High voltage test mechanism used for producing flat bridge and working method thereof

A technology of high-voltage testing and flat bridge, which is applied in the field of high-voltage testing institutions, can solve problems such as the inability to guarantee long-term efficient and stable testing, the complicated operation process of high-pressure testing institutions, and high manufacturing and operating costs, so as to achieve the goal of not being prone to deviations and failures, The effect of high test efficiency and low manufacturing and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

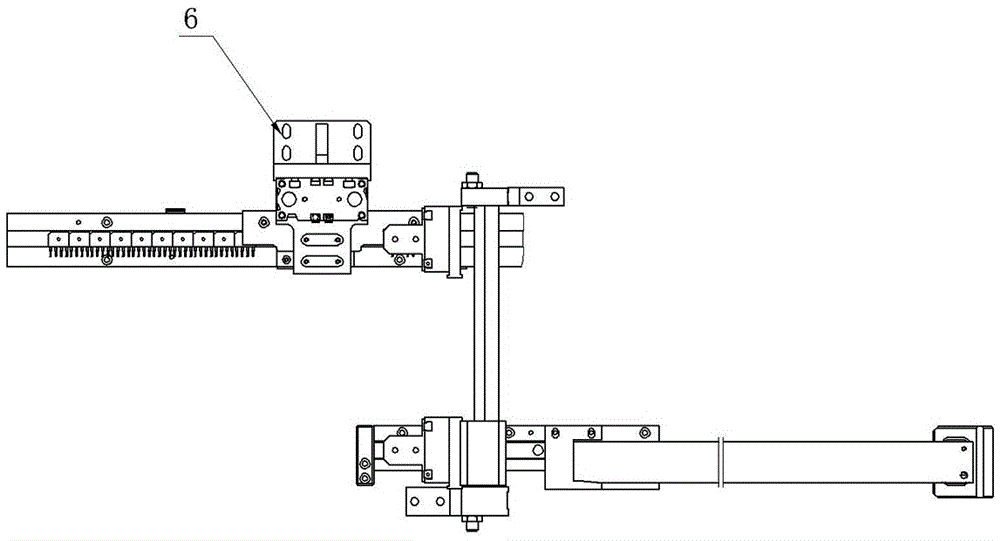

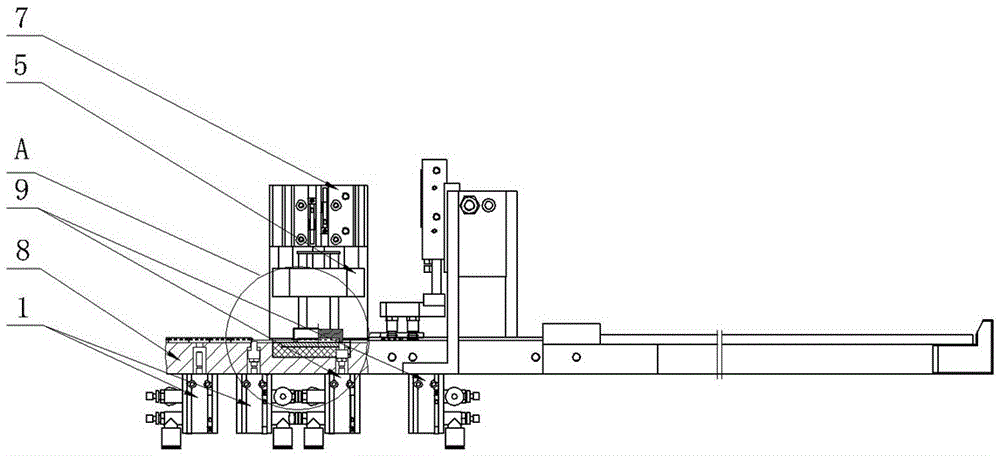

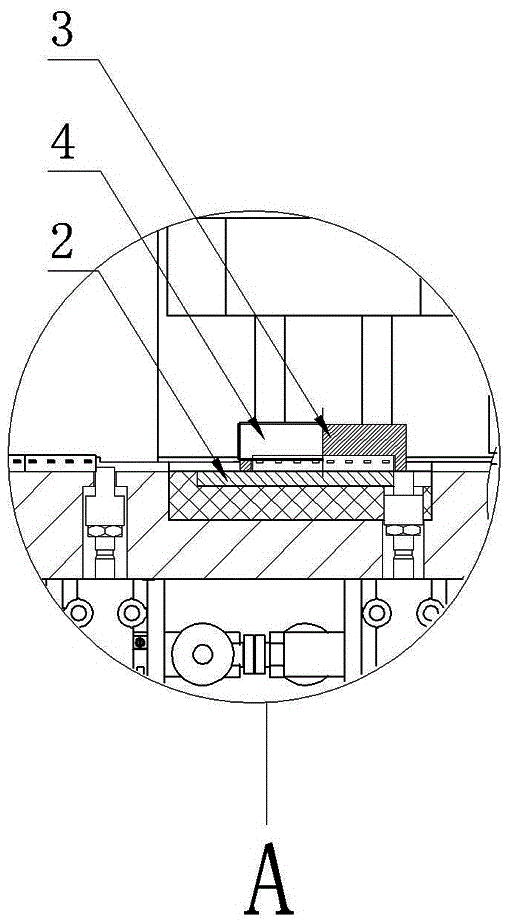

[0030] Such as Figure 1-Figure 3 As shown, a high-voltage test mechanism for producing flat bridges in this embodiment includes: switch cylinder 1, lower electrode 2, upper inner electrode 3, upper outer electrode 4, high-voltage test seat 5, high-voltage test cylinder seat 6, High pressure test cylinder 7, track 8 and material blocking cylinder 9.

[0031] The connection relationship of the above-mentioned components is as follows: the double switch cylinder 1 and the retaining cylinder 9 are all fixed on one side of the track 8, the track 8 and the high-voltage test cylinder seat 6 are all fixed on the frame panel, and the high-voltage test seat 5 is installed at the lower end of the high-voltage test cylinder 7; the upper inner electrode 3 and the upper outer electrode 4 are installed side by side on the high-voltage test seat 5, and an insulating layer is provided between the lower electrode 2 and the track 8. Wherein the upper inner electrode 3, the upper outer electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com