Patents

Literature

45results about How to "Easy loading, unloading and maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

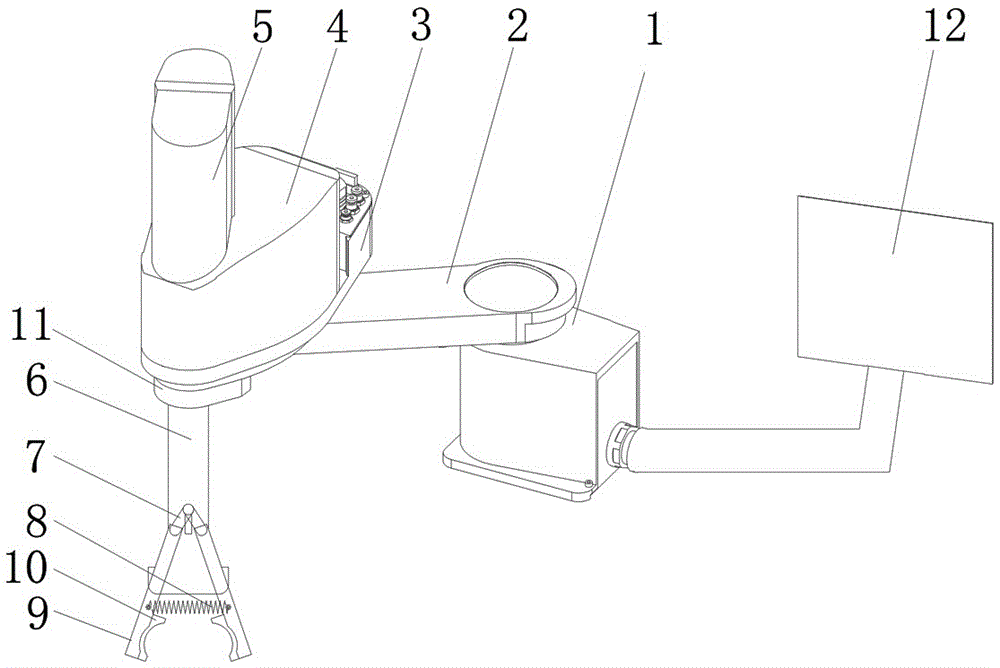

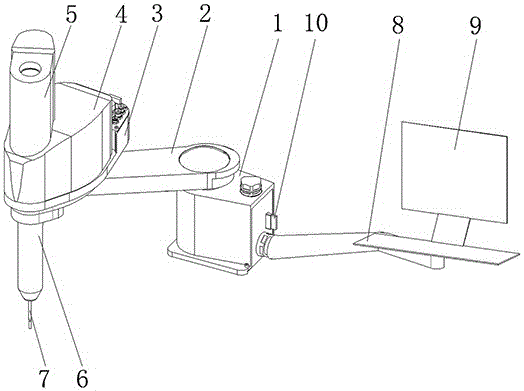

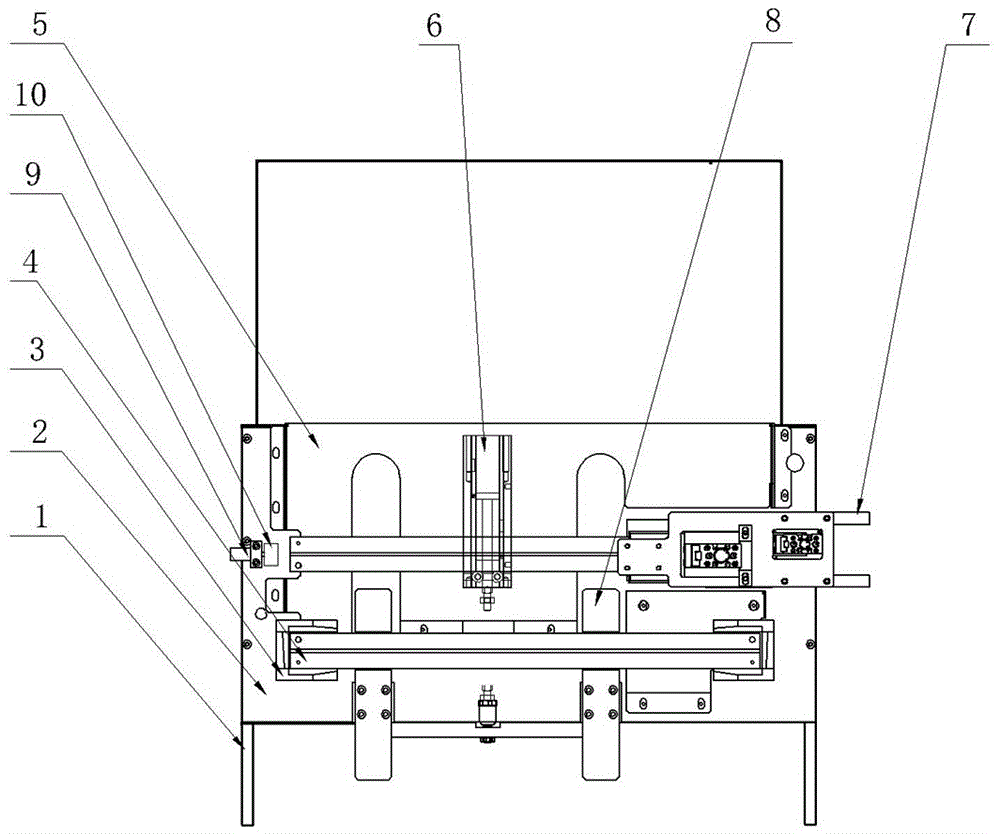

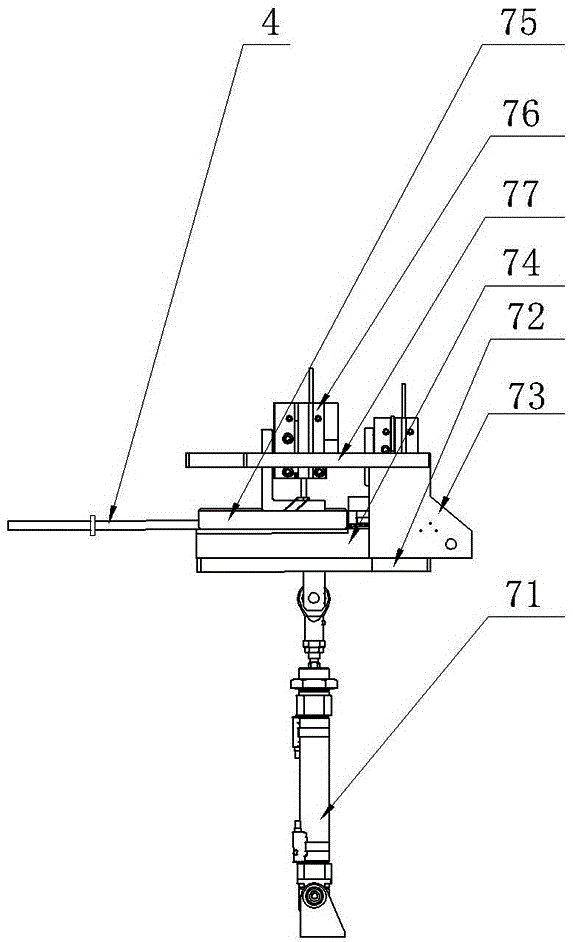

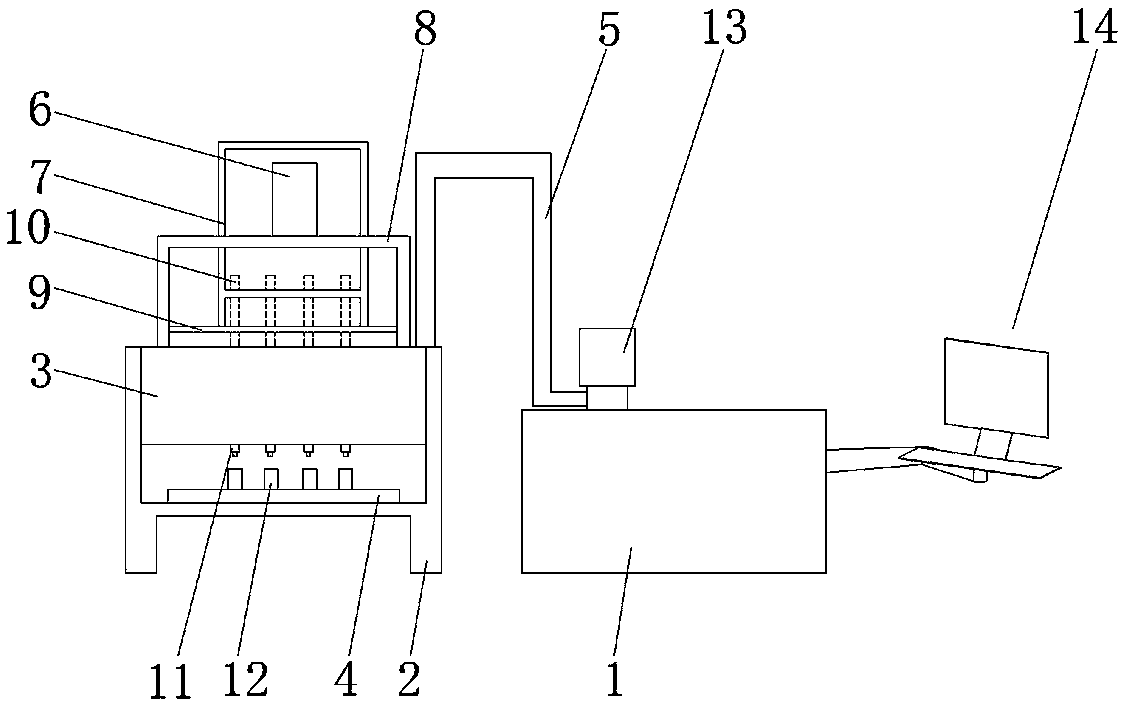

Automatic clamping manipulator with displayer

InactiveCN106113084AInterconnected firmlyEasy loading, unloading and maintenanceGripping headsDisplay deviceElectric machinery

The invention discloses an automatic clamping manipulator with a display, and mainly relates to the technical field of manipulators; The clamping fingers are all driven by the servo motor inside the fuselage, and the upper surface of the second joint shaft is connected with a fixed seat; the upper part of the telescopic sleeve passes through the second joint shaft and is connected with the fixed seat, and the top is connected with a motor; the clamping fingers pass through The connecting rod is connected with the telescopic sleeve, a spring is arranged between the clamping fingers, and a liner is arranged on the inner side of the end; a display is connected to one side of the fuselage, and a visual sensor connected to the display is arranged at the bottom of the second joint shaft; the manipulator of the present invention The damage to the workpiece is small, and the operator can easily monitor its operation status. The overall structure is simple, the assembly and maintenance are very convenient, the manufacturing and operation costs are low, and it can maintain efficient and stable operation for a long time.

