Safety automatic welding manipulator

An automatic welding and manipulator technology, applied in the field of manipulators, can solve the problems of inability to guarantee long-term, efficient and stable operation of welding work, high manufacturing and operating costs, and complex overall structure of manipulators. Easy and fast maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

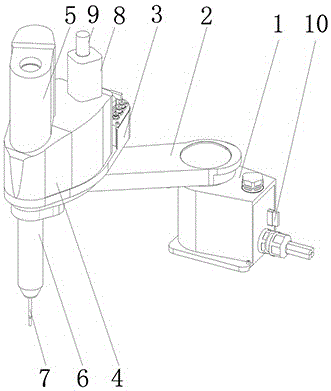

[0024] Such as figure 1 As shown, a safe automatic welding manipulator in this embodiment includes: machine base 1, first articulated arm 2, second articulated arm 3, fixed seat 4, cylinder 5, sliding sleeve 6, welding torch 7, detection device 8 , automatic alarm 9 and emergency shutdown button 10.

[0025] The connection relationship of the above-mentioned components is as follows: the two ends of the first articulated arm 2 are respectively connected with the base 1 and the second articulated arm 3, and the first articulated arm 2 and the second articulated arm 3 pass through the inside of the base 1 Driven by a servo motor provided, the upper surface of the second articulated arm 3 is connected with a fixed seat 4; the upper part of the sliding sleeve 6 passes through the second articulated arm 3 and the fixed seat 4 in turn, and the top of the sliding sleeve 6 is connected to the fixed seat 4. The cylinder 5 above the seat 4 is connected in cooperation; the welding torch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com