An intelligent automatic discharge device and its working method

An automatic discharge device and intelligent technology, applied in the field of machinery and equipment, can solve the problems of inability to monitor real-time operating conditions, high manufacturing and operating costs, prone to deviations and failures, etc., to ensure long-term efficient and stable operation, improve The quality of material transportation and the effect of not easy to fail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

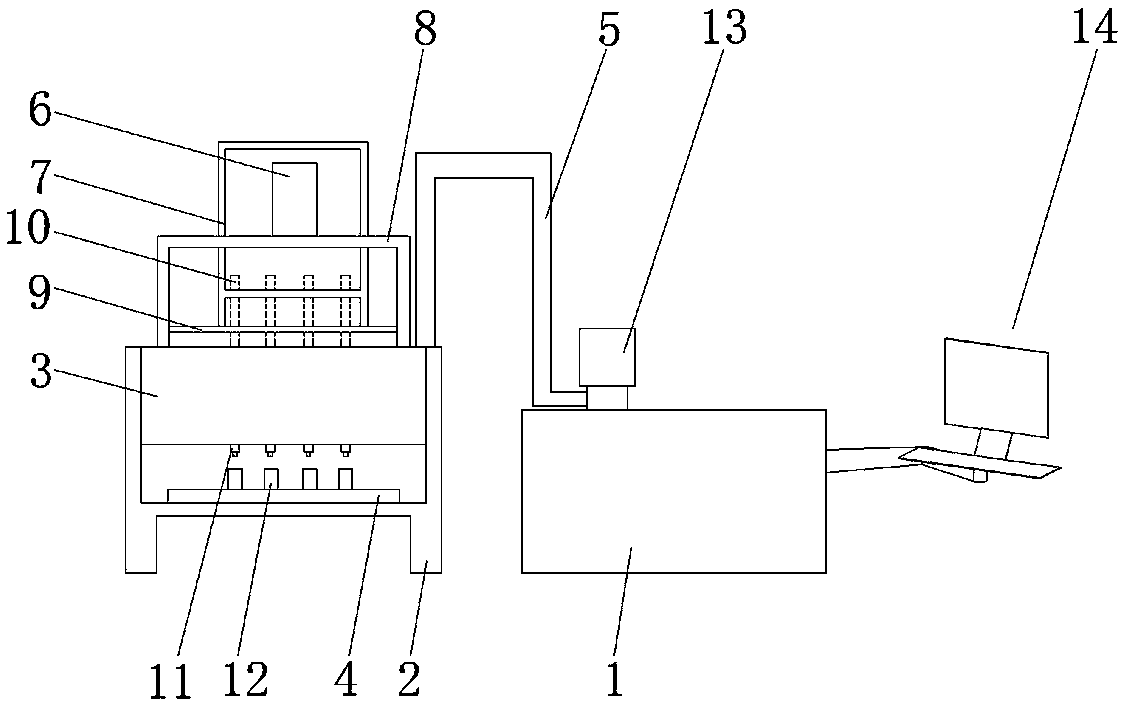

[0033] Such as figure 1 As shown, a kind of intelligent automatic discharge device of the present embodiment includes: storage box 1, frame 2, discharge box 3, material receiving box 4, feeding pipe 5, cylinder 6, connecting frame 7, fixing seat 8. Fixed plate 9, pull rod 10, discharge port 11, receiving bottle 12, motor 13 and intelligent control mechanism 14.

[0034] The connection relationship of the above-mentioned components is as follows: the motor 13 is arranged on the top of the material storage box 1, and the two ends of the feed pipe 5 are respectively connected with the discharge box 3 and the storage box 1; the bottom of the discharge box 3 is provided with a A group of discharge ports 11, the lower part of the pull rod 10 is slidingly connected with the discharge port 11, and the top passes through the fixed seat 8 and is connected with the cylinder 6; the surface of the receiving box 4 is inlaid with a set of Receiving bottle 12; the frame 2 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com