Material receiving mechanism used for manufacturing semiconductor module and working method of mechanism

A collection mechanism and semiconductor technology, which is used in semiconductor/solid-state device manufacturing, conveyor objects, electrical components, etc., can solve the problem of inability to ensure long-term efficient and stable operation, complicated operation process of the collection mechanism, and high manufacturing and operating costs. and other problems, to achieve the effect of low operating costs, low manufacturing and operating costs, and smooth and efficient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

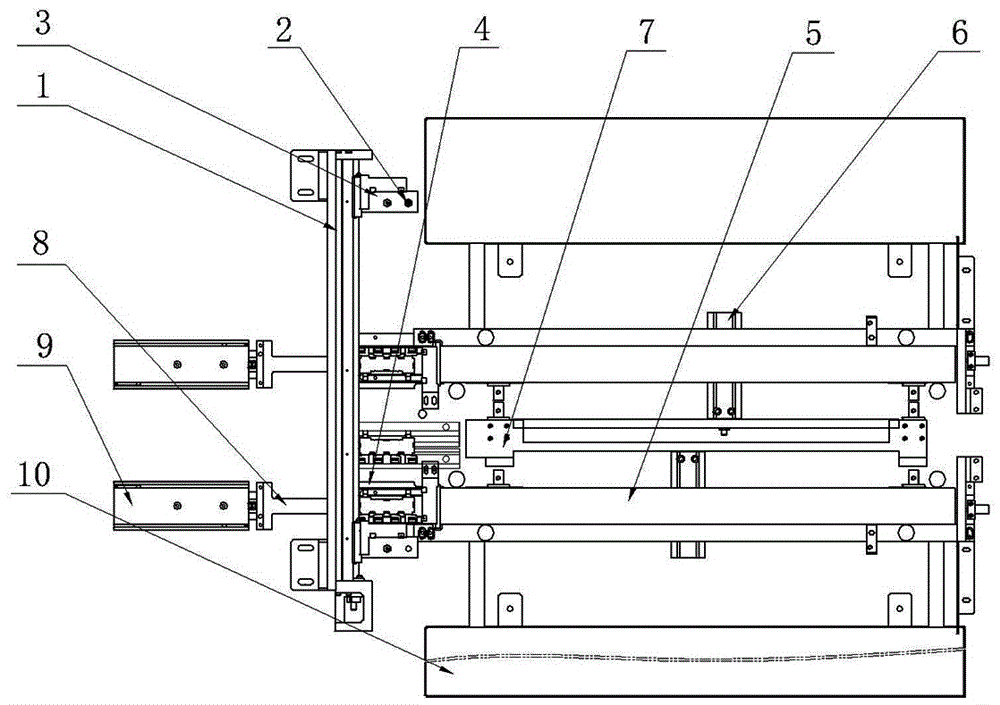

[0028] Such as figure 1 As shown, a material receiving mechanism for manufacturing semiconductor modules in this embodiment includes: a linear module 1, a suction nozzle 2, a suction nozzle cylinder 3, a material receiving track 4, a material receiving tube 5, a push tube cylinder 6, Material tube push block 7, push plate 8, push material cylinder 9 and material receiving bucket 10.

[0029] The connection relationship of the above-mentioned components is as follows: one end of the linear module 1 is connected with a suction nozzle 2, and the two ends of the receiving track 4 are respectively connected with the linear module 1 and the receiving pipe 5; one side of the receiving track 4 A push plate 8 and a material pushing cylinder 9 are connected in sequence, and a material tube push block 7 and a material receiving barrel 10 are respectively arranged on both sides of the material receiving tube 5 . Wherein the suction nozzle 2 is driven by the suction nozzle cylinder 3 conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com