Material collecting mechanism used for producing flat bridge and working method for material collecting mechanism

A technology of receiving mechanism and flat bridge, which is applied in the direction of object stacking, transportation and packaging, etc. It can solve the problems that the long-term efficiency and stability of the mechanism cannot be guaranteed, the high cost of material collection, manufacturing and operation, prone to deviation and failure, etc. , to achieve the effect of not easy deviation and failure, low manufacturing and operating costs, smooth and efficient operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

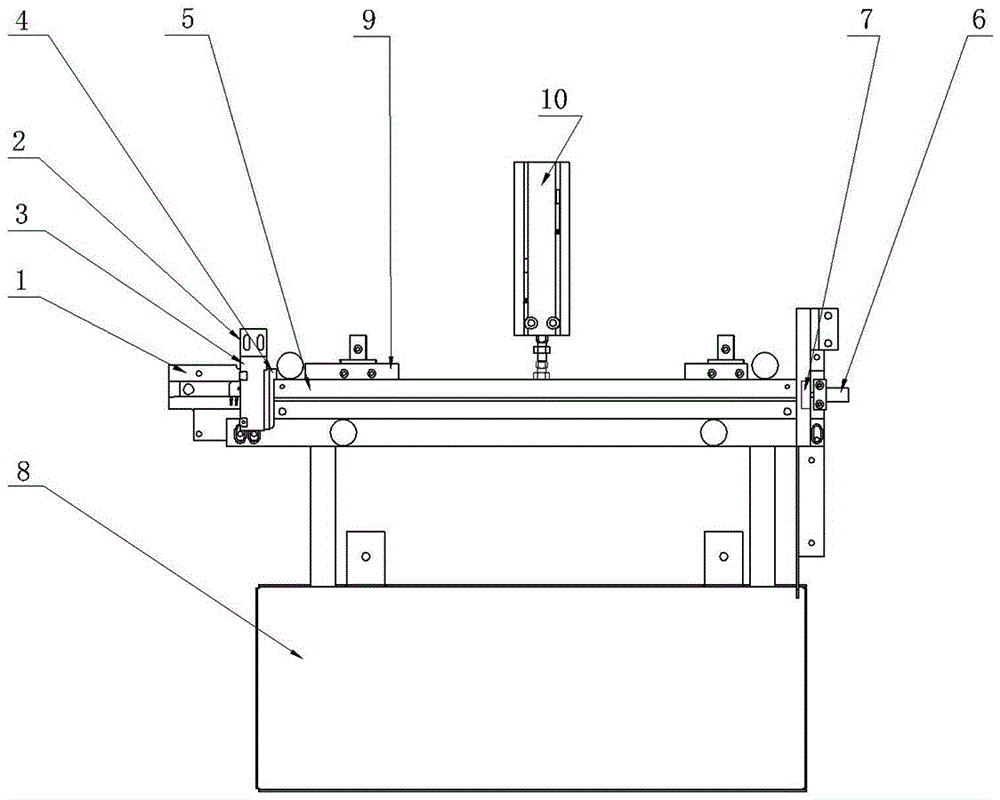

[0028] Such as figure 1 As shown, a material receiving mechanism for producing flat bridges in this embodiment includes: material receiving track 1, pressure tube cylinder frame 2, pressure tube cylinder 3, material tube positioning block 4, material tube 5, and tube jacking cylinder 6. Tube jacking block 7, tube receiving box 8, material tube pushing plate 9 and tube pushing cylinder 10.

[0029] The connection relationship of the above-mentioned components is as follows: the receiving track 1, the pressure pipe cylinder frame 2 and the push pipe cylinder 10 are directly installed on the outer frame panel, and the material pipe push plate 9 cooperates with the outlet shaft of the push pipe cylinder 10 Connection; the pipe jacking block 7 connected to the front end of the pipe jacking cylinder 6 is close to one end of the receiving track 1, the material pipe positioning block 4 is fixed on the lower end of the pressure pipe cylinder 3, and one side of the material pipe 5 Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com