Owner:苏州塞默机械有限公司

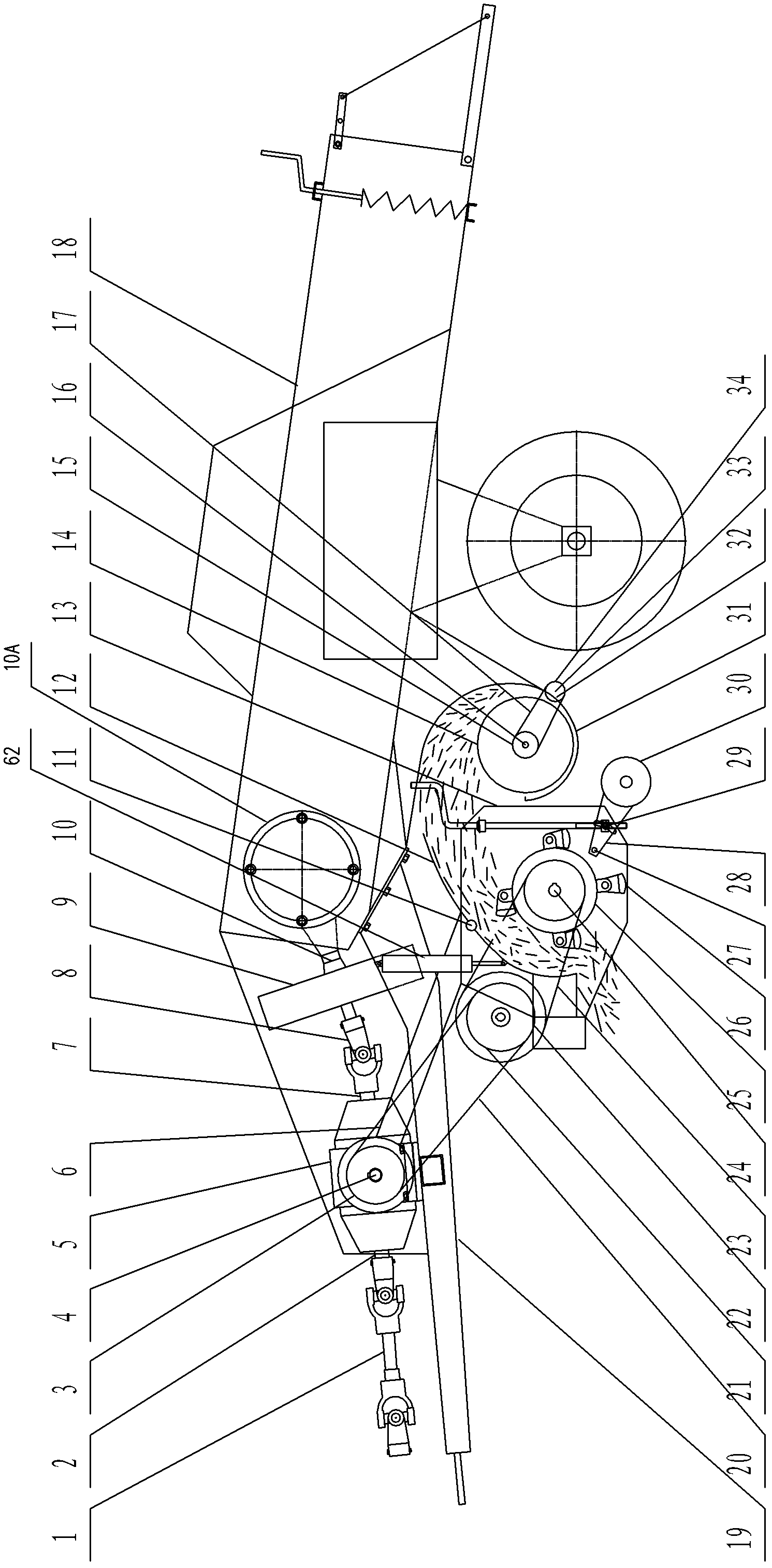

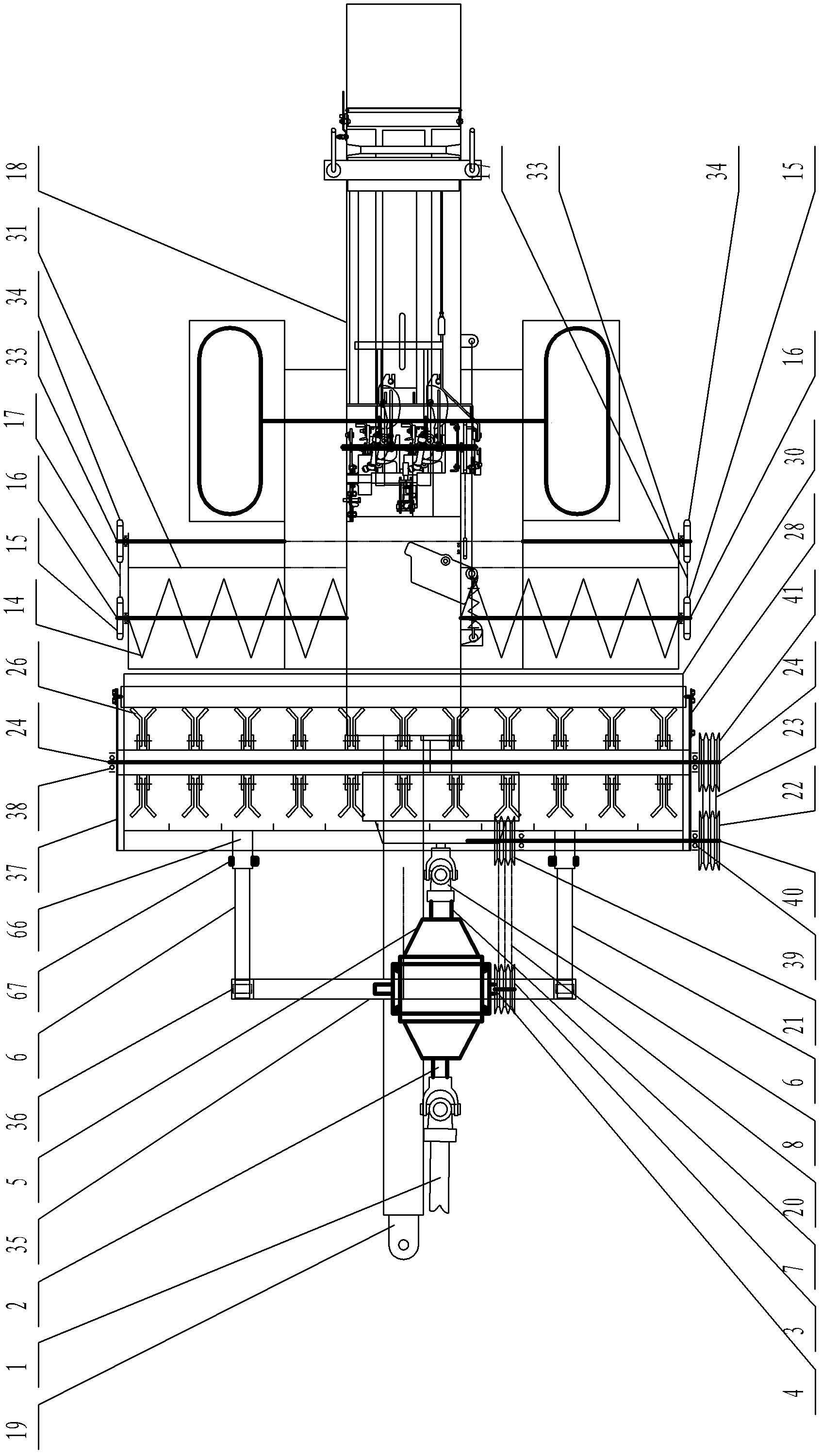

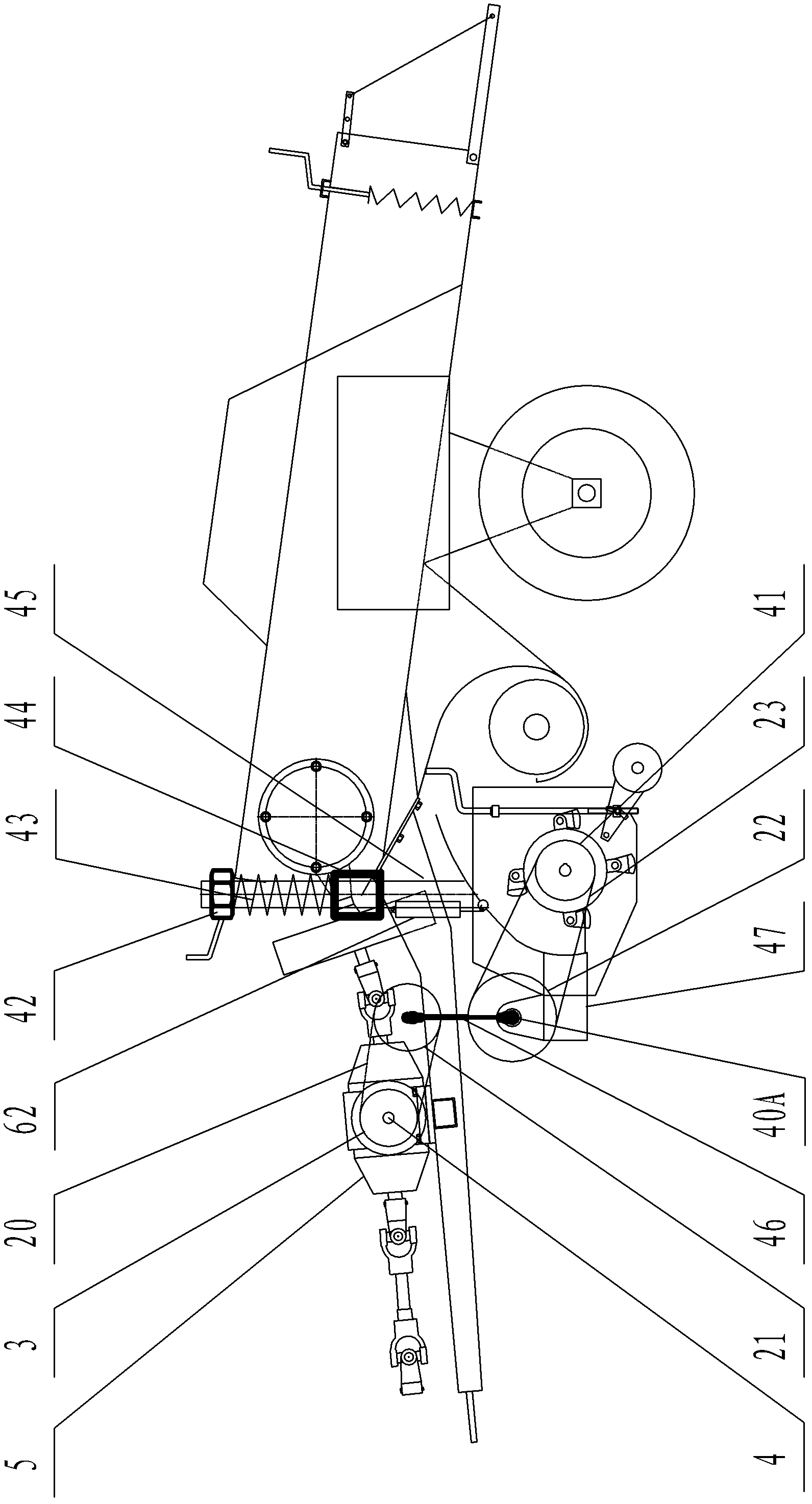

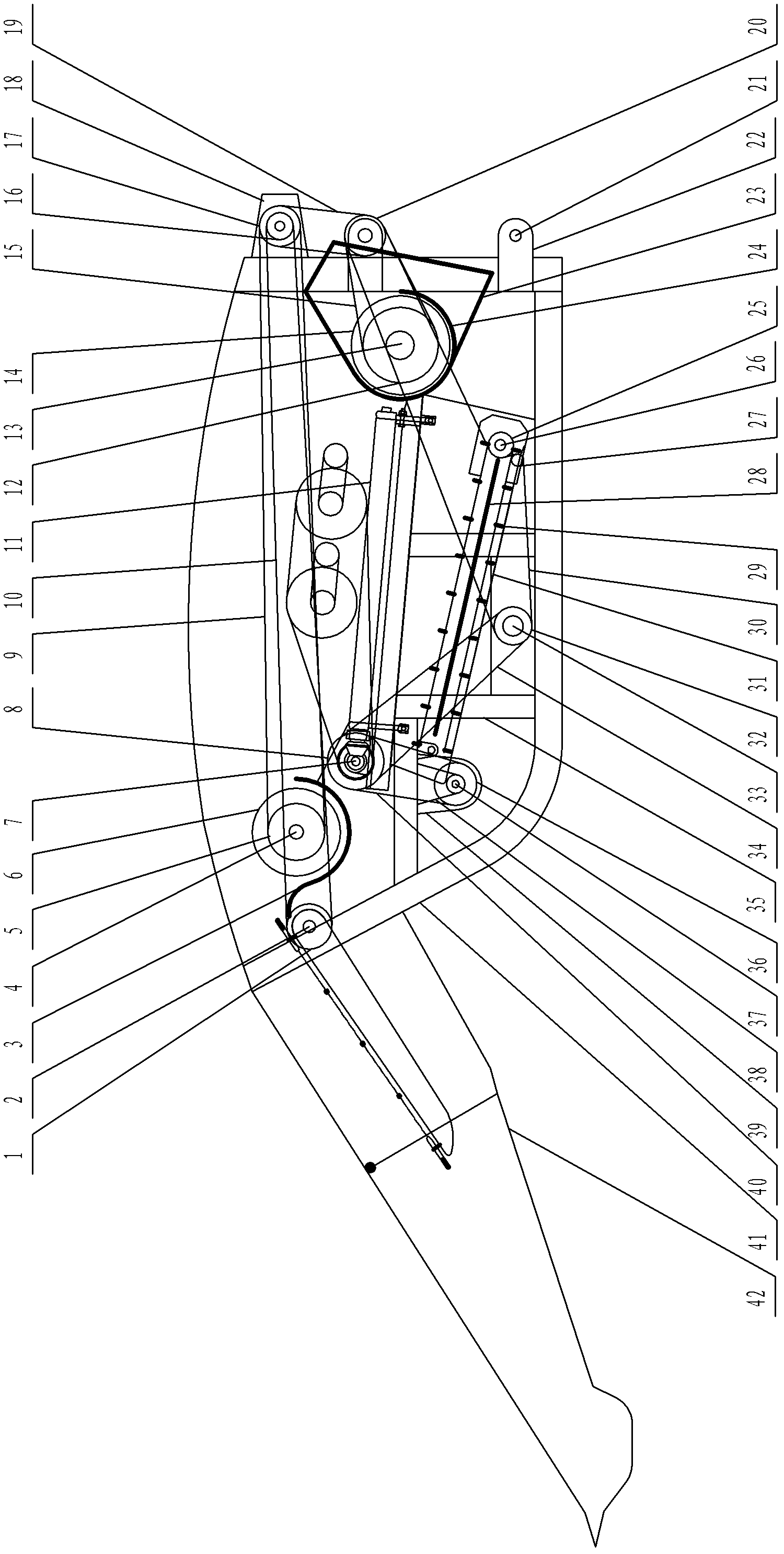

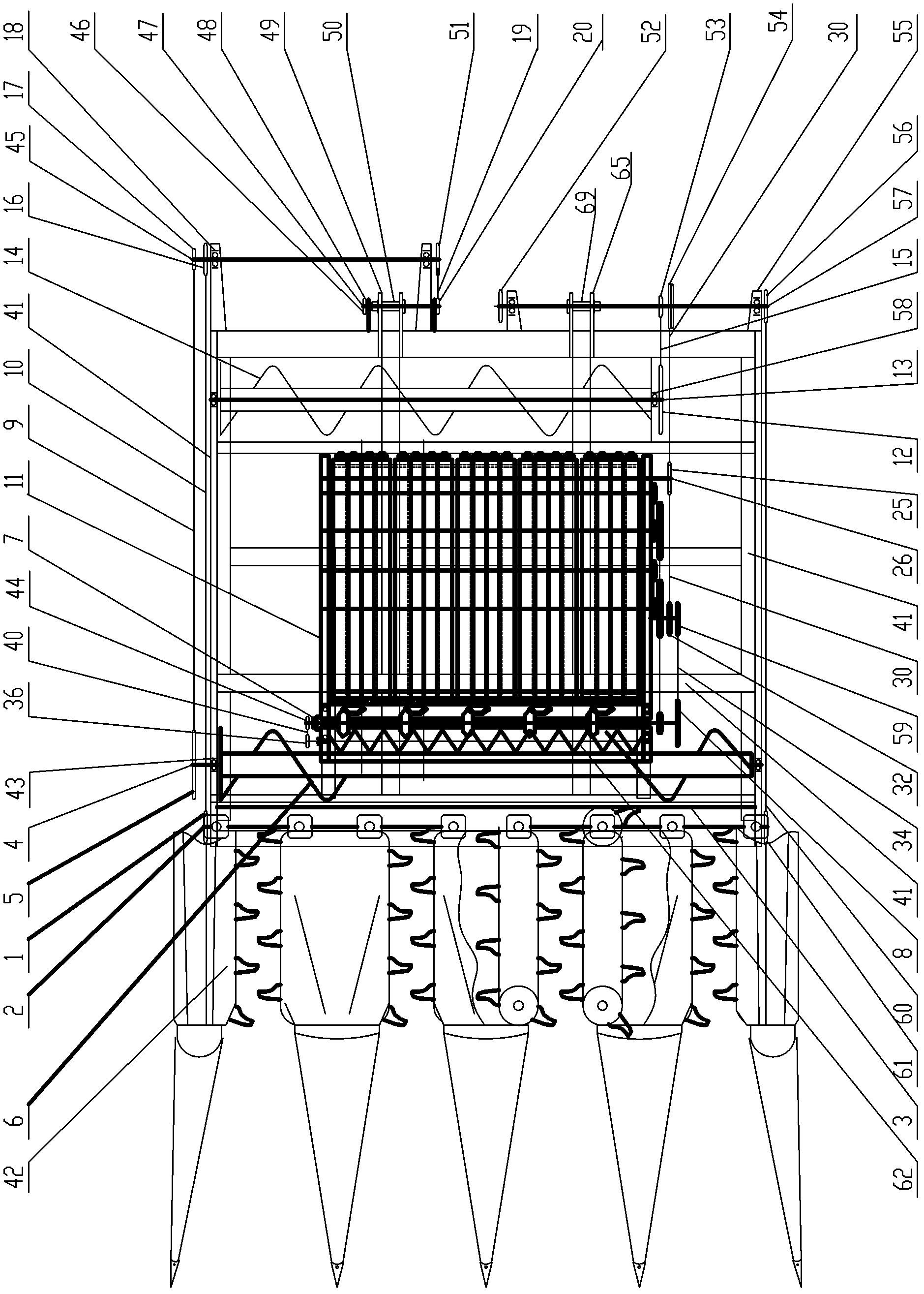

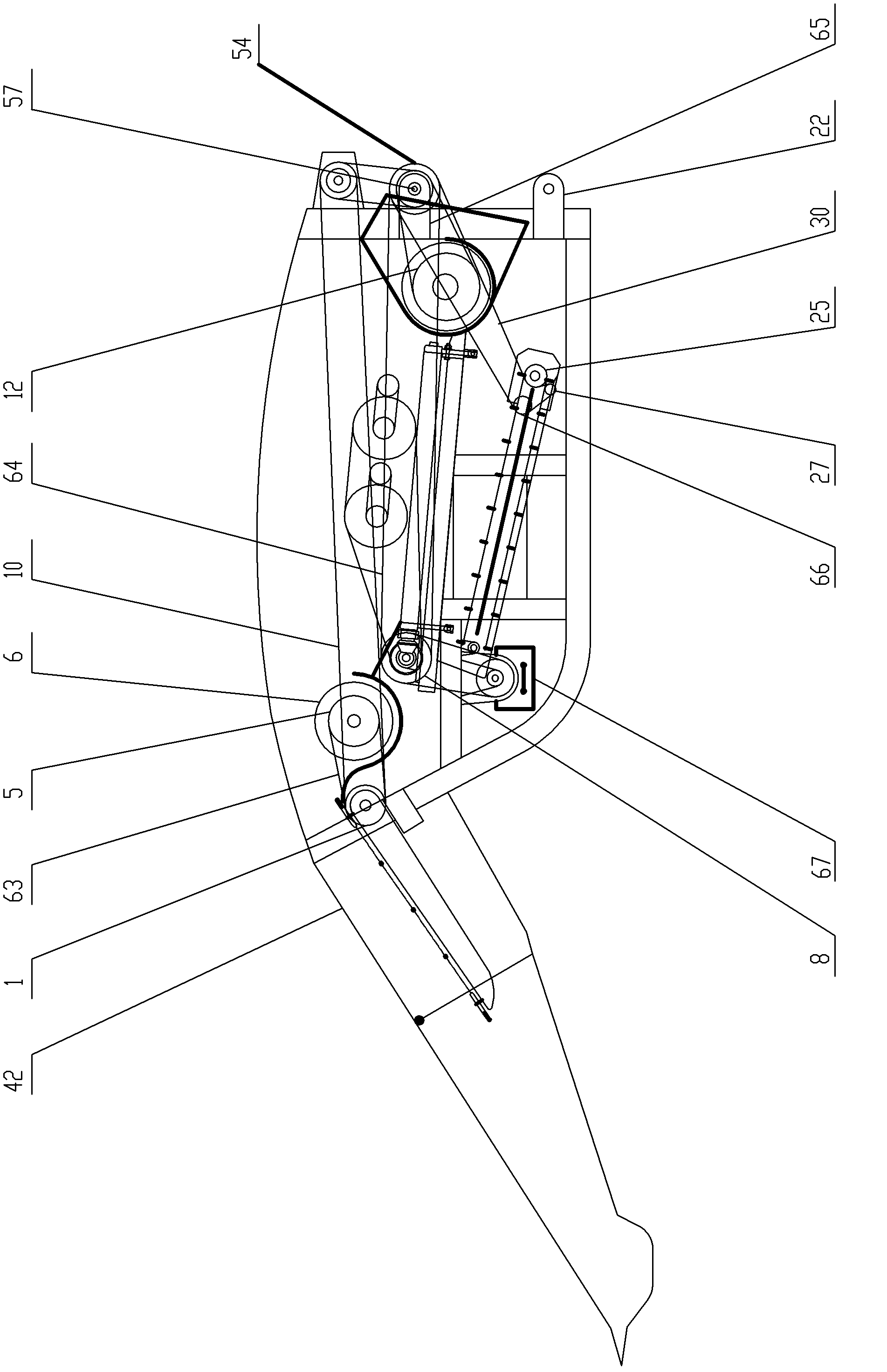

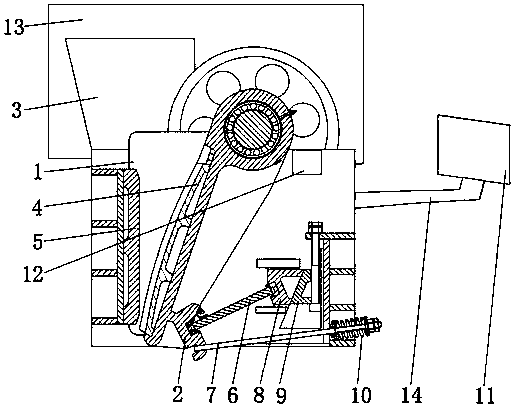

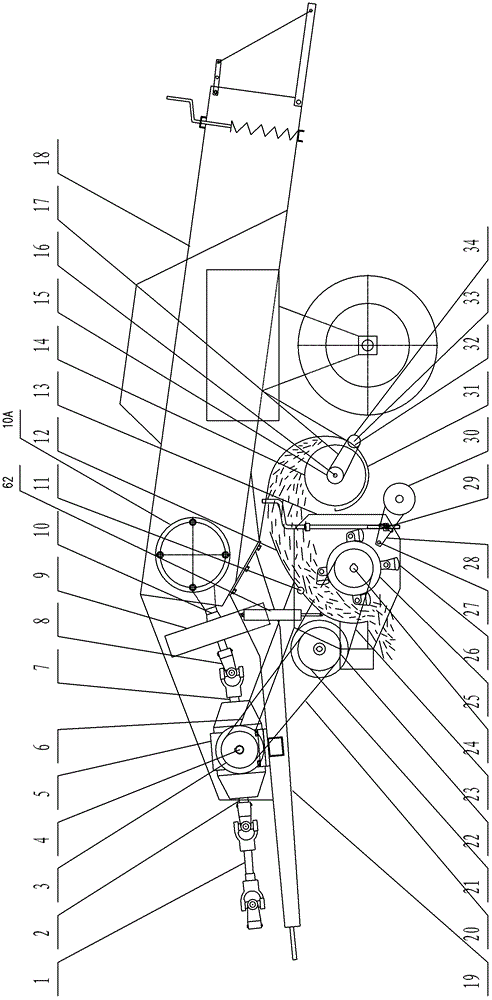

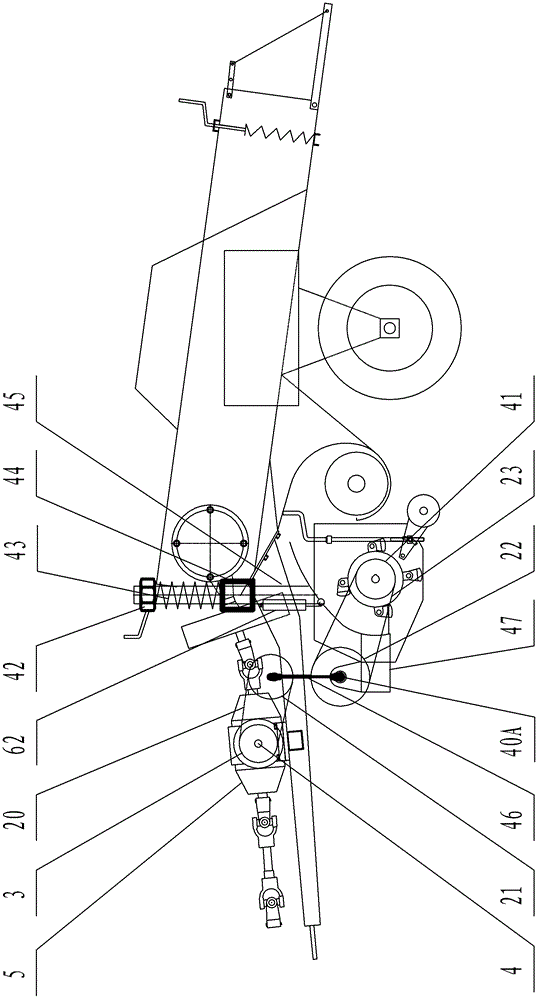

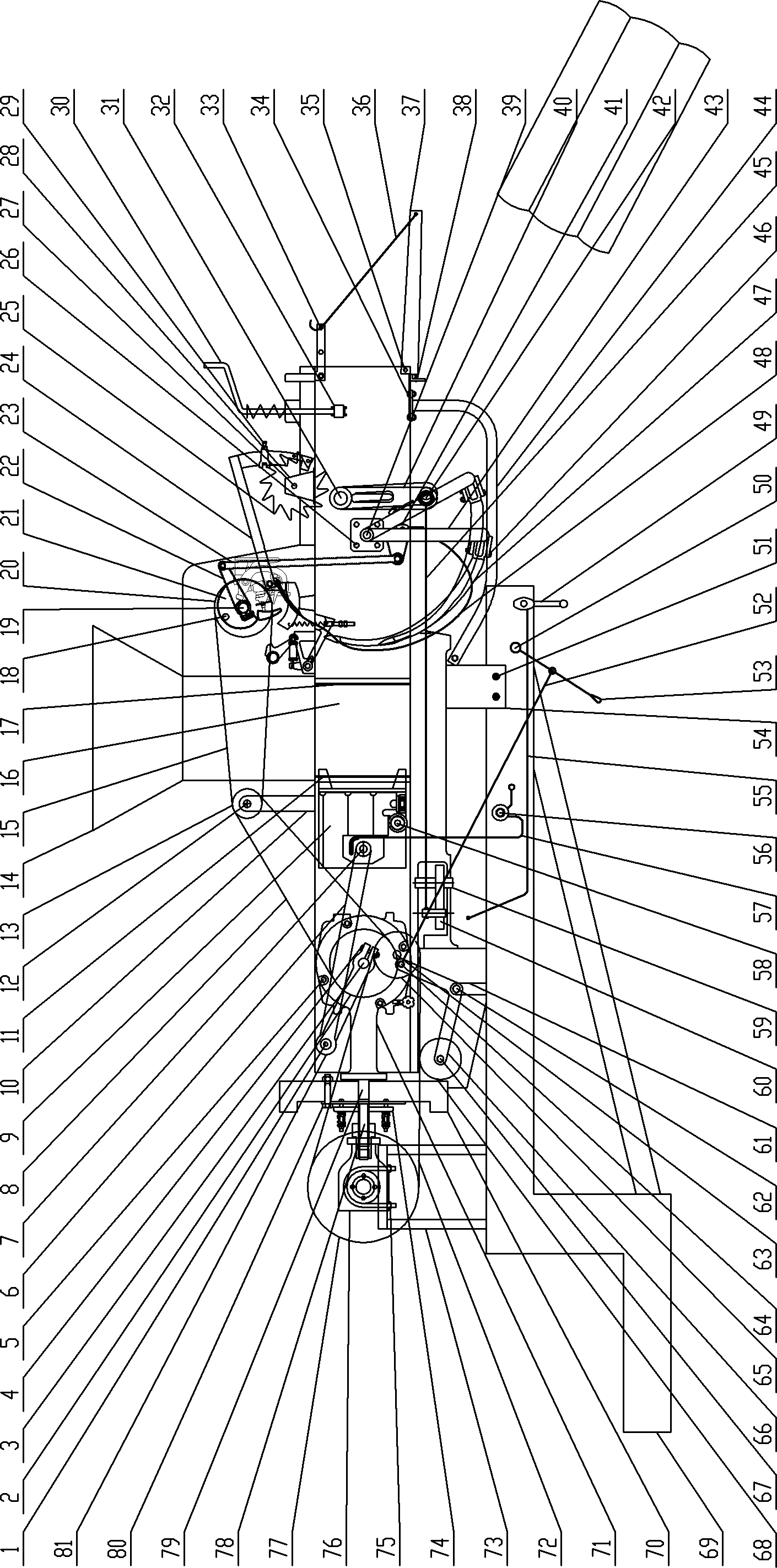

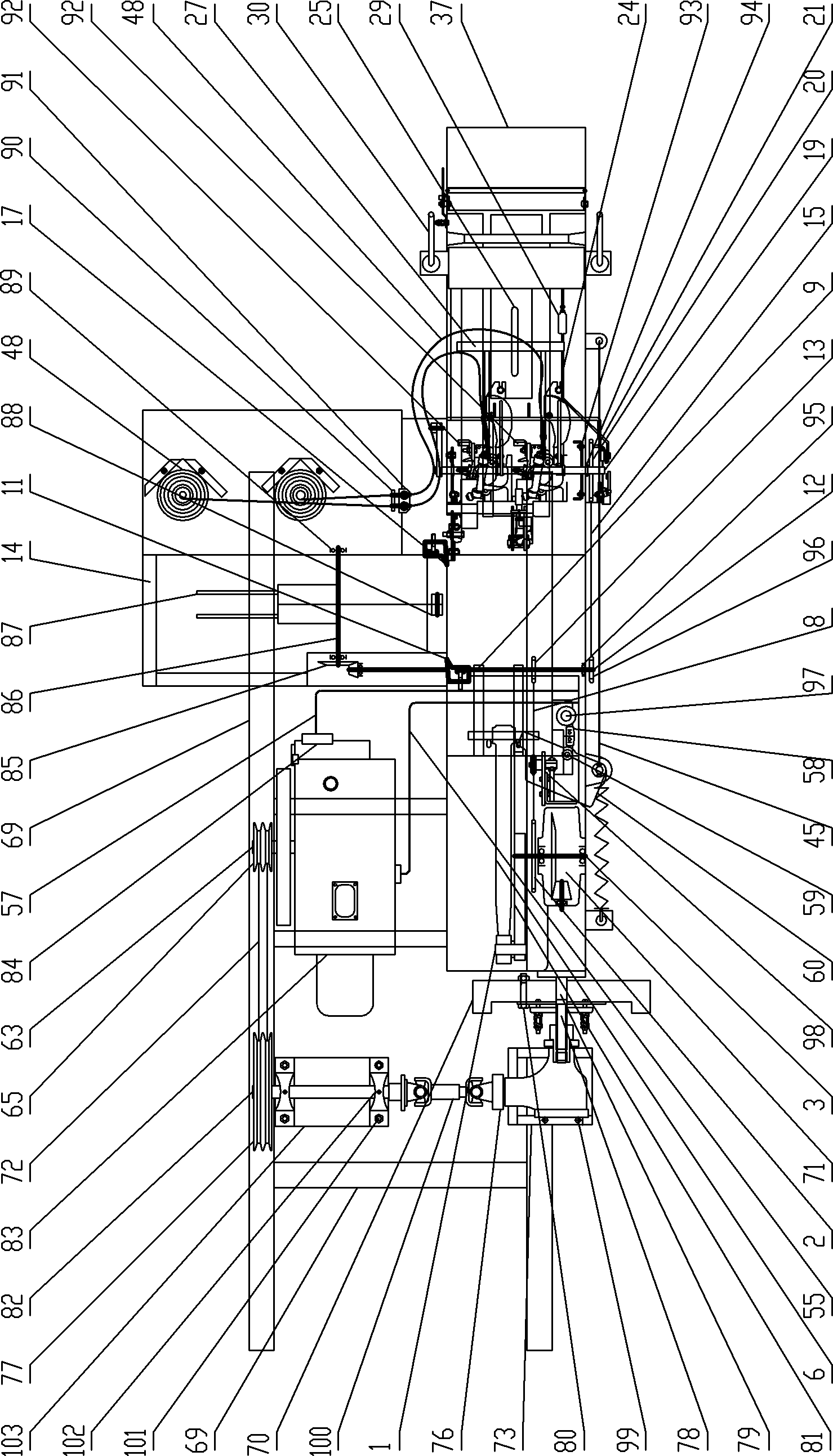

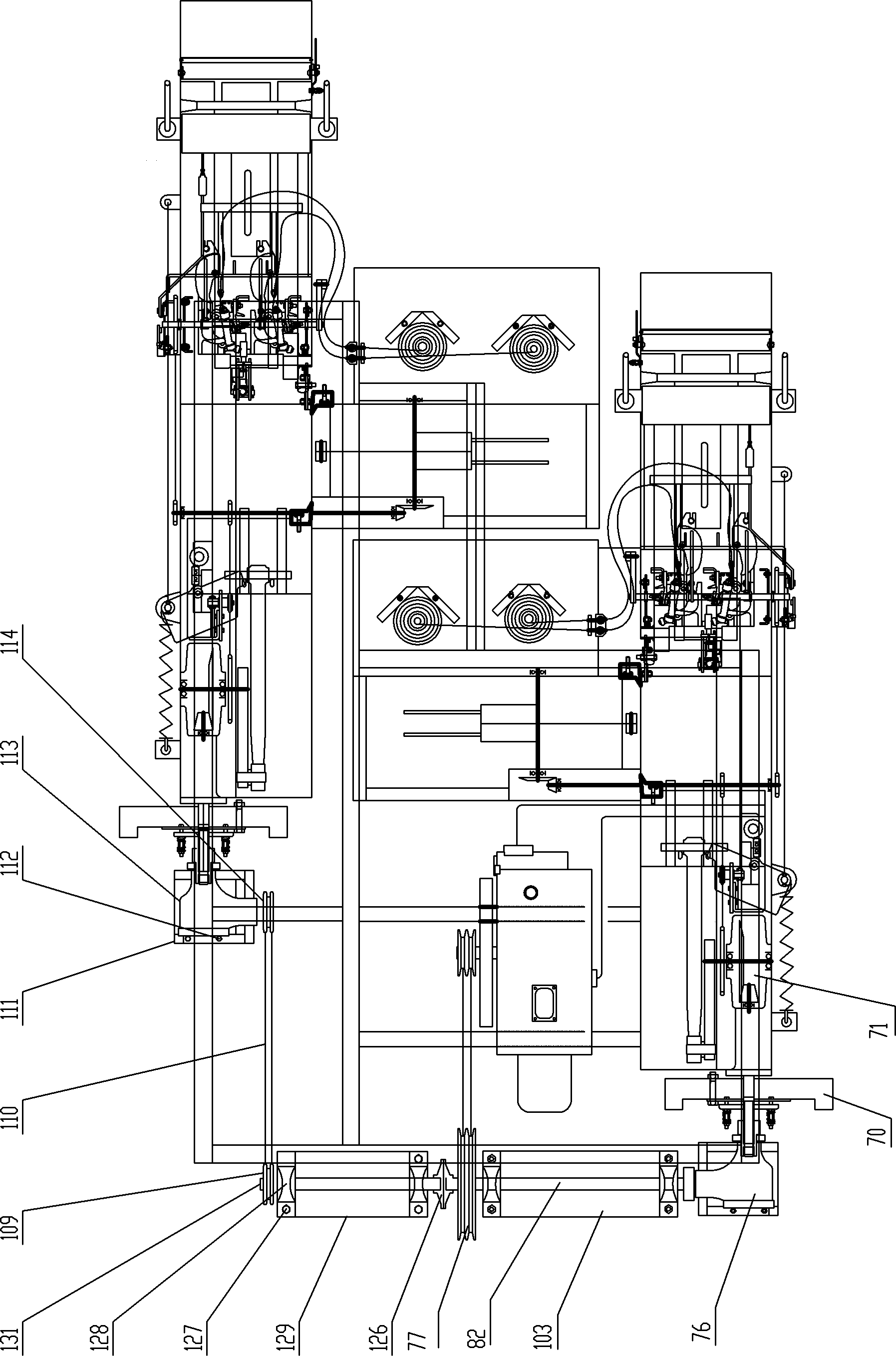

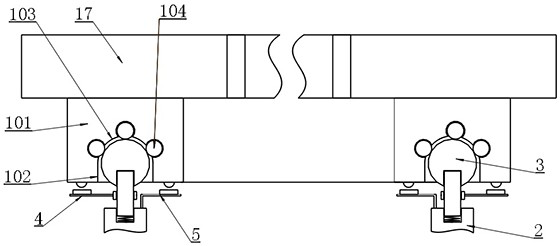

Cornstalk smashing recycling press-baler

The invention discloses a cornstalk smashing recycling press-baler. The cornstalk smashing recycling press-baler is characterized by comprising a main transmission device, a first transmission mechanism, a second transmission mechanism, a cornstalk picking smashing device (13), a cornstalk press-baling device (18), and an auger device, wherein the main transmission mechanism is connected with an external power device and installed on a draft arm (19), the first transmission mechanism is connected with the main transmission device, the second transmission mechanism is connected with the main transmission device, the cornstalk picking smashing device (13) is connected with the draft arm (19) and connected with the main transmission device through the first transmission mechanism, the cornstalk press-baling device (18) is connected with the draft arm (19) and connected with the main transmission device through the second transmission mechanism, and the auger device is installed between the cornstalk picking smashing device (13) and the cornstalk press-baling device (18) and connected with the second transmission mechanism through a third transmission mechanism. The cornstalk