Jaw crushing device with pulleys

A jaw crushing and pulley technology, applied in grain processing, etc., can solve the problems of high manufacturing and operating costs, low crushing accuracy and efficiency, and rising temperature in the working area, and achieve low manufacturing and operating costs, convenient loading and unloading maintenance, and high crushing efficiency. The effect of capacity enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

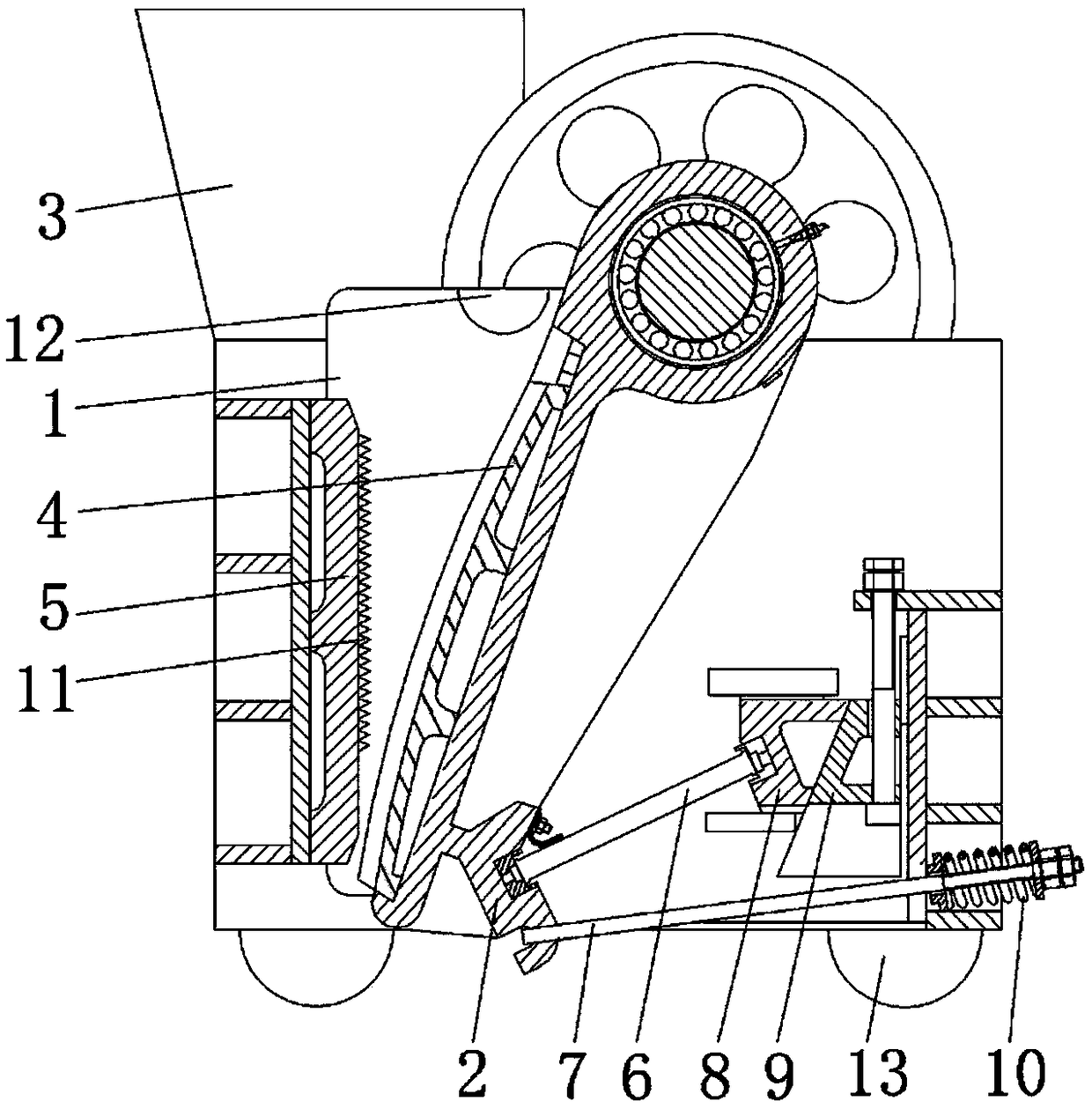

[0022] Such as figure 1 As shown, a jaw crushing device with pulleys in this embodiment includes: frame 1, movable jaw 2, feeding mechanism 3, movable tooth plate 4, fixed tooth plate 5, toggle plate 6, pull rod 7, toggle Board seat 8, adjusting inclined iron 9, spring 10, sawtooth 11, cooling mechanism 12 and pulley 13.

[0023] The connection relationship of the above-mentioned components is as follows: the frame 1 is sequentially connected with the feeding mechanism 3, the crushing mechanism, the adjustment mechanism and the cooling mechanism 12, and a group of pulleys 13 are arranged at the bottom; the crushing mechanism includes the movable jaw 2, movable teeth Plate 4, fixed tooth plate 5 and saw teeth 11, the fixed tooth plate 5 is fixed on one side of the frame 1, the movable tooth plate 4 is fixedly connected with the movable jaw 2, and the fixed tooth plate 5 is facing the movable tooth plate 4 There is a sawtooth 11 connected to one side of the side; the adjustment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com