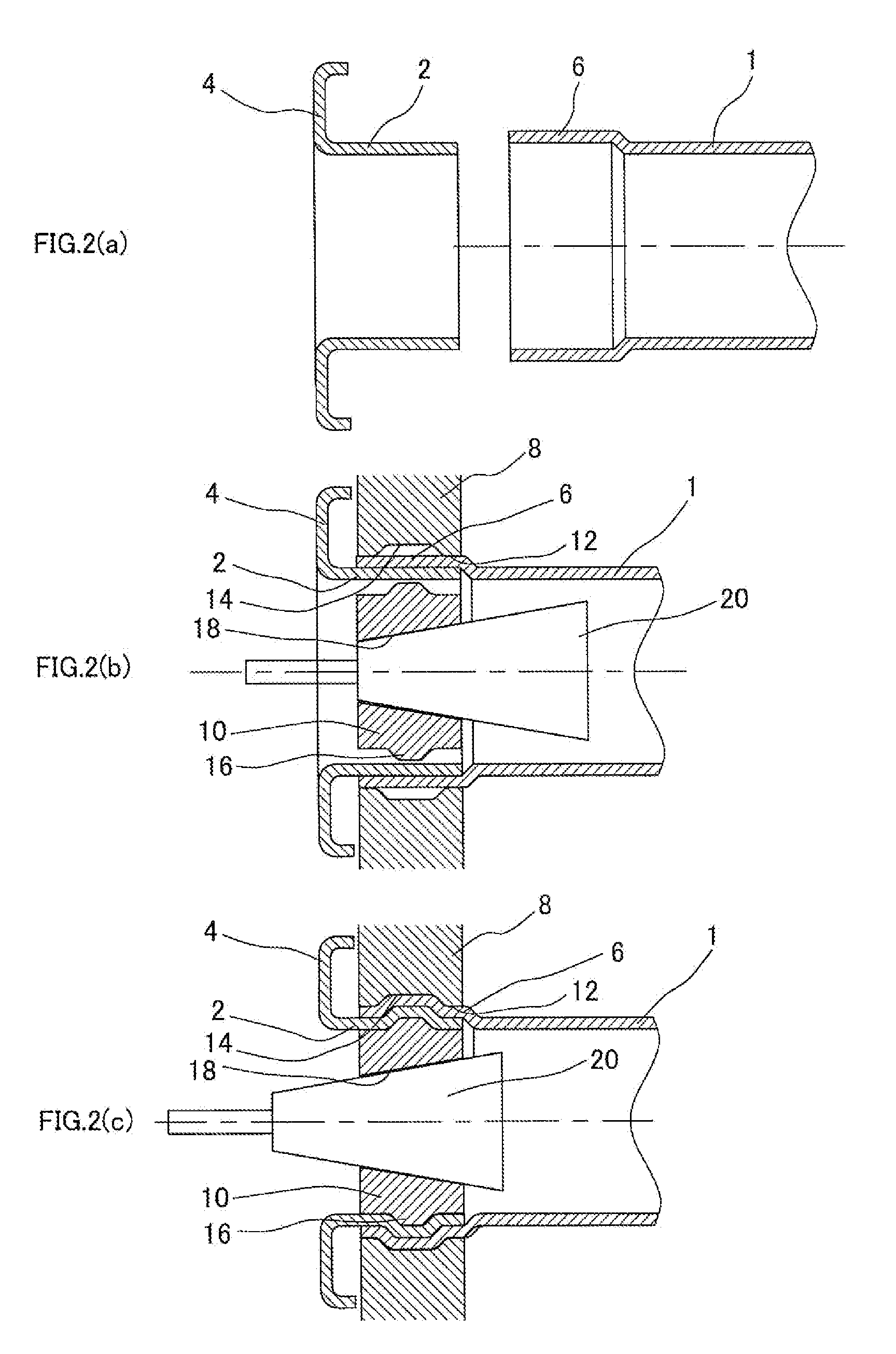

Exhaust pipe connection structure and exhaust pipe connection method

InactiveUS20110215573A1Easy to shapeEasy interconnectionExhaust apparatusJoints with sealing surfacesEngineeringInternal combustion engine

An exhaust pipe connection structure for interconnecting a connection pipe and an exhaust pipe that are arranged in an exhaust system of an, internal combustion engine. Either of the connection pipe or the exhaust pipe is inserted into the other, and the portion where the connection pipe and the exhaust pipe overlap each other is radially deformed and swaged.