smashing recycling press-baler can be used for cutting or picking, smashing, recycling, compressing and baling stand cornstalks, cornstalks which are cut off and cornstalks which are wasted by a header of a combine-harvester in the field. The cornstalk smashing recycling press-baler is simple in structure and high in efficiency.

Owner:孙首泉

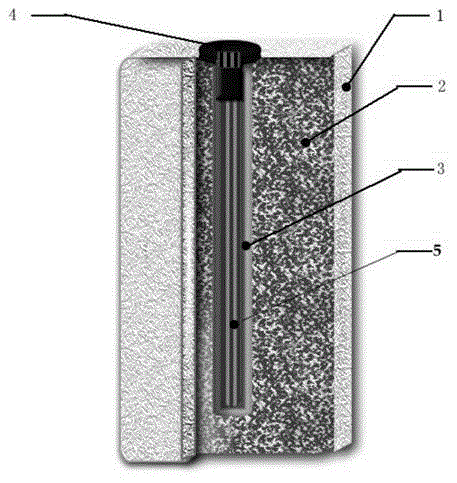

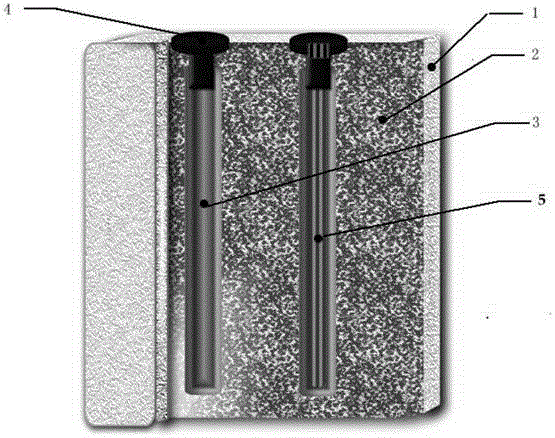

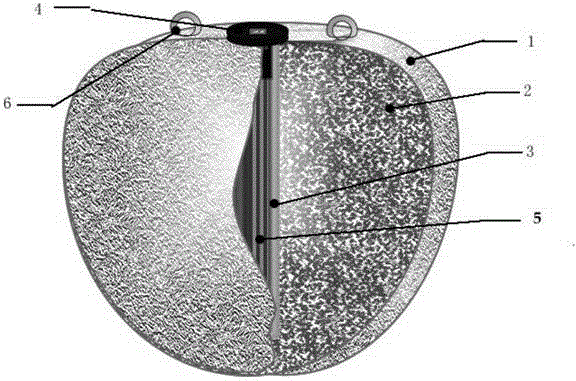

Portable multi-energy and multi-use heater made of shaped composite phase-change materials

InactiveCN104595968ASimple preparation processEasy loading, unloading and maintenanceLighting and heating apparatusElectric heating systemPorosityElectricity

The invention relates to the technical field of phase-change energy storage and usage, and particularly relates to a portable multi-heat source and multi-use heater made of shaped composite phase-change materials. The portable multi-heat source and multi-use heater made of the shaped composite phase-change materials comprises open-cell foamed aluminum plates of which porosity factors are 80% and densities are 0.5g / cm<3>; phase-change paraffin material of which melting point is 50-60 DEG C and melting heat is 200J / g, wherein the phase-change paraffin material is filled in a foamed aluminum hole; and a spare electric heating element inserted in the heater. The foamed aluminum plate is used for carrying, shaping, supporting and conducting heat; the paraffin is used as the working medium for phase-change heat storage and heat emission, and the electric heating element is adopted as spare energy. When being used, the electric heating element is inserted in the heater; when using other energies, the electric heating element is taken out and stored in spare bags.

