An Efficient Dyeing and Finishing Cloth Dehydration Device

A dehydration device and cloth technology, applied in the direction of instruments, liquid/gas/steam removal by centrifugal force, alarm, etc., can solve problems such as corrosion, achieve high stability, good early warning effect, and convenient loading and unloading maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

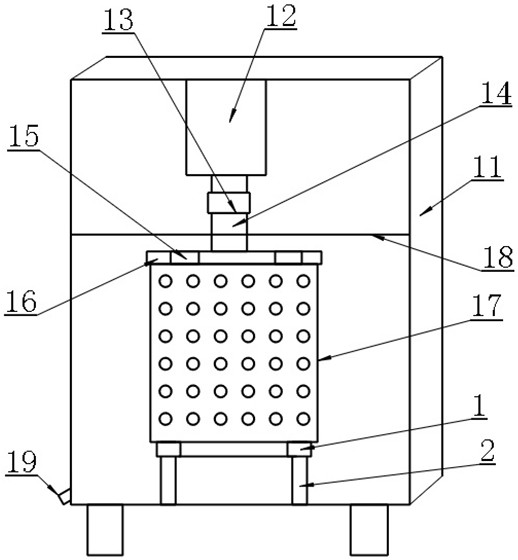

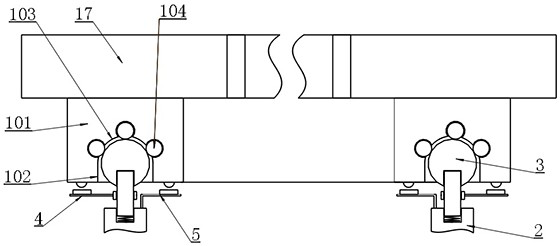

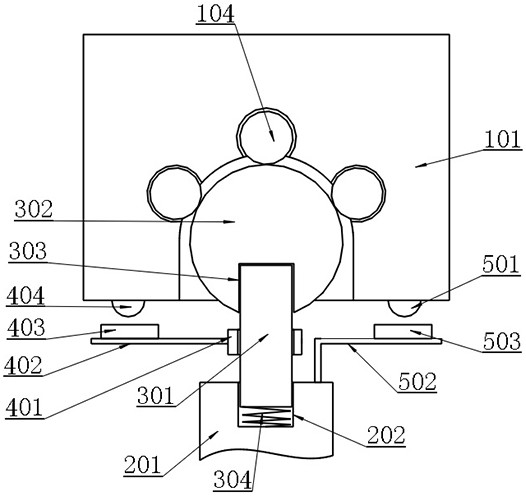

[0023] Example: as attached figure 1 , 2 , 3 and attached Figure 4 As shown, a kind of efficient dyeing and finishing fabric dehydration device includes a casing 11 for receiving water, and also includes a driving motor 12 arranged on the inner top surface of the casing 11, and the driving motor 12 is arranged on the The coupling 13 on the shaft, the rotating shaft 14 arranged on the coupling 13, the upper end plate 16 of the drum which is arranged on the rotating shaft 14 and provided with the cloth inlet and outlet 15, is arranged on the upper end plate of the drum 16 the dehydration drum main body 17 on the lower surface, the ring groove unit 1 arranged on the lower surface of the dehydration drum main body 17, the support column unit 2 arranged on the inner bottom surface of the casing 11, the support column unit 2 arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com