A high-efficiency and rapid production process method for needle-punched composite fabrics

A technology of acupuncture compounding and production technology, which is applied in the direction of chemical instruments and methods, layered products, adhesive types, etc., can solve the problems of poor flexibility in production process operation, achieve flexible and adjustable heating temperature, reasonable and effective process, Flexible and adjustable heating position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

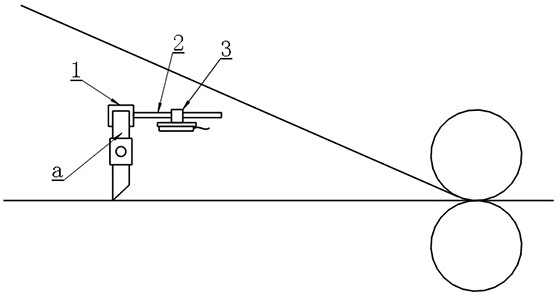

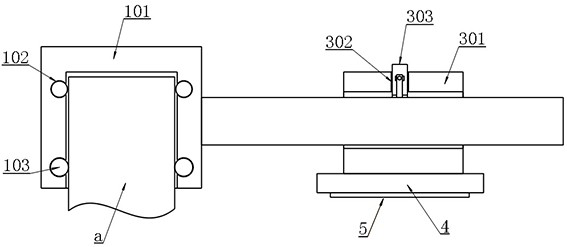

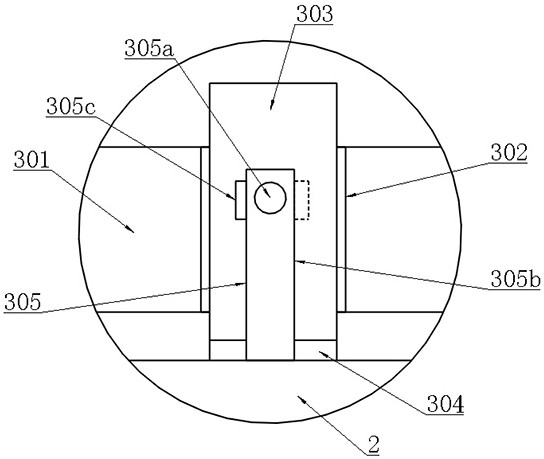

[0030] Example: as attached figure 1 , 2 , 3, 4 and attached Figure 5 As shown, an efficient and rapid production process method for needle-punched composite fabrics, including four operations of needle-punched cotton manufacturing, needle-punched cotton pretreatment, roll bonding and post-treatment of needle-punched composite fabrics, the roll bond The operation is realized by single-layer scraper coating and upper and lower roller rolling, the adhesive used is water-based adhesive, and the coating amount is 5-11g / m 2 , the coating humidity is 35-50%, and the rolling pressure of the upper and lower rollers is 30-50kg / cm 2 .

[0031] In this embodiment, the upper surface of the needle-punched cotton horizontally above is coated with a binder, and then the needle-punched cotton added obliquely above is compacted between the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com