Owner:FUTABA IND CO LTD

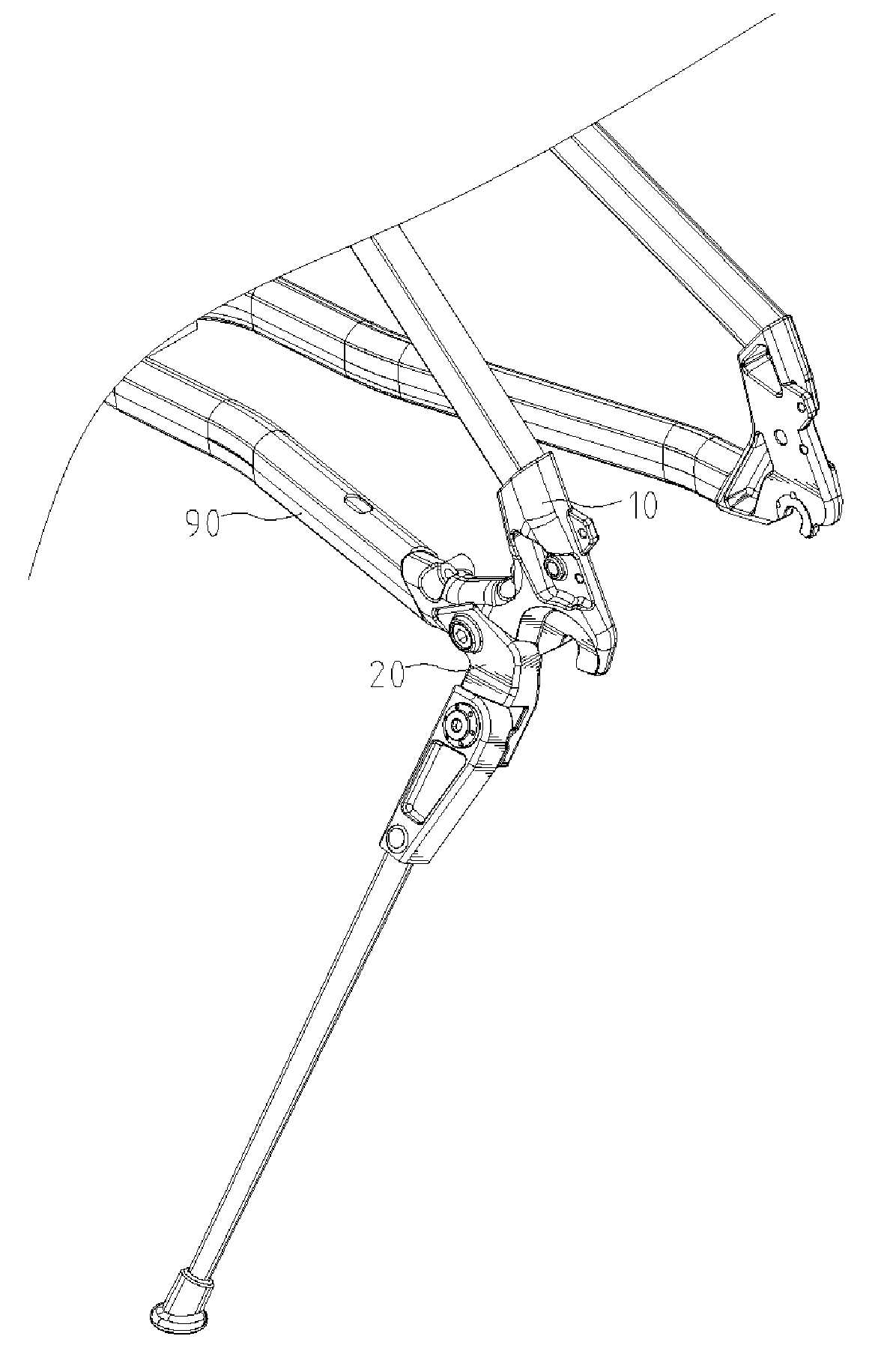

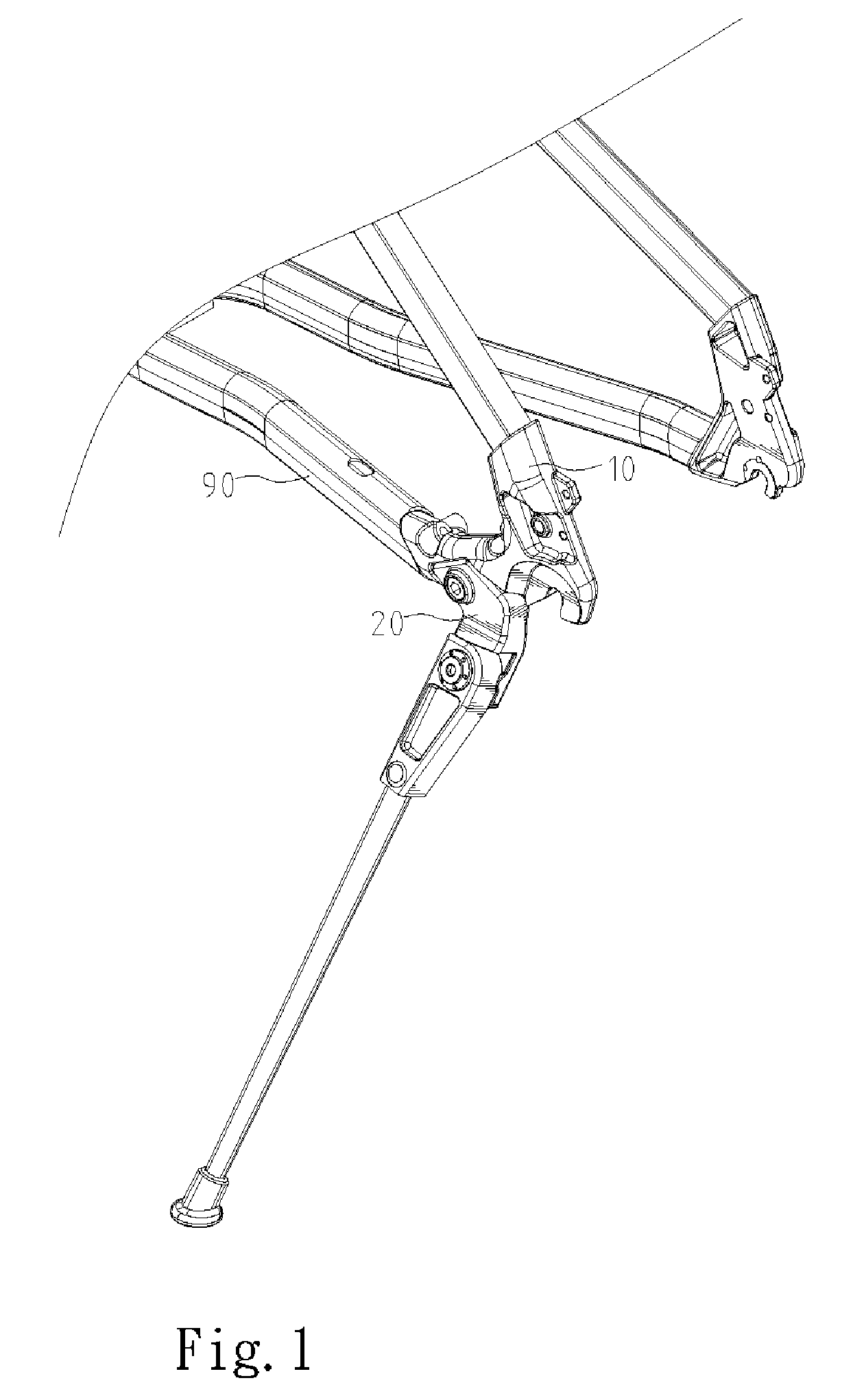

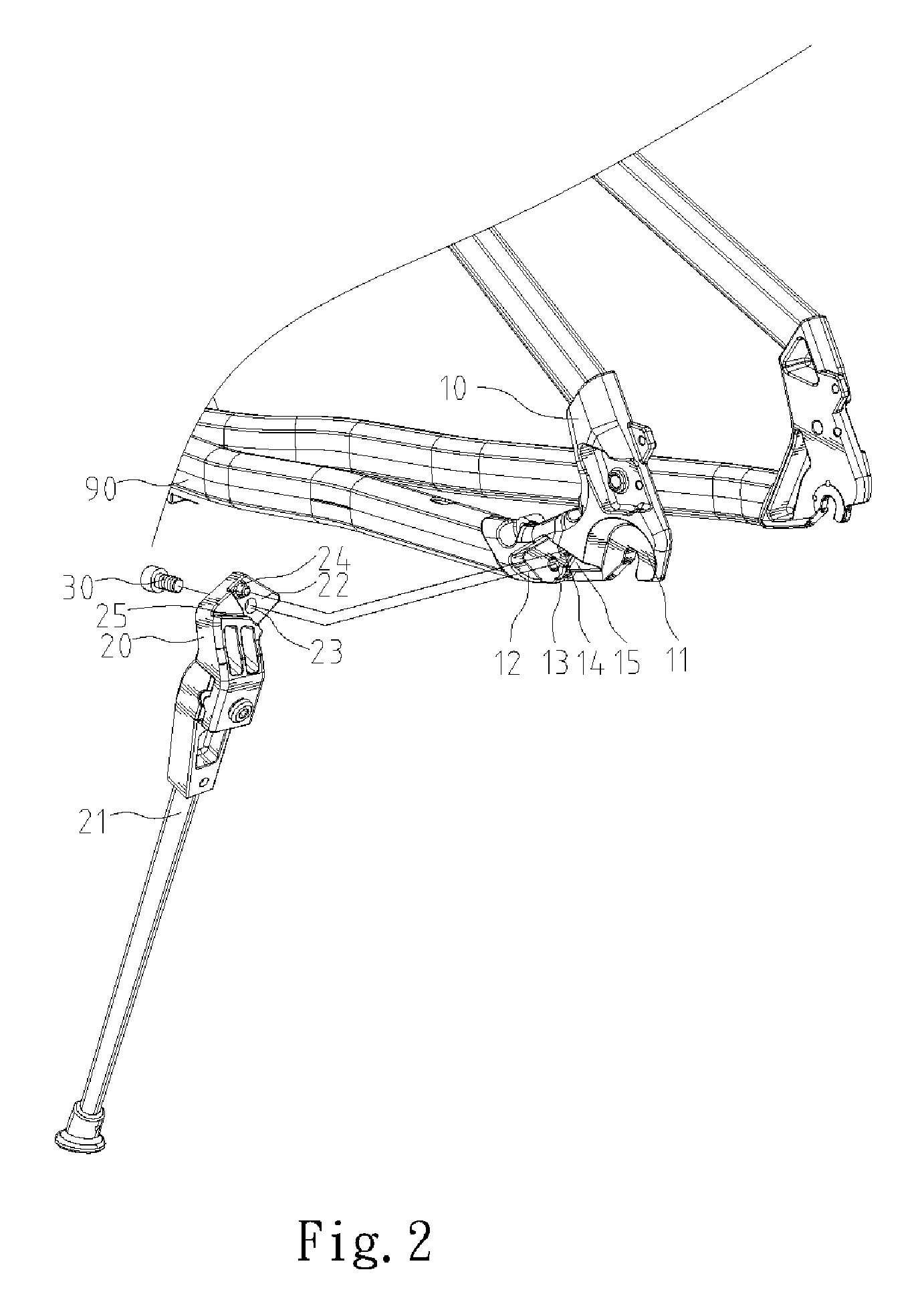

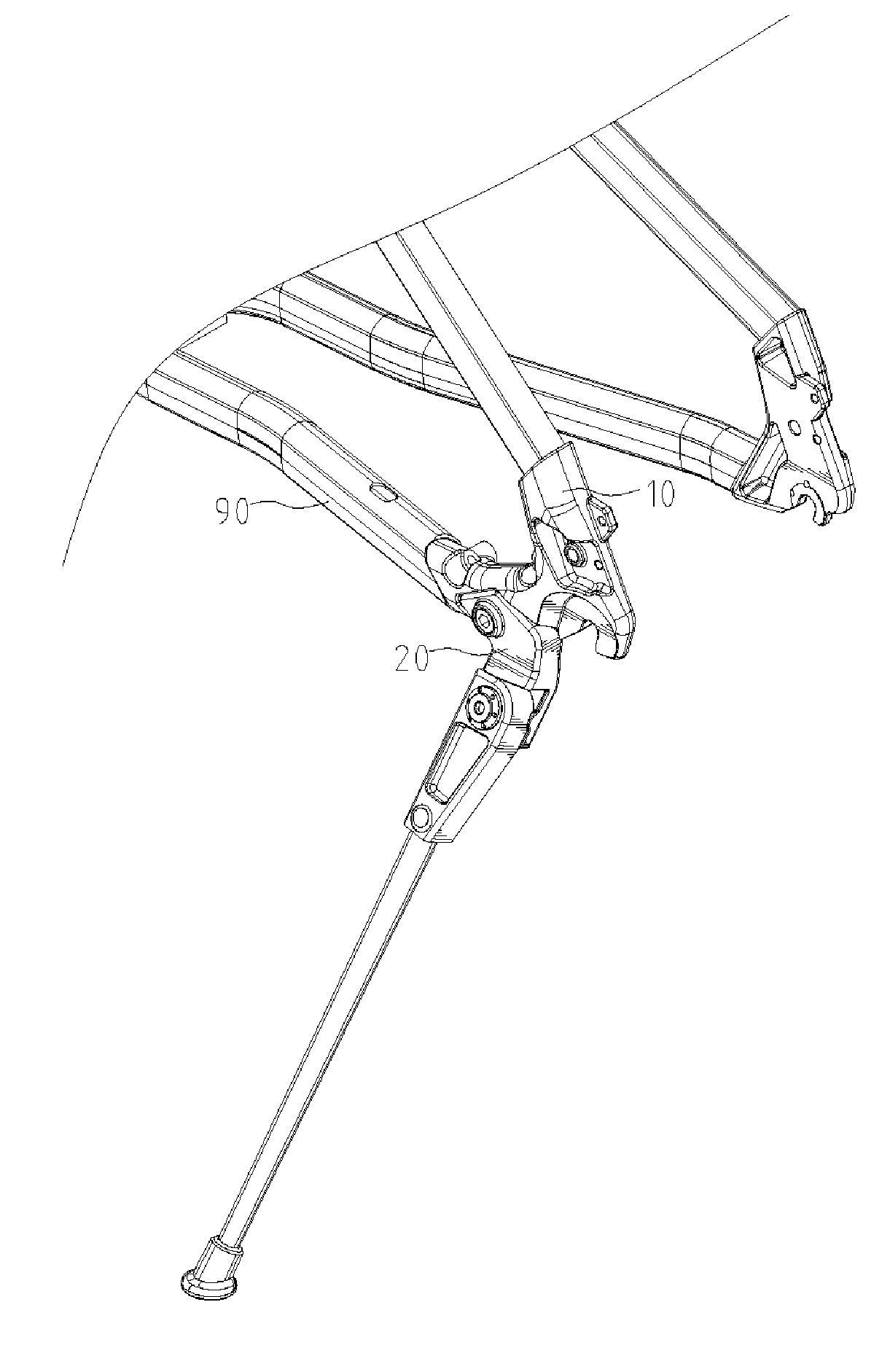

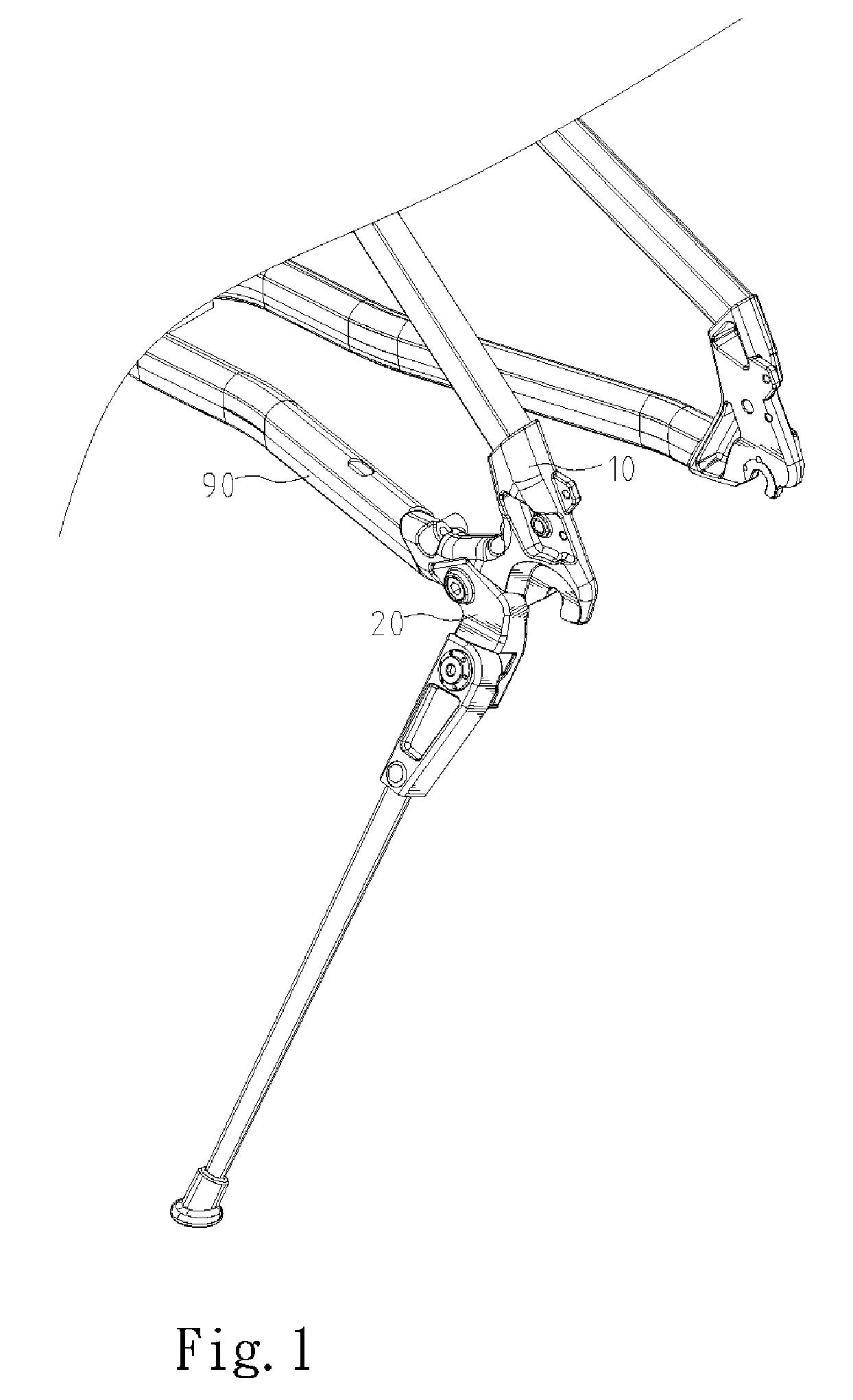

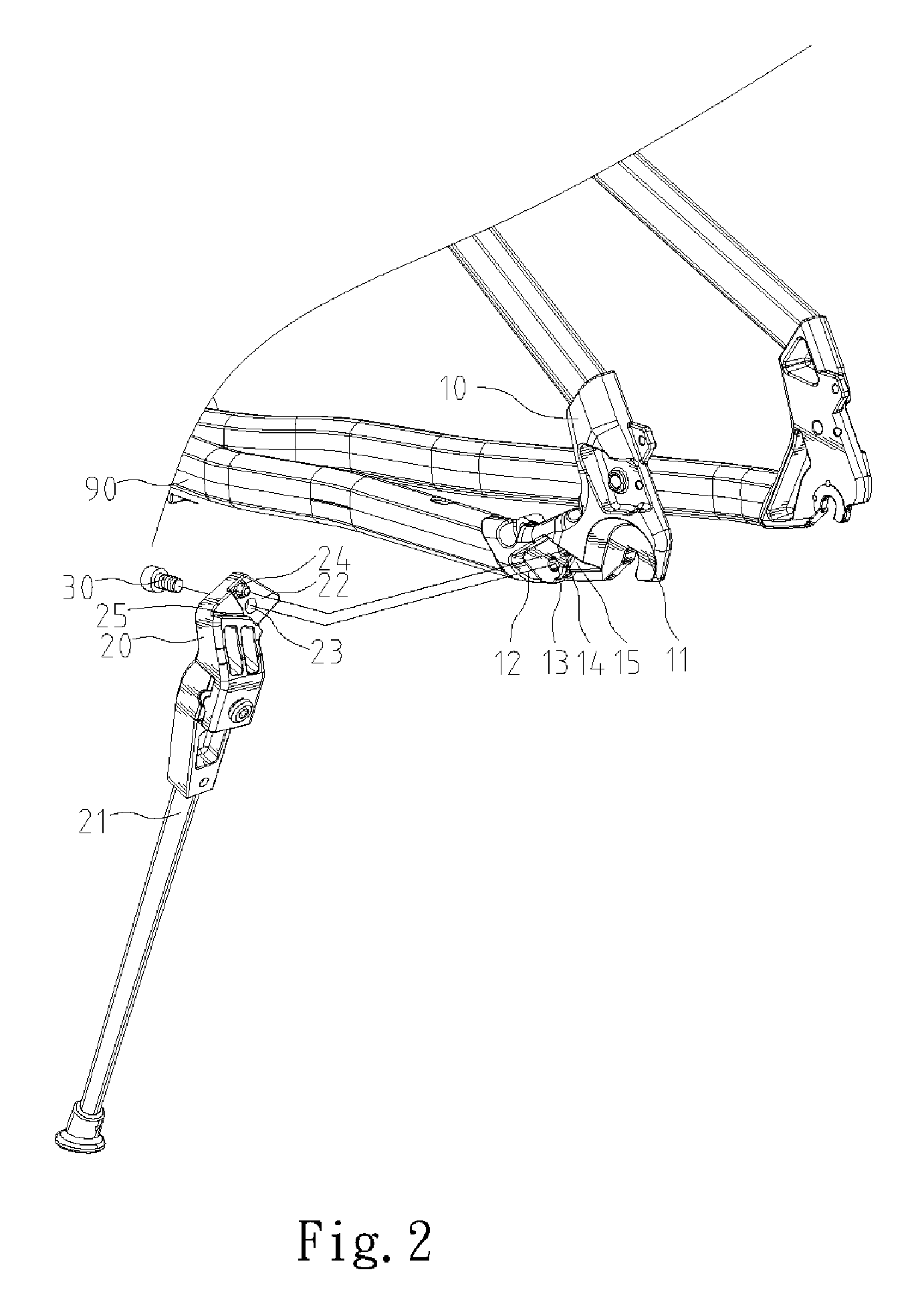

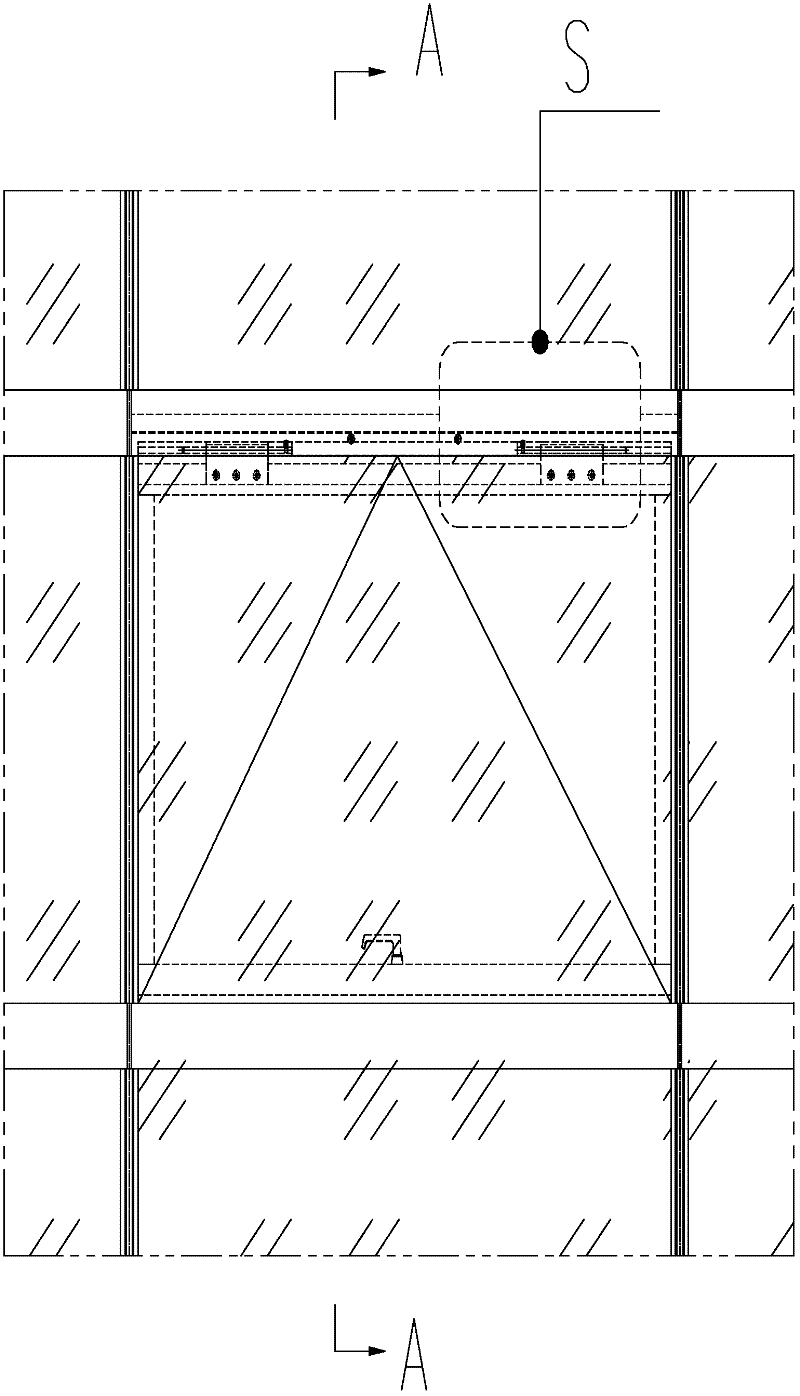

Device for connecting a kickstand to a bicycle

A device is disclosed for connecting a kickstand to a bicycle. The device includes a first connective member, a second connective member and a fastener. The first connective member is connected to a chain stay and a seat stay. The first connective member includes a claw formed thereon for holding a shaft of a rear wheel and a cavity defined therein. The kickstand is pivotally connected to the second connective member. The second connective member includes a block fit in the cavity so that the first and second connective members cannot be rotated with respect to each other. The fastener is used for fastening the first and second connective members to each other.

Owner:CHUANG LOUIS

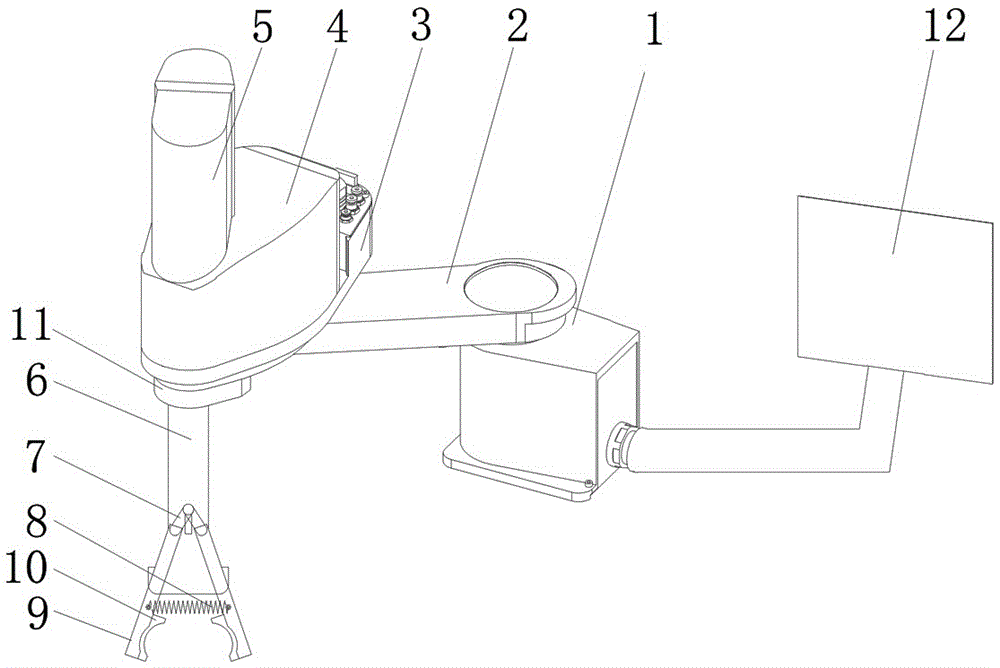

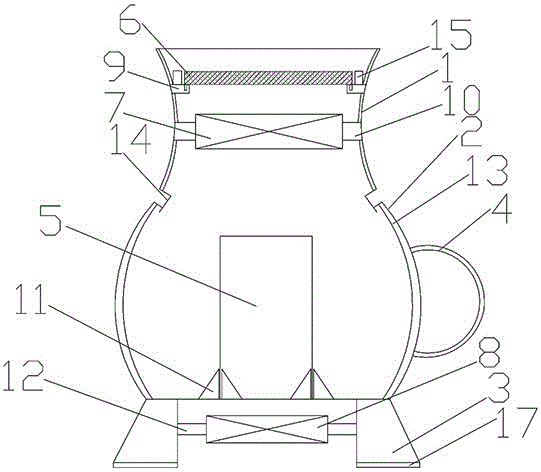

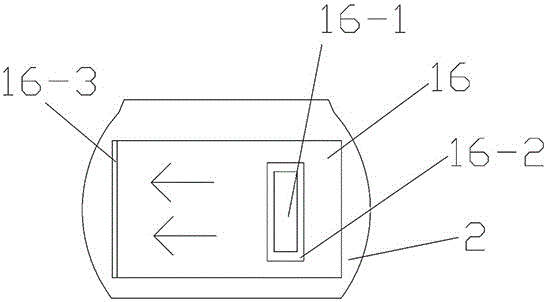

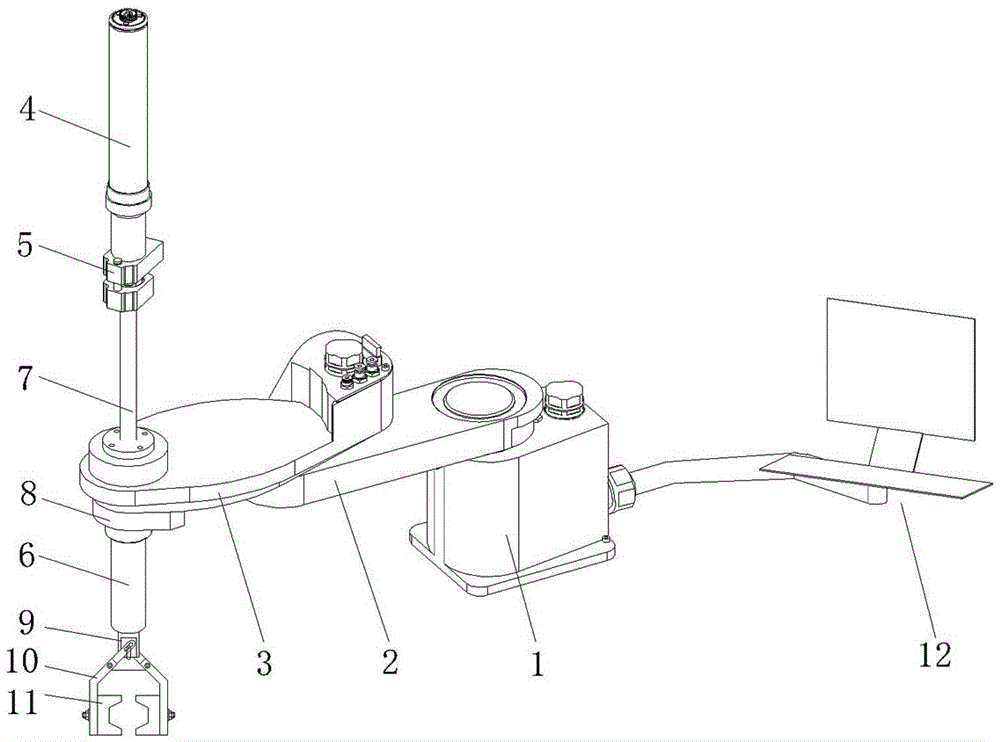

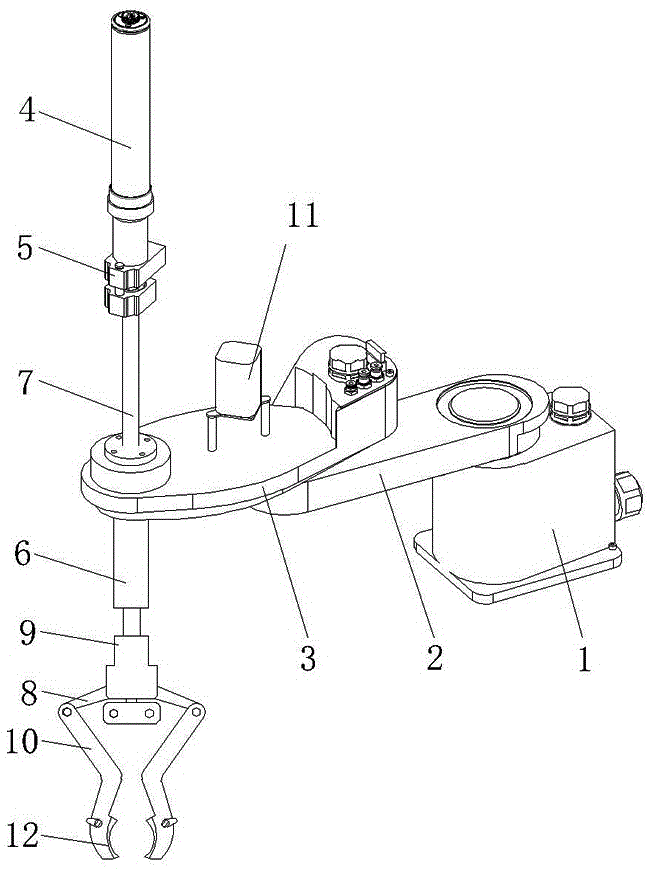

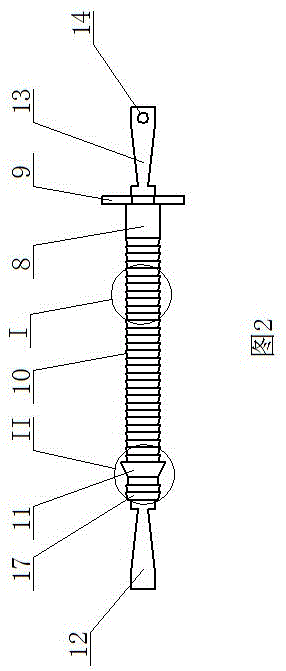

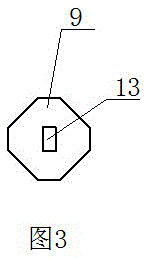

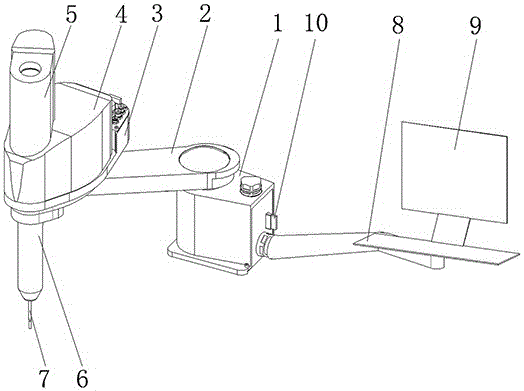

Automatic clamping manipulator with displayer

InactiveCN106113084AInterconnected firmlyEasy loading, unloading and maintenanceGripping headsDisplay deviceElectric machinery

The invention discloses an automatic clamping manipulator with a display, and mainly relates to the technical field of manipulators; The clamping fingers are all driven by the servo motor inside the fuselage, and the upper surface of the second joint shaft is connected with a fixed seat; the upper part of the telescopic sleeve passes through the second joint shaft and is connected with the fixed seat, and the top is connected with a motor; the clamping fingers pass through The connecting rod is connected with the telescopic sleeve, a spring is arranged between the clamping fingers, and a liner is arranged on the inner side of the end; a display is connected to one side of the fuselage, and a visual sensor connected to the display is arranged at the bottom of the second joint shaft; the manipulator of the present invention The damage to the workpiece is small, and the operator can easily monitor its operation status. The overall structure is simple, the assembly and maintenance are very convenient, the manufacturing and operation costs are low, and it can maintain efficient and stable operation for a long time.

