Wave wheel washing machine, eccentricity sensing method and device, and storage medium

A pulsator washing machine and eccentric technology, applied in the field of washing machines, can solve the problems of large fluctuation in the effective range of the detection interval, poor versatility, and inability to stop dehydration in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Combine below Figure 2 to Figure 8 The pulsator washing machine according to the embodiment of the present invention will be specifically described.

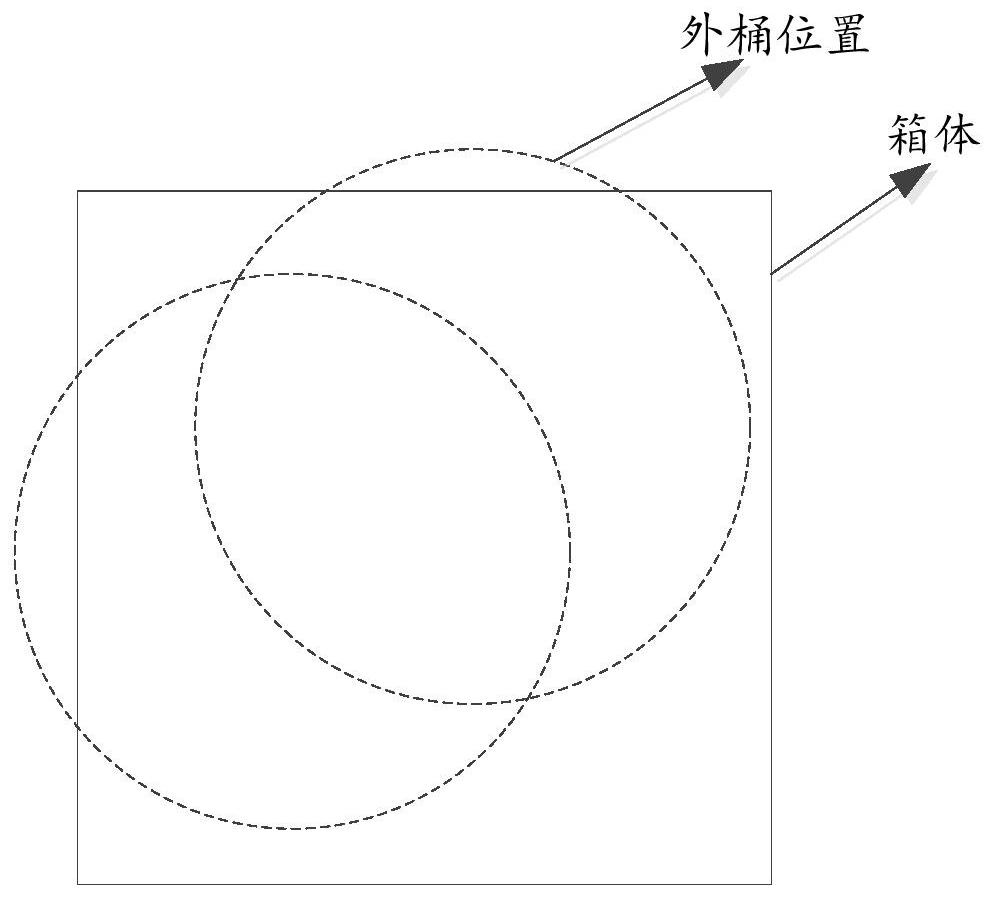

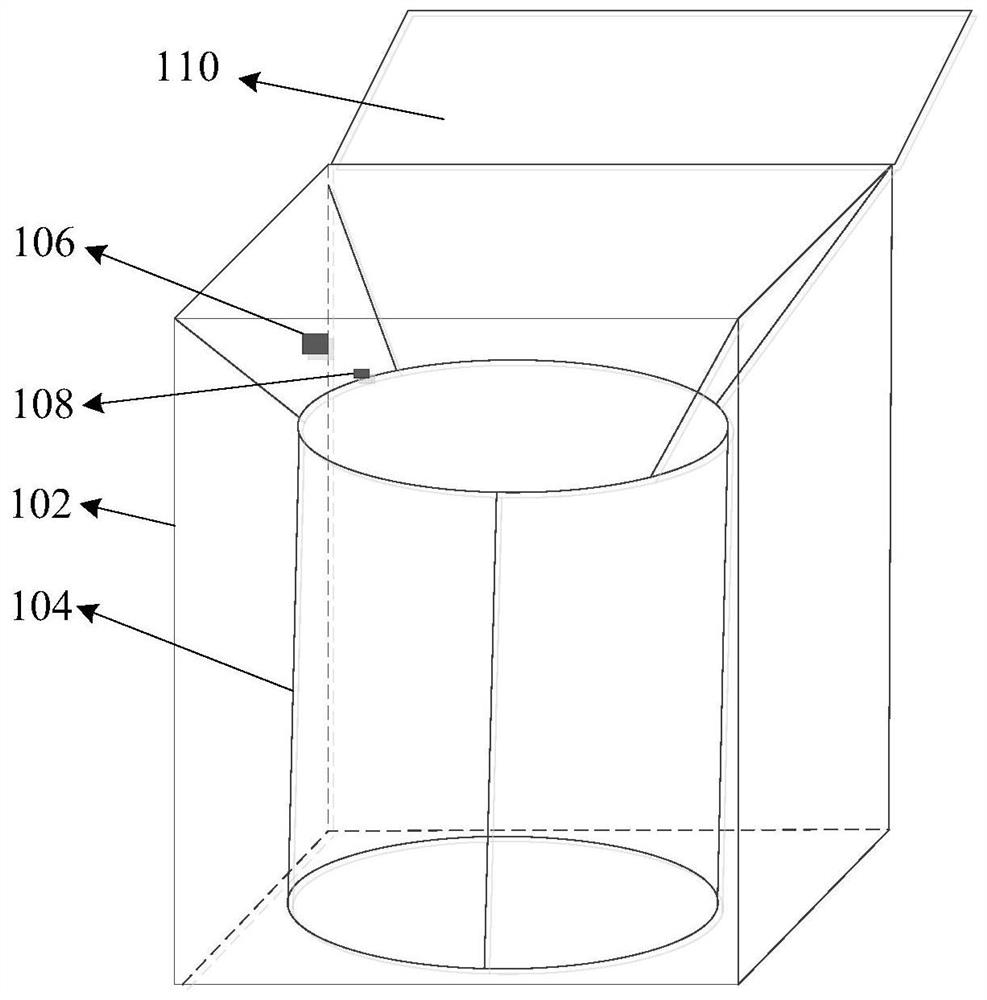

[0055] Such as figure 2 and Figure 5 As shown, the pulsator washing machine according to the embodiment of the present invention includes: a box body 102, an outer tub 104, a TMR sensor 106, a magnetic element 108 and a controller (not shown in the figure).

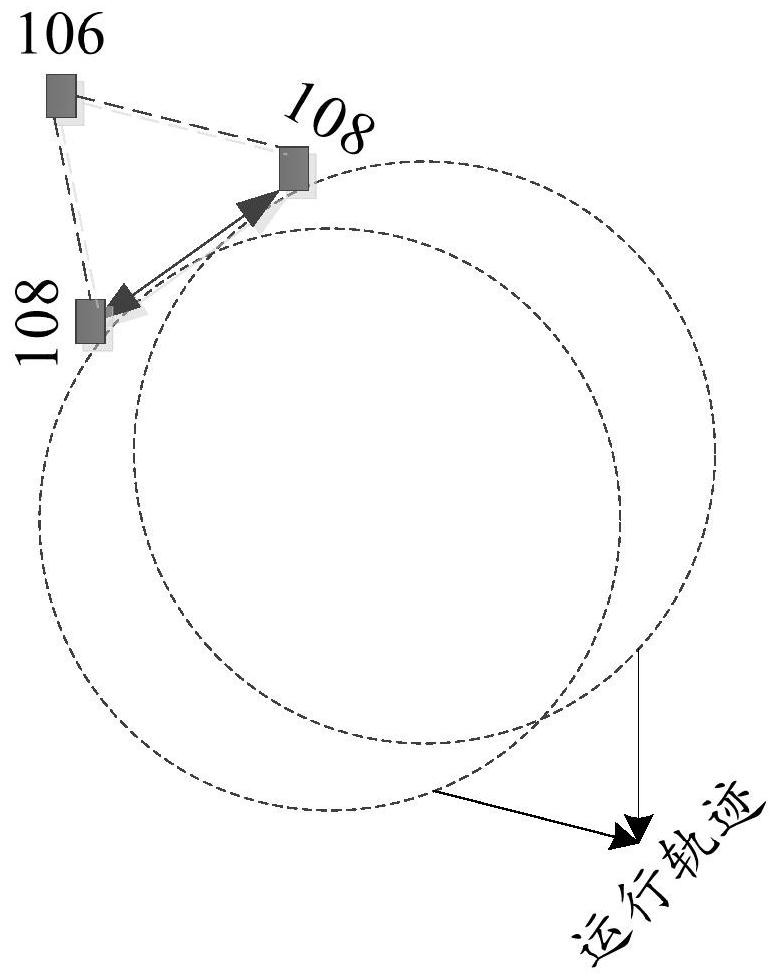

[0056] Wherein, the outer barrel 104 is placed in the box body 102; the TMR sensor 106 is arranged on the box body 102, the magnetic element 108 is arranged on the outer barrel 104, and the TMR sensor 106 and The magnetic elements 108 are located on the same horizontal plane and are arranged oppositely; and the TMR sensor 106 is used to detect the real-time position of the magnetic element 108 relative to the box body 102 when the pulsator washing machine performs a dehydration program; the control The sensor is electrically connected to the TMR sensor 106 and ...

Embodiment 2

[0081] Combine below Figure 9 to Figure 11 The eccentricity sensing method of the embodiment of the present invention will be described in detail.

