Environment-friendly extrusion forming device and working method thereof

An extrusion molding and environment-friendly technology, which is applied in the direction of material forming presses, heat preservation, presses, etc., can solve the problems of high manufacturing and operating costs, short overall service life, and inability to recycle finished products, and achieve manufacturing and operating costs. Low cost, high raw material delivery efficiency, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

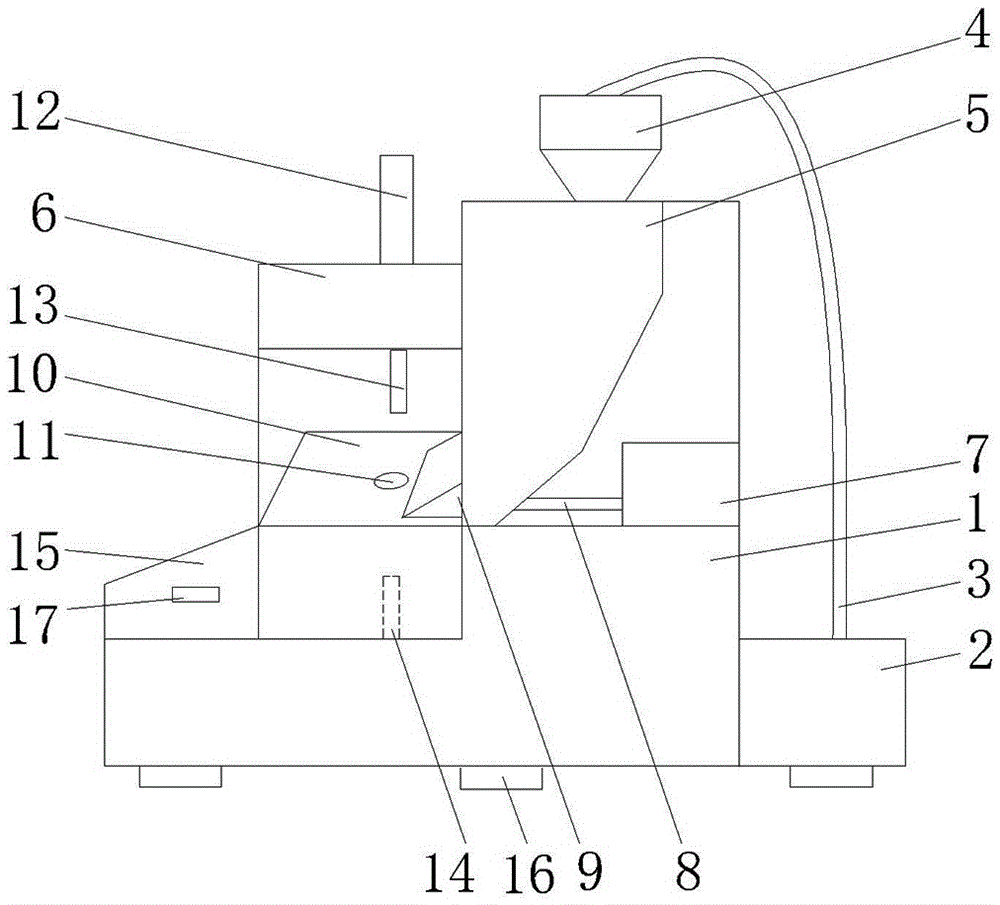

[0033] like figure 1 As shown, an environment-friendly extrusion molding device of this embodiment includes: a frame 1, a raw material trough 2, a feeding pipe 3, a hopper 4, a storage box 5, a fixed frame 6, a hydraulic cylinder 7, and a push rod 8 , Feed box 9, console 10, heating tank 11, telescopic rod 12, upper ejector rod 13, lower ejector rod 14, recovery bin 15, rubber mat 16 and handle 17.

[0034] The connection relationship of the above-mentioned components is as follows: the frame 1 is sequentially connected with a feeding mechanism, a feeding mechanism, a heating and forming mechanism and a recovery mechanism; Material box 5; the feeding hopper 4 is connected to the raw material tank 2 through the feeding pipe 3, and the bottom of the feeding hopper 4 is connected with the through hole at the top of the material holding box 5; the feeding mechanism includes: a hydraulic cylinder 7, a push rod 8 and the feeding box 9; the hydraulic cylinder 7 drives the feeding bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com