Owner:HUNAN UNIV

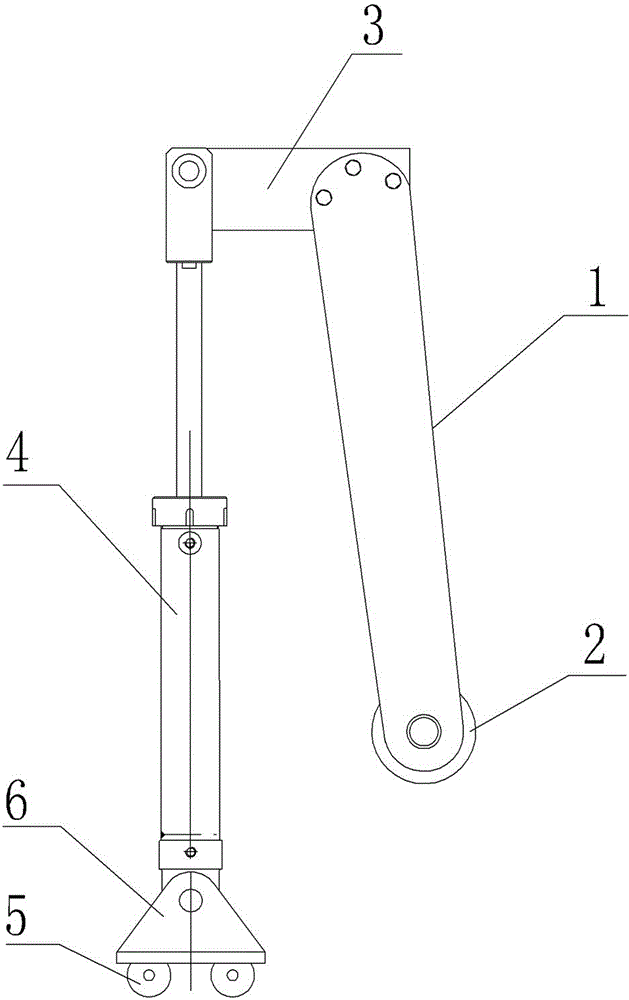

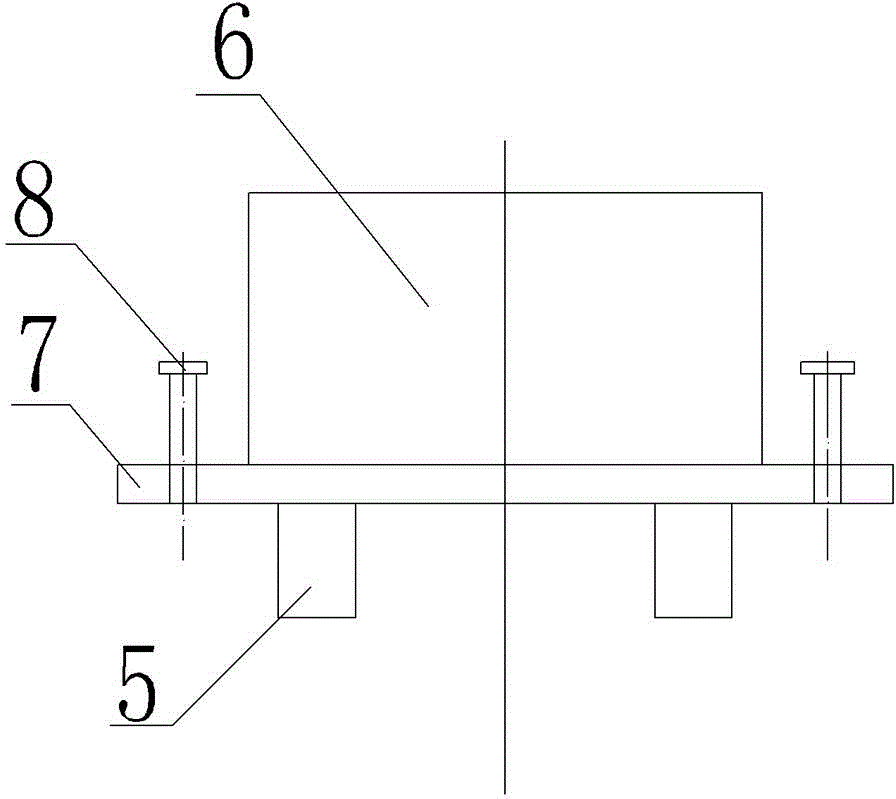

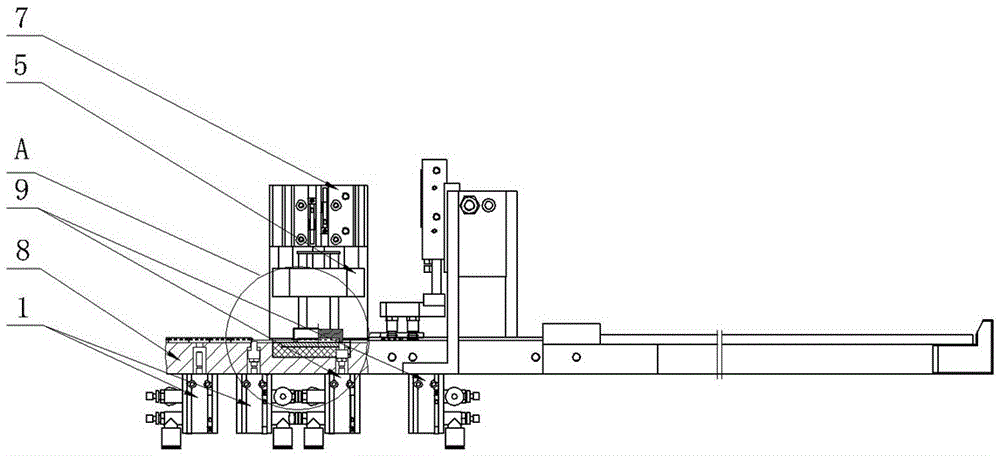

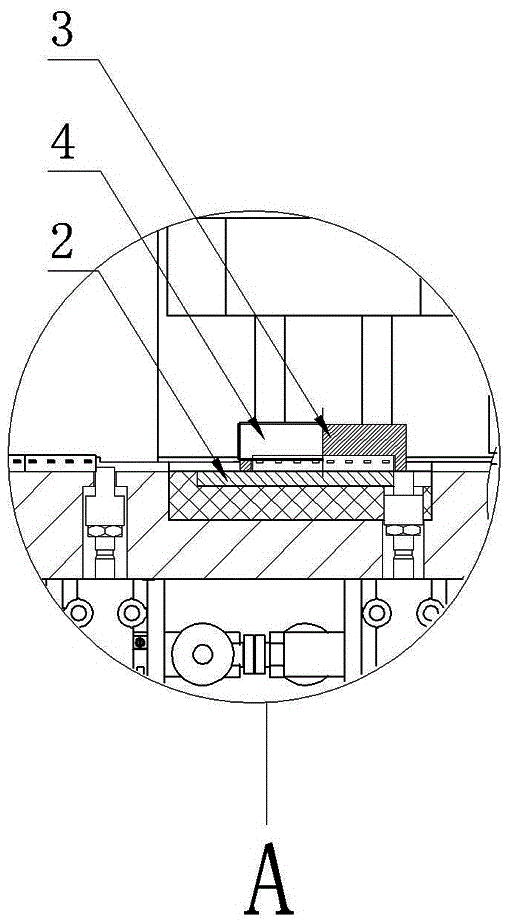

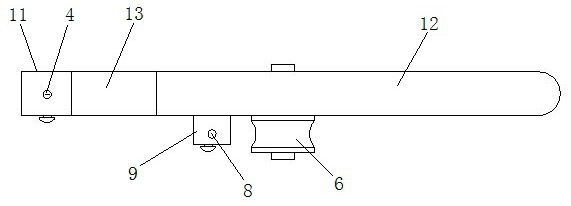

Pressing device for steel tape head

InactiveCN105710140AFew partsSmall footprintGuiding/positioning/aligning arrangementsIdler-wheelPiston rod

The invention provides a pressing device for a steel tape head. The pressing device is simple in structure, small in occupied working space, capable of being moved flexibly, and convenient to mount, dismount and maintain. The pressing device comprises a pressing rod and a driving oil cylinder. One end of the pressing rod is connected with a pressing wheel. The pressing device is characterized in that the oil cylinder is vertically installed on an idler wheel structure; a piston rod of the oil cylinder is connected with the pressing rod through a horizontal connecting rod; and the idler wheel structure comprises idler wheels and an idler wheel base.

Owner:WUXI AIBO METAL PROD

Safety automatic welding manipulator

InactiveCN106041383AReal-time monitoring of temperature and humidityTimely responseProgramme-controlled manipulatorWelding/cutting auxillary devicesTime efficientElectric machinery

The invention discloses a safety automatic welding manipulator and mainly relates to the technical field of manipulators. The safety automatic welding manipulator is characterized in that the two ends of a first articulated arm are respectively connected with an engine base and a second articulated arm in a matched manner, the first articulated arm and the second articulated arm are driven by a servo motor arranged in the engine base, the upper surface of the second articulated arm is connected with a fixed seat, the upper part of a sliding sleeve sequentially penetrates the second articulated arm and the fixed seat, the top of the sliding sleeve is connected with a cylinder at the top of the fixed seat in a matched manner, a welding gun is fixedly connected to the interior of the sliding sleeve, the head part of the welding gun penetrates a through hole formed in the bottom of the sliding sleeve, the engine base is directly connected with an external controller, an emergency shutdown button is arranged on one side of the engine base, and a detection device connected with an automatic alarm and the external controller in sequence is arranged on the surface of the fixed seat. The safety automatic welding manipulator is good in integral safety and high in workpiece calibration precision, can guarantee long-time efficient and stable operation of the welding operation, and is simple in overall structure, convenient and quick in assembly, disassembly and maintenance and low in manufacturing and operating cost.

Owner:JIANGSU JIEDI ROBOT

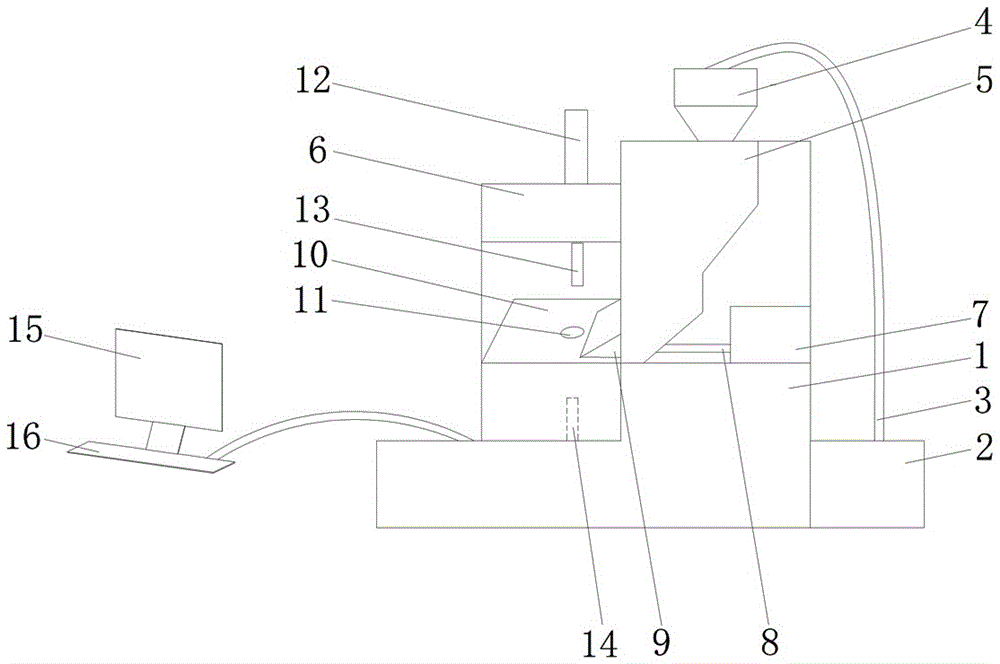

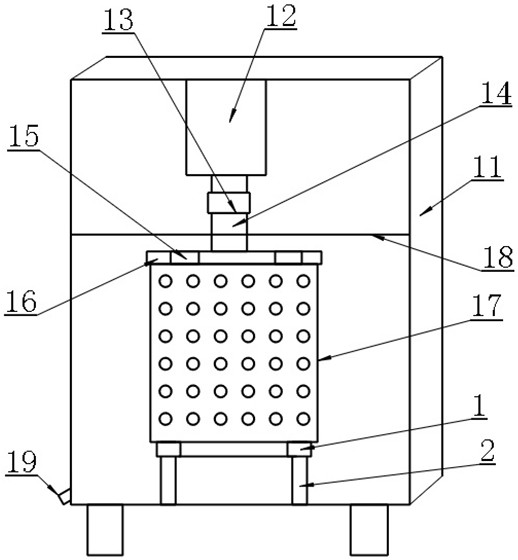

Efficient intelligent extrusion molding device and operating method thereof

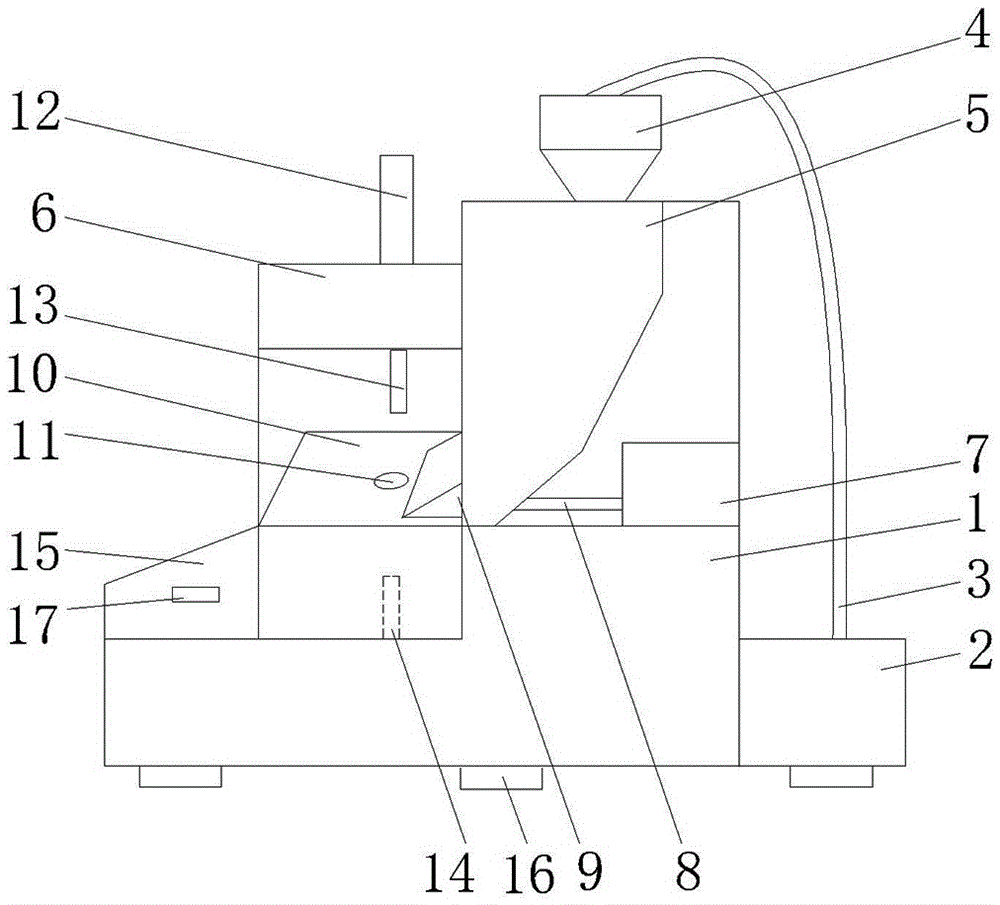

InactiveCN106113558AImprove delivery efficiencyGuaranteed uptimeShaping pressHydraulic cylinderFixed frame

The invention discloses a high-efficiency and intelligent extrusion molding device, which mainly relates to the technical field of mechanical equipment; the feeding hopper is connected to the raw material tank through a feeding pipe, and the bottom of the feeding The rod drives the feeding box to slide back and forth, the operating table is connected to the fixed frame through the column, and the telescopic rod is slidably connected to the fixed frame; there is a heating tank in the middle of the operating table, and the upper and lower ejector rods are respectively arranged on the upper and lower sides of the heating tank. The rod is fixedly connected with the telescopic rod; the feeding box is slidably connected with the operating table, and the bottom is provided with a through hole corresponding to the heating tank; the display and the PLC controller are connected to each other, and the surface of the display is provided with an emergency shutdown button; the overall structure of the device of the present invention and Its operation process is very simple, its maintenance is convenient and fast, and its cost is low. Operators can easily monitor its operation status, and the labor load of personnel is small. The invention also discloses a working method of an efficient and intelligent extrusion molding device.

Owner:TAICANG BEST MECHANICAL EQUIP

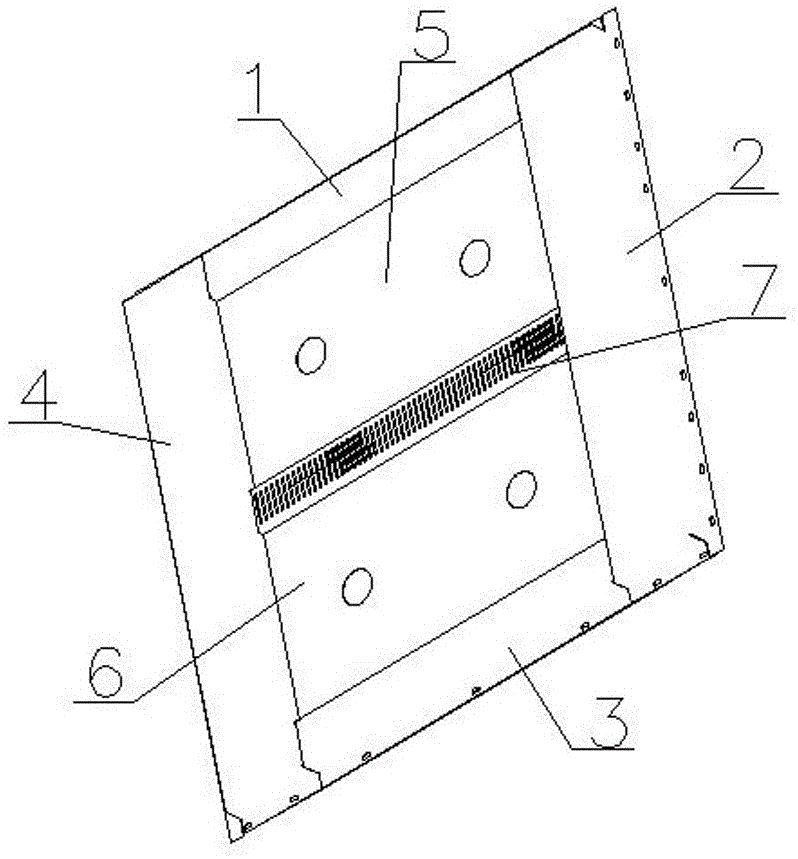

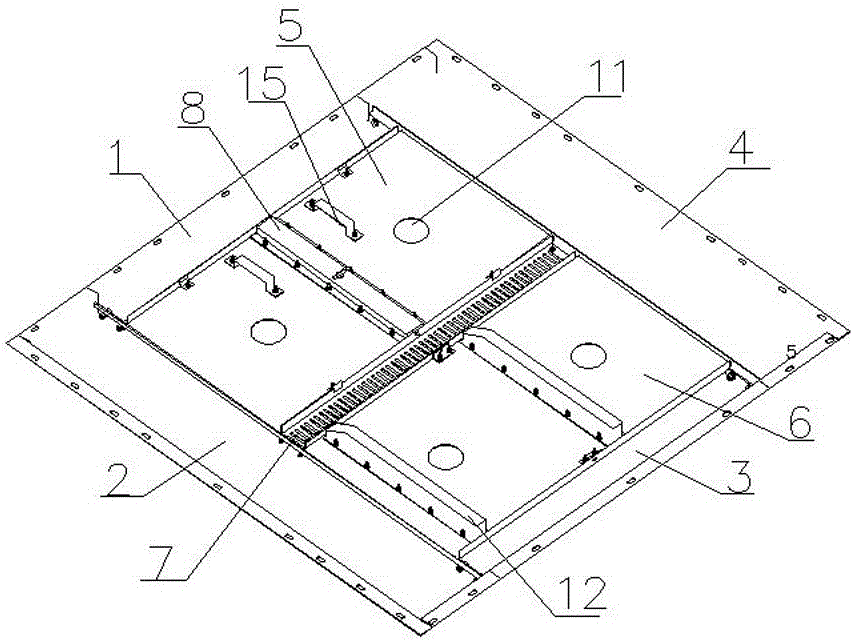

Elevator decoration suspended ceiling capable of preventing ceiling core fall

ActiveCN106241566ARealize the function of anti-fallPrevent accidental injury to passengersBuilding liftsLocking mechanismEngineering

The invention relates to an elevator decoration suspended ceiling capable of preventing ceiling core fall. The elevator decoration suspended ceiling comprises a suspended ceiling framework, the suspended ceiling framework is composed of a front top groove frame body, a left top groove frame body, a back top groove frame body and a right top groove frame body, which are fixedly connected with each other at heads and tails in sequence, a front ceiling core and a back ceiling core are sequentially installed in the suspended ceiling framework along the length direction of the left top groove frame body, an air guide groove body is installed between the front ceiling core and the back ceiling core, both ends of the air guide groove body are respectively fixed on the left top groove frame body and the right top groove frame body, the back ceiling core is fixed between the left top groove frame body and the right top groove frame body by bolts, and a ceiling core locking mechanism is arranged on the front ceiling core. According to the elevator decoration suspended ceiling provided by the invention, a key is controlled to rotate to drive a disk to rotate so as to drive a first lock rod and a second lock rod to carry out telescopic movement along the length direction of a fixing plate, the first lock rod and the second lock rod are respectively inserted in a first slotted hole and a second slotted hole to lock the ceiling cores so as to realize the anti-fall function of the ceiling cores, and the situation that the ceiling cores fall in the case of elevator cab vibration or other cases to accidentally injure the passengers can be prevented.

