Cornstalk smashing recycling press-baler

A technology for corn stalks and balers, which is applied to agricultural machinery and implements, cutting equipment, applications, etc., can solve the problems of low labor efficiency, high labor intensity, complex structure, etc. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

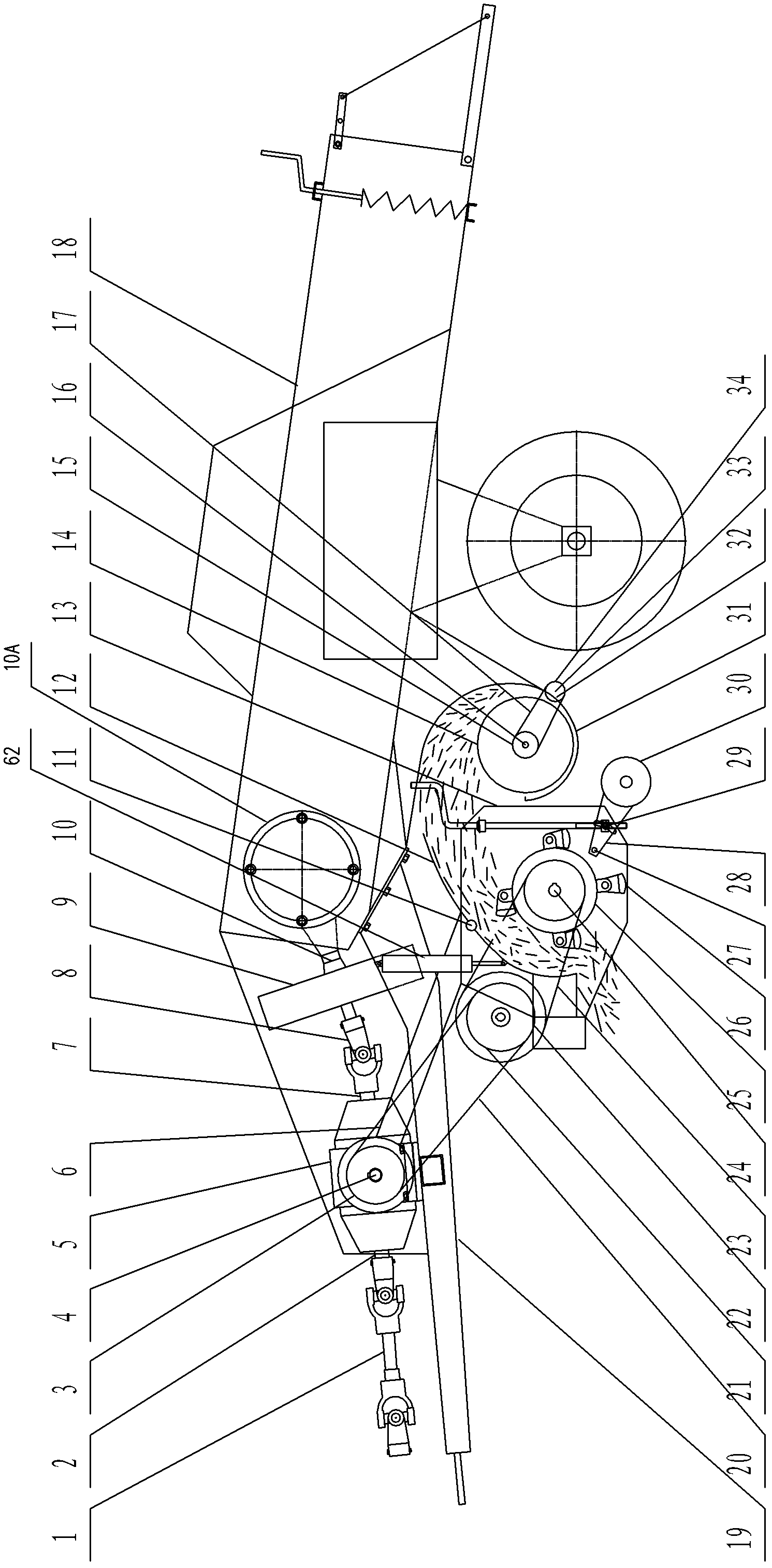

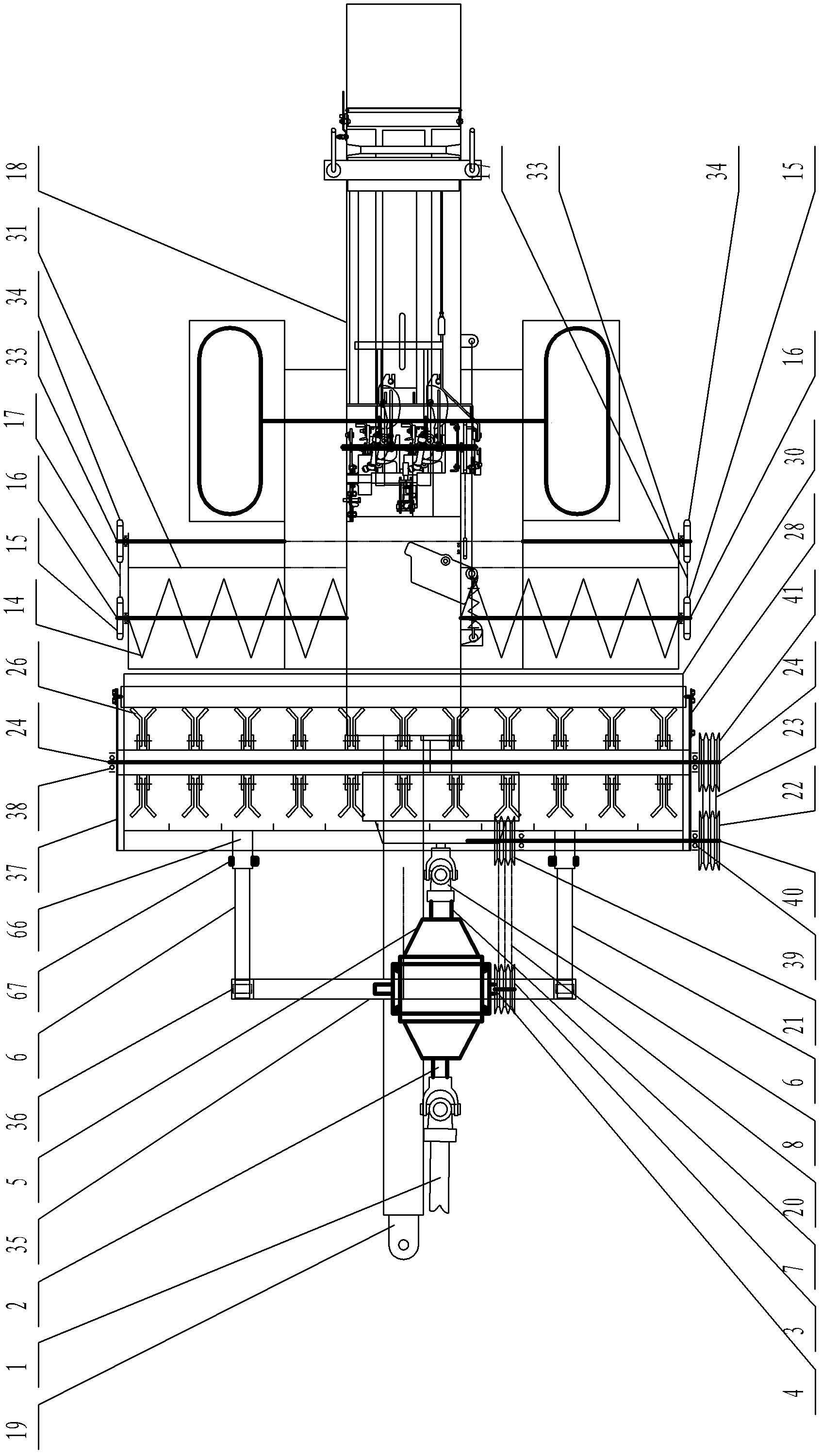

[0029] like figure 1 The structural diagram of the first embodiment of the corn stalk crushing and recycling baler of the present invention and figure 2 As shown, the corn stalk crushing and recycling baler of the present invention includes: a main transmission device connected to an external power device, installed on the traction arm 19; a first transmission mechanism connected with the main transmission device; a second transmission mechanism connected with the main transmission device; Transmission mechanism: the straw picking and crushing device 13 is connected with the main transmission device through the first transmission mechanism, so as to transmit the power of the main driving device to the straw picking and crushing device 13, so that the straw picking and crushing device 13 can cut or pick up and crush corn stalks work; the straw baler device 18 is connected to the main drive device through the second transmission mechanism, so that the power of the main drive de...