Owner:苏州塞默机械有限公司

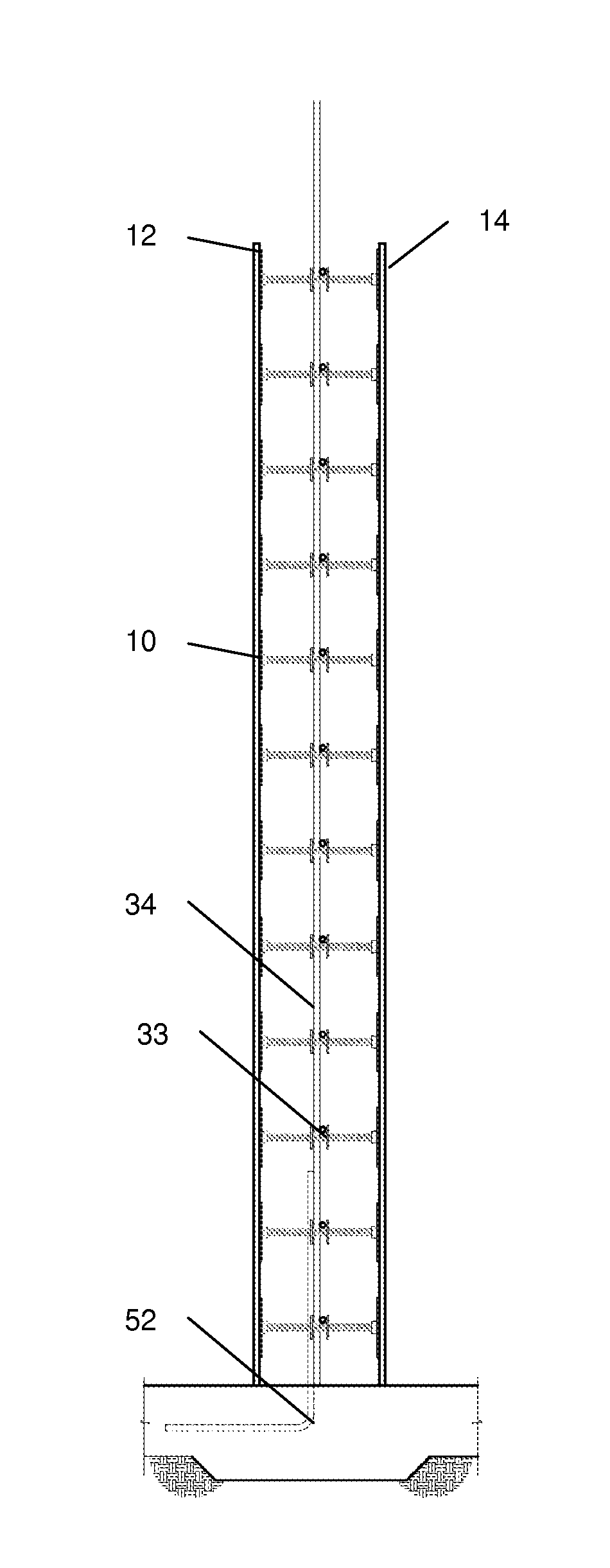

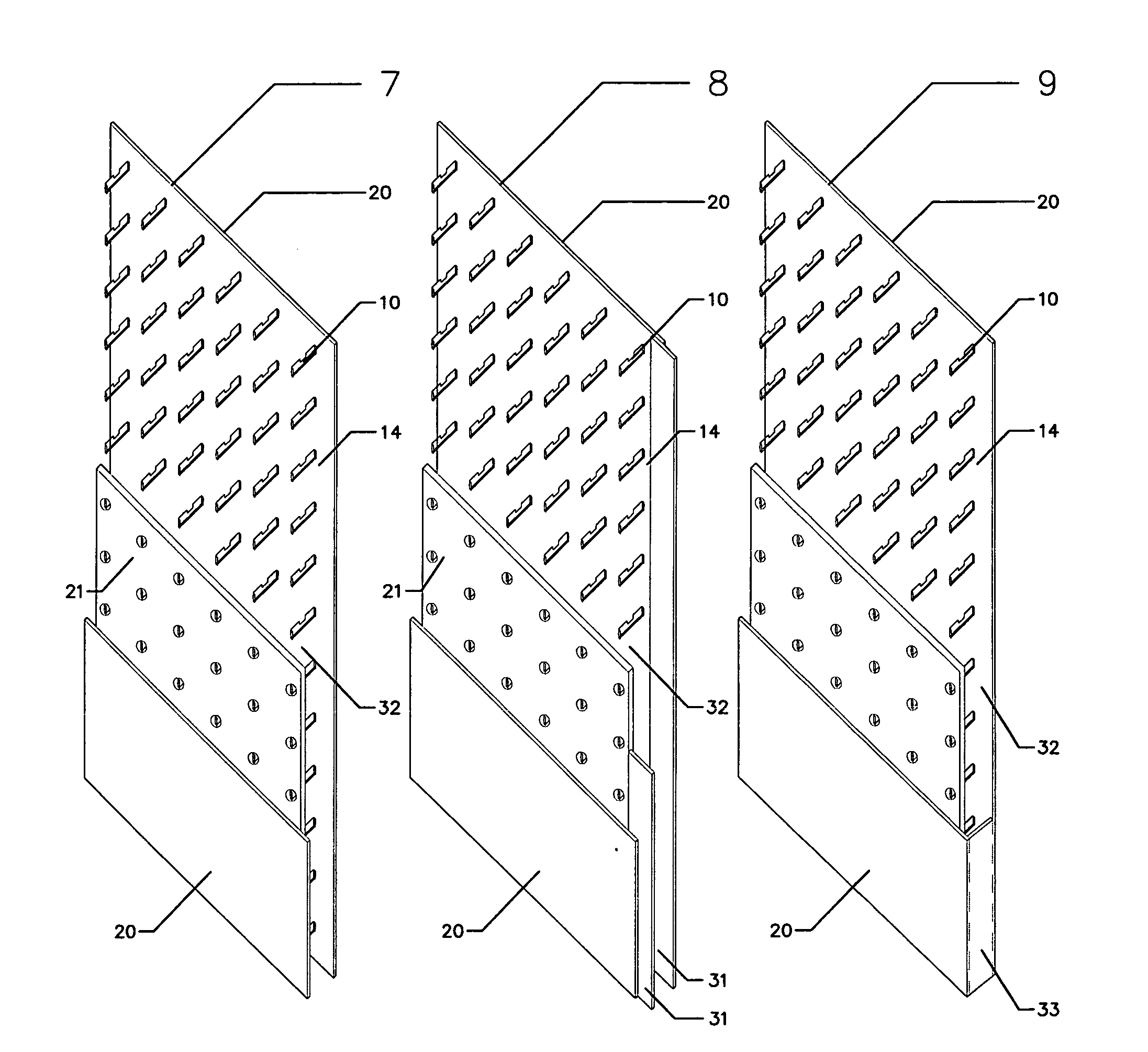

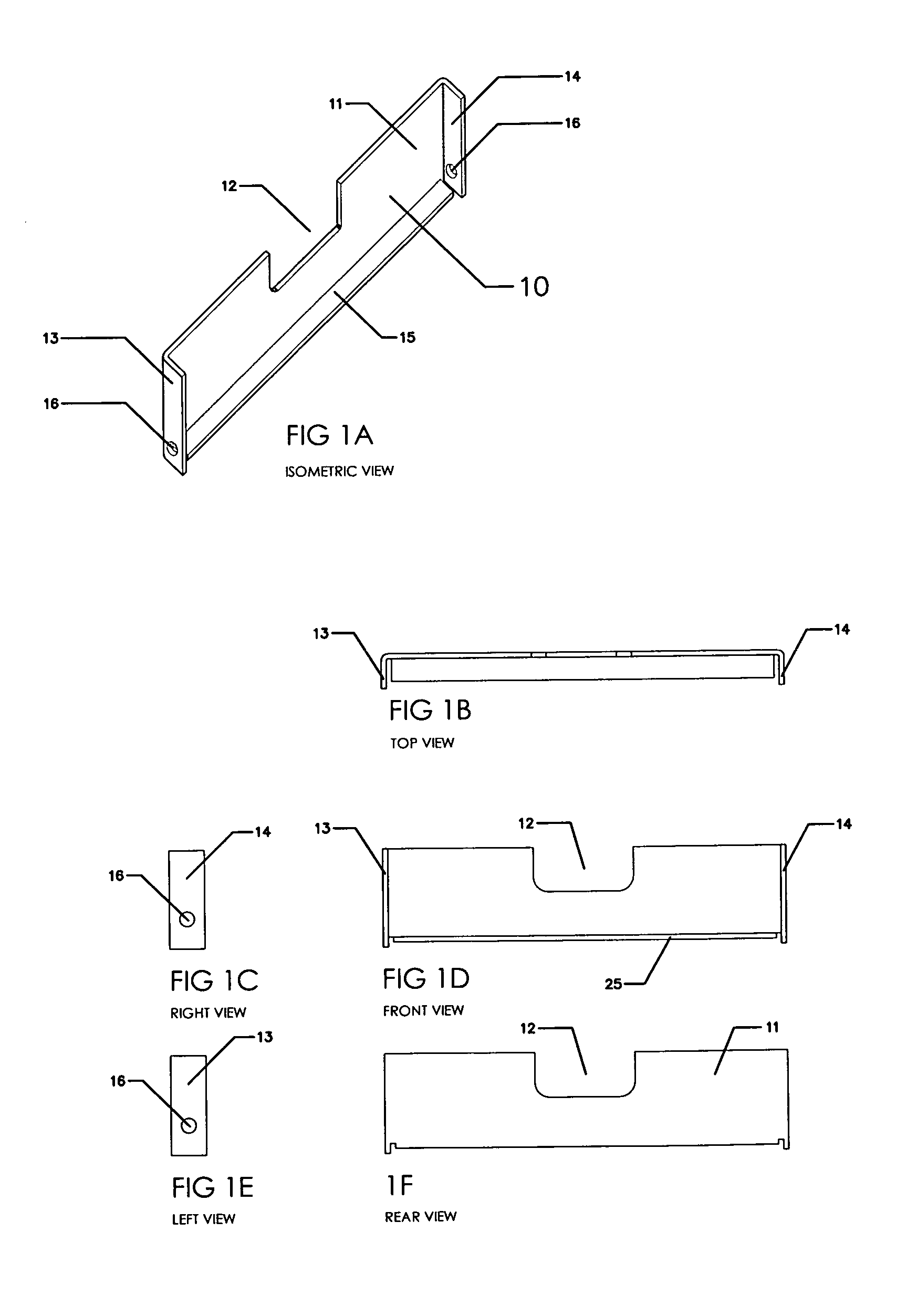

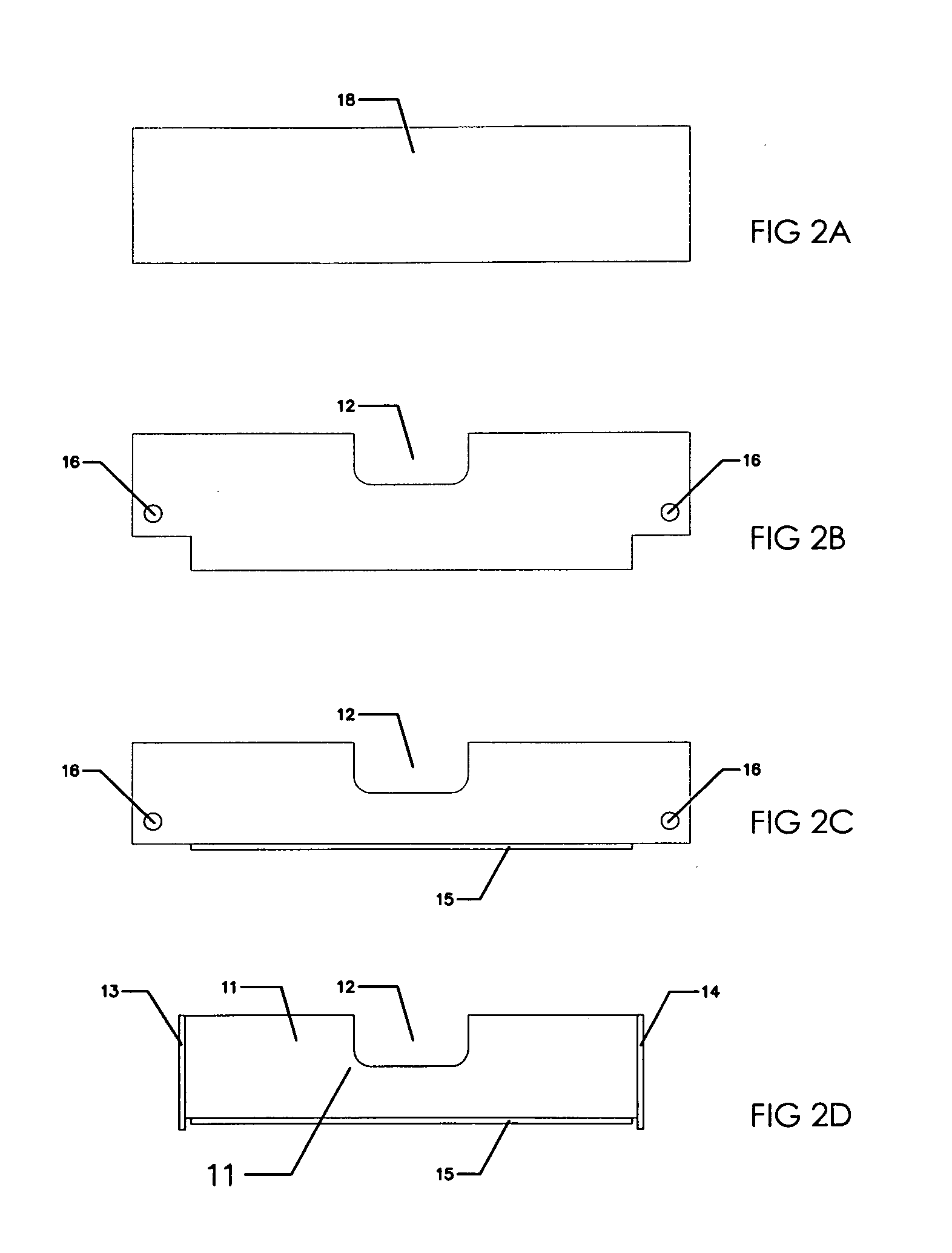

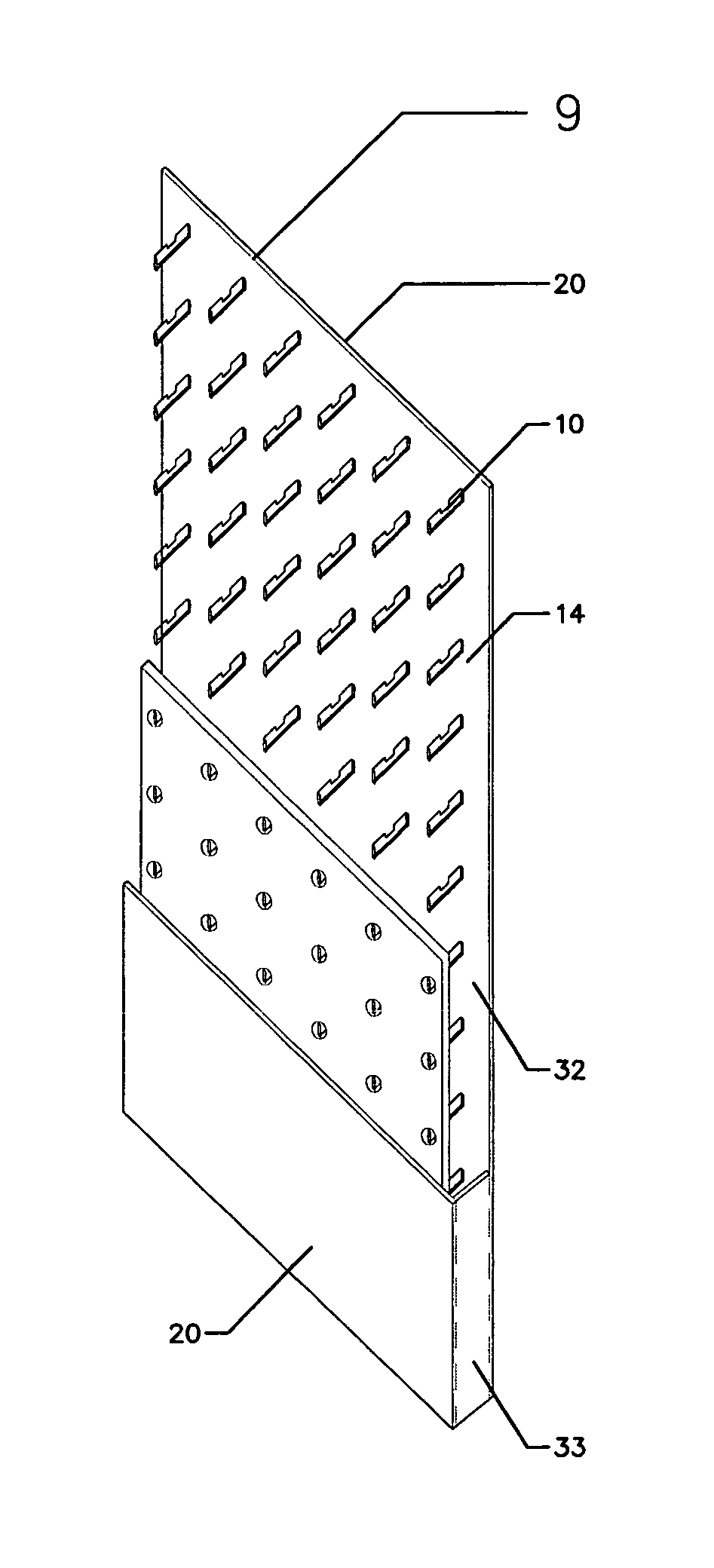

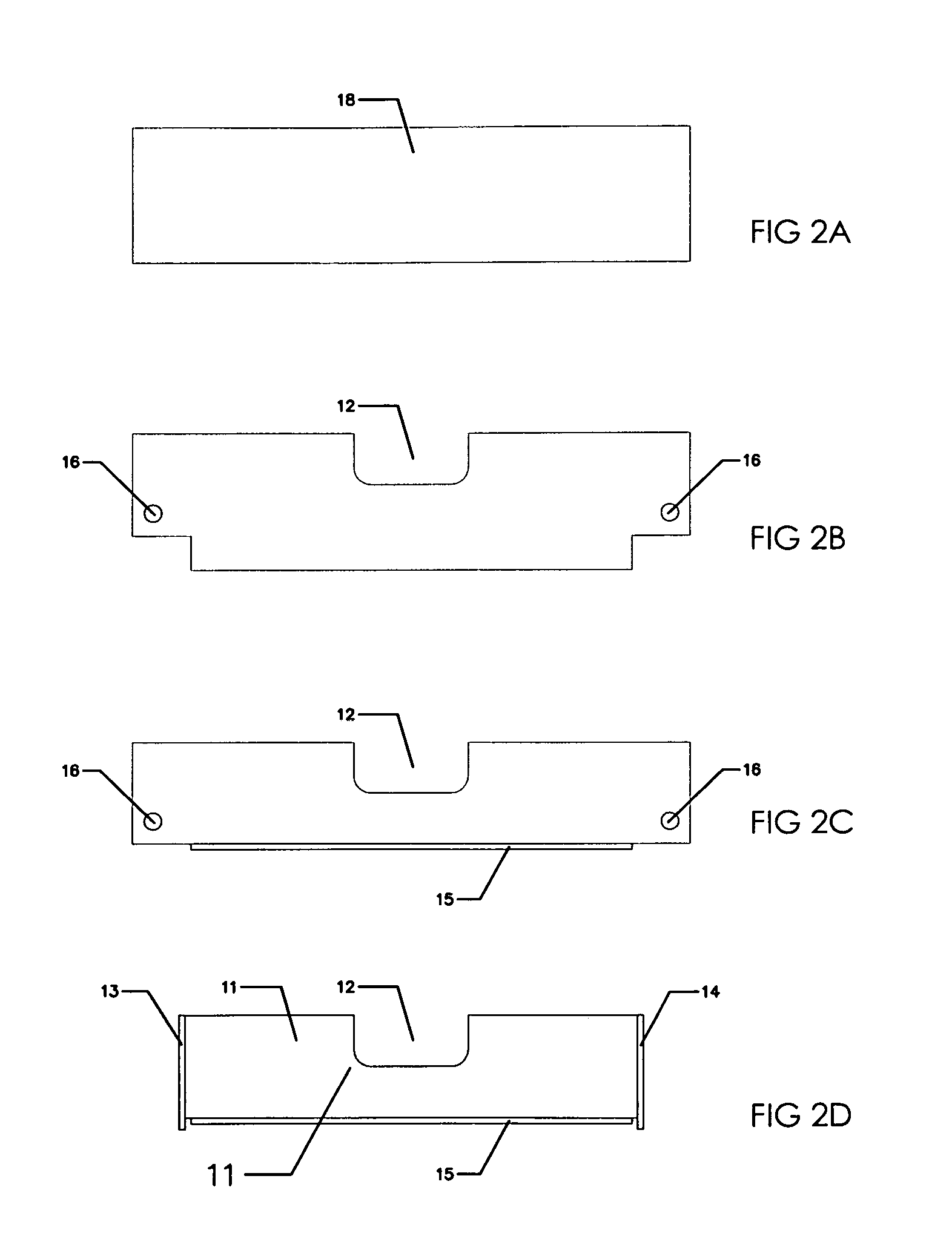

Holding Units for Stay in Place Molds

InactiveUS20140007537A1Strong firmnessImprove the immunityWallsAuxillary members of forms/shuttering/falseworksCement boardInternal cavity

The instant invention provides stay in place molds for the construction of concrete structures comprising two boards or panels held together by a series of holding units that are fastened only to the interior surfaces of the cement panels by fastening means that are kept inside of the width of said panels. The holding units are selectively distributed at the internal cavity of the molds and are designed by a main cylindrical body having at least two internal ring units inside and two supporting plates at each one of the extremes of the main cylindrical body. The external, flat surface of the plates is permanently fastened only to the internal surface of the cement boards, thus forming strong stay in place construction molds having smooth external surfaces.

