High-temperature-resistant friction press for hardware machining

A friction press, high temperature resistance technology, applied in the field of presses, can solve the problems of inability to guarantee the efficient and stable operation of stamping work, high manufacturing and operating costs, complex overall structure, etc., and achieve good cooling and cooling effect, manufacturing and operating costs. The effect of low cost and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

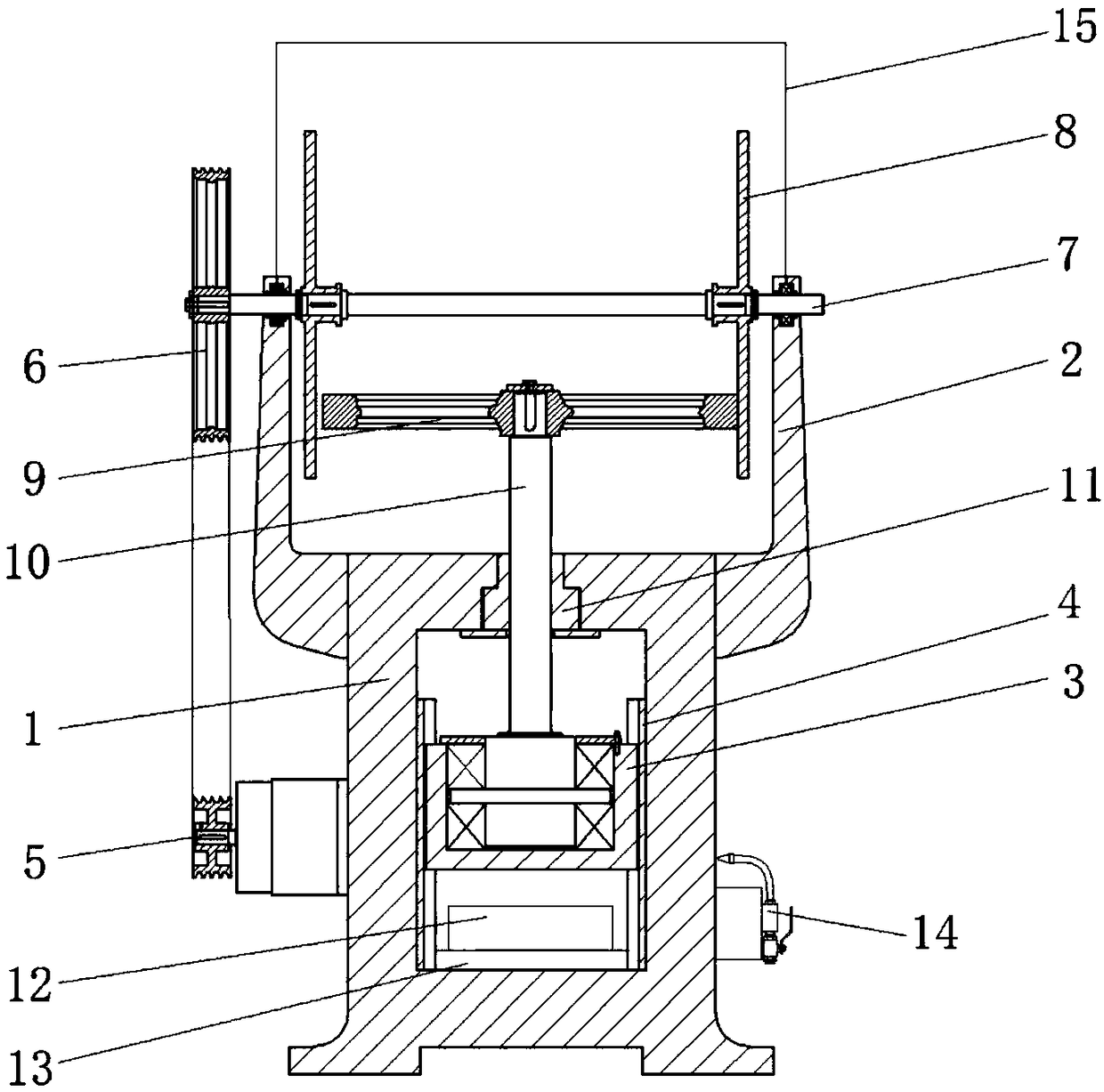

[0019] like figure 1 As shown, a high-temperature-resistant friction press for metal processing in this embodiment includes: a frame 1, a frame arm 2, a slider 3, a slide rail 4, a small pulley 5, a large pulley 6, a rotating shaft 7, Friction disc 8, flywheel 9, screw rod 10, nut 11, positioning mechanism 12, buffer pad 13, cooling mechanism 14 and protective cover 15.

[0020] The connecting relation of above-mentioned each parts is as follows: described frame 1 top two sides are symmetrically provided with frame arm 2, and described frame 1 middle part is respectively provided with slide rail 4 and positioning mechanism 12, and described positioning mechanism 12 and frame 1 A buffer pad 13 is arranged between them; the transmission mechanism includes a small pulley 5, a large pulley 6, a rotating shaft 7, a friction disc 8 and a flywheel 9; the upper end of the frame arm 2 is equipped with a rotating shaft 7, and the rotating shaft 7 The two ends of the inner side of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com