[0082] Such as Figure 9 As shown, the eccentricity sensing method according to the embodiment of the present invention is used in the pulsator washing machine as described in the first embodiment above, and the eccentricity sensing method includes the following process steps:

[0083] Step S202, controlling the pulsator washing machine to perform a dehydration program.

[0084] Step S204, acquiring the real-time position of the magnetic element relative to the box detected by the TMR sensor.

[0085] Step S206, determining whether the eccentricity of the pulsator washing machine is abnormal according to the real-time position.

[0086] In this embodiment, in order to effectively avoid the bucket collision event caused by the eccentricity of the outer tub due to the knotting of the clothes, when the pulsator washing machine ex...

specific Embodiment 1

[0089] Such as Figure 10As shown, the step S206 can specifically execute the following process steps:

[0090] Step S302, when one real-time location is acquired each time, determine the real-time distance between the outer tub and the box according to the real-time location.

[0091] Step S304, judging whether the real-time distance is less than or equal to the preset safety distance, if so, execute step S306, otherwise, execute step S308.

[0092] Step S306, controlling the pulsator washing machine to execute a self-balancing program.

[0093] Step S308, controlling the pulsator washing machine to continue executing the dehydration program.

[0094] In this embodiment, when only one real-time position of the magnetic element detected by the TMR sensor is obtained each time, that is, when only a pair of TMR sensors and magnetic elements are set in the pulsator washing machine, the position detected by the TMR sensor can be The real-time position of the magnetic element re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com