Owner:QUILES PEREZ PEDRO

Device for connecting a kickstand to a bicycle

Owner:CHUANG LOUIS

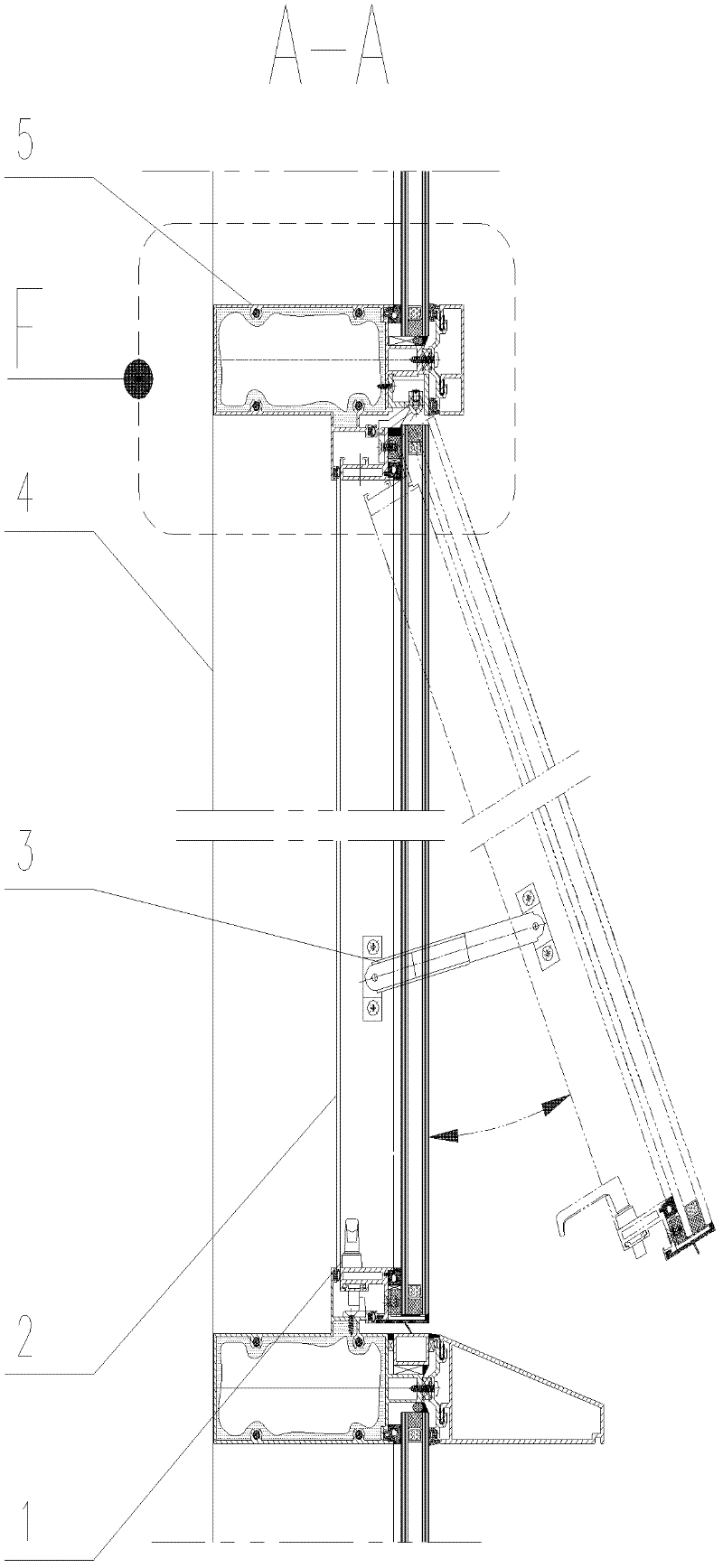

Pivot-hung window rotating mechanism for anti-fall glass curtain wall

The invention discloses a pivot-hung window rotating mechanism for an anti-fall glass curtain wall. The front part of a transverse keel (5) is provided with a bump; a square pipe (8) is fixed on the lower part of the bump; the lower wall of the square pipe is provided with an opening; both sides of the square pipe are provided with shaft holes; the two ends of a pin shaft (18) are fixed in the shaft holes; a rotatable metal plate (19) is sleeved on the pin shaft; and the lower part of the metal plate is bent vertically downwards, and is fixedly connected with the upper frame (22) of a pivot-hung window. Compared with the conventional hook type pivot-hung window rotating mechanism, the pivot-hung window rotating mechanism has the advantages that: mechanism assemblies are connected tightly and reliably and are prevented from being separated along with the increase of the wind pressure, the anti-fall safety coefficient of the pivot-hung window is high, and the pivot-hung window falling accident is avoided.

Owner:SHENYANG YUANDA ALUMINUM IND GROUP

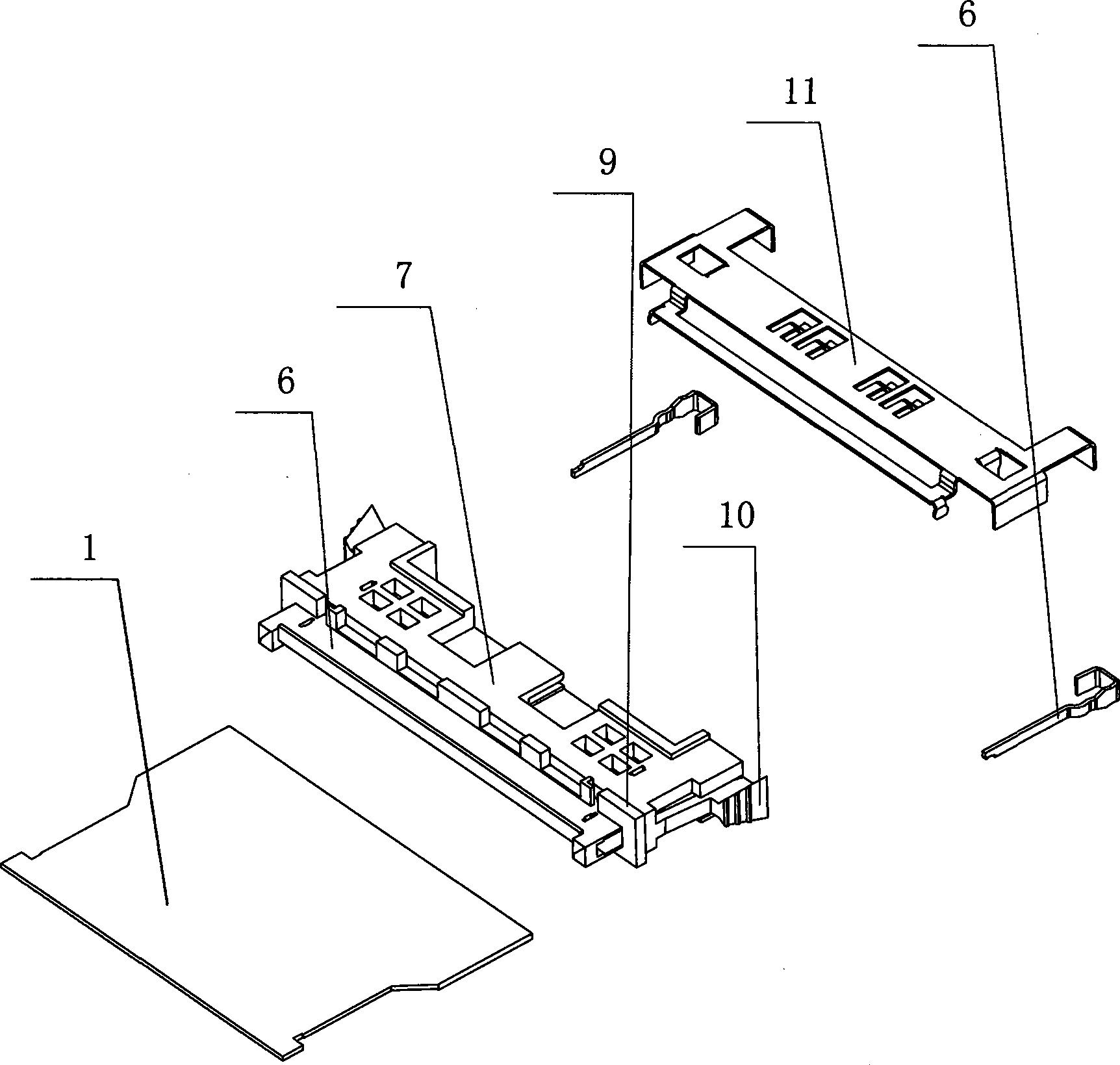

Drawplate-bearing electrostatic air purifier

InactiveCN105135548AEasy to openEasy to closeMechanical apparatusLighting and heating apparatusLow noiseActivated carbon filtration

The invention discloses a drawplate-bearing electrostatic air purifier which comprises a grip, a clamping groove, silencing cotton, a buckle, an air refreshing agent, a drawplate, a tongue, a groove, a fixed block and a nonskid mat, wherein the buckle is arranged on the bottom end of a bottle opening; the bottle opening is connected with a bottle body through the buckle; the grip is arranged on the outer wall of the bottle body; an electrostatic adsorption device is fixed to the inner wall of the bottle body through the clamping groove; an activated carbon filter screen is fixed to the inner wall of the bottle opening through a first locating piece; the outer wall of the bottle body is provided with the drawplate; the inner walls of the bottle opening and bottle body are respectively provided with the silencing cotton; the surface of the first locating piece is provided with the air refreshing agent; and the bottom of a base is provided with the nonskid mat. The air purifier is convenient for cleaning and maintenance, is simple for assembling and disassembling the internal and external structures, has low noise in the working process, can effectively remove pungent odor caused by ozone, has the advantages of beautiful appearance and high base fixing capacity, and is convenient for the user to take and transport.

Owner:苏州瓷气时代净化设备有限公司

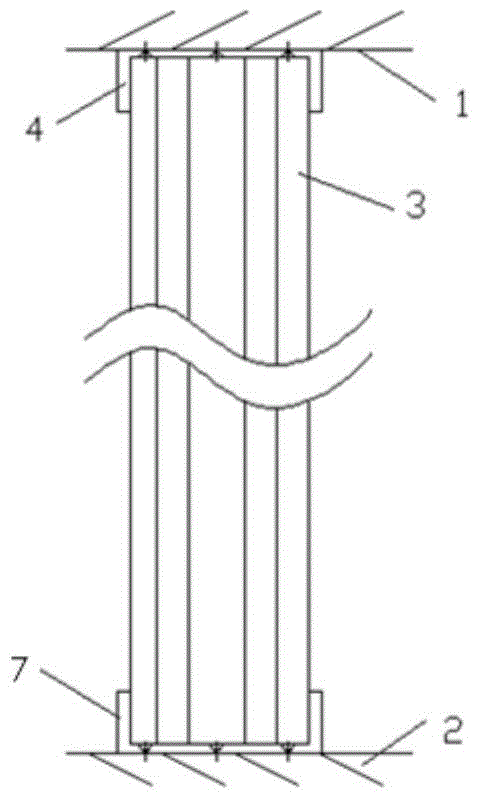

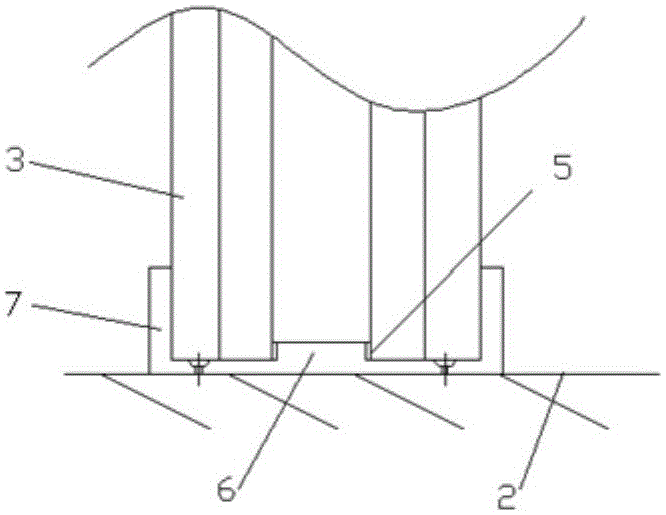

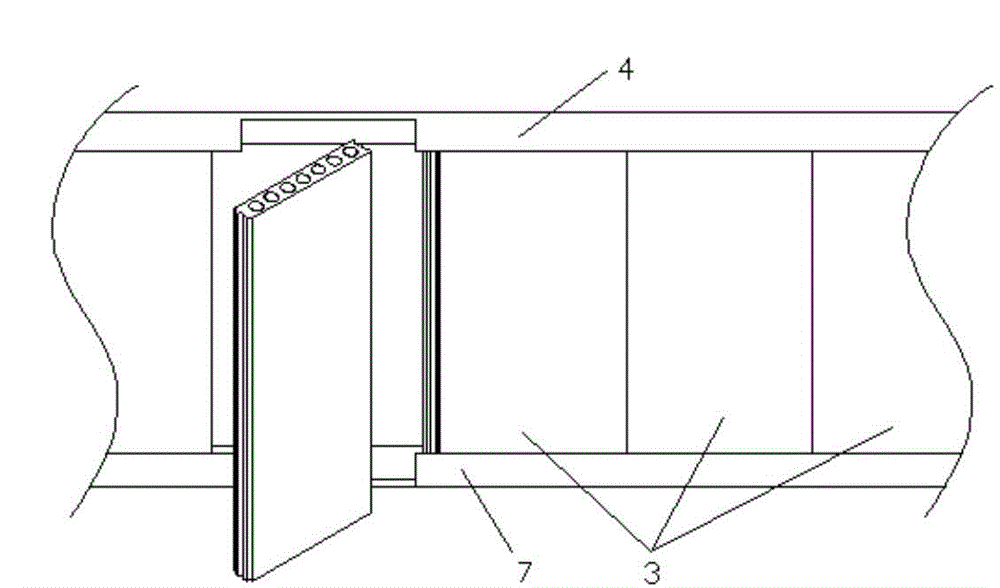

Guide structure and installation method used for installation of light wall boards

InactiveCN104912344AEasy to separateIncrease profitBuilding material handlingInterconnectionEngineering

The invention discloses a guide structure used for installation of light wall boards. An upper guide rail and a lower guide rail, correspondingly arranged, are arranged on the bottom surface of an upper floorslab and a lower floorslab along the laying direction of the light wall boards. Openings used for installing and restricting the positions of the light wall boards are arranged in the upper guide rail and the lower guide rail. The guide structure is arranged for guiding the assembling process of the light wall boards such that assembly is convenient, interconnection is more reliable and fine flatness is obtained. The invention further discloses an installation method. Therefore, installation is conveniently performed. The overall light wall boards can be conveniently separated during detachment such that the light wall boards can be utilized repeatedly. Cost is saved. The utilization rate of the light wall boards is increased.

Owner:中国国检测试控股集团西安有限公司

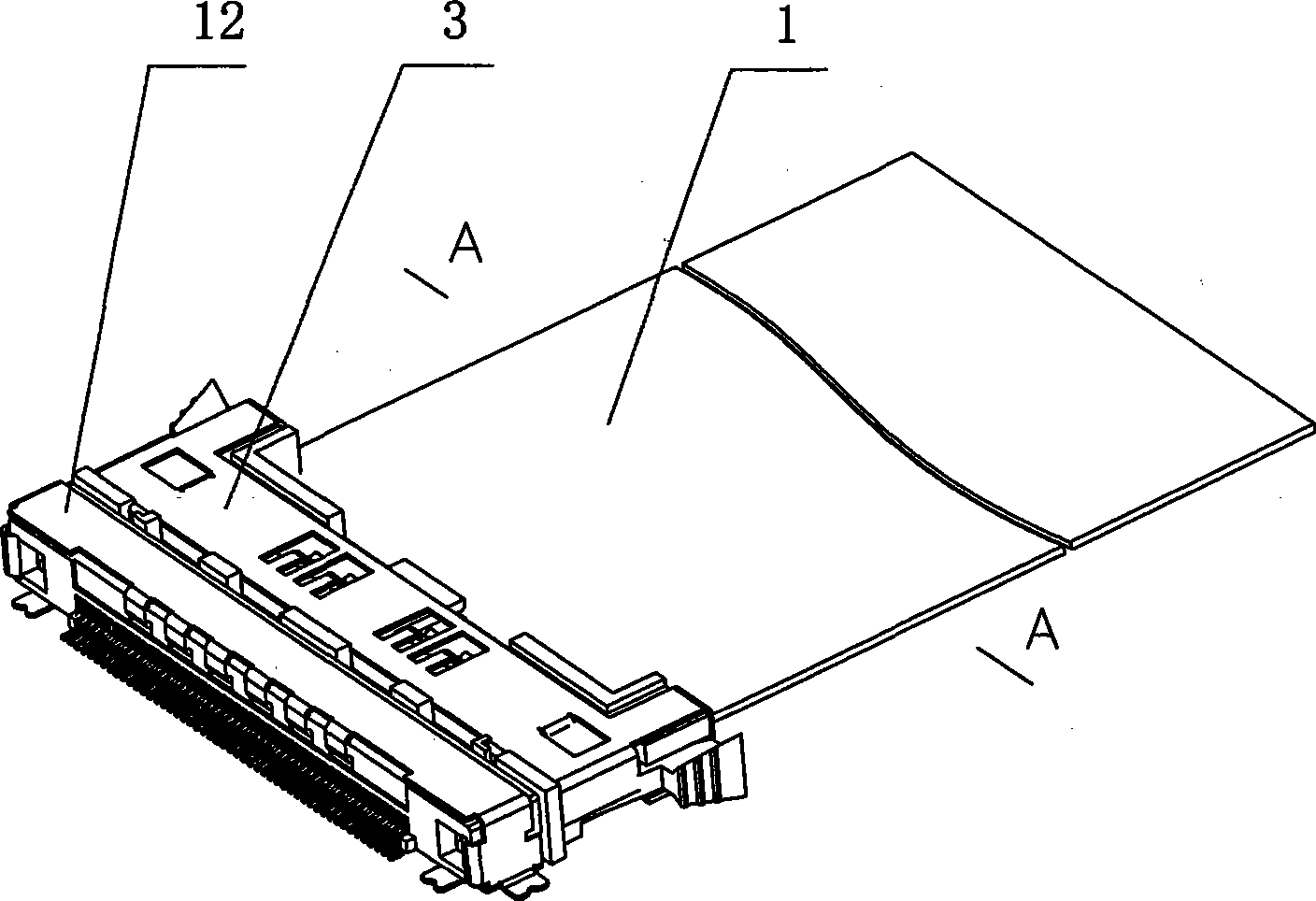

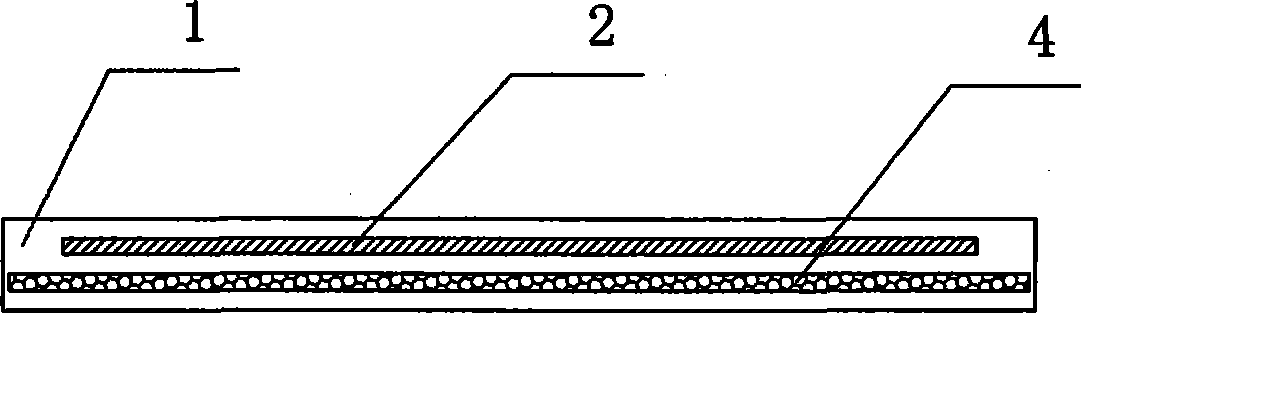

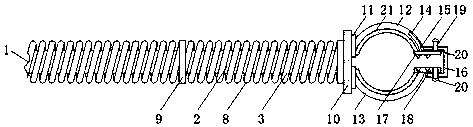

Winding flexible flat cable

InactiveCN101465481AImprove seismic performanceReliable interconnectionCoupling device detailsFlat/ribbon cablesElectrical conductorElectrical connection

The invention relates to the technical field of data transmission, in particular to a reelable soft drop-out line, comprising an insulating layer, a core wire conductor layer coated in the insulating layer and a connector; the reelable soft drop-out line is characterized in that: a foam with aluminum foil is arranged on the insulating layer, locating hooks are respectively arranged at the two sides of the connector, and the natural impedance with the drop-out line can be adjusted, and the application scope is wide; a shielding layer is arranged on the drop-out line, thus leading the capacity of whole resisting disturbance to be strengthened; the connector is provided with a locating device which leads the connector to be reliably and stably connected with the corresponding sockets, thus ensuring electrical connection between the connecting point of the connector and the socket, and the application scope is wide; the reelable drop-out line is provided with a reinforced rubber sheet and a folding-prevention rubber sheet, thus effectively preventing the conductor wires in the soft drop-out line from being broken or damaged in the using process.

Owner:WEIHAI HONGLIN ELECTRIC POWER TECH CO LTD

Holding units for stay in place molds

InactiveUS20110265413A1Strong firmnessImprove the immunityWallsSurface layering apparatusDistribution patternCement board

The instant invention provides stay in place molds for the construction of concrete structures comprising fiber cement panels held together by a series of holding units that are fastened only to the interior surfaces of the cement panels by fastening means that are kept inside of the width of said panels. The holding units are selectively distributed at the internal surfaces of the cement panels in a series of columns separated from each other at predetermined distance. Within each column each holding unit are apart form the next one at a predetermined distance. The particular structure of the holding units, particularly its small size and its distribution pattern at the interior surface of the molds facilitates the uniform contact of the liquid cement mixture and increases the strength and resistance of the structure prepared using the molds.