Embodiment 2

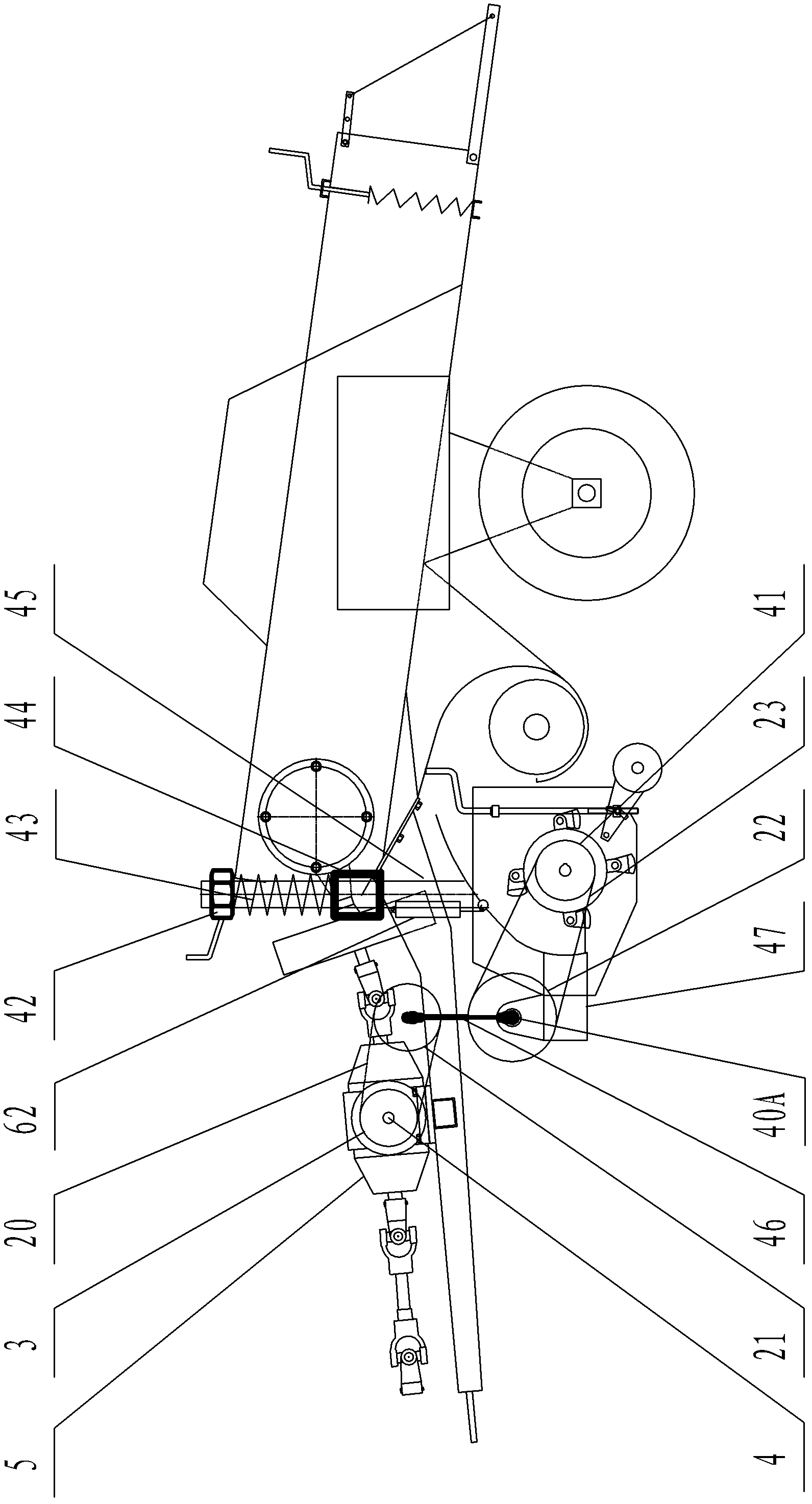

[0040] like image 3 , 4 , 5, the first transmission mechanism of this embodiment includes: the first driving wheel 3 installed on the first output shaft 4 of the main transmission device; the first transmission shaft 48 installed on the traction arm 19; The first driven wheel 52 installed on the first transmission shaft 48; the first drive belt 20 installed on the first driving wheel 3 and the first driven wheel 52; and installed on the frame 37 through the universal joint drive shaft 46 the second power transmission shaft 40A that is connected with the first power transmission shaft 48; The second drive wheel 22 that is installed on the second power transmission shaft 40A; Be installed on the second driven wheel 41 on the described picking up pulverization power transmission shaft 24; The second drive belt 23 on the two driving wheels 22 and the second driven wheel 41.

[0041] Guide sleeve 44 links to each other with support 53, and support 53 links to each other with str...

Embodiment 3

[0044] like Figure 6 , 7 As shown, the first transmission mechanism of this embodiment includes: a bracket 47 installed on the frame 37; the first transmission shaft 54 installed on the bracket 47 is connected to the first output shaft 4 of the main transmission device through the universal joint transmission shaft 46 Connection; the driving wheel 22' installed on the first transmission shaft 54; the driven wheel 41' installed on the picking and crushing transmission shaft 24; and the transmission belt 23' installed on the driving wheel 22' and the driven wheel 41'.

[0045] Other structures of the corn stalk crushing and recycling baler in this embodiment are the same as those in Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com