Owner:XJ SCHINDLER XUCHANG ELEVATOR

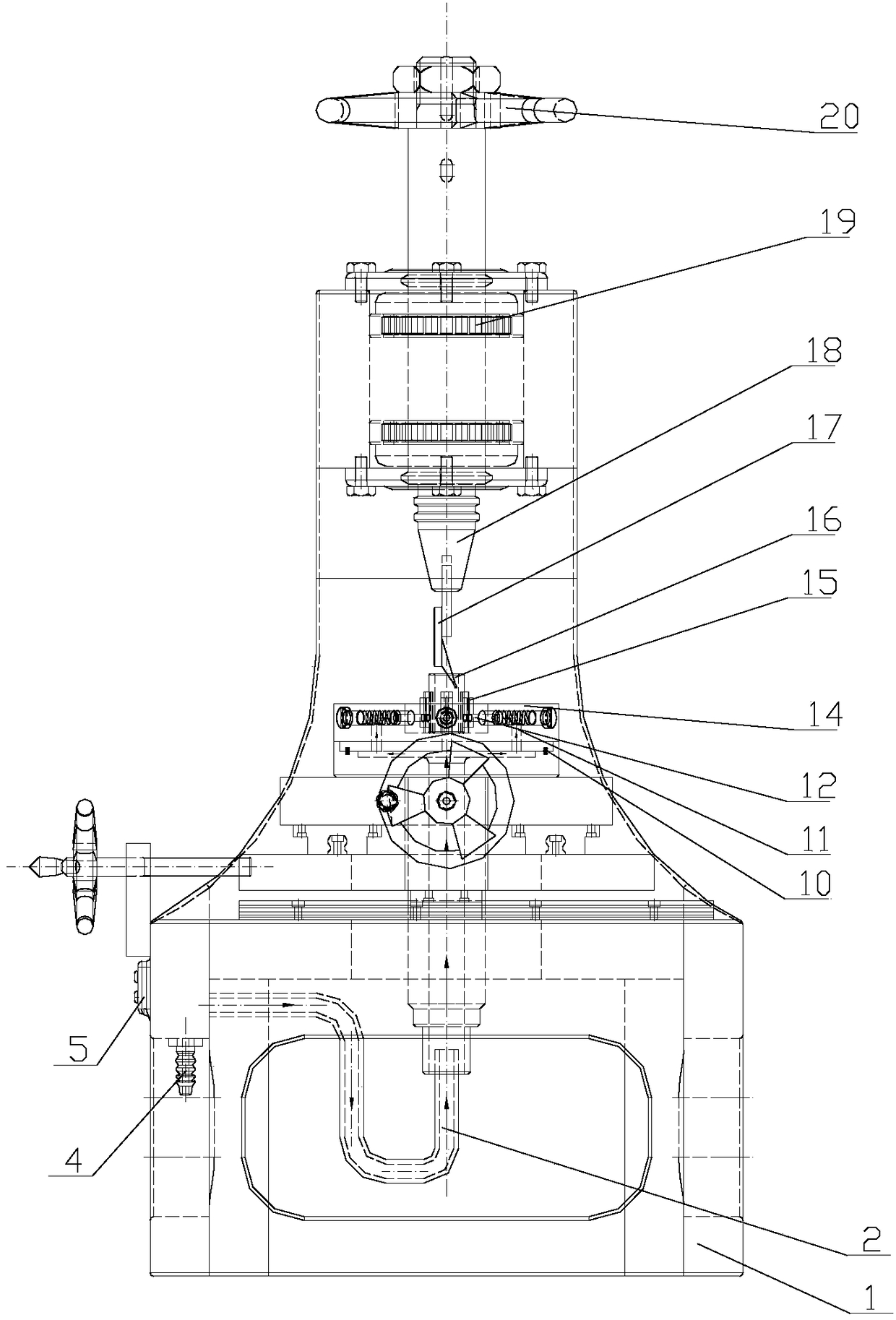

High-temperature-resistant friction press for hardware machining

The invention discloses a high-temperature-resistant friction press for hardware machining, and mainly relates to the technical field of presses. A punching mechanism comprises a sliding block, a screw rod and a nut, wherein the upper end and the lower end of the screw rod are connected with a flywheel and the sliding block in a matched mode respectively, the nut sleeves the position where the screw rod penetrates through a machine frame, of the screw rod, and the sliding block is connected with a sliding rail on the machine frame in a sliding mode; a cooling mechanism is connected with a cooling liquid tank inside the machine frame through a plastic pipe and a water pump, the head of the cooling mechanism can rotate by 180 degrees, a protection layer is arranged on the surface of the machine frame, and the protection layer is composed of an acid-alkali-corrosion-resistant layer, a high-temperature-resistant layer and a wear-resistant layer. The overall structure of the press is very simple, the mounting, dismounting and maintenance are convenient and fast, the service life is long, and the cost is low; the press has a convenient cooling function; and the overall safety is good, and the efficient and stable operation of the punching work for a long time can be ensured.

Owner:太仓市鼎祥五金制品厂

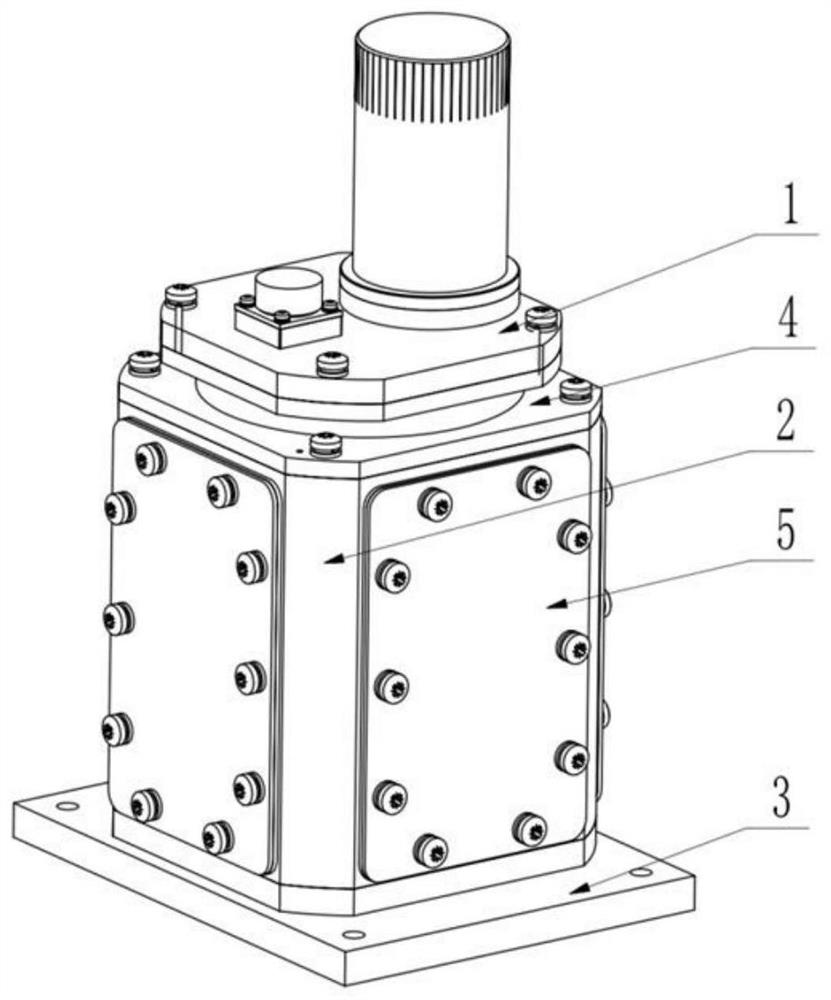

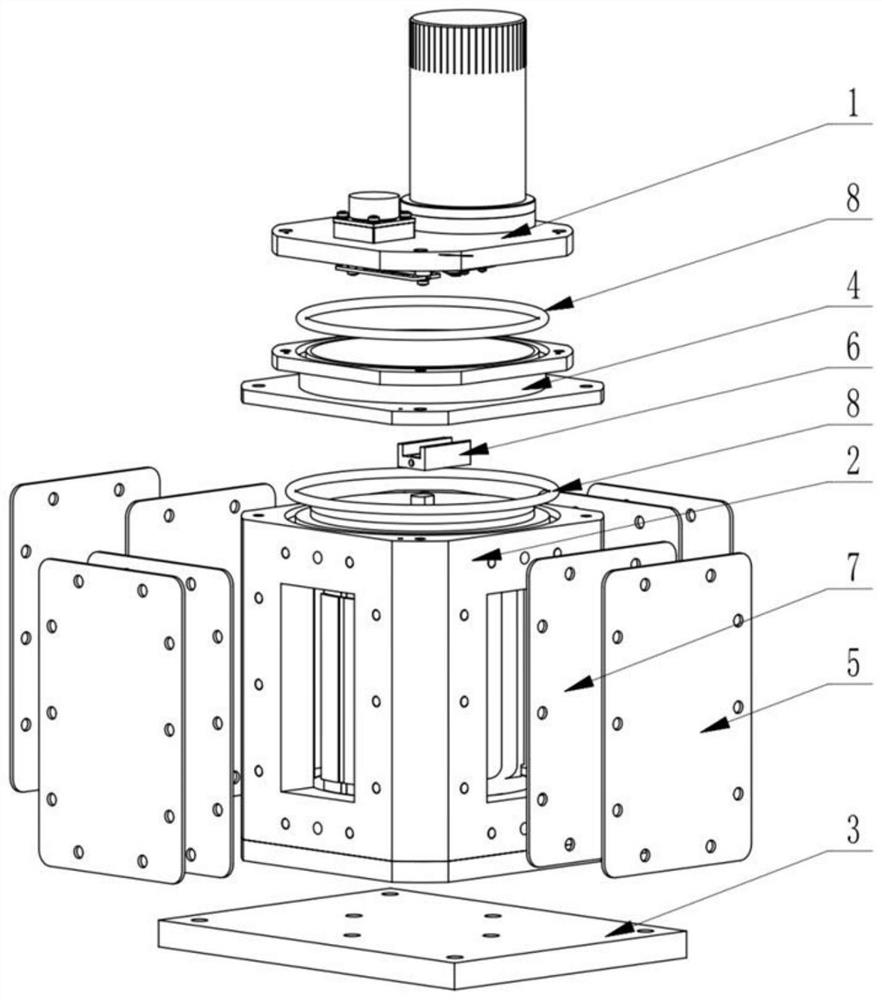

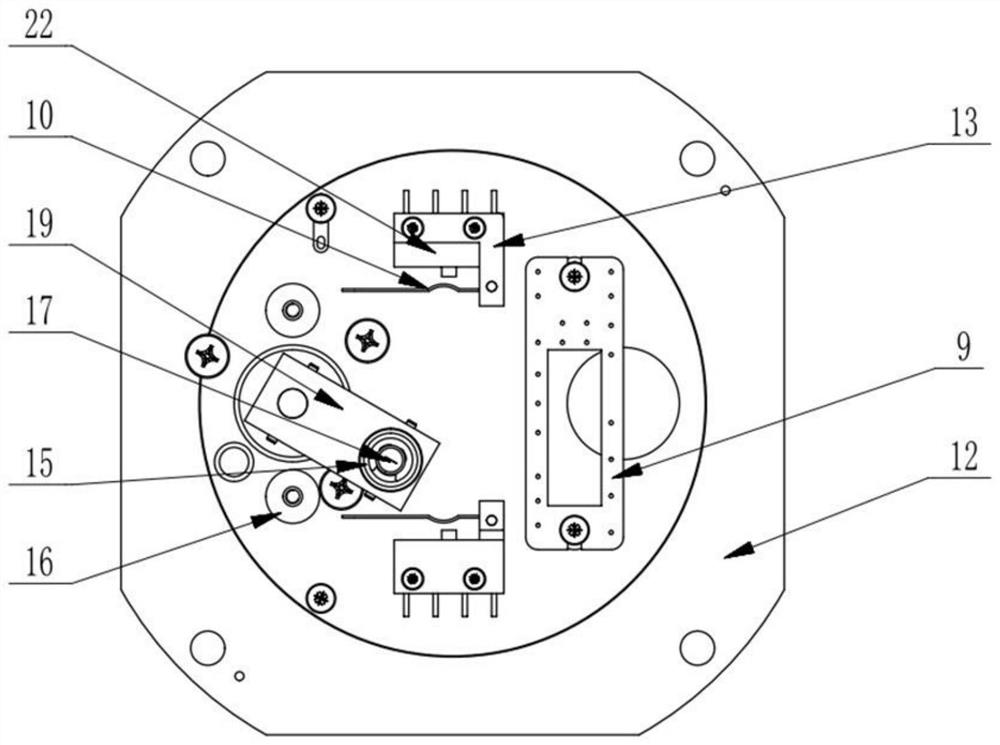

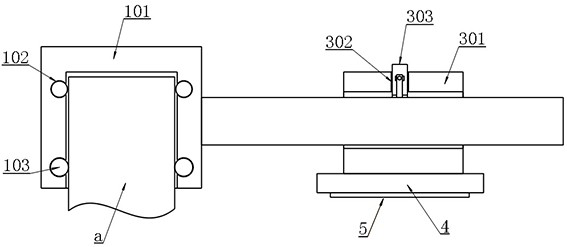

Waveguide switch with novel structure

ActiveCN114335929AGuaranteed self-lockingAvoid failureWaveguide type devicesElectric machineryMicromotor

The invention discloses a waveguide switch with a novel structure, which comprises a control device and a rotor assembly, a control rotating shaft of the control device is connected with a motor shifting block, the motor shifting block is provided with a slip ring, a rotor rotating shaft of the rotor assembly is connected with a rotor shifting block, and the slip ring is slidably clamped in a chute of the rotor shifting block. According to the waveguide switch, the 90-degree special micromotor is matched with the rocker sliding block transmission mechanism, 90-degree reciprocating rotation of the motor is converted into 90-degree rotation of the rotor, and four-channel corner cut conversion is achieved; a manual switching mechanism is designed to meet the requirement of manual control in the mechanical assembly and joint test process, and dual control of electric control and manual control is achieved; and after setting in place, an automatic power-off measure ensures the safety of the waveguide switch. According to the waveguide switch, the complexity of a control circuit is reduced, the insertion loss is small, the isolation degree is high, the bearing power is large, the performance is stable and reliable, and the safety is high.