Owner:CERAME JOSE JAVIER

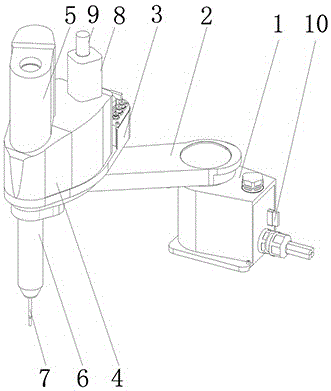

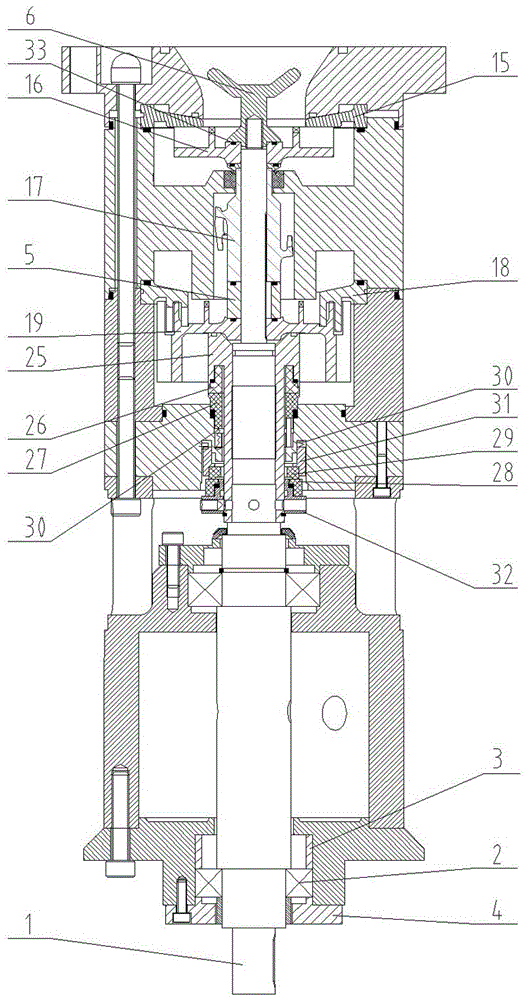

Safety automatic welding manipulator

InactiveCN106041383AReal-time monitoring of temperature and humidityTimely responseProgramme-controlled manipulatorWelding/cutting auxillary devicesTime efficientElectric machinery

The invention discloses a safety automatic welding manipulator and mainly relates to the technical field of manipulators. The safety automatic welding manipulator is characterized in that the two ends of a first articulated arm are respectively connected with an engine base and a second articulated arm in a matched manner, the first articulated arm and the second articulated arm are driven by a servo motor arranged in the engine base, the upper surface of the second articulated arm is connected with a fixed seat, the upper part of a sliding sleeve sequentially penetrates the second articulated arm and the fixed seat, the top of the sliding sleeve is connected with a cylinder at the top of the fixed seat in a matched manner, a welding gun is fixedly connected to the interior of the sliding sleeve, the head part of the welding gun penetrates a through hole formed in the bottom of the sliding sleeve, the engine base is directly connected with an external controller, an emergency shutdown button is arranged on one side of the engine base, and a detection device connected with an automatic alarm and the external controller in sequence is arranged on the surface of the fixed seat. The safety automatic welding manipulator is good in integral safety and high in workpiece calibration precision, can guarantee long-time efficient and stable operation of the welding operation, and is simple in overall structure, convenient and quick in assembly, disassembly and maintenance and low in manufacturing and operating cost.

Owner:JIANGSU JIEDI ROBOT

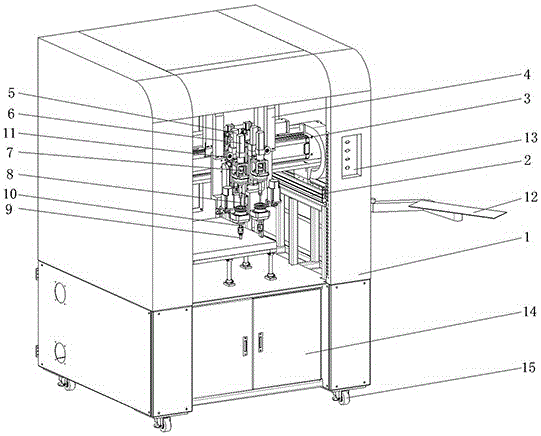

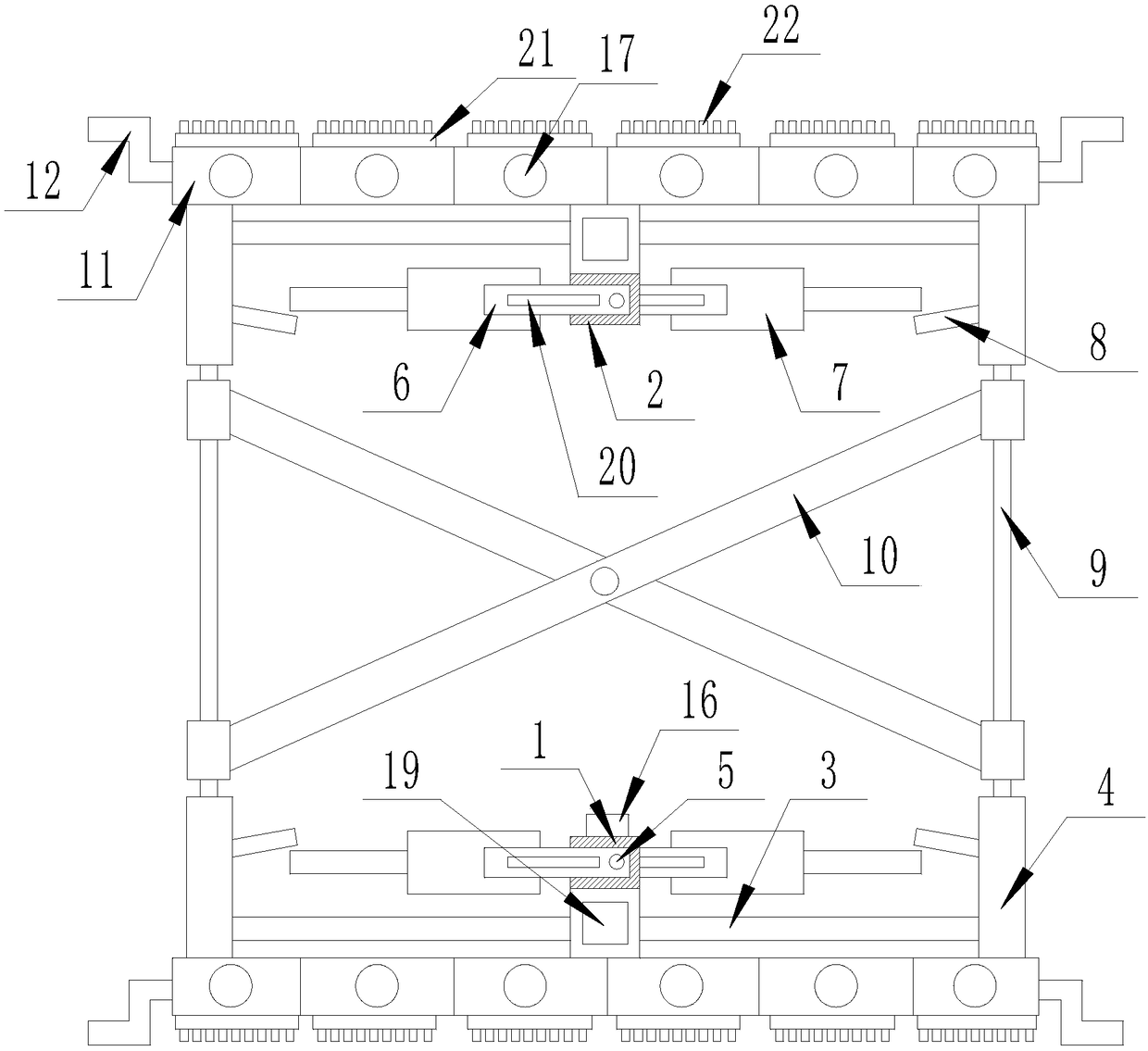

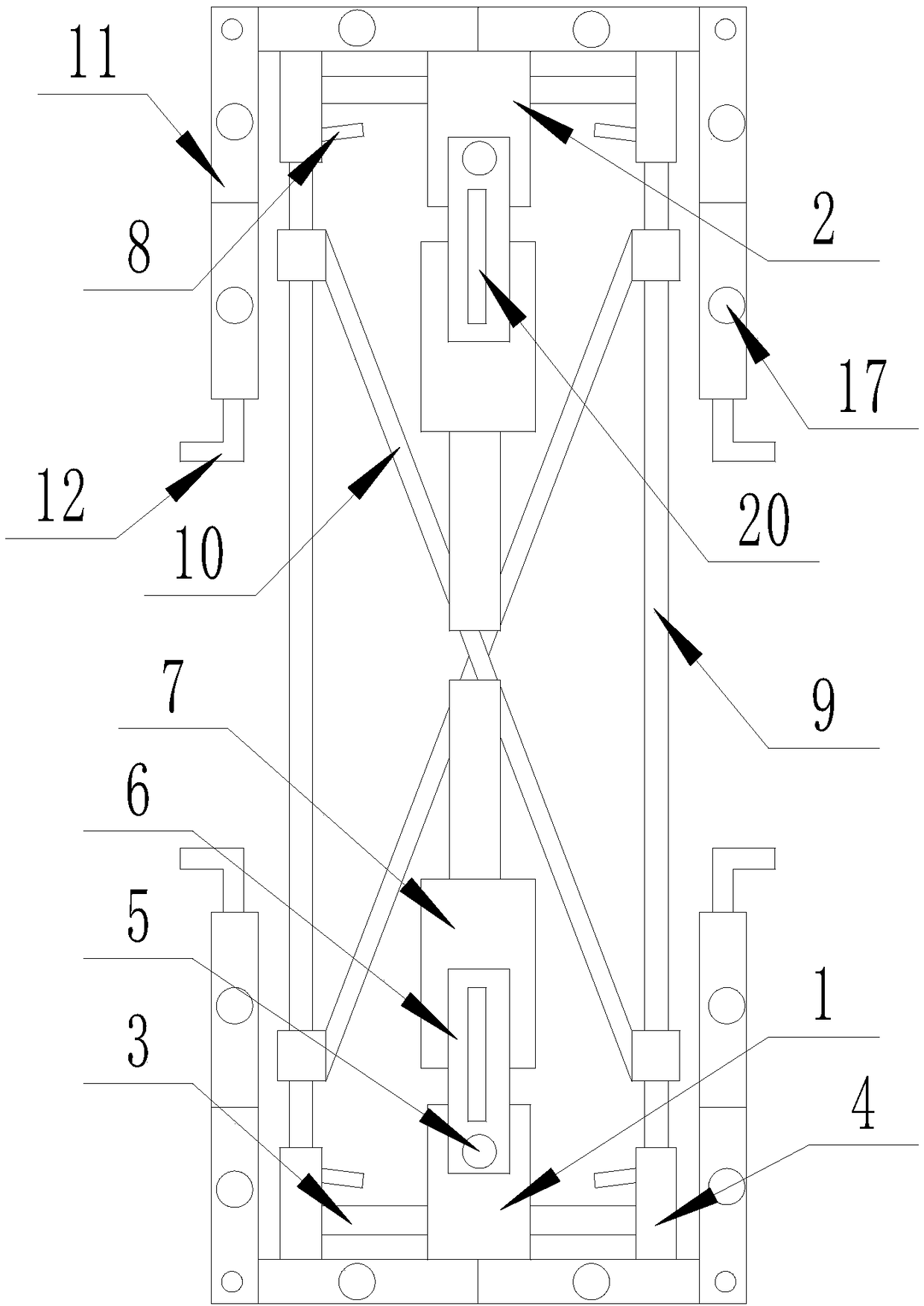

Movable assembling mechanism based on joint robot

The invention discloses a movable assembling mechanism based on a joint robot, and mainly relates to the technical field of joint robots. The movable assembling mechanism based on the joint robot is characterized in that a first manipulator is fixedly connected to the inner wall of a mechanism body, wherein a second manipulator slides forwards and backwards on slide rails arranged on the first manipulator; a third manipulator slides forwards and backwards on slide rails arranged on the second manipulator; an up-down moving and mounting electric cylinder and a vision sensor are sequentially connected to the third manipulator; a coupling arranged between a motor and a screw is in slide connection with the up-down moving and mounting electric cylinder; a spring is connected to the middle part of the screw in a sleeving manner, and the lower end of the screw is connected with a sleeve in a fitting manner; a control panel and a toolbox are arranged at one side of the mechanism body, a pulley set is connected to the bottom part of the mechanism body, and a handheld programmer is connected to the outer part of the mechanism body; the vision sensor is connected to an outer display. The assembling mechanism is high in positioning accuracy, and a workpiece is hard to be damaged by the assembling mechanism; the assembling mechanism is convenient and quick to carry, repair and maintain; workers can operate the assembling mechanism simply, and can monitor the running state of the assembling mechanism in real time.

Owner:JIANGSU JIEDI ROBOT

Automatic clamping mechanical hand with buffer damping function

InactiveCN106393099AStable and accurate operationEasy to operateProgramme-controlled manipulatorGripping headsDamping functionCoupling

The invention discloses an automatic clamping mechanical hand with a buffer damping function and mainly relates to the technical field of mechanical hands. The automatic clamping mechanical hand comprises a machine body, a first joint shaft, a second joint shaft, a buffer mechanism and a clamping finger. The two ends of the first joint shaft are in matched connection with the machine body and the second joint shaft correspondingly. The first joint shaft, the second joint shaft and the clamping finger are all driven by a servo motor arranged in the machine body. The upper end of a piston rod is in matched connection with an air cylinder through the buffer mechanism, the lower portion of the piston rod penetrates through the second joint shaft and is embedded in a connection pipe in a sleeved mode, and the bottom of the piston rod is fixedly connected with a coupling. The clamping finger is in matched connection with the piston rod through the coupling, and V-shaped blocks are fixedly connected to the inner sides of the two ends of the clamping finger. The machine body is connected with an external controller. According to the automatic clamping mechanical hand with the buffer damping function, the damage to a workpiece is small, a worker can operate the mechanical hand easily, and the joint shafts can be precisely and stably operated for a long time; and moreover, the mechanical hand is small in redundant structure, very convenient to assemble, disassemble and maintain and low in manufacturing and operating cost.

Owner:苏州塞默机械有限公司

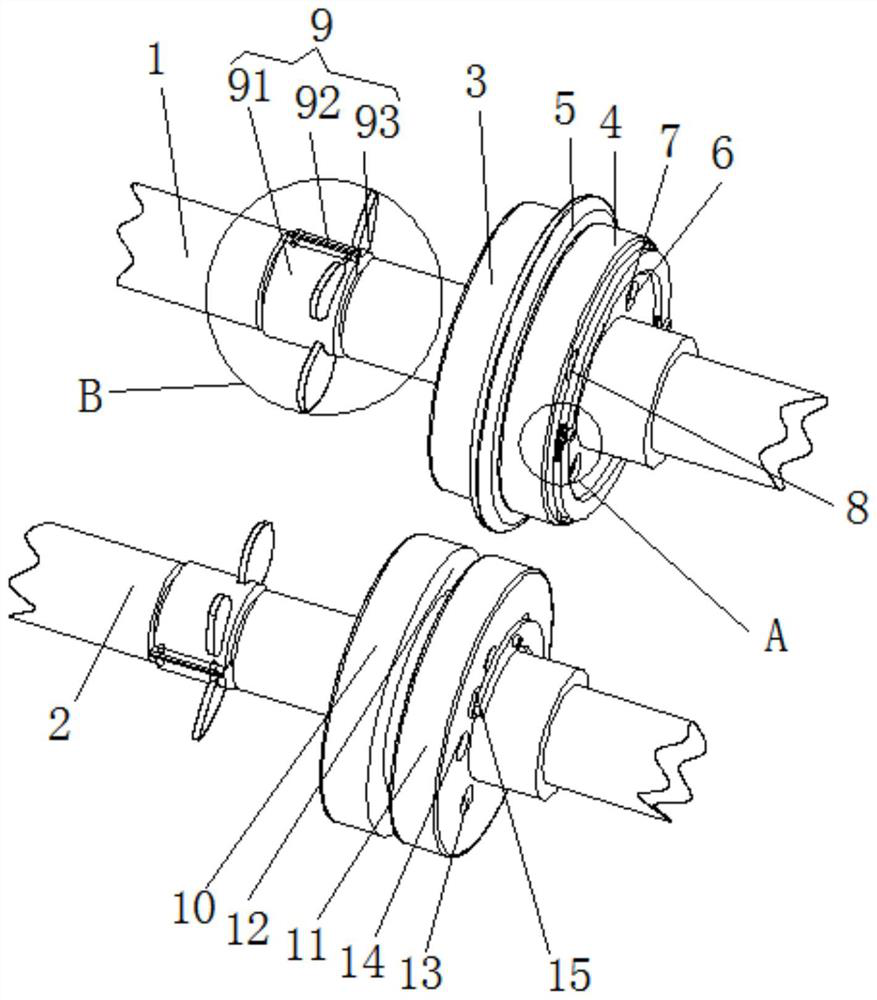

Safety roller for spinning machine drafting mechanism

The invention discloses a safety roller for a spinning machine drafting mechanism, and mainly relates to the technical field of textile machinery. A bearing inner sleeve is integrally nested in an outer sleeve, a bearing is nested in the outer sleeve, and the two ends of the bearing abut against the outer sleeve and a first check ring respectively; a dust cover is clamped in the outer sleeve; a detection mechanism is arranged on one side of the outer sleeve, the detection mechanism comprises a temperature sensor, a humidity sensor and a smoke sensor; an automatic alerter is connected to the top of the detection mechanism; a protection layer is arranged on the surface of a shaft and composed of an acid-base corrosion resistance layer, a high temperature resistance layer and a wear resistance layer. The roller can perform enough compensation, the sealing property is good, the service life is long, the application arrange is wide, the safety is good, and it is guaranteed that spinning isperformed with high quality for a long time.

Owner:苏州益垚精密机械有限公司

Line pressing device of corrugated carton printing and slotting machine

ActiveCN113232363ARealize cooling protectionExtended service lifeBox making operationsPaper-makingCartonCooling fluid

The invention relates to the technical field of corrugated carton processing, and discloses a line pressing device of a corrugated carton printing and slotting machine. The line pressing device comprises a top pressing shaft rod, the bottom of the top pressing shaft rod is provided with a bottom pressing shaft rod, the surface of one end of the top pressing shaft rod is fixedly sleeved with a first line pressing wheel, one side of the first line pressing wheel is movably connected with a second line pressing wheel, and the interior of the middle of the second line pressing wheel is clamped to the surface of one end of the top pressing line shaft rod. According to the line pressing device of the corrugated carton printing and slotting machine, six sealed containers, namely four first hollow cylinders in the interior of a first liquid type cooling mechanism and two second hollow cylinders in the interior of a second liquid type cooling mechanism, are used for receiving cooling liquid, so that cooling protection of the first line pressing wheel, the second line pressing wheel, a line pressing convex disc, a third line pressing wheel and a fourth line pressing wheel is realized, the heat dissipation efficiency of the structure after heat production due to processing is improved, the service life of the line pressing convex disc is prolonged, and the processing quality of a corrugated board is improved.

