Efficient intelligent extrusion molding device and operating method thereof

An extrusion molding and intelligent technology, applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of cumbersome maintenance, high load requirements, high manufacturing and operating costs, etc., to improve work efficiency and Product quality, smooth and efficient operation process, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

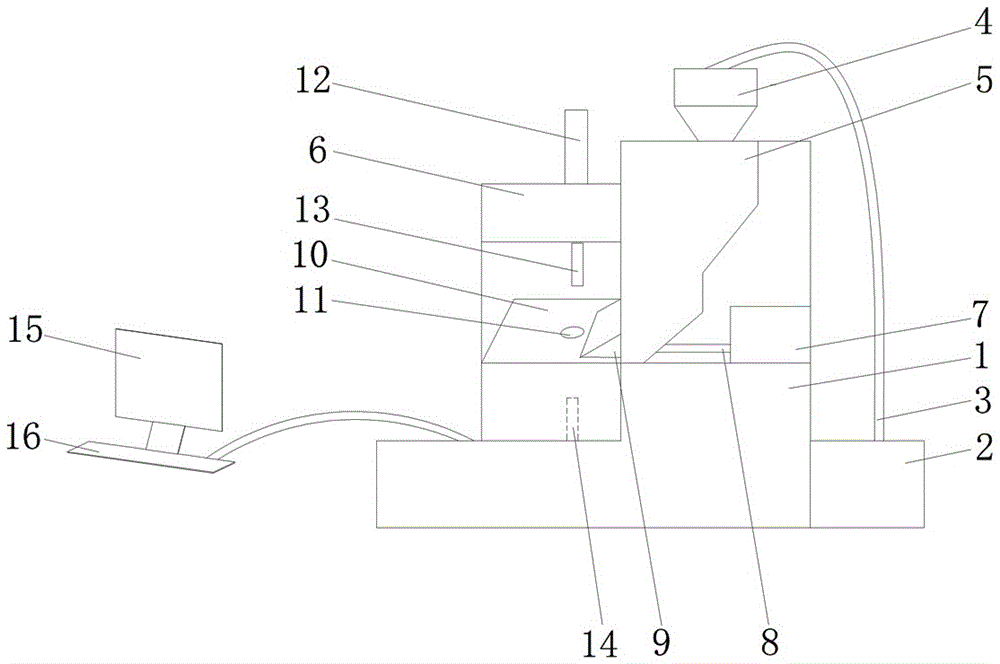

[0034] Such as figure 1 As shown, a high-efficiency and intelligent extrusion molding device of this embodiment includes: a frame 1, a raw material tank 2, a feeding pipe 3, a hopper 4, a storage box 5, a fixed frame 6, a hydraulic cylinder 7, and a push rod 8. Feeding box 9, console 10, heating tank 11, telescopic rod 12, upper ejector rod 13, lower ejector rod 14, display 15 and PLC controller 16.

[0035] The connection relationship of the above-mentioned components is as follows: the frame 1 is sequentially connected with a feeding mechanism, a feeding mechanism, a heating and forming mechanism and an intelligent control mechanism; The material storage box 5; the feed hopper 4 is connected to the raw material tank 2 through the feed pipe 3, and the bottom of the feed hopper 4 is connected with the through hole on the top of the material storage tank 5; the feeding mechanism includes: a hydraulic cylinder 7, a push rod 8 and feeding box 9; the hydraulic cylinder 7 drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com