Owner:10TH RES INST OF CETC

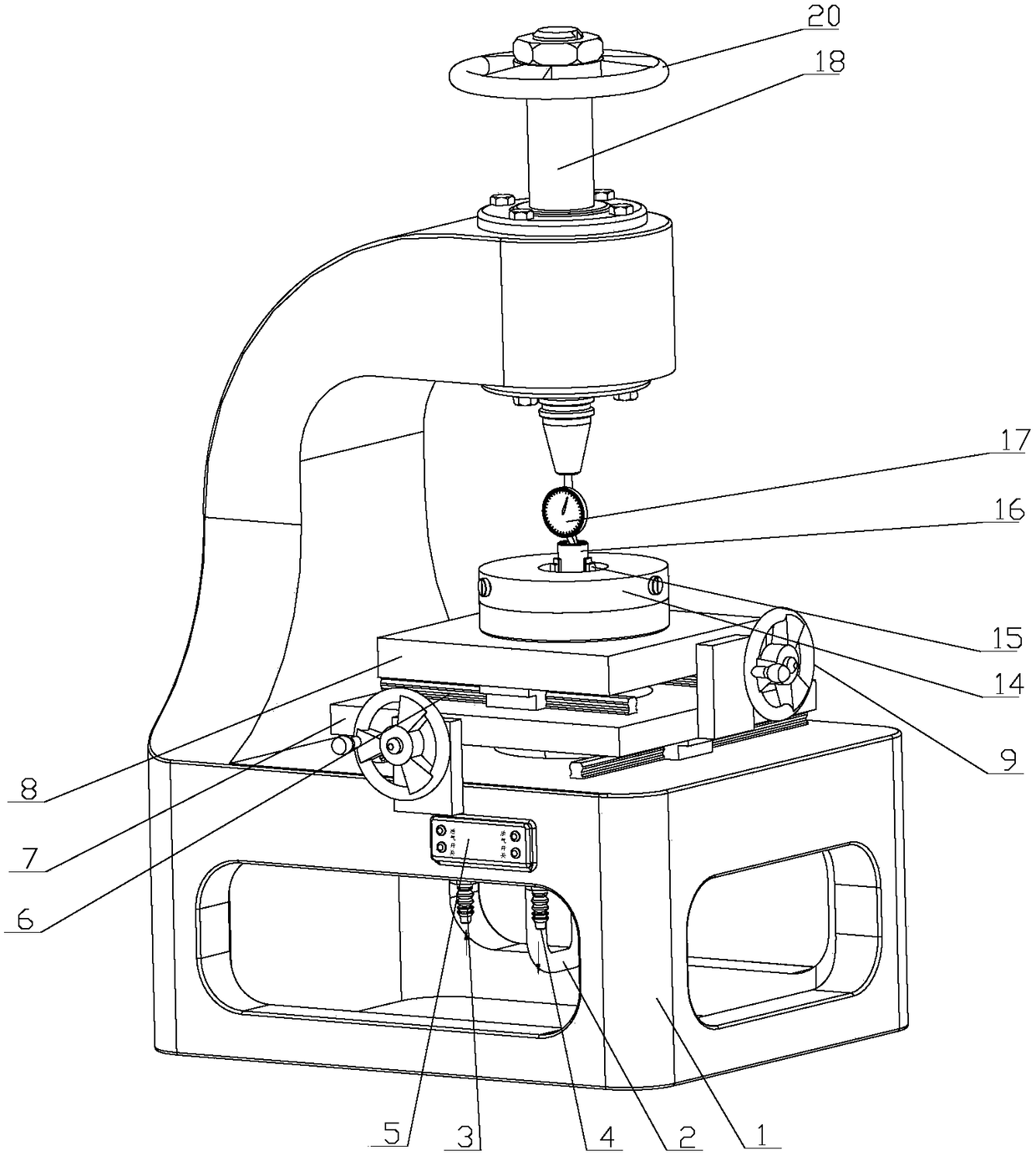

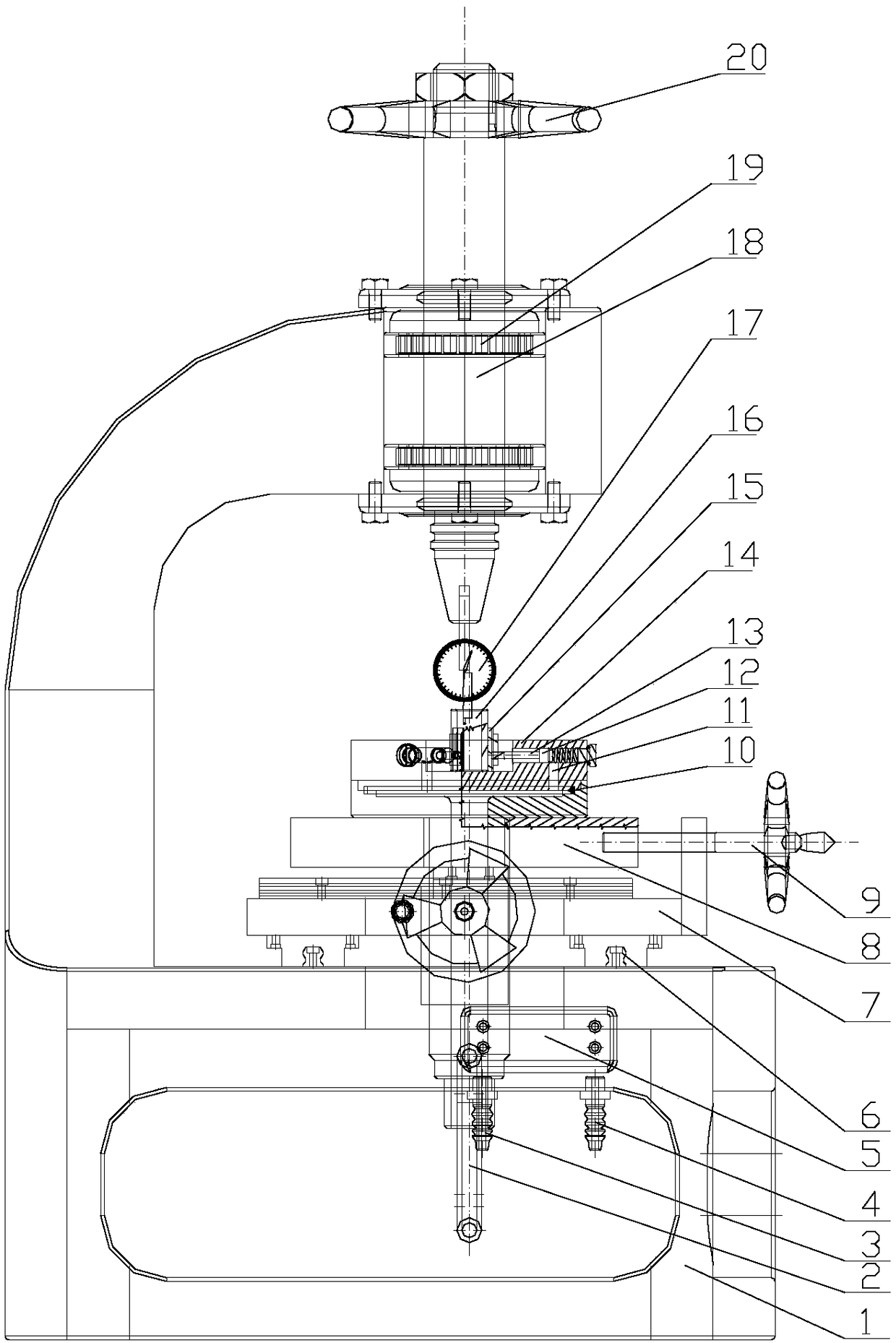

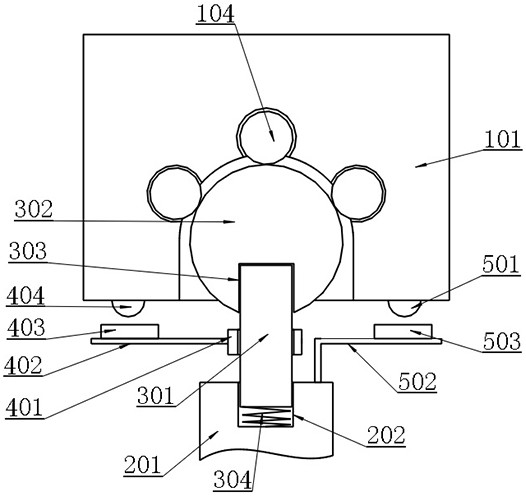

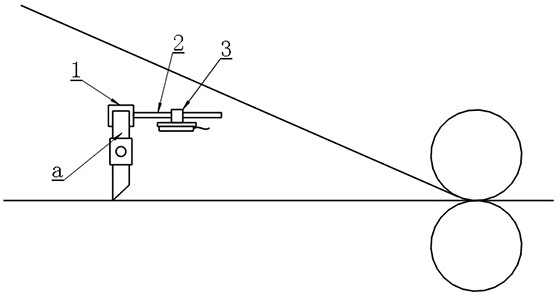

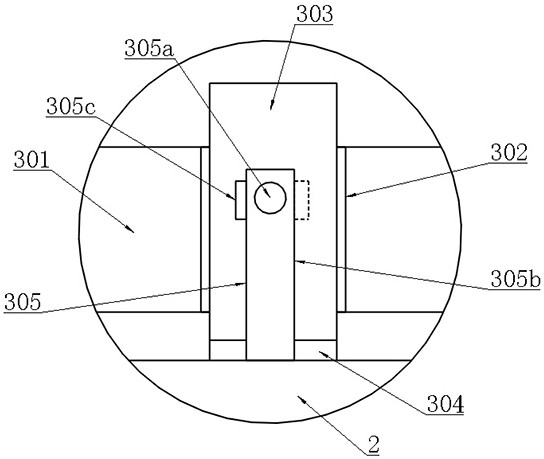

Pneumatic device for detecting coaxiality of inner hole

The invention discloses a pneumatic device for detecting coaxiality of an inner hole and is aimed at providing a pneumatic clamp detection device with easy operation, rapid clamping, small detection error and flexible adjustment. The invention is realized through the following technical scheme: a clamping plate clamping up a to-be-measured workpiece communicates with trisected radial vents of an air inlet channel, and the front segment rectangular rod body of a pneumatic spring push rod is fixedly connected to an equant arc clamping jaw through a shaft end of a radial hole of the same segmentin each radial vent; air flow passes through trisected circumferential holes at the bottom of the clamping plate to communicate with the radial vents, the air flow pushes the pneumatic spring push rodto move toward the axis of a clamping hole, and the equant arc clamping jaw fixedly connected to the shaft end of the pneumatic spring push rod is pushed to center to press the to-be-measured workpiece; and a scale rod measuring head of a numeric scale falls into an inner hole of the to-be-measured workpiece, contacts with a containment area of the hole wall of the inner hole of the to-be-measured workpiece within a detected length, measures each part needing the coaxiality of the to-be-measured workpiece, determines a maximum runout and a minimum runout, and obtains the coaxiality of the to-be-measured workpiece.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

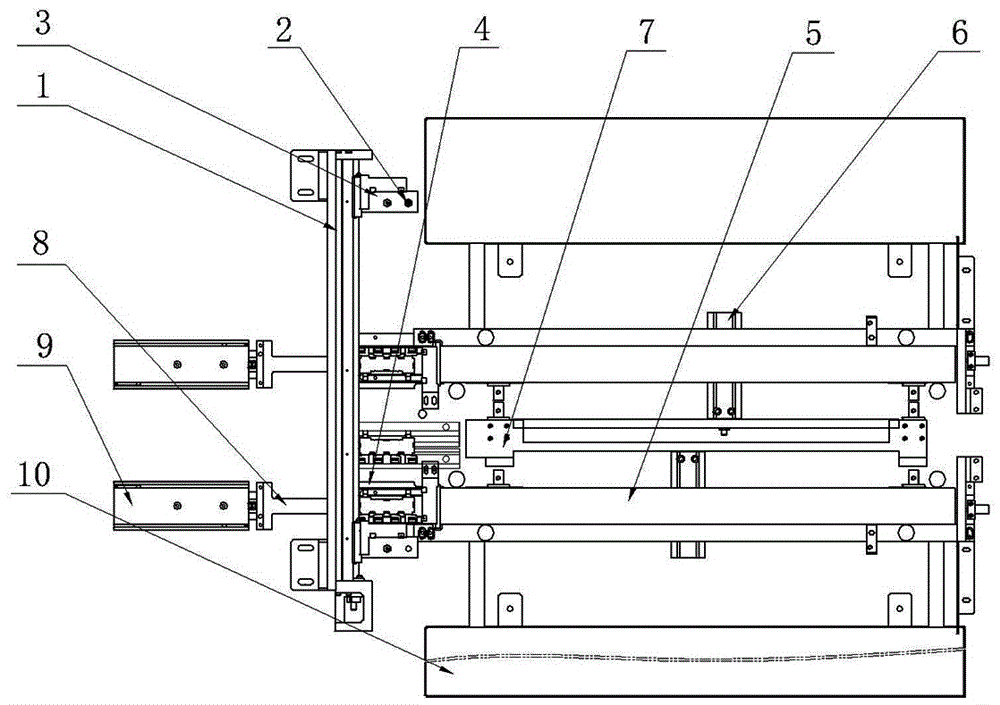

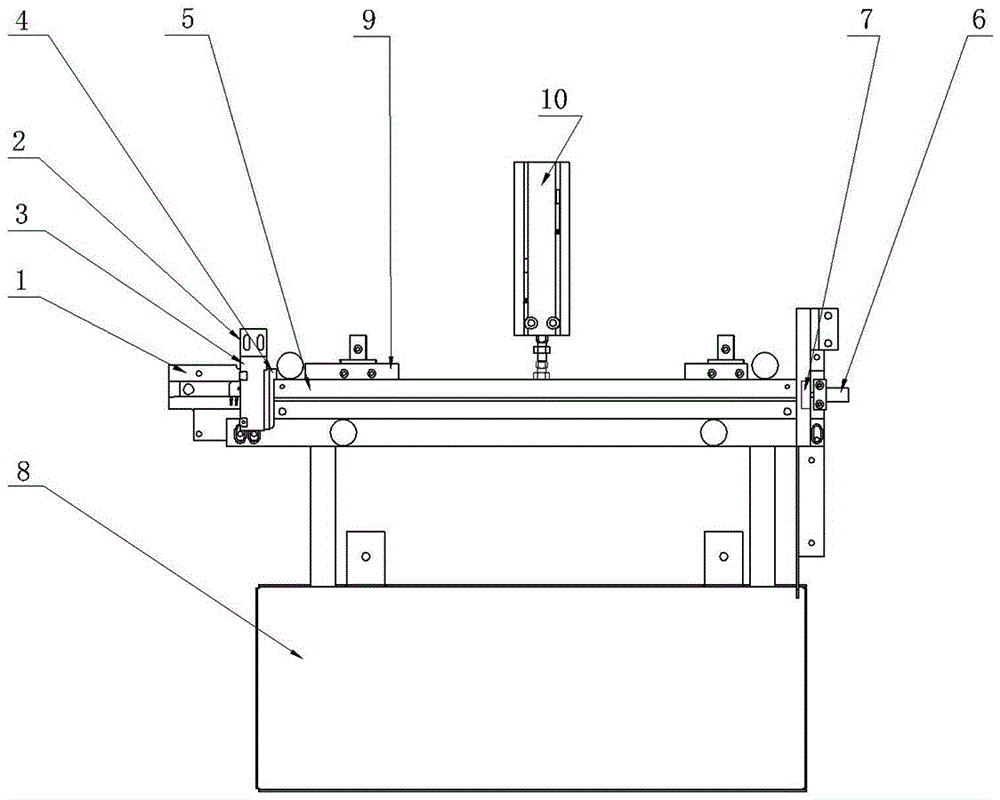

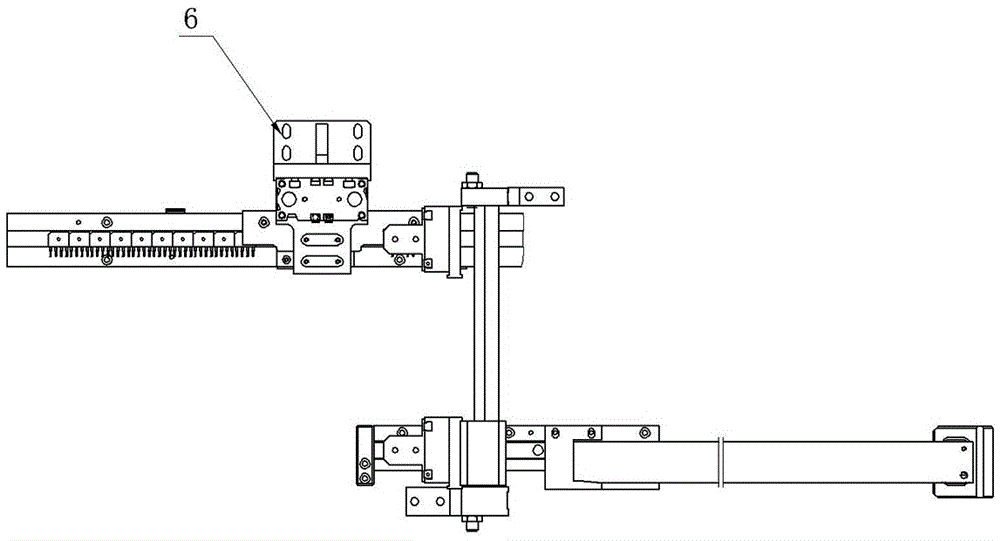

Material receiving mechanism used for manufacturing semiconductor module and working method of mechanism

InactiveCN106169436ATimely responseImprove work efficiencySemiconductor/solid-state device manufacturingConveyor partsTime efficientSemiconductor

The invention discloses a material receiving mechanism for manufacturing semiconductor modules, which mainly relates to the technical field of semiconductor manufacturing, including a linear module, a suction nozzle, a material receiving track, a material receiving pipe, a material pipe pushing block, a pushing plate, a pushing material cylinder and material receiving barrel; one end of the linear module is connected with a suction nozzle, and the two ends of the material receiving track are respectively connected with the linear module and the material receiving pipe; one side of the material receiving track is sequentially connected with a push plate and a push material cylinder, the two sides of the material receiving pipe are respectively provided with a material pipe push block and a material receiving barrel; the overall structure and operation process of the material receiving mechanism of the present invention are very simple, the maintenance is convenient and fast, the cost is low, and its degree of automation is high. The operation is simple and can ensure long-term efficient and stable operation. The invention also discloses a working method of a material receiving mechanism for manufacturing semiconductor modules.

Owner:TAICANG GAOCHUANG ELECTRICAL TECH

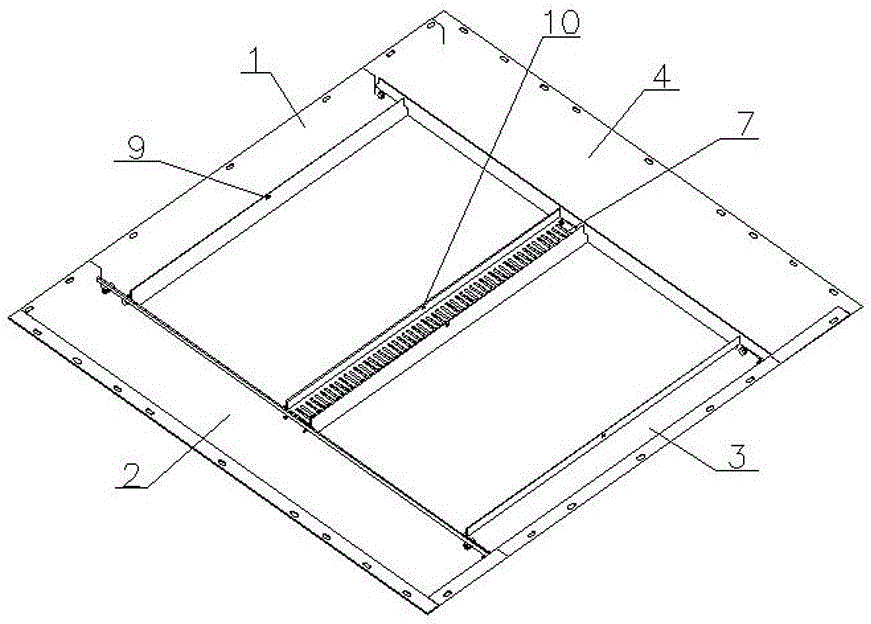

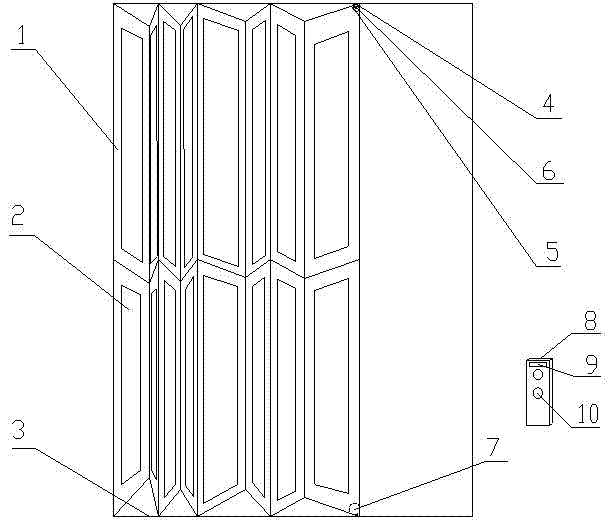

Remote control type foldable screen window

InactiveCN102817549ALittle effortFlexible useInsect protectionPower-operated mechanismRemote controlEmbedded system

The invention relates to a remote control type foldable screen window, comprising a framework (1), a window screening (2), a window rail (3) and pulleys (7). The pulleys (7) are arranged at the upper end and the lower end of one side of the framework (1); and the framework (1) consists of n mutually-connected framework bodies. The remote control type foldable screen window further comprises a remote control device; the remote control device consists of a remote controller (8) and a driving device (4), wherein the driving device (4) comprises signal receivers (6) arranged on the pulleys (7) and a driver (5) communicated with the pulleys (7); and the remote controller comprises a signal emitter (9) and a switch (10). According to the remote control type foldable screen window provided by the invention, the screen window can be stretched through a remote control device on the screen window, namely the screen window can be entirely unfolded, and be folded without use. The remote control type foldable screen window has the advantages of simple structure, firm structure and flexible use, can be used together with various windows, and is convenient for people to use.

Owner:WUXI INST OF COMMERCE

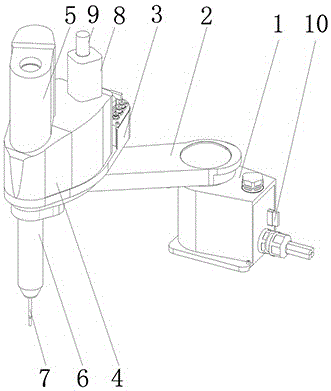

Intelligent automatic welding manipulator

InactiveCN106078026AImprove reliabilityImprove stabilityProgramme-controlled manipulatorWelding/cutting auxillary devicesProgrammable logic controllerEngineering

The invention discloses an intelligent automatic welding manipulator, which mainly relates to the technical field of manipulators. The intelligent automatic welding manipulator comprises an engine base, a first articulated arm, a second articulated arm, a sliding sleeve and a welding gun. Two ends of the first articulated arm are respectively connected with the engine base and the second articulated arm in a matching way; the first articulated arm and the second articulated arm are respectively driven through a servo motor arranged inside the engine base; a fixing seat is connected to an upper surface of the second articulated arm; the upper part of the sliding sleeve penetrates through the second articulated arm and is connected with the fixing seat in a matching way; a lifting motor is connected to the top part of the sliding sleeve; the welding gun is fixedly connected into the sliding sleeve; the lower end of the welding gun penetrates through a through hole formed in the bottom part of the sliding sleeve; the engine base is respectively connected with a PLC (Programmable Logic Controller) and a display panel; and an automatic warning device connected with the display panel is arranged at one side of the engine base. The intelligent automatic welding manipulator provided by the invention is high in workpiece positioning accuracy and welding efficiency, and convenient to operate, can manufacture products with excellent performance, and is simple in overall structure, convenient to assemble, disassemble and maintain, and low in manufacturing and operating cost.