Owner:石家庄图瑞包装制品有限公司

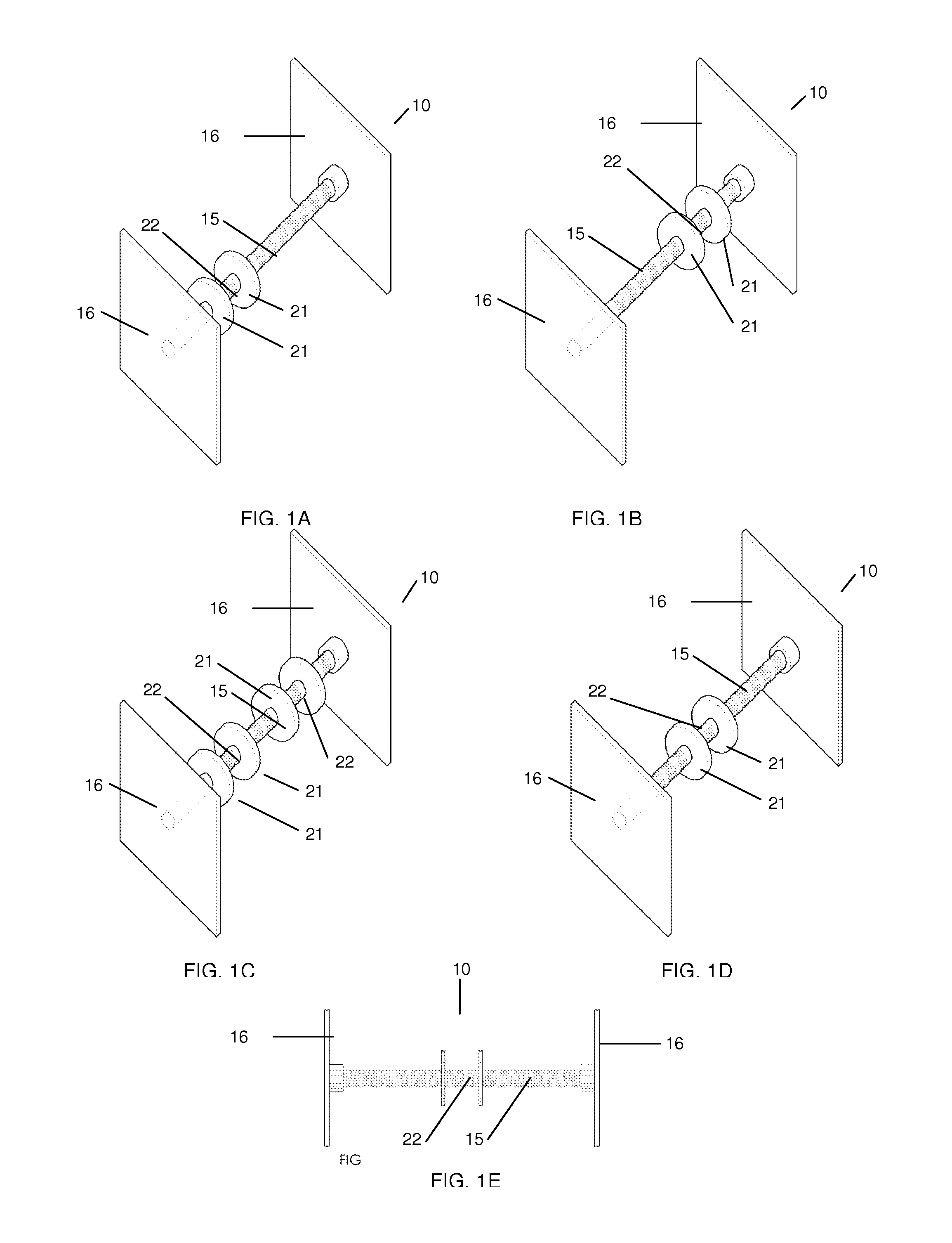

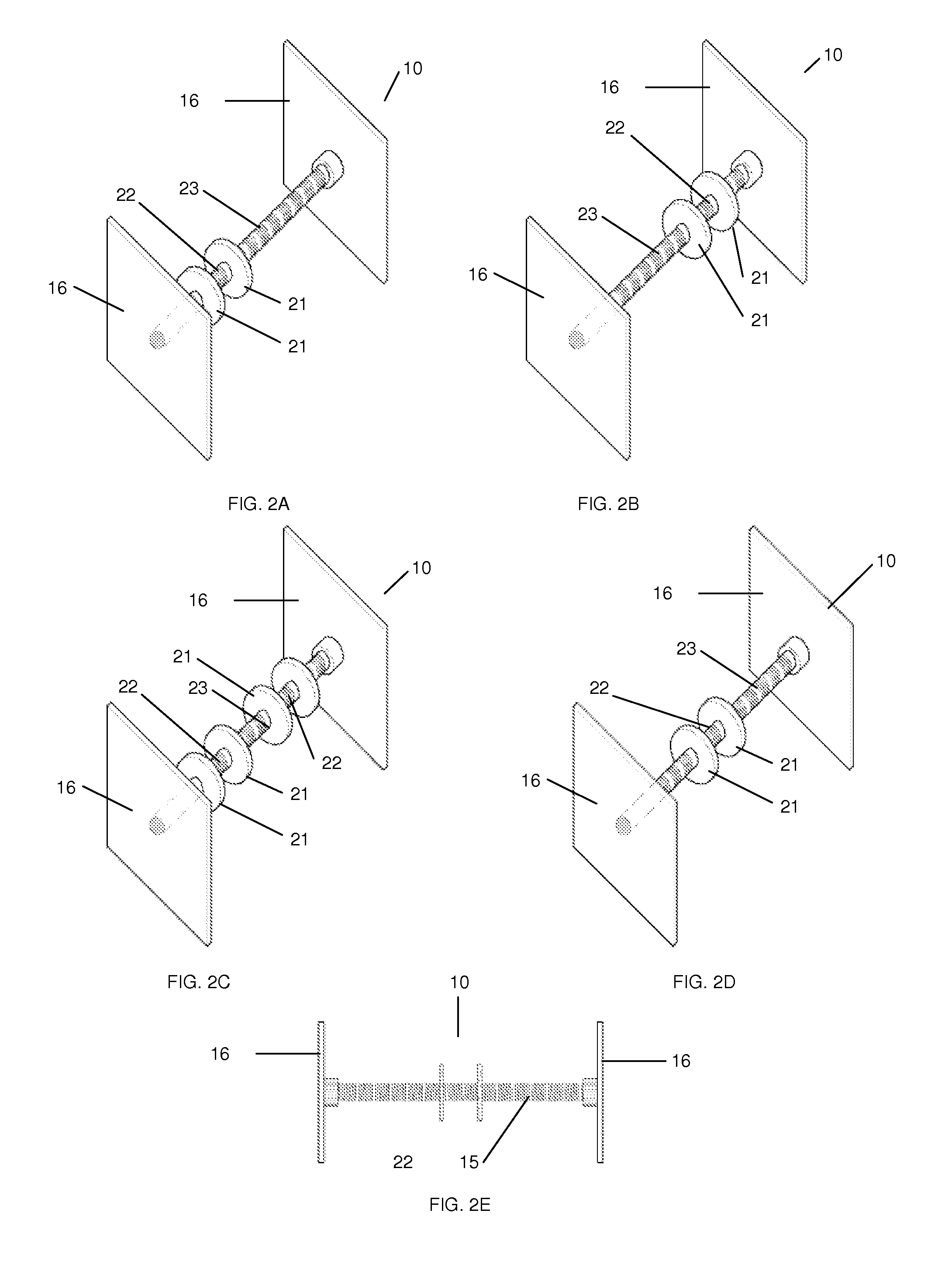

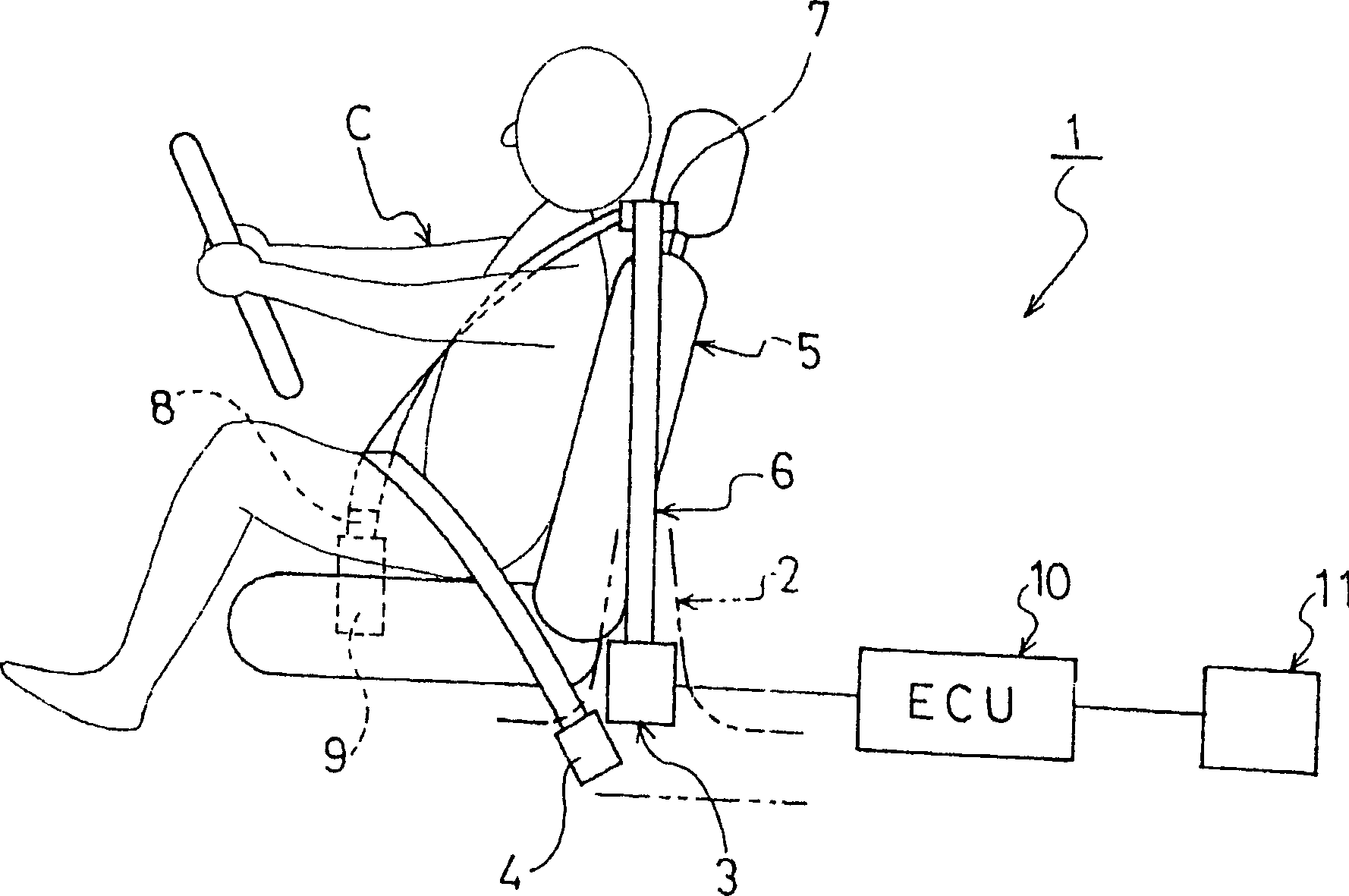

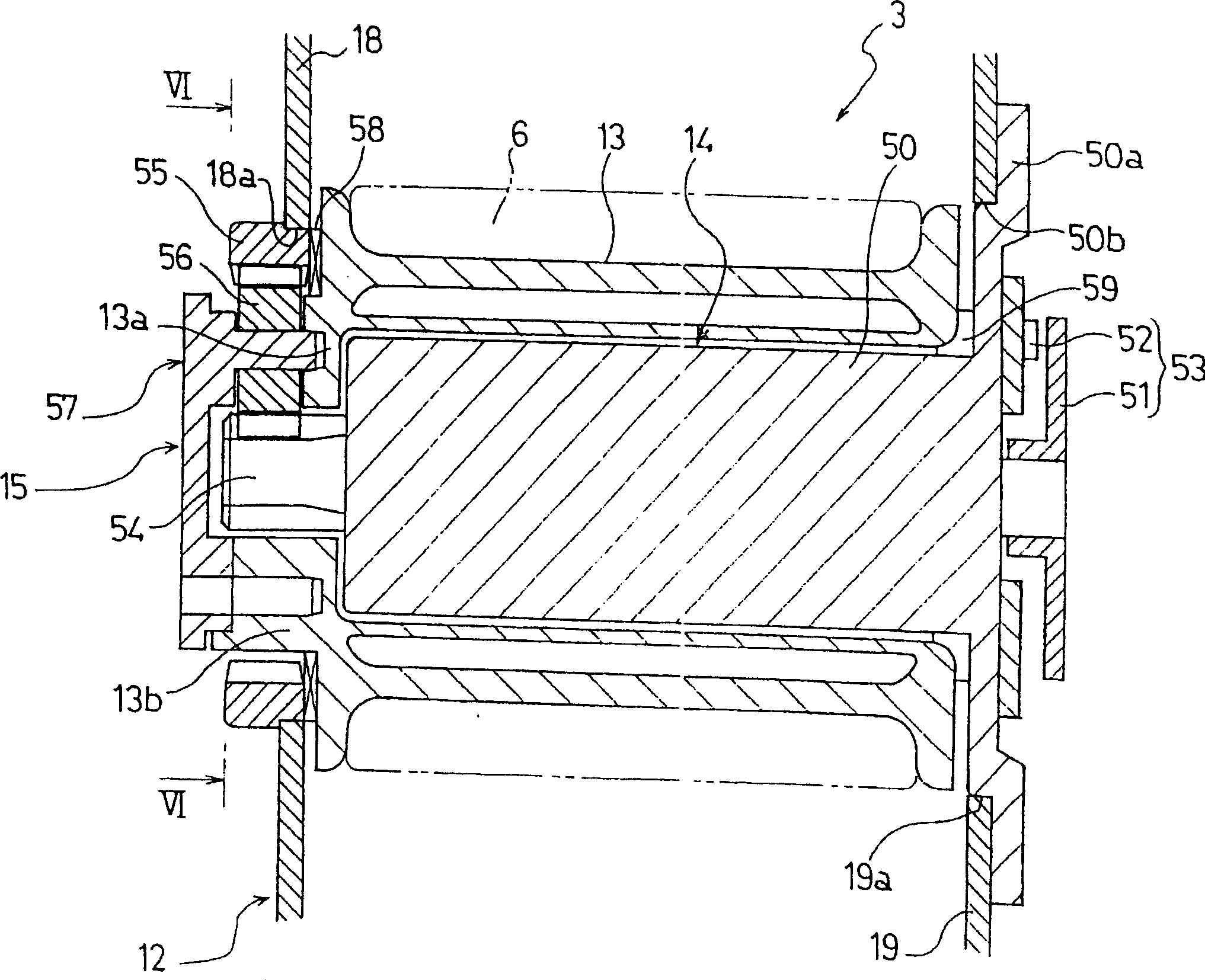

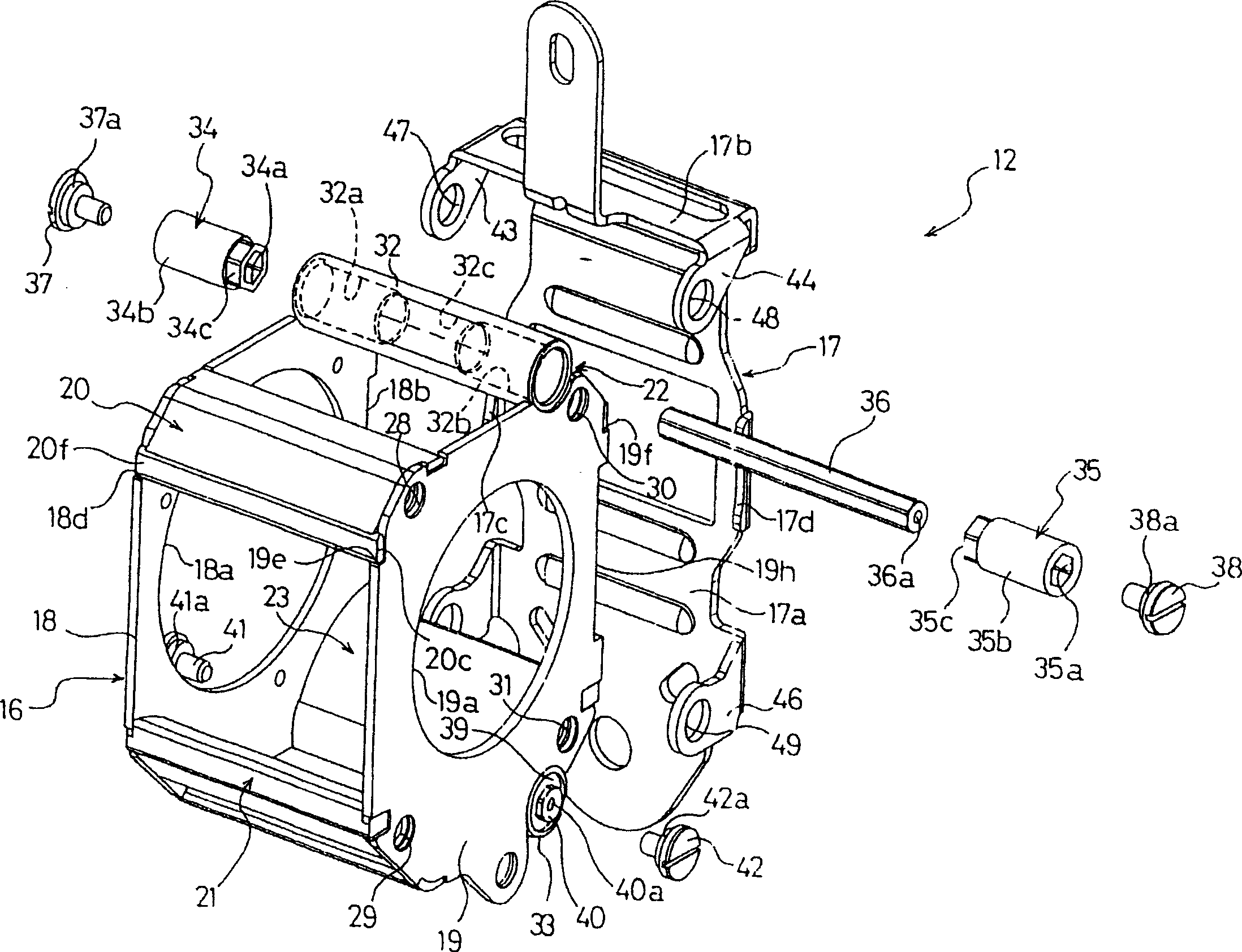

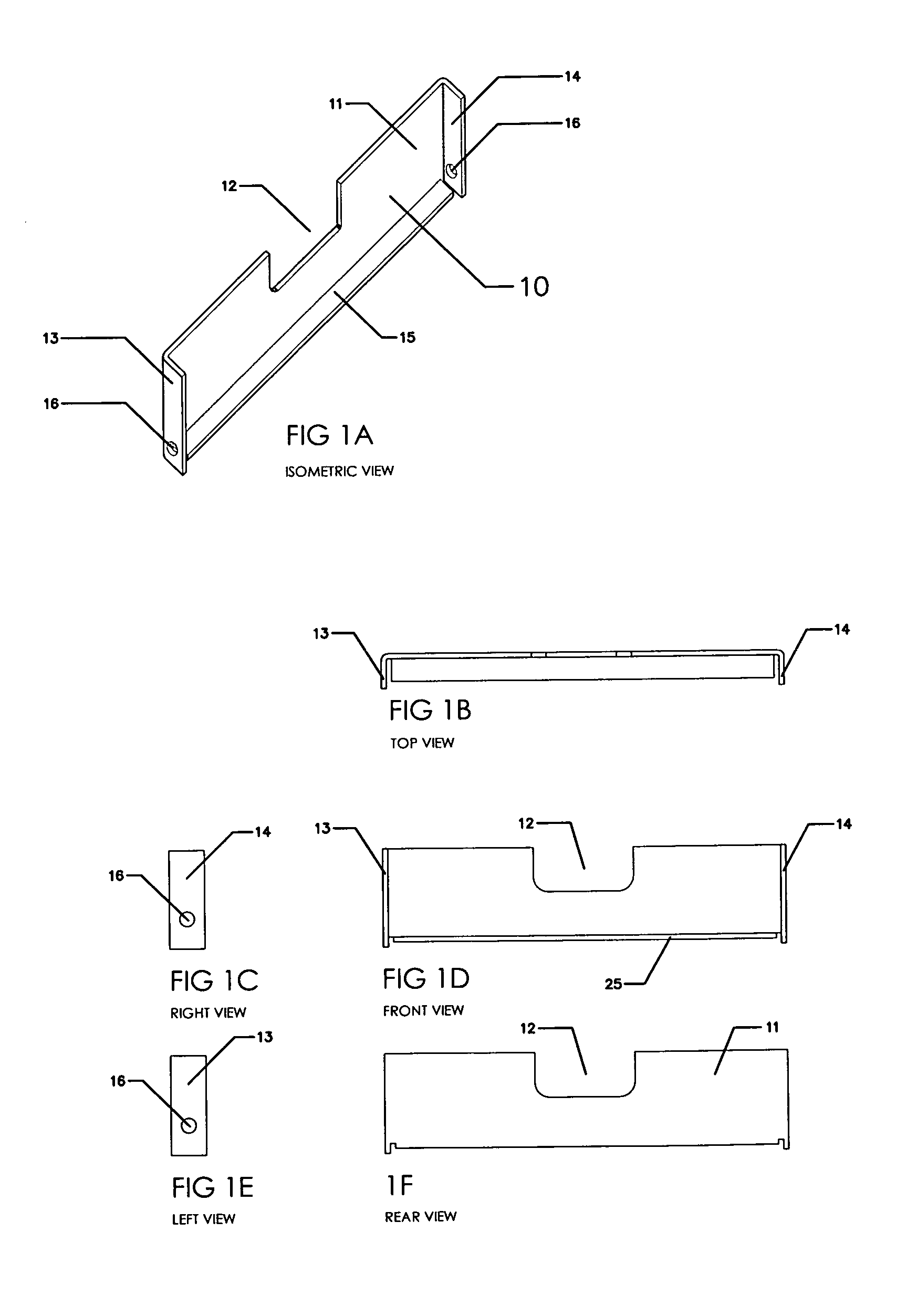

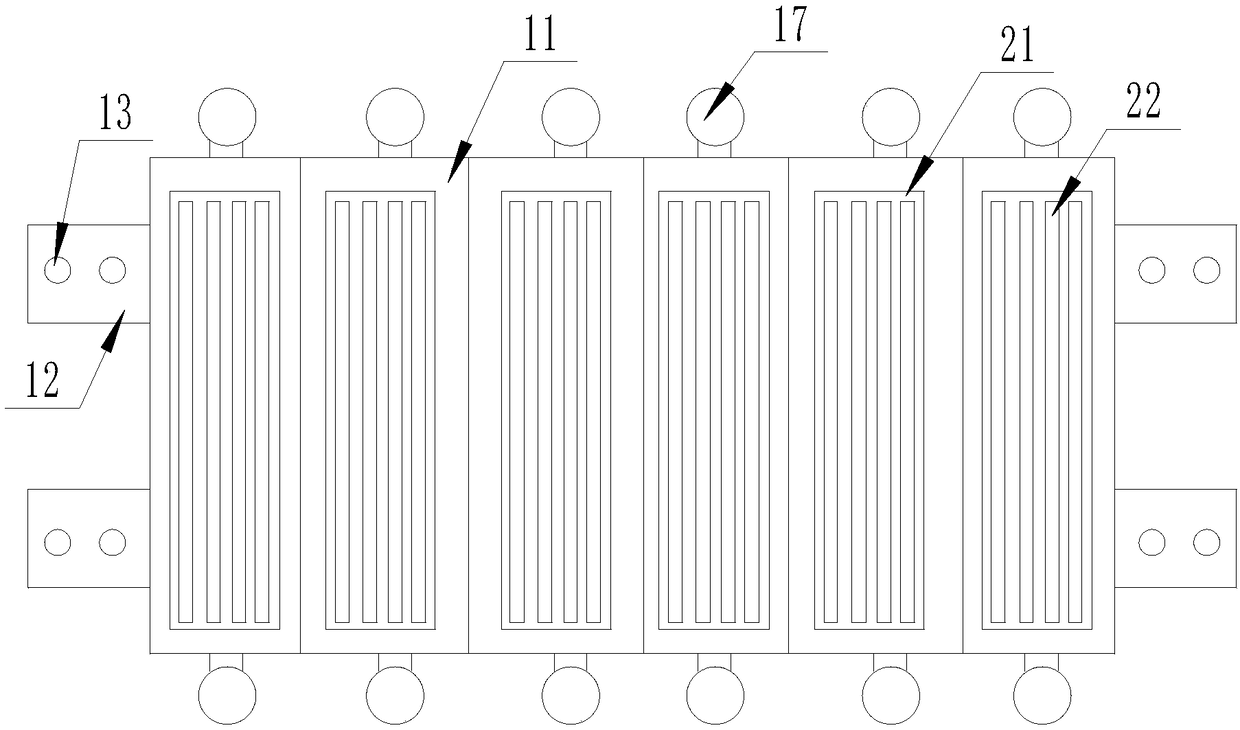

Seatbelt retractor and a seatbelt apparatus having the same

InactiveCN1843812AGuaranteed parallelismImprove assembly accuracyBelt retractorsEngineeringMechanical engineering

This invention provides a seatbelt retractor capable of effectively suppressing occurrence of a vibration and a noise, a base frame (12) is composed of a first frame (16) for rotatably supporting a spool, and a second frame (17) to be attached to a motor vehicle body. The first frame (16) is composed of a pair of flat plate-shaped first and second supporting members (18 and 19), and spacing members (20, 21, 22, and 23) that couple the pair of the first and second supporting members (18 and 19). Further, the degree of the parallelization of the pair of the first and second supporting members (18 and 19) is obtained with high accuracy by the spacing member. Accordingly, an assembling accuracy for a spool can be improved and, thereby, a vibration and a noise caused by a rotation of the spool can be suppressed.

