Oil tank dewatering device

A technology of dehydration device and oil tank, which is applied in the direction of liquid separation, chemical instruments and methods, separation methods, etc., and can solve problems such as dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

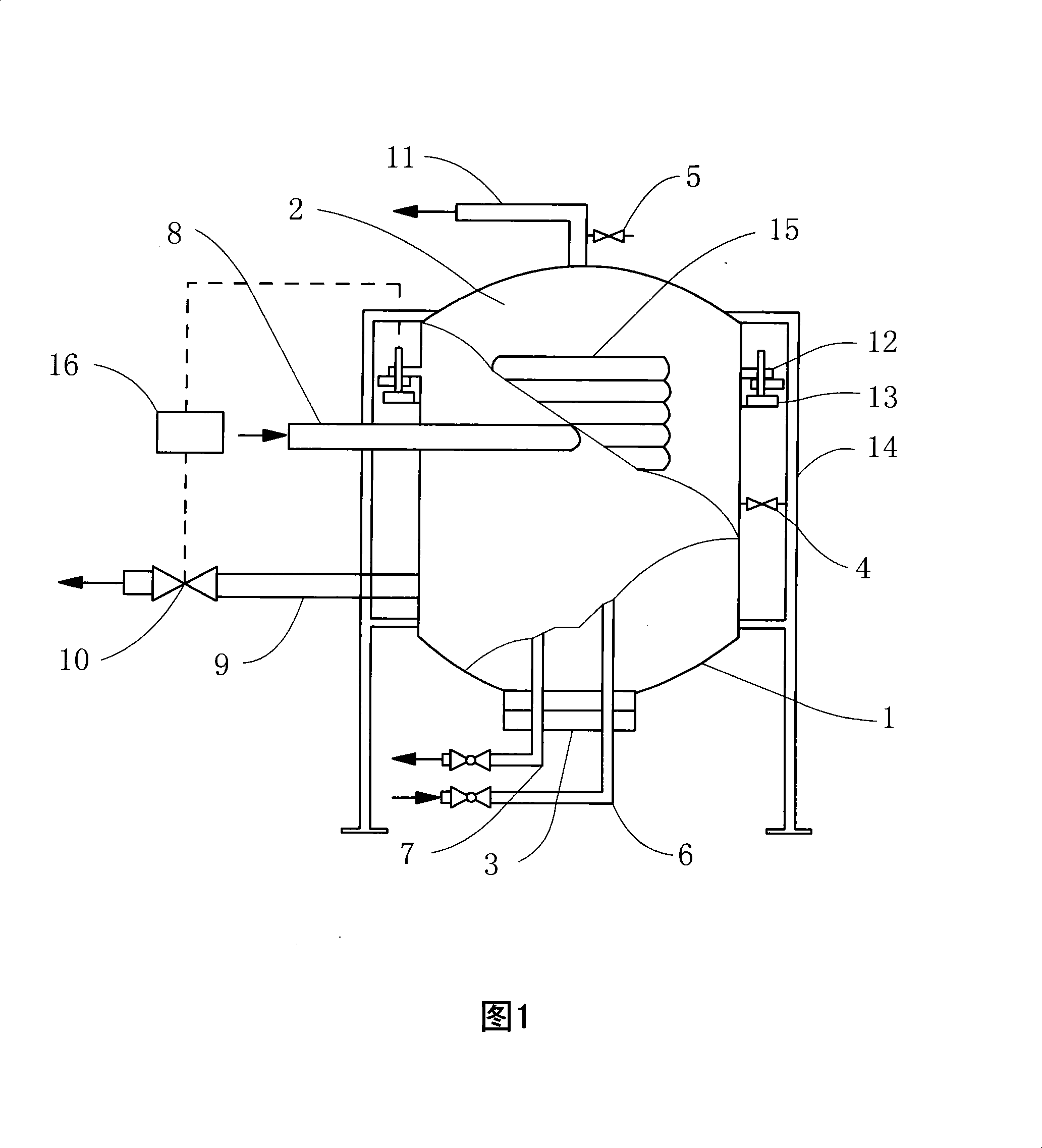

[0008] As shown in Figure 1, a chamber 2 is provided in the dehydrator body 1, and heat exchange tubes 15 are arranged spirally in the dehydrator chamber, the two ends of which are connected with the steam inlet pipe 6 and the steam outlet pipe 7 respectively. The bottom is provided with a sewage outlet 3, the upper part is provided with an oil phase connecting pipe 11, the water inlet pipe 4 is connected to the lower side of the dehydrator, and the water outlet pipe 5 is connected to the upper side or the oil phase connecting pipe, and the lower part of the other side of the dehydrator A drain pipe 9 is connected, on which a drain valve 10 is installed, and an oil-water inlet pipe 8 is connected at a tangent angle in the middle of the dehydrator, and a weighing support ring 12 is provided in the upper middle of the dehydrator, and a weighing sensor 13 is in contact with the support ring Connect, be connected with weight acquisition controller 16 by wire between drain valve and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com