Owner:JIANGSU JIEDI ROBOT

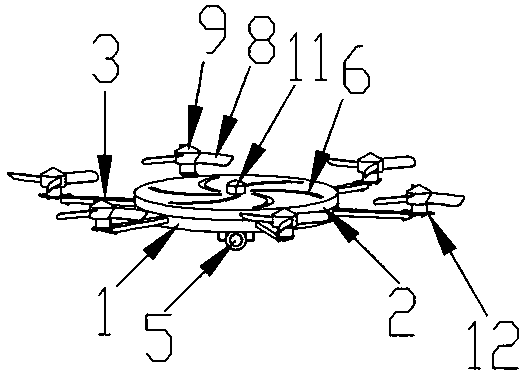

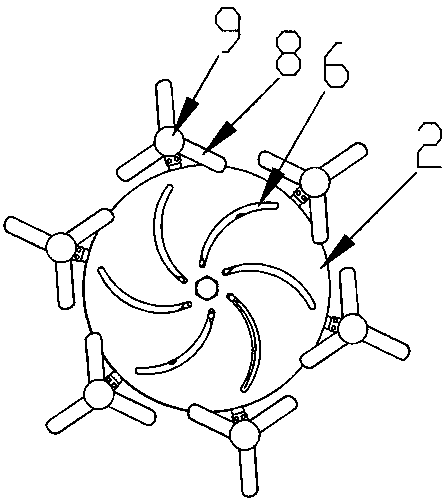

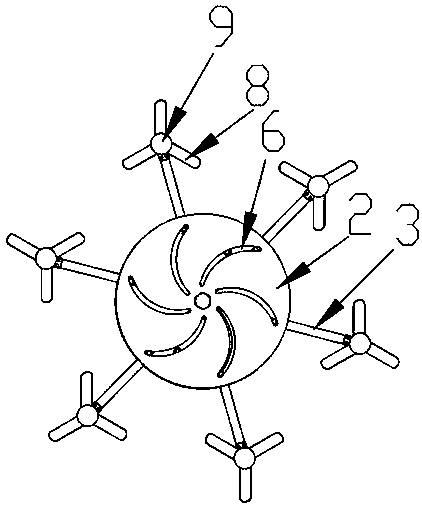

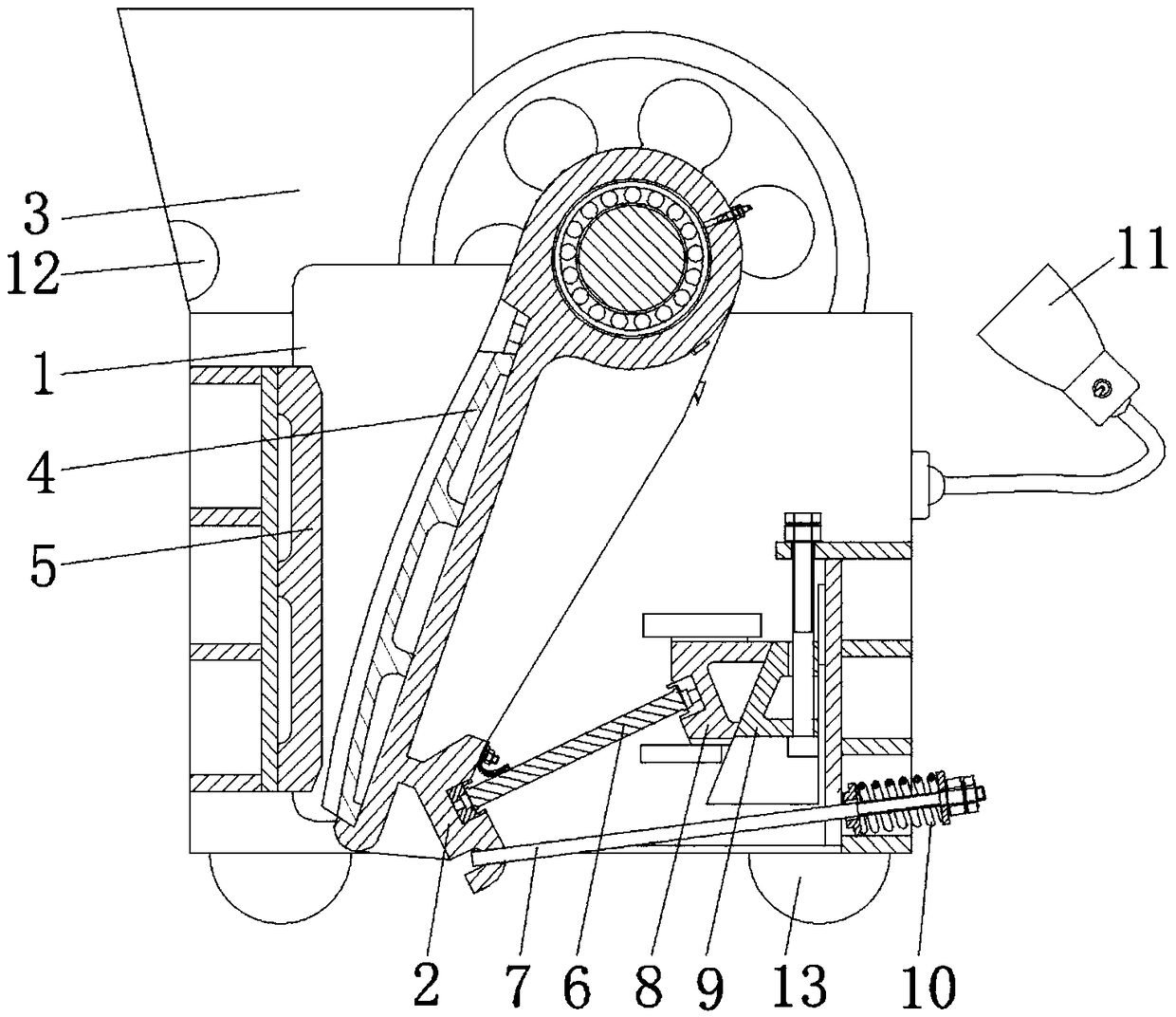

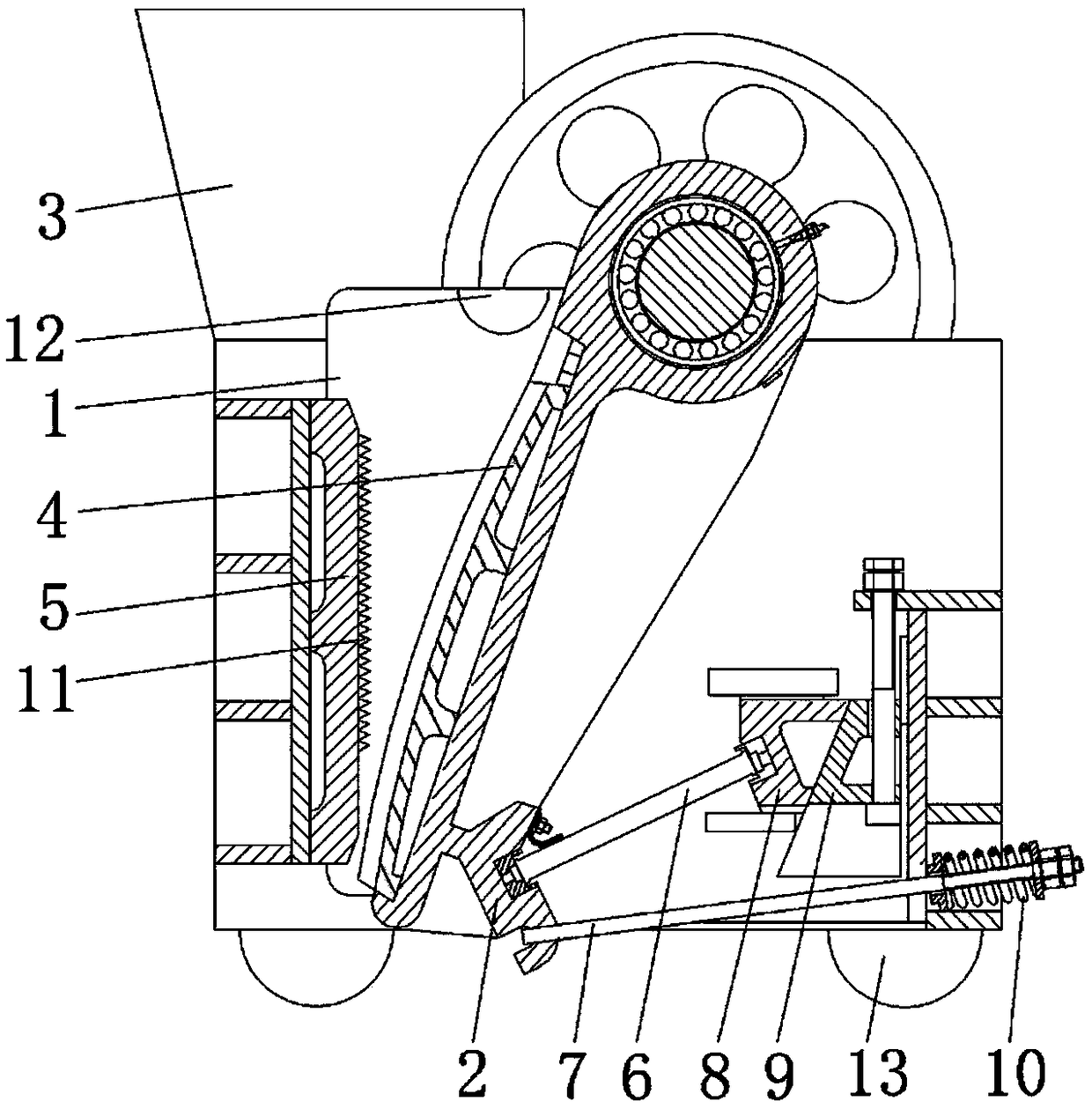

Telescopic rotor and aircraft based on rotor

The invention discloses a telescopic rotor and an aircraft based on the rotor. The rotor comprises a rotor shaft, a chassis, a main drive motor and a drive disc which is driven by the main drive motorto rotate, wherein an arc-shaped slide slot is formed in the drive disc; a T-shaped slide slot is formed in the chassis; and the front end of the rotor shaft can be equipped with a flange which can simultaneously slide in the arc-shaped slide slot and the T-shaped slide slot without drop. On the premise of guaranteeing requirements of flight, the flange at the front end of the rotor shaft bears tangential force in the rotor shaft ring through the arc-shaped slide slot in the drive disc when the main drive motor drives the drive disc to rotate, so that power is provided for simultaneously sliding the rotor shaft in the arc-shaped slide slot and the T-shaped slide slot, and therefore, the rotor shaft linearly moves in the T-shaped slide slot, and the rotor shaft is controlled to extend andshrink relative to the drive disc. Radial extension and shrinkage of the rotor shaft can change ascending force and descending force of the aircraft, so that the aircraft can fly in a complex environment, and therefore, obstacle avoiding ability and reachable range are greatly increased.

Owner:LUOYANG INST OF SCI & TECH

Crushing device with illumination function for building materials

InactiveCN108906183AGood weather resistanceExtended service lifeGrain treatmentsTime efficientEngineering

The invention discloses a crushing device with the illumination function for building materials, and mainly relates to the technical field of crushers. According to the crushing device, a fixed toothplate is fixed on one side of a machine frame, a movable tooth plate is fixedly connected to a movable jaw, an adjusting mechanism comprises a toggle plate, a pull rod, a toggle plate base, adjustingtapered iron and a spring, one end of the pull rod is connected to a hook at the lower part of the movable jaw, the other end of the pull rod is connected to the spring in a sleeved mode, the movablejaw is connected to the toggle plate base in a matched mode through the toggle plate, the toggle plate base is connected to the adjusting tapered iron in a sliding mode, the surface of the machine frame is coated with a self-luminous layer, and the self-luminous layer is made of a long-afterglow luminescent material. The crushing device has the advantages that the whole structure is very simple, carrying is easy and labor-saving, the maintenance is convenient and fast, the cost is low, meanwhile, the convenient illumination function is achieved, the labor amount of workers is small, and long-time efficient and stable operation can be kept.

Owner:太仓市太丰船舶钢梁建筑有限公司

Supply mechanism for producing flat bridge and working method of supply mechanism

The invention discloses a feeding mechanism for producing flat bridges, and mainly relates to the technical field of bridge rectifiers; The tube cylinder, the rotating tube group and the tube jacking cylinder are all installed on the feeding panel; the material tube is arranged in the magazine and connected with the tube pushing plate; the tube jacking cylinder is connected with the tube jacking block The riser cover plate and the riser bottom plate are connected by a riser vertical plate, and the feeding track is installed on the riser bottom plate; the riser cylinder is connected to the bottom of the riser bottom plate, and the front end of the guide plate is connected The material pipes are connected; the overall structure and operation process of the feeding mechanism of the present invention are very simple, convenient and fast maintenance, low cost, high degree of automation, simple operation by personnel, and can ensure long-term efficient and stable feeding. The invention also discloses a working method of a feeding mechanism for producing flat bridges.

Owner:TAICANG GAOCHUANG ELECTRICAL TECH

Safe and durable type jaw crushing device

The invention discloses a safe and durable type jaw crushing device and mainly relates to the technical field of crushing machines. One end of a pull rod is connected with a hook position of the lowerpart of a moving jaw, and a spring sleeves the other end of the pull rod; the moving jaw is matched and connected with a toggle plate seat through a toggle plate; the toggle plate seat is in slidingconnection with an adjustment tapered iron; a force sensor is connected with the moving jaw and a display respectively; the surface of a rack is provided with a protective layer; and the protective layer is formed by an acid and alkali corrosion resistance layer, a high temperature resistance layer and a wear resistance layer. The safe and durable type jaw crushing device is very simple in whole structure, convenient and rapid to maintain and low in cost, enables an operator to conveniently monitor a running state of the safe and durable type jaw crushing device and is very good in safety andsealing effect and long in service life.

Owner:太仓市鼎祥五金制品厂

Material collecting mechanism used for producing flat bridge and working method for material collecting mechanism

InactiveCN106144617AEfficient and stable receivingImprove securityStacking articlesBridge typeEngineering

The invention discloses a material collecting mechanism used for producing a flat bridge, and mainly relates to the technical field of bridge type rectifiers. The material collecting mechanism comprises a material collecting rail, a pressure tube air cylinder rack, a pressure tube air cylinder, a material tube positioning block, a material tube, a tube jacking air cylinder, a tube jacking block, a tube collecting box, a material tube pushing plate and a tube pushing air cylinder; the material collecting rail, the pressure tube air cylinder rack and the pushing tube air cylinder are directly mounted on an external rack panel; the material tube pushing plate is connected to an output shaft of the pushing tube air cylinder in a matched manner; the tube jacking block connected at the front end of the tube jacking air cylinder abuts against one end of the material collecting rail; the material tube positioning block is fixedly arranged at the lower end of the pressure tube air cylinder; and the tube collecting box is arranged at one side of the material tube. The material collecting mechanism disclosed by the invention is very simple in integral structure and operation process, is quick and convenient to maintain and repair, is low in cost, is high in degree of automation, is simple in personnel operation, and can guarantee long-time, efficient and stable discharge. The invention further discloses a working method for the material collecting mechanism used for producing the flat bridge.

Owner:TAICANG GAOCHUANG ELECTRICAL TECH

Printing and testing mechanism and working method thereof for flat bridge production

InactiveCN106346959AEasy to operateImprove printing efficiencyMaterial analysis by optical meansTypewritersLaserRectifier

The invention discloses a printing and testing mechanism for flat bridge production, which mainly relates to the technical field of bridge rectifiers; the printing mechanism includes: a printing bottom plate, a printing vertical plate, a switch cylinder, a material blocking cylinder and a laser printer; the printing The bottom plate and the printing vertical board are connected to each other and fixed on the frame panel together; the laser printer is installed on the printing vertical board, and the switch cylinder and the stopper cylinder are connected to one side of the frame panel; the testing mechanism includes : test frame, material lowering cylinder frame, material lowering block and material lowering cylinder; the test frame is provided with an image system, and the front end of the material lowering cylinder frame is equipped with a material lowering block and a material lowering cylinder; the overall structure of the mechanism of the present invention Its operation process is very simple, its maintenance is convenient and fast, its cost is low, its automation degree is high, its operation is simple, and its printing efficiency and printing quality are very high. The invention also discloses a working method of a printing and testing mechanism for flat bridge production.

Owner:TAICANG GAOCHUANG ELECTRICAL TECH

Environment-friendly extrusion forming device and working method thereof

InactiveCN106182876AImprove delivery efficiencyAvoid influenceThermal insulationNon-rotating vibration suppressionHydraulic cylinderFixed frame

The invention discloses an environment-friendly extrusion forming device, and mainly relates to the technical field of mechanical equipment. A feed hopper is connected with a raw material tank through a feeding pipe, and the bottom of the feed hopper communicates with a through hole in the top of a material containing box. A hydraulic cylinder drives a feeding box to slide back and forth through a push rod. An operation table is connected with a fixed frame through a stand column. A telescopic rod is in sliding connection with the fixed frame. A heating tank is arranged in the middle of the operation table. The upper portion and the lower portion of the heating tank are provided with an upper ejector rod and a lower ejector rod correspondingly, and the upper ejector rod is fixedly connected with the telescopic rod. The feeding box is in sliding connection with the operation table, and a through hole corresponding to the heating tank is formed in the bottom of the feeding box. A set of rubber pads is arranged at the bottom of a rack. A recycling box is fixedly connected with the operation table in an embedded manner, and handles are arranged on the two sides of the recycling box. The environment-friendly extrusion forming device is quite simple in overall structure and operating process, convenient and fast to maintain, low in cost, capable of automatically recycling finished products, economical, environment-friendly and long in service life. The invention further discloses a working method of the environment-friendly extrusion forming device.

Owner:TAICANG BEST MECHANICAL EQUIP

Jaw crushing device with pulleys

InactiveCN109012813AImprove cooling effectPrevent accidents such as fireGrain treatmentsCrusherPulley

The invention discloses a jaw crushing device with pulleys, and mainly relates to the technical field of crushers. An adjusting mechanism comprises a bracket, a pull rod, a bracket base, adjusting tapered iron and a spring, one end of the pull rod is connected with a lower hook of a movable jaw, the other end of the pull rod is sleeved with the spring, the movable jaw is in cooperation connectionwith the bracket base through the bracket, and the bracket base is in sliding connection with the adjusting tapered iron. A cooling mechanism is connected with a cooling liquid box arranged in a machine frame through a plastic pipe and a water pump. The head of the cooling mechanism can rotate by 180 degrees. The jaw crushing device is very simple in overall structure, easy to carry in a labor-saving mode, convenient and fast to maintain and low in cost and has a convenient cooling function, and the crushing quality and the crushing efficiency are very high.