Owner:TAKATA CORPORATION

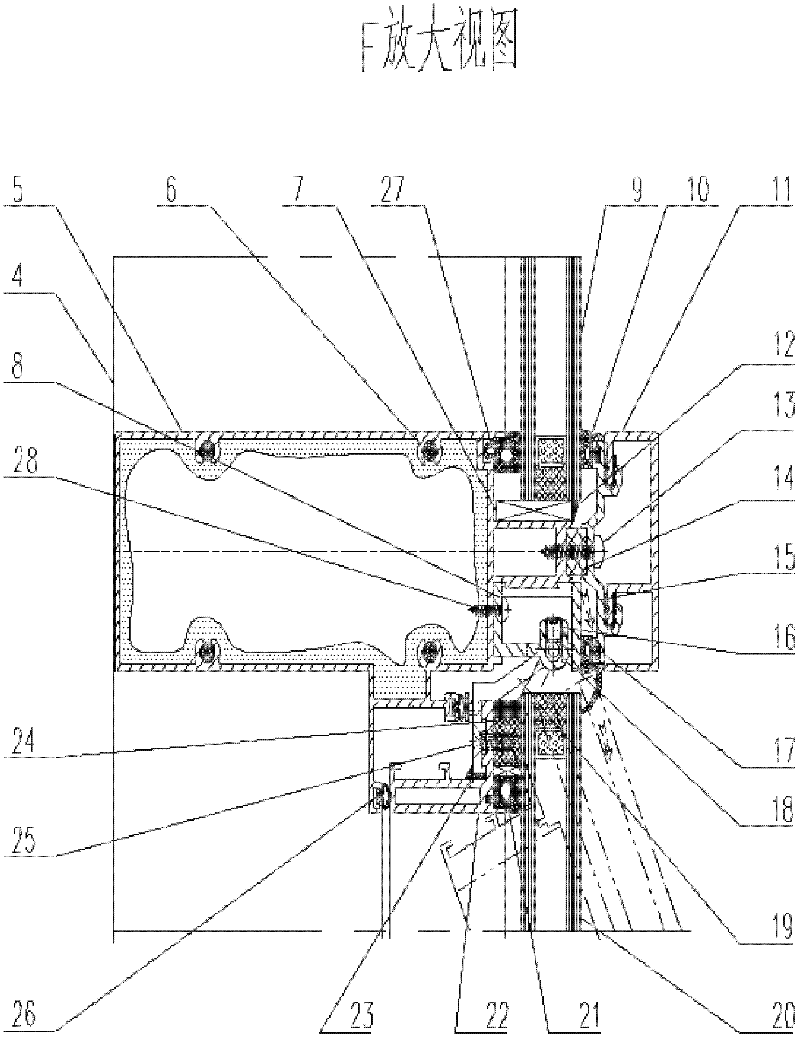

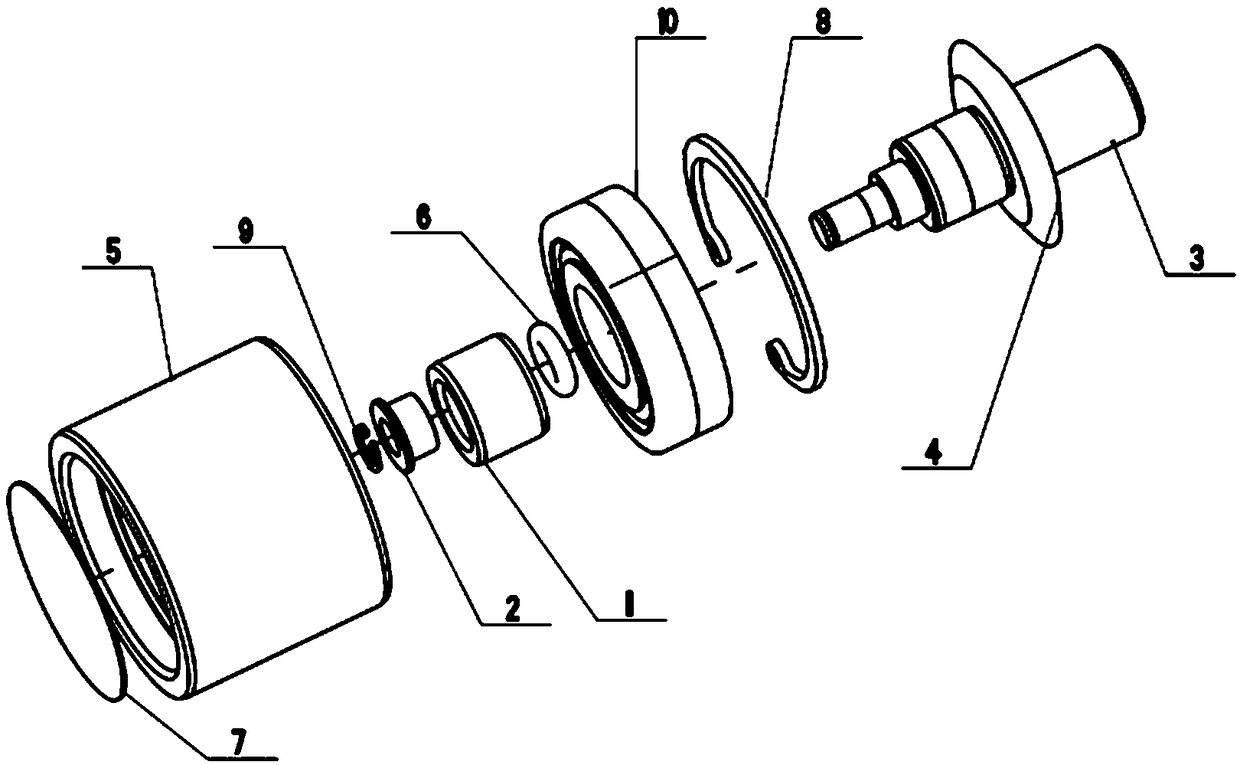

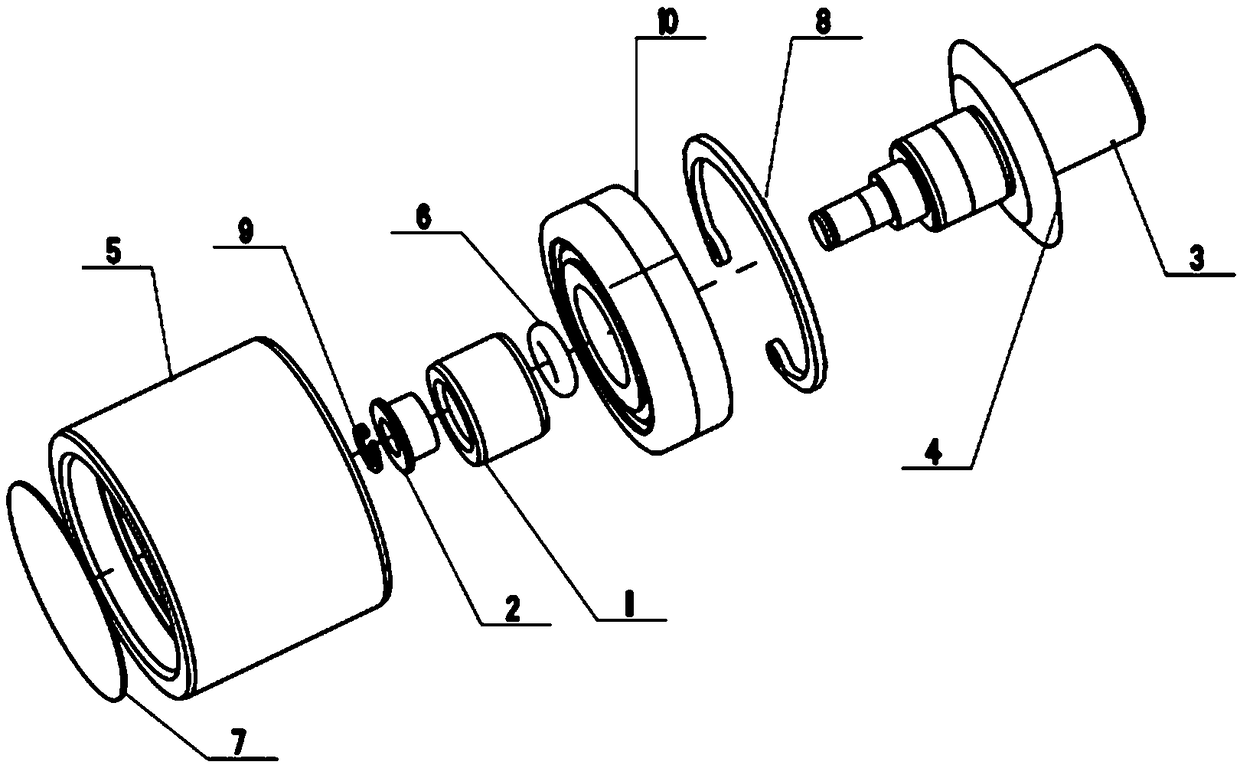

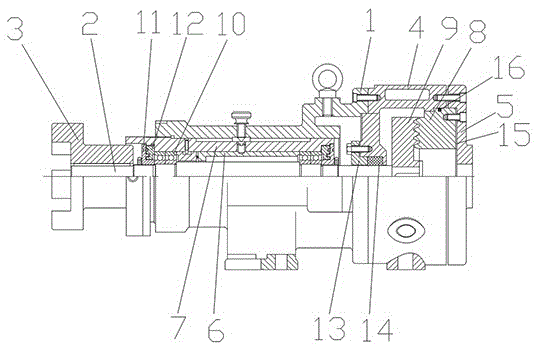

Combined type roller for spinning machine drafting mechanism

InactiveCN108796693AQuality assuranceIncrease contactDrafting machinesRubber ringAgricultural engineering

The invention discloses a combined type roller for spinning machine drafting mechanism, and mainly relates to the technical field of textile machinery. The roller comprises a bearing inner sleeve, a shaft sleeve, a shaft, an outer sleeve and a bearing; the shaft penetrates through a rubber ring to be cooperatively connected with the bearing inner sleeve and the bearing sleeve in sequence, a secondcheck ring sleeves the end of the shaft, and a second gasket abuts against the shaft sleeve; a nylon ring sleeves the middle of the shaft, and the lower portion of a shaft sleeve is sleeved with theinner side of a bearing inner sleeve; the bearing inner sleeve is integrally nested in the bearing, the bearing is nested in the outer sleeve, and the two ends of the bearing abut against the outer sleeve and a first check ring respectively; a dust cover is clamped in the outer sleeve. The roller can perform enough compensation, the spinning quality is greatly guaranteed, the sealing property is good, the service life is long, and the application range is wide.

Owner:苏州益垚精密机械有限公司

Holding units for stay in place molds

Stay in place molds for the construction of concrete structures having fiber cement panels held together by multiple holding units is described. The holding units requires a flat rectangular main body; an indentation substantially located at the center of the upper side of the flat rectangular main body; left and right lateral edges perpendicularly located at the lateral sides of the rectangular body and a lower edge perpendicularly positioned at the lower side of the bottom side of the flat rectangular main body. They are selectively distributed at the internal cavity of the molds as a series of columns and rows separated from each other at predetermined distance. The particular structure and its distribution pattern facilitate the uniform contact of the liquid cement mixture and increase the strength and resistance of the structure prepared using the molds.

Owner:CERAME JOSE JAVIER

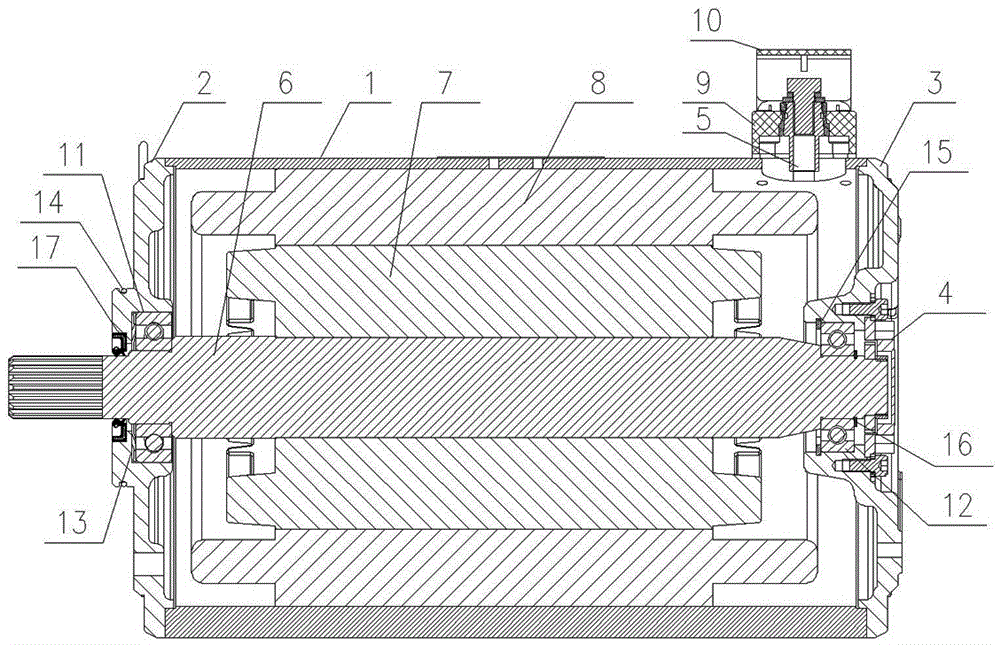

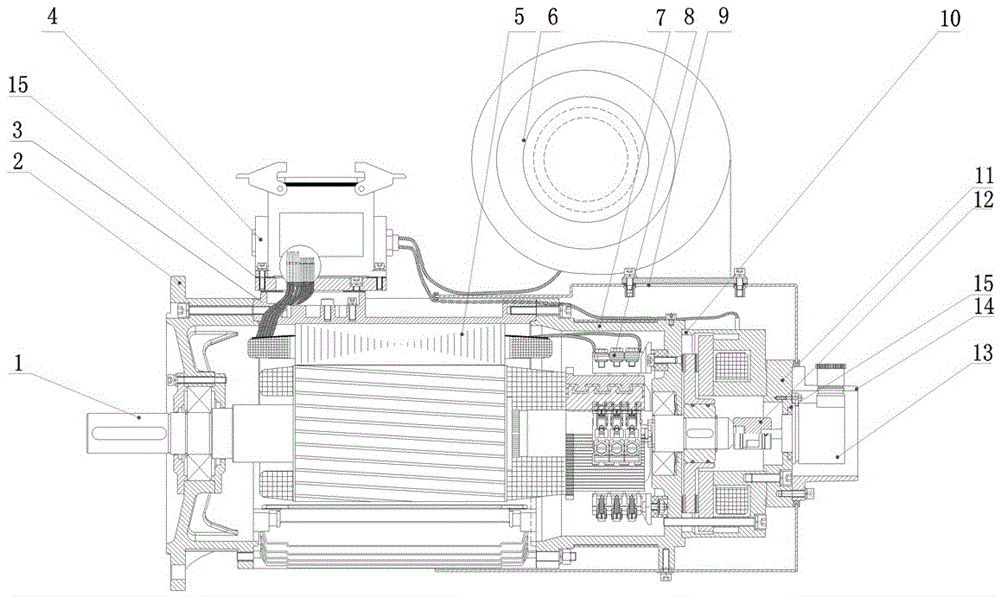

Protection-type AC variable frequency motor for electric fork-lift truck

ActiveCN106026534AAvoid accidentsLong-term efficient and stable operationStructural associationSupports/enclosures/casingsCouplingWave shape

The invention discloses a protection-type AC variable frequency motor for an electric fork-lift truck, and mainly relates to the technical field of AC variable frequency motors. A main shaft passes through an external housing which is formed by the connection of a front end cover, an engine base and a rear end cover. One end of the engine base is fixedly connected with a wiring board, wherein the interior of the wiring board is provided with a temperature sensor, and the exterior of the wiring board is provided with a wiring board cover. A rotor assembly is cooperatively connected with the main shaft and a stator assembly in the engine base. Two ends of the main shaft are respectively in cup joint with a first bearing and a second bearing. A coder is connected with the main shaft through a shaft coupler. A waveform spring piece is disposed between the front end cover and the first bearing, and an oil seal is disposed between the front end cover and the main shaft. Two ends of the second bearing are respectively provided with a circlip for a hole, and a circlip for a shaft. The motor is simple in overall structure, and greatly reduces the assembly difficulty. Moreover, the excellent performances of the motor can meet the actual demands, and the motor is good in sealing performance, is high in protection level, is wide in application range, and is safe and reliable.

Owner:苏州新能健电气有限公司

Safety protection type automatic clamping mechanical hand

InactiveCN106002999AReal-time monitoring of temperature and humidityTimely responseProgramme-controlled manipulatorGripping headsCouplingElectric machine

The invention discloses a safety protection type automatic clamping mechanical hand, and mainly relates to the technical field of mechanical hands. The two ends of a first joint shaft are separately connected to a machine body and a second joint shaft in a matched manner; the first joint shaft, the second joint shaft and clamping fingers are driven by a servo motor arranged inside the machine body; the upper end of a piston rod is connected to an air cylinder in a matched manner through a buffer mechanism, the lower part of the piston rod passes through a second joint arm, and is nested in a sealing sleeve, and the bottom of the piston rod is fixedly connected to a shaft coupler; the clamping fingers are connected to the shaft coupler in a matched manner through connecting rods; magnetic blocks are inlaid inside the end parts of the clamping fingers; the surface of the second joint shaft is provided with a detecting device connected to an audible and visible alarm; and paint is coated on the surfaces of the clamping fingers. The mechanical hand disclosed by the invention is small in damage on a workpiece, is good in integral safety, can guarantee efficient and stable operation of clamping work, has fewer redundant structures, is very convenient to mount, dismount and maintain, and is low in manufacturing and operation cost.

