Pressing device for steel tape head

A technology of pressing device and steel coil, which is applied in the direction of guiding/positioning/aligning device, etc., can solve the problems of large working space, worker injury, inconvenient loading and unloading and maintenance, and achieve small working space, convenient loading and unloading and maintenance, and occupy small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

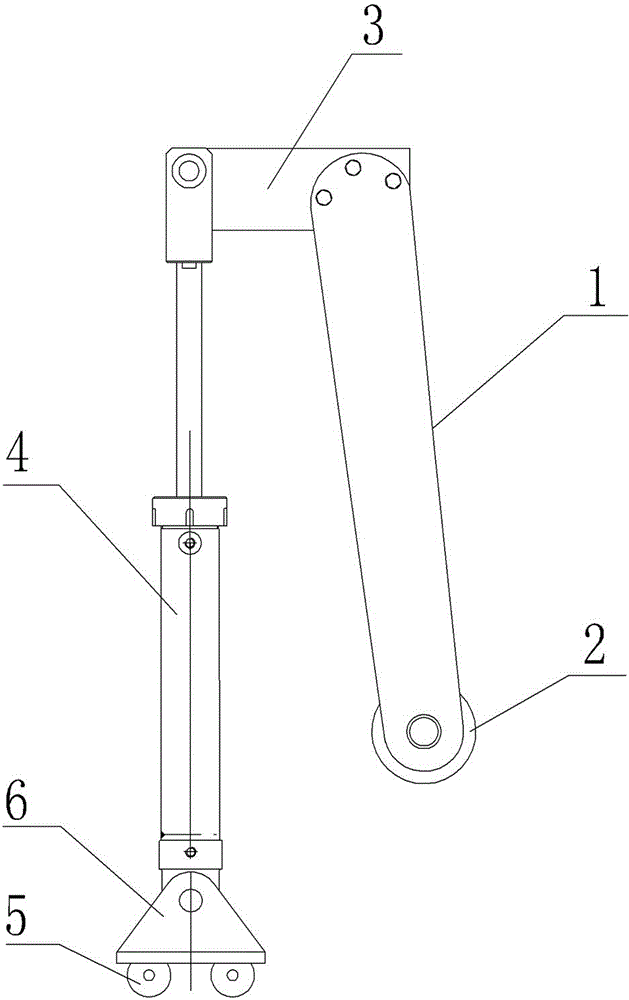

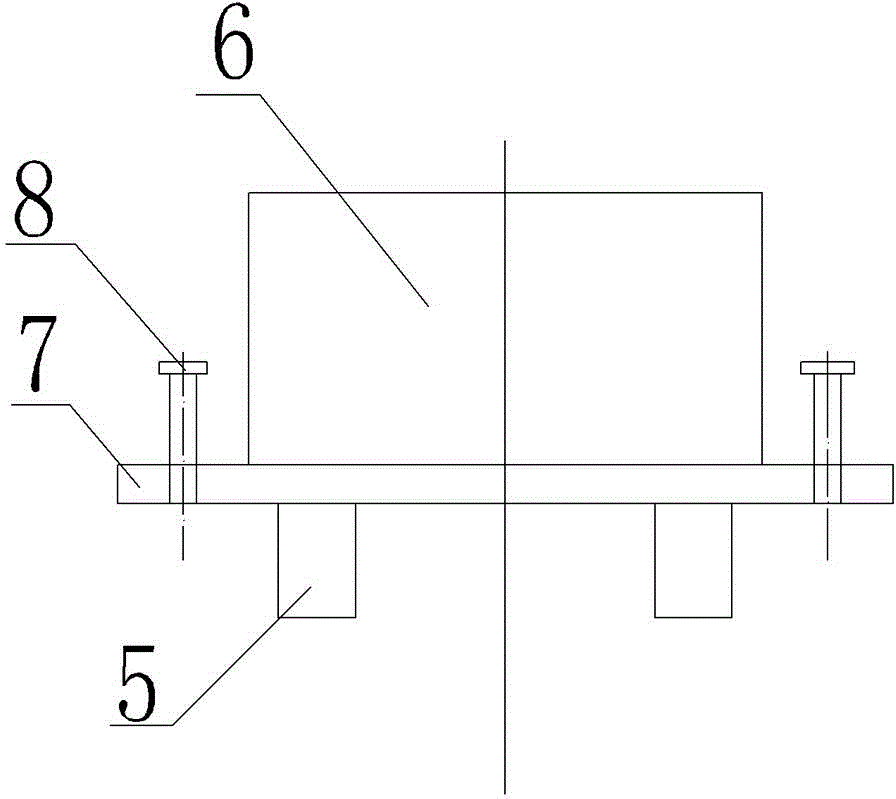

[0010] See figure 1 , 2 , the present invention includes a pressing rod 1, one end of the pressing rod 1 is connected with a pressing wheel 2, and the other end of the pressing rod 1 is connected to one end of the horizontal connecting rod 3 (using fastening connection methods such as screws or welding). The rod 1 is obliquely connected to the horizontal connecting rod 3, and the pressure rod 1 is installed at a certain angle in the vertical direction, which is beneficial to the pressure wheel 2 connected to the pressure rod 1 to reliably press the strip head of the steel coil during work; The other end of the connecting rod 3 is connected to the piston rod of the oil cylinder 4; the oil cylinder 4 is vertically installed on the roller structure, and the roller structure includes a roller 5 and a roller seat 6, and the oil cylinder 4 is fastened to the roller seat 6, and the bottom of the roller seat 6 is provided with Base plate 7, roller 5 is arranged on the bottom of base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com