Owner:太仓市鼎祥五金制品厂

A corn stalk crushing and recycling baler

The invention discloses a cornstalk smashing recycling press-baler. The cornstalk smashing recycling press-baler is characterized by comprising a main transmission device, a first transmission mechanism, a second transmission mechanism, a cornstalk picking smashing device (13), a cornstalk press-baling device (18), and an auger device, wherein the main transmission mechanism is connected with an external power device and installed on a draft arm (19), the first transmission mechanism is connected with the main transmission device, the second transmission mechanism is connected with the main transmission device, the cornstalk picking smashing device (13) is connected with the draft arm (19) and connected with the main transmission device through the first transmission mechanism, the cornstalk press-baling device (18) is connected with the draft arm (19) and connected with the main transmission device through the second transmission mechanism, and the auger device is installed between the cornstalk picking smashing device (13) and the cornstalk press-baling device (18) and connected with the second transmission mechanism through a third transmission mechanism. The cornstalk smashing recycling press-baler can be used for cutting or picking, smashing, recycling, compressing and baling stand cornstalks, cornstalks which are cut off and cornstalks which are wasted by a header of a combine-harvester in the field. The cornstalk smashing recycling press-baler is simple in structure and high in efficiency.

Owner:孙首泉

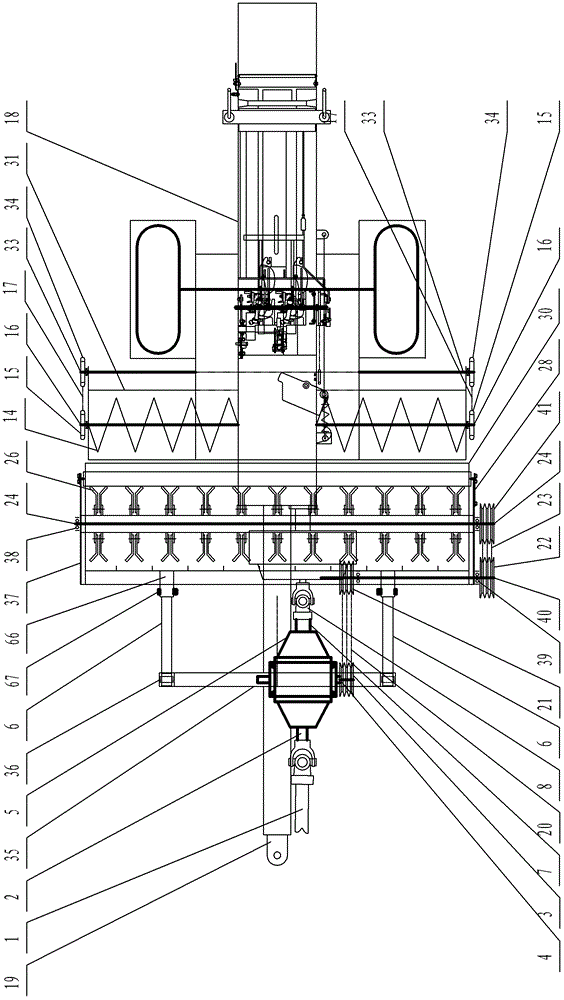

Suspended type baler

Owner:孙首泉

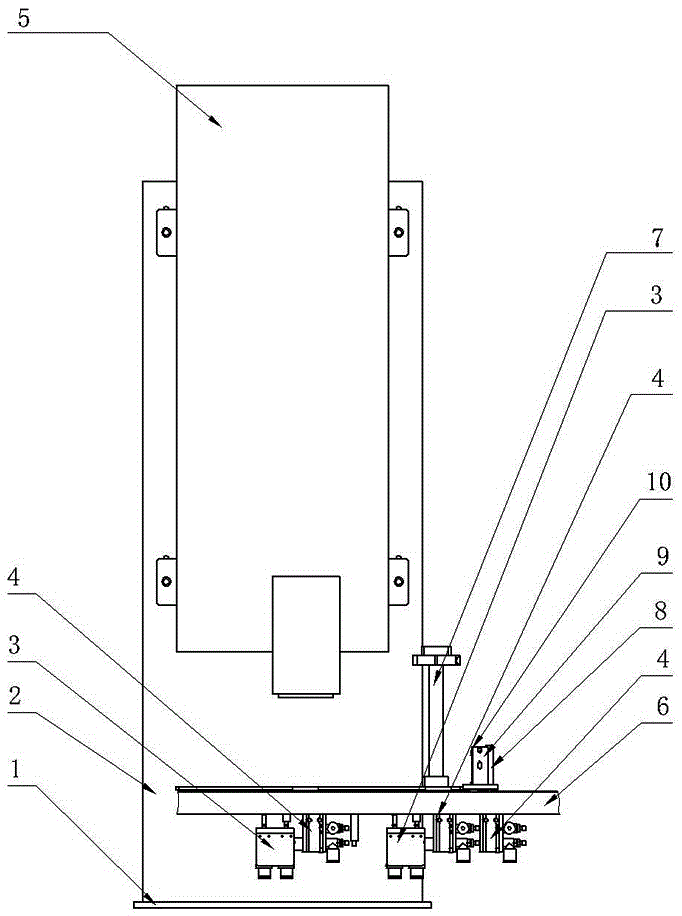

High voltage test mechanism used for producing flat bridge and working method thereof

The invention discloses a high voltage test mechanism used for producing a flat bridge, and mainly relates to the technical field of bridge rectifiers. The high voltage test mechanism comprises a double-switch cylinder, a lower electrode, an upper internal electrode, an upper external electrode, a high voltage test base, a high voltage test cylinder base, a high voltage test cylinder, a track and a material blocking cylinder. The double-switch cylinder and the material blocking cylinder are fixed at one side of the track. The track and the high voltage test cylinder base are fixed on a rack panel. The high voltage test base is installed at the lower end of the high voltage test cylinder. The upper internal electrode and the upper external electrode are installed on the high voltage test base in parallel. An insulating layer is arranged between the lower electrode and the track. The high voltage test mechanism is quite simple in overall structure and operation process, convenient and rapid in maintenance, low in cost, high in degree of automation and simple in manual operation and can guarantee long-time and high-efficiency stable testing. The invention also discloses a working method of the high voltage test mechanism used for producing the flat bridge.

Owner:TAICANG GAOCHUANG ELECTRICAL TECH

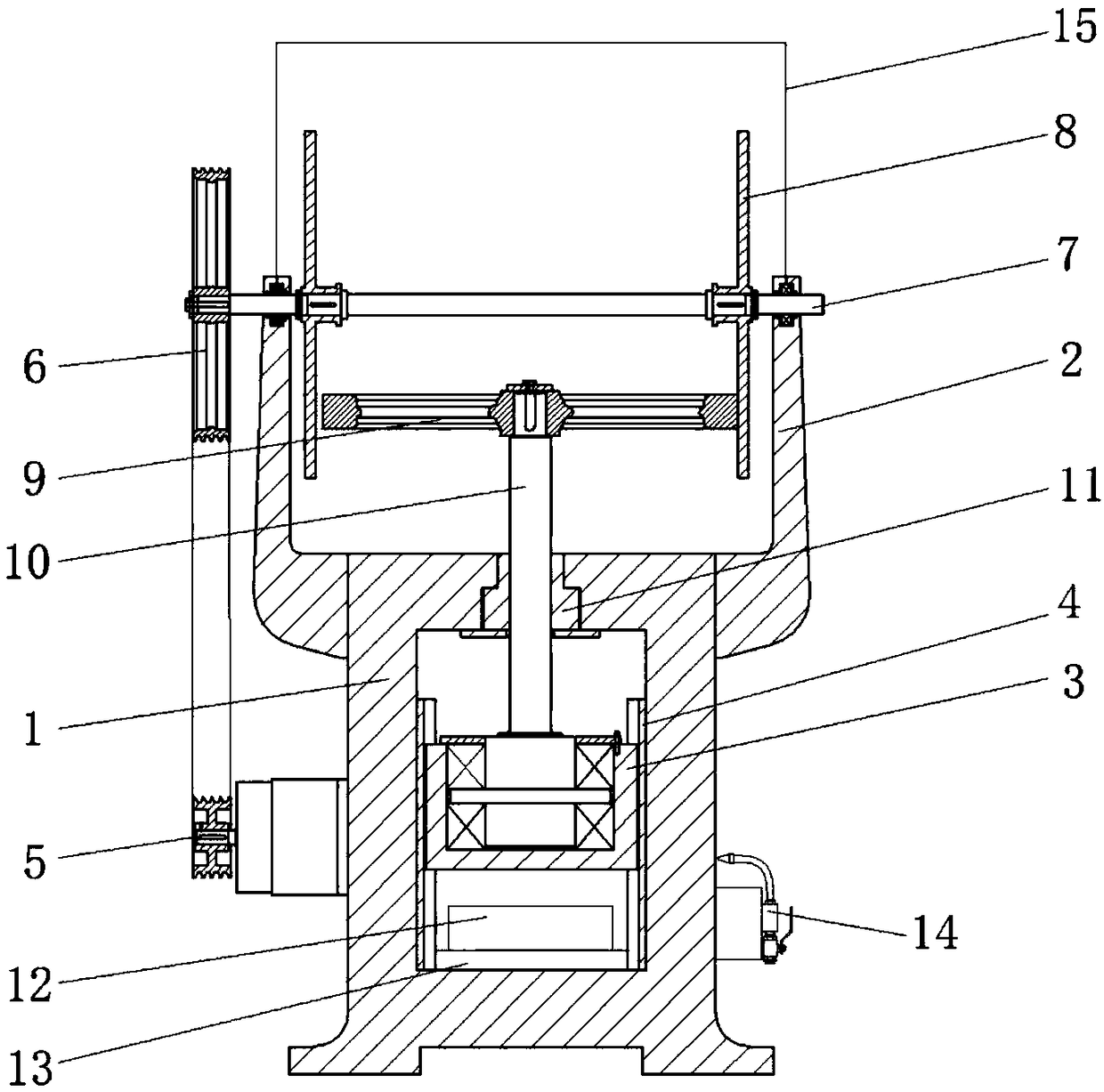

An Efficient Dyeing and Finishing Cloth Dehydration Device

ActiveCN110863311BDehydration safeImprove structural stabilityLiquid/gas/vapor removal by centrifugal forceAlarmsWater immersionElectric machinery

The invention belongs to the technical field of dehydration equipment structure, and in particular relates to an efficient dehydration device for dyeing and finishing fabrics. In the present invention, a drive motor is arranged above the casing, and a ring groove unit, a support column unit, an installation ring unit, an inclination warning unit and an overweight warning unit are arranged on the lower surface of the main body of the dehydration drum to achieve efficient and safe dehydration. Effect. The invention has the advantages of reasonable and effective dehydration structure, the motor is not easy to be corroded by water immersion, the early warning effect is good when the drum is overweight or tilted, the early warning structure is simple and flexible, does not affect the normal dehydration operation, and the overall structure of the dehydration device has high stability and is convenient for loading, unloading and maintenance.

Owner:FUJIAN HANGGANG TEXTILE TECH CO LTD

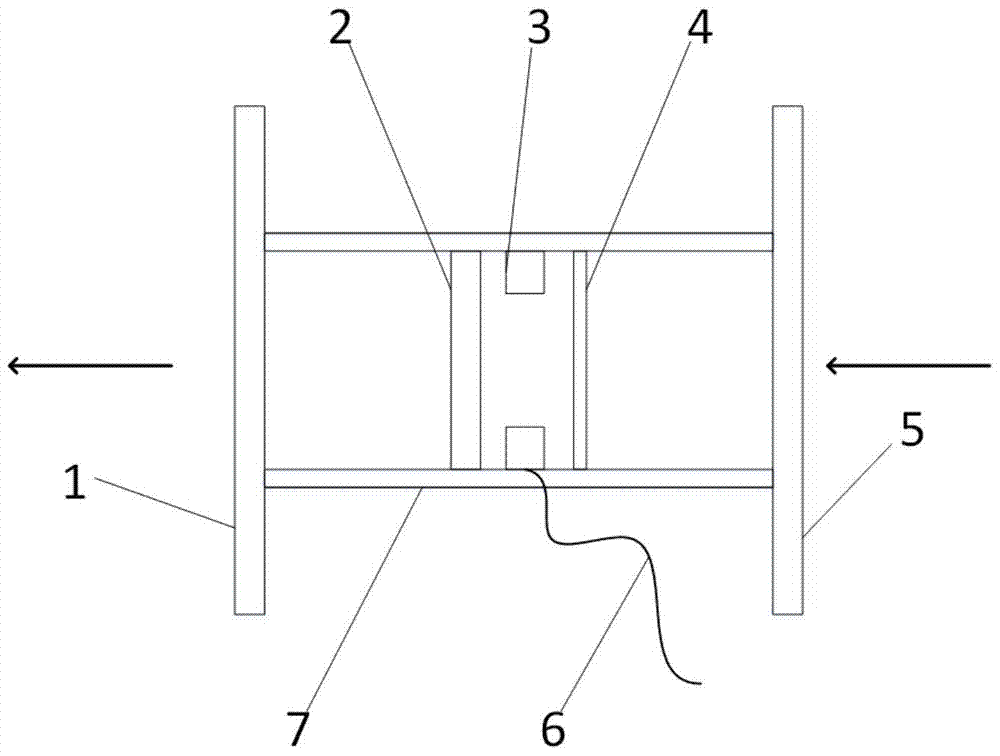

A fast filter device for low viscosity liquid

ActiveCN105381642BIncrease the differential pressureIncrease flow rateSemi-permeable membranesStationary filtering element filtersUltrasonic cavitationFilter media

The invention discloses a rapid filtering apparatus used for a low viscosity liquid. The apparatus comprises a pipeline, an inlet flange plate arranged at the inlet of the pipeline, and an outlet flange plate arranged at the outlet of the pipeline, a filter membrane, an ultrasonic cavitation generator and a porous filtering medium are arranged in the pipeline along a liquid flow direction, the ultrasonic cavitation generator is arranged on the inner wall of the pipeline between the filter membrane and the porous filtering medium, and the frequency of the ultrasonic cavitation generator is adjustable. And low pressure and jetting effects of cavitation bubbles generated in a space between the elastic filtering membrane and the rigid porous filtering medium is used to improve a pressure difference between two sides of the filtering membrane, accelerate the flow velocity of a filtration liquid, accelerate the filtering permeation effect and improve the permeability and the filtering efficiency.

Owner:ZHEJIANG UNIV

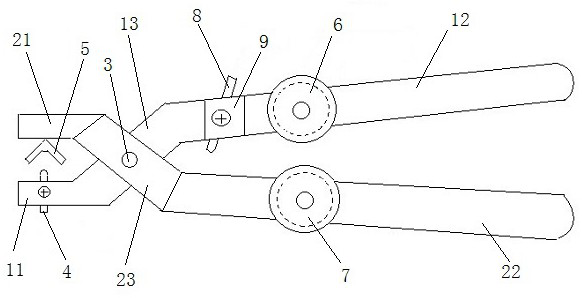

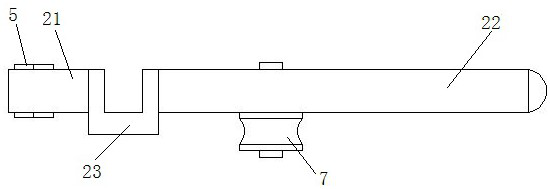

Portable secondary cable stripping knife

PendingCN113972597ARealize the circumcision functionImprove work efficiencyApparatus for removing/armouring cablesTool bitStructural engineering

The invention provides a portable secondary cable stripping knife, which comprises a lever A and a lever B. The portable secondary cable stripping knife is characterized in that: the lever A is composed of a working part A, a handheld part A and a hinge part A, the lever B is composed of a working part B (21), a handheld part B (22) and a hinge part B (23), the middle of the hinge part B is hinged to the middle of the hinge part A through a pin shaft, a vertically upward tool bit A is arranged at the left end of the upper surface of the working part A, a positioning groove with a downward opening is formed in the left end of the lower surface of the working part B, and the axis of the positioning groove is parallel to the axis of the pin shaft; and a rotatable guide wheel A is arranged in the middle of one side face of the handheld part A, and a tool bit B is arranged on one side of the guide wheel A. According to the invention, girdling and side cutting of the sheath of the secondary cable can be rapidly realized, the process is safe and stable, the efficiency is high, and the portable secondary cable stripping knife has the advantages of convenience in carrying, simplicity in operation and adaptability to conventional secondary cables with different wire diameters.

Owner:国网河南省电力公司宜阳县供电公司 +1

A high-efficiency and rapid production process method for needle-punched composite fabrics

ActiveCN110789214BImprove structural stabilityWide adaptabilityNon-macromolecular adhesive additivesStarch adhesivesAdhesiveAcupuncture

The present invention is a composite fabric technology field, and especially involves an efficient and fast production process of acupuncture composite fabrics.The present invention can be used to add electric heating machine devices to the method of heating and removing water after the adhesive coating. The same adhesive can be applied to different types of acupuncture adhesion after regulating the moisture content.Purpose.The present invention has a reasonable and effective effect of acupuncture cotton bonding composite process, wide adaptability of water -based bonding agent, and after adjustment of the hydration rate of binders, it is applicable to different types of acupuncture bonding composite.It can meet the requirements of removing water from different times before bonding, as well as the advantages of high structural stability of the electric heating machine, which is convenient for loading and unloading and maintenance.

Owner:FUJIAN HANGGANG TEXTILE TECH CO LTD

An intelligent automatic discharge device and its working method

ActiveCN106082072BReduce laborImprove work efficiencyFilling without pressureDisplay deviceEngineering

The invention discloses an intelligent automatic discharging device and mainly relates to the technical field of mechanical equipment. A motor is arranged on the top of a material storage box. One end of a feeding pipe is connected with a discharging box, and the other end of the feeding pipe is connected with the material storage box. The bottom of the discharging box is provided with a group of discharging ports. The lower portions of pull rods are connected with the discharging ports in a sliding manner. The tops of the pull rods penetrate a fixing seat to be connected with an air cylinder in a matched manner. A group of material receiving bottles corresponding to the discharging ports are embedded in the surface of a material receiving box. A machine frame is successively connected with the discharging box and the material receiving box. The fixing seat and a fixing plate are successively connected to the top of the discharging box. The bottom of a connecting frame is connected with the fixing plate. The air cylinder is installed on the fixing seat. An intelligent control mechanism is connected with the discharging box, a feeding mechanism and a discharging mechanism in sequence. An automatic alarming device is arranged on the top of a displayer. The intelligent automatic discharging device is simple in integral structure, convenient to repair and maintain and low in cost and can efficiently and stably operate for a long time, and operators can conveniently monitor the operation state of the intelligent automatic discharging device. The invention further discloses a work method of the intelligent automatic discharging device.

Owner:TAICANG BEST MECHANICAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com