Pneumatic device for detecting coaxiality of inner hole

A technology of pneumatic device and coaxiality, applied in measuring devices, instruments, etc., can solve the problems of insufficient length of dial indicator head and difficult to measure, and achieve stable and reliable clamping, high disassembly efficiency, and reduced labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

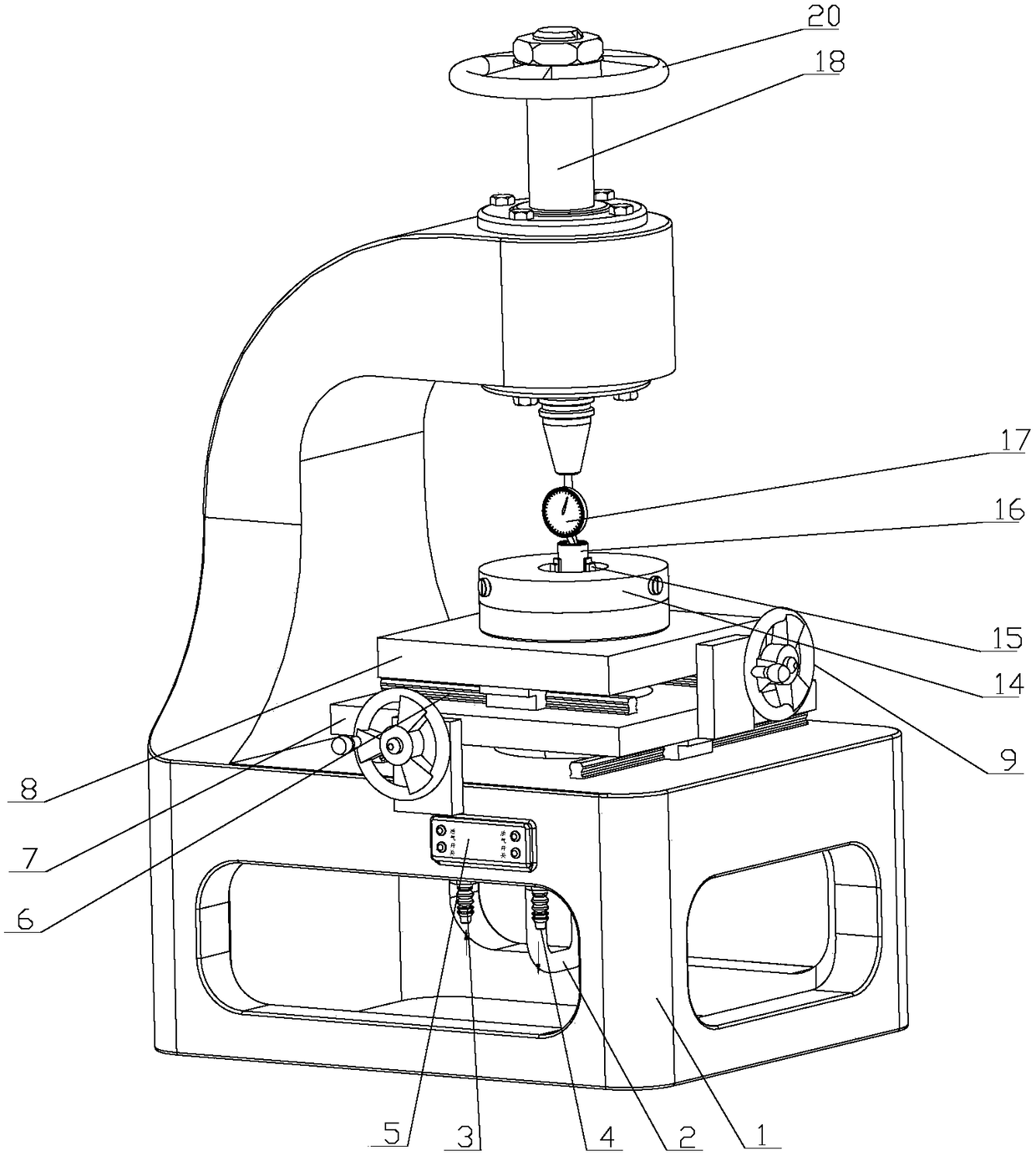

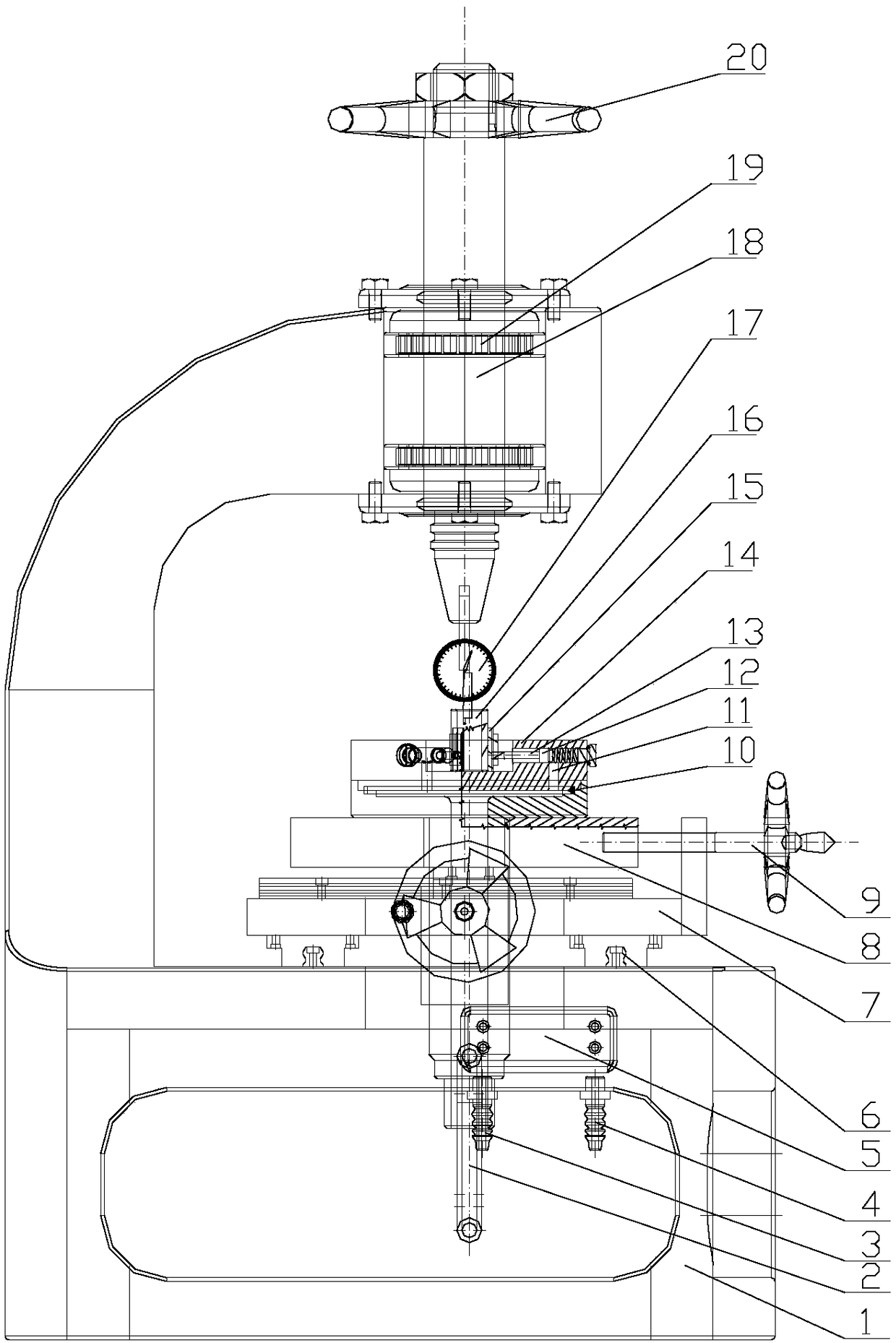

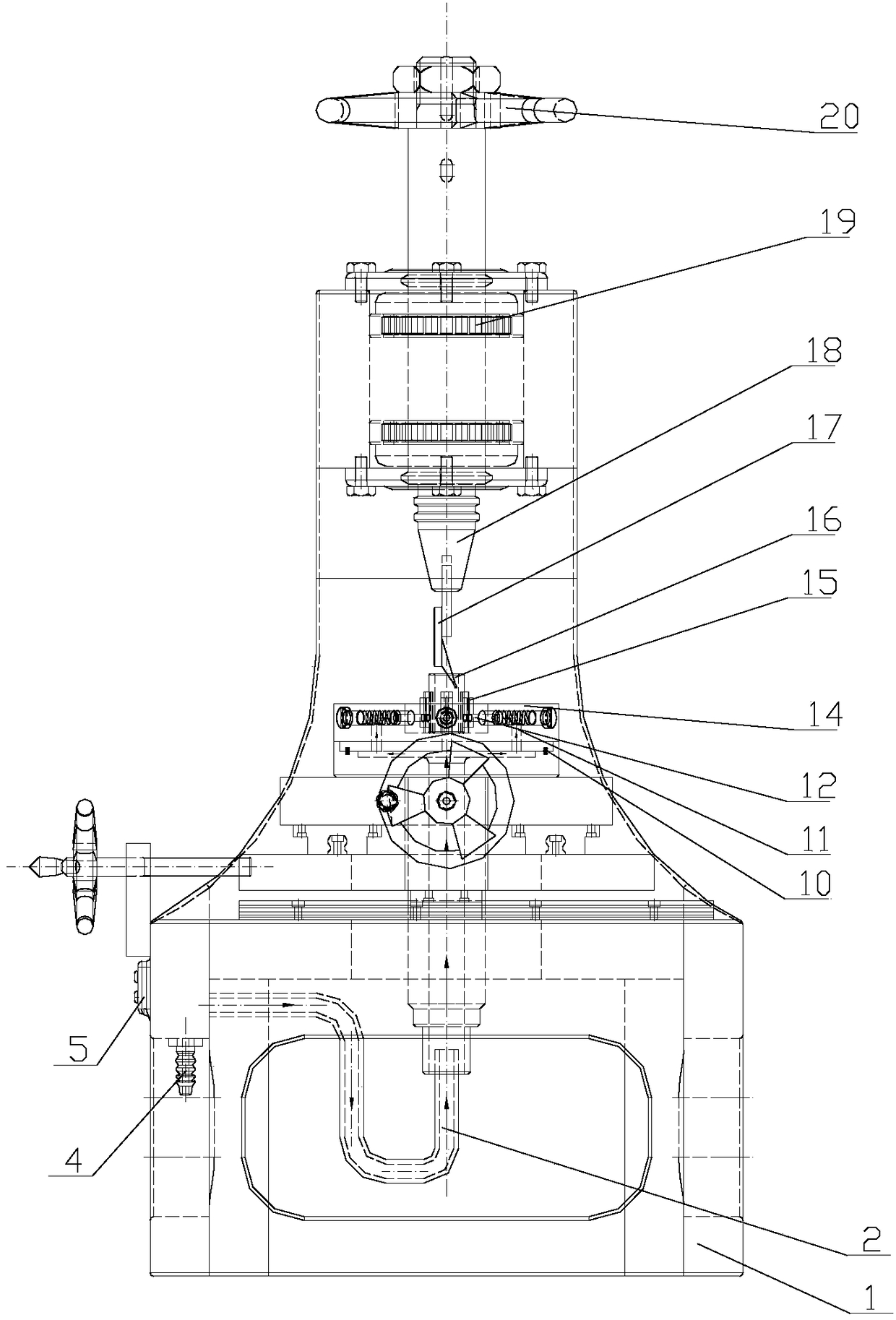

[0016] refer to Figure 1-Figure 3 . In the embodiment described below, a pneumatic device for detecting the coaxiality of the inner hole includes: a table-top pneumatic device composed of a base with a hollow base and its working platform, and a column bow arm perpendicular to the base. machine. The working platform is provided with the L-shaped horizontal dragging plate 7 which is pushed by the longitudinal handle screw and moves along the horizontal dovetail guide rail on the working platform. There is also a longitudinal dragging plate 8 pushed by connecting the longitudinal handle 9 through the screw hole of the side vertical plate. The plate 8 is provided with a clamping disc 14 that communicates with the air intake channel 2 downwards and clamps the workpiece 16 to be measured upwards. Radial ventilation holes 11, each radial ventilation hole 11 is equipped with a pneumatic spring push rod 12, the rectangular rod body of the front section of the pneumatic spring push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com