Owner:苏州塞默机械有限公司

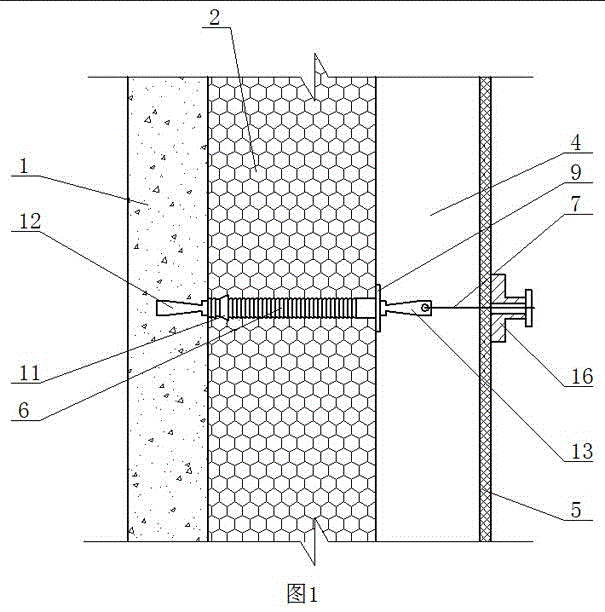

A construction method for a building sandwich composite wall

ActiveCN104060831BImprove insulation effectEasy constructionWallsBuilding material handlingProduction lineBuilding construction

The invention provides a construction method for a building sandwich composite wall. The construction method for the building sandwich composite wall comprises the following steps: (1) manufacturing a concrete external wall on an industrialized production line; compounding an insulating layer on the external wall; enabling a non-metallic connecting rod to penetrate the insulating layer, enabling a first anchoring body on the connecting rod to be placed in the external wall, and enabling a second anchoring body on the connecting rod to be located at the outer side of the right end of the insulating layer to form a two-layer composite wall after external wall maintenance; (2) transporting the two-layer composite wall to a construction site, and then, arranging a template at the right side of the insulating layer; connecting the second anchoring body on the connecting rod and a wire cable, and enabling the other end of the wire cable to pass through the template to be connected with a permanent seat to form a cavity between the template and the insulating layer; (3) pouring concrete in the cavity to form an internal wall after maintenance; (4) removing the permanent seat and the template in sequence to form the building sandwich composite wall. According to the construction method provided by the invention, compounding of the external wall and the insulating layer is finished during industrialized production, and pouring of the internal wall is finished at the construction site, so that the defects of the prior art are solved.

Owner:山东万斯达建筑工业化研究院有限公司

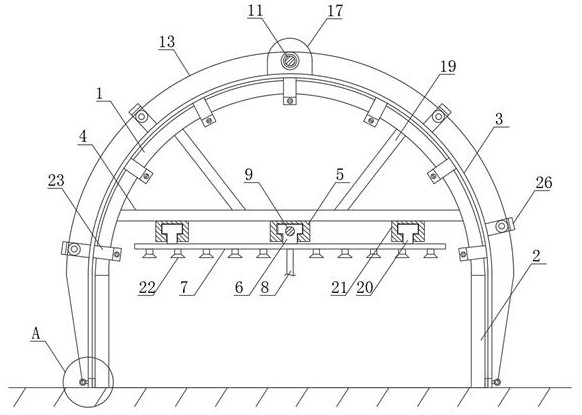

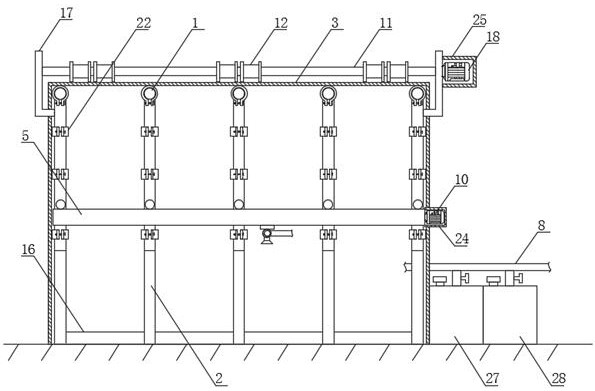

Planting greenhouse for polygonatum sibiricum seedling culture

PendingCN113575217ASprinkle water evenlyReduce labor intensityClimate change adaptationGreenhouse cultivationGreenhouseMetal framework

The invention discloses a planting greenhouse for polygonatum sibiricum seedling culture, and relates to the technical field of greenhouse planting. The planting greenhouse comprises a plurality of arc-shaped metal frameworks and a plurality of groups of supporting rods, the two ends of the lower sides of the plurality of arc-shaped metal frameworks are fixedly connected with the plurality of groups of supporting rods respectively, the outer sides of the plurality of arc-shaped metal frameworks and the plurality of groups of supporting rods are jointly sleeved with a sunshade film, transverse cross beams are fixedly connected to the lower sides of the interiors of the plurality of arc-shaped metal frameworks, the middles of the lower ends of the plurality of cross beams are jointly and fixedly connected with a longitudinal T-shaped sliding rail, a T-shaped sliding block is slidably connected to the interior of the T-shaped sliding rail, a transverse water spraying pipe is fixedly connected to the lower end of the T-shaped sliding block, and the middle of the rear side pipe wall of the water spraying pipe is fixedly connected with an external hose. The planting greenhouse has the effects that water can be uniformly sprayed to polygonatum sibiricum seedlings planted in the greenhouse automatically and uniformly, the greenhouse can be automatically ventilated and closed, and the planting greenhouse is high in automation degree, reduces the labor intensity of people, and is convenient for people to use.

Owner:庐山市环绿时代农业科技开发有限公司

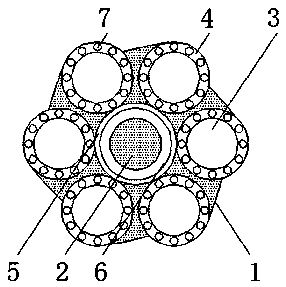

Wire rope

ActiveCN108411661AFirmly connectedInterconnected firmlyCoatingsTextile cablesWear resistanceIndustrial engineering

The invention discloses a wire rope, and relates to the technical field of wire ropes. The wire rope comprises a wire rope body, a wire rope core is arranged in the middle of the wire rope body, an iron wire body is wound on the outer part of the wire rope core, a second wear resistance layer is arranged on the outer part of the wire rope core, a rust prevention layer is arranged in the second wear resistance layer, and the wire rope body is divided into small sections of wires. According to the wire rope, by the arrangement of a connecting block, a pin shaft, an upper clamping strip, a lowerclamping strip, a sliding groove, a sliding block, a limiting strip, a limiting block, a limiting groove, a first bolt, a clamping block and a second bolt, when a user connects the rear end of the wire rope with an external object, the effect is good by connecting the external object with the upper clamping strip and the lower clamping strip, the external object is not easily loosened, the clamping effect is good by clamping the limiting block and the limiting groove, and double fixing can be achieved when the limiting strip is fixedly connected with the limiting groove through the second bolt.

Owner:JIANGSU KAIWEI ADVANCED MATERIAL TECH CO LTD

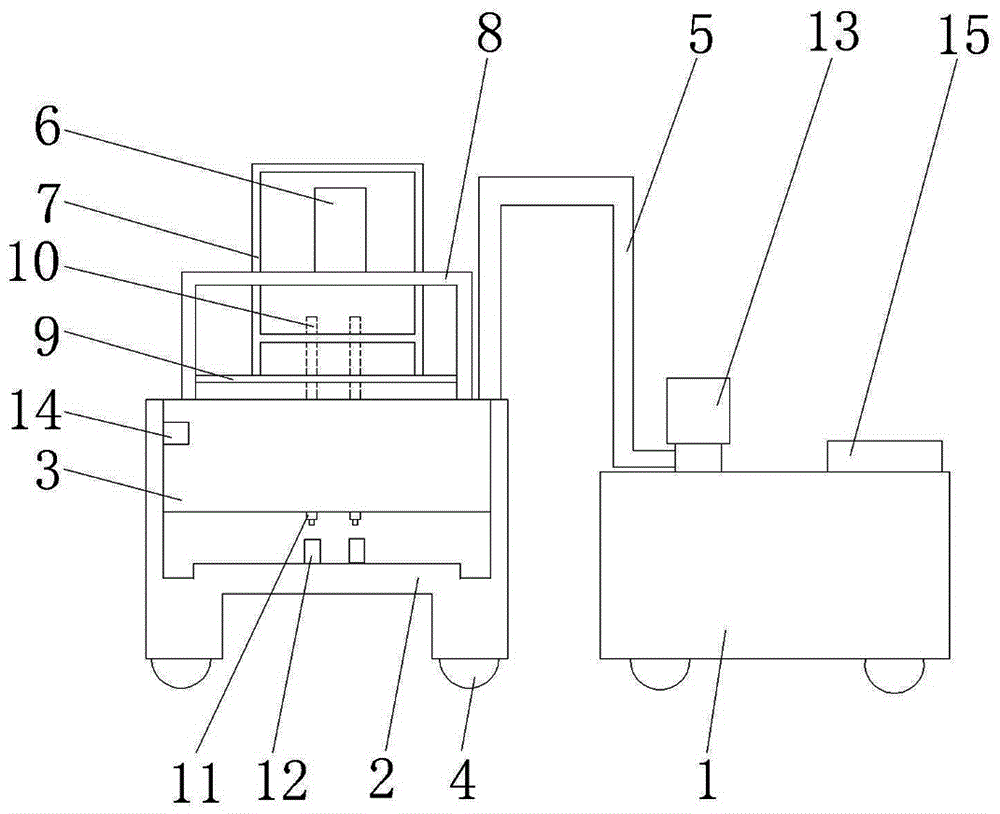

Movable automatic discharging device and work method thereof

The invention discloses a movable automatic discharging device and a work method and mainly relates to the technical field of mechanical equipment. A motor is arranged on the top of a material storage box. One end of a feeding pipe is connected with a discharging box, and the other end of the feeding pipe is connected with the material storage box. A group of discharging ports and an infrared sensor are arranged in the discharging box. Material receiving bottles are located under the discharging ports. The lower portions of pull rods are connected with the discharging ports in a sliding manner. The tops of the pull rods penetrate a fixing seat to be connected with an air cylinder in a matched manner. A machine frame is fixedly connected with the discharging box in an embedded manner. The fixing seat and a fixing plate are successively connected to the top of the discharging box. The bottom of a connecting frame is connected with the fixing plate. The air cylinder is installed on the fixing seat. A control mechanism is arranged on the top of the material storage box. The bottom of the material storage box and the bottom of the machine frame are each provided with a group of sliding wheels. The movable automatic discharging device is quite simple in integral structure and operation process, convenient and rapid to carry, repair and maintain, low in cost and small in labor amount, and workers can easily operate the movable automatic discharging device. The invention further discloses a work method of the movable automatic discharging device.

Owner:TAICANG BEST MECHANICAL EQUIP

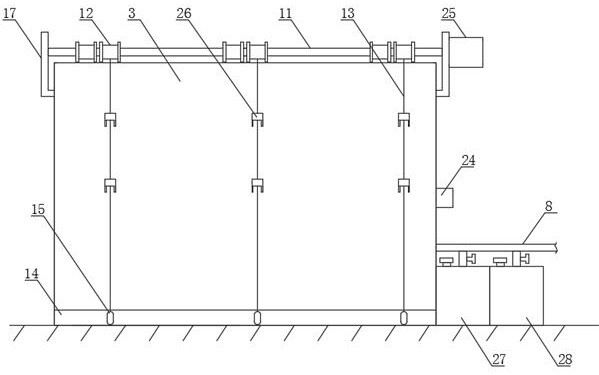

Steel-structured scaffold device for machinery aspect

ActiveCN108625583AInterconnected firmlyEasy to adjustBuilding scaffoldsEngineeringMechanical engineering

The invention discloses a steel-structured scaffold device for the machinery aspect. The steel-structured scaffold device comprises a first strip-type supporting block, wherein a second strip-type supporting block matched with the first strip-type supporting block is arranged above the first strip-type supporting block; a scaffold mechanism is arranged between the first strip-type supporting blockand the second strip-type supporting block. The steel-structured scaffold device disclosed by the invention has the beneficial effect that the device is convenient for adjusting supporting width according to a supporting location and achieving interconnection stability, is convenient to collect when not used, reduces the occupied area and is relatively convenient for overall connection.

Owner:杭州富阳春江汽车空调厂

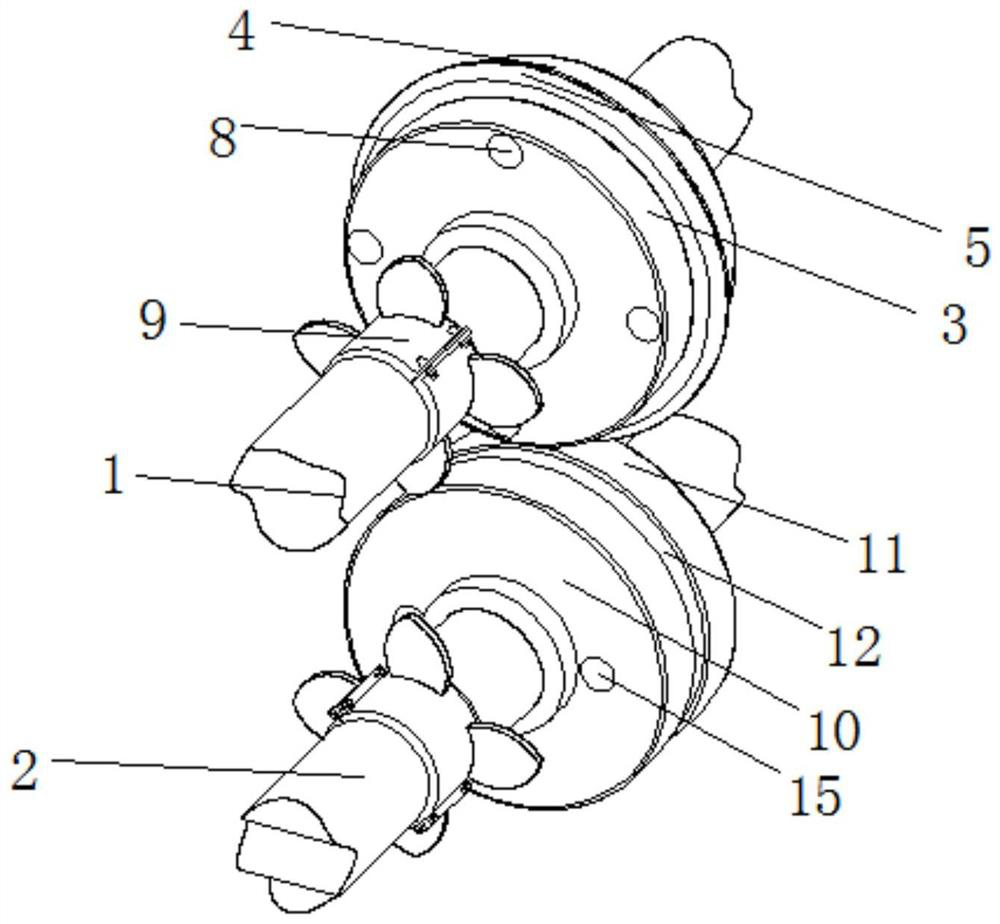

Low-energy-consumption colloid grinder type emulsifying machine

The invention discloses a low-energy-consumption colloid grinder type emulsifying machine. The two ends of a stator shell of the emulsifying machine are connected with a shell body and an end cover correspondingly. The shell body is internally provided with a main shaft. A shaft body of the main shaft of the emulsifying machine is sequentially connected with a coupler, a bearing and a rotor in a matched mode. One end of the rotor and one end of a stator are each provided with eight layers of conical grinding teeth. The rotor and the stator are engaged with each other through the grinding teeth. A fixing sleeve, a sliding sleeve and the baring of the emulsifying machine are located in the shell body and connected with one another. A sealing cover and a sealing ring are arranged between the main shaft and the sliding sleeve and are connected with each other. A gland and fillers are sequentially arranged between the stator shell and the main shaft of the emulsifying machine. A paper washer is arranged between the stator and the end cover. A sealing washer is arranged at one end of the stator. The emulsifying machine has super high shearing and grinding functions, the production efficiency is high, energy consumption is low, the overall sealing performance of the emulsifying machine is remarkably improved, and the service life of the emulsifying machine is significantly prolonged.

Owner:太仓液压元件有限公司

Intelligent automatic welding manipulator

InactiveCN106078026AImprove reliabilityImprove stabilityProgramme-controlled manipulatorWelding/cutting auxillary devicesProgrammable logic controllerEngineering

The invention discloses an intelligent automatic welding manipulator, which mainly relates to the technical field of manipulators. The intelligent automatic welding manipulator comprises an engine base, a first articulated arm, a second articulated arm, a sliding sleeve and a welding gun. Two ends of the first articulated arm are respectively connected with the engine base and the second articulated arm in a matching way; the first articulated arm and the second articulated arm are respectively driven through a servo motor arranged inside the engine base; a fixing seat is connected to an upper surface of the second articulated arm; the upper part of the sliding sleeve penetrates through the second articulated arm and is connected with the fixing seat in a matching way; a lifting motor is connected to the top part of the sliding sleeve; the welding gun is fixedly connected into the sliding sleeve; the lower end of the welding gun penetrates through a through hole formed in the bottom part of the sliding sleeve; the engine base is respectively connected with a PLC (Programmable Logic Controller) and a display panel; and an automatic warning device connected with the display panel is arranged at one side of the engine base. The intelligent automatic welding manipulator provided by the invention is high in workpiece positioning accuracy and welding efficiency, and convenient to operate, can manufacture products with excellent performance, and is simple in overall structure, convenient to assemble, disassemble and maintain, and low in manufacturing and operating cost.

Owner:JIANGSU JIEDI ROBOT

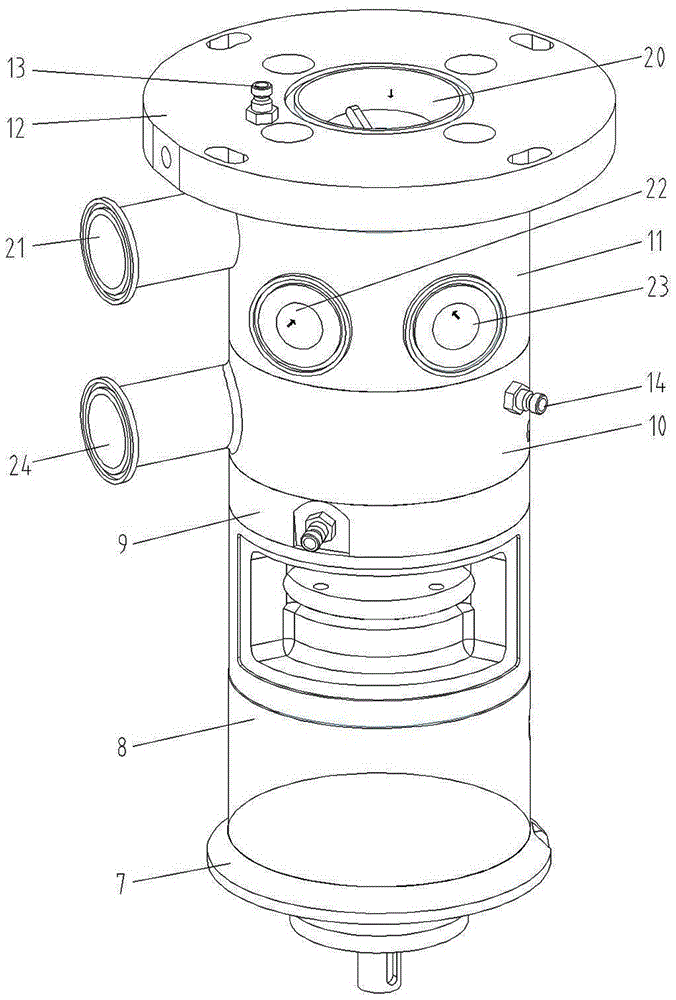

Multifunctional medium-capacity even-dispersion grinding machine and operation method thereof

ActiveCN105921224AHigh matching precisionImprove rotational stabilityGrain treatmentsImpellerEngineering

The invention discloses a multifunctional medium-capacity even-dispersion grinding machine and mainly relates to the technical field of production of colloidal solutions. A spindle of the grinding machine is connected with a bearing in a sleeved mode. The two ends of the bearing are connected with a bearing check ring and a bearing end cap correspondingly. One end of the bearing is connected with a special-shaped nut in a matched mode. A water inlet is formed in the upper portion of a cavity top cover of the grinding machine, and a water outlet is formed in the side wall of a discharging cavity. The spindle penetrates through a grinding rotor, a stirring impeller and an impeller rotor sequentially. A stator is compressed between an even-dispersion cavity and the cavity top cover. A grinding stator is compressed between the discharging cavity and the even-dispersion cavity. A supporting block is arranged between the grinding rotor and the stirring impeller. A plurality of sets of sealing rings are arranged inside a mechanical seal shell, the discharging cavity, the even-dispersion cavity and the cavity top cover. The multifunctional medium-capacity even-dispersion grinding machine has various functions, a high rotation speed and good airtightness, various substances can be mixed at the same time, the service life of the overall machine is long, and components are stable in performance. The invention further discloses an operation method of the multifunctional medium-capacity even-dispersion grinding machine.

Owner:江苏思峻机械设备有限公司

High-torque high-sealing variable paddle direct current motor

ActiveCN105978236AEasy to controlGuaranteed uptimeStructural associationSupports/enclosures/casingsCouplingEngineering

The invention discloses a high-torque high-sealing variable paddle direct current motor, relating to the technical field of direct current motors. A rotor penetrates into a casing formed by the connection of a front end cover, a cover plate, and a rear end cover, the front end of the cover plate is fixedly connected with a conjunction box, and a blower fan hook is arranged outside the rear end cover. A stator is cooperatively connected with the rotor, the two ends of the stator are connected with the conjunction box and a brush respectively via leads, the other end of the conjunction box is connected with a blower fan and an electromagnetic brake via leads, the electromagnetic brake is directly connected with the rotor, an encoder is connected with the rotor via a shaft coupling, the two ends of the encoder are respectively provided with an encoder base and an encoder cover, and a sealing pad is arranged between the cover plate and the conjunction box, and a sealing pad is arranged between the encoder base and the encoder. The motor is simple in integral structure, and the assembling difficulty of the motor is greatly reduced, so that the high reliability, high stability, and high precision of a wind power generation device can be guaranteed; in addition, the sealing property is good, and the wind power generation device can be used in a severe environment.

Owner:苏州新能健电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com