Supply mechanism for producing flat bridge and working method of supply mechanism

A feeding mechanism and feeding technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of inability to guarantee long-term efficient and stable feeding, complex operation process of feeding mechanism, high manufacturing and operating costs, etc. To achieve the effect of low operating cost, low manufacturing and operating cost, and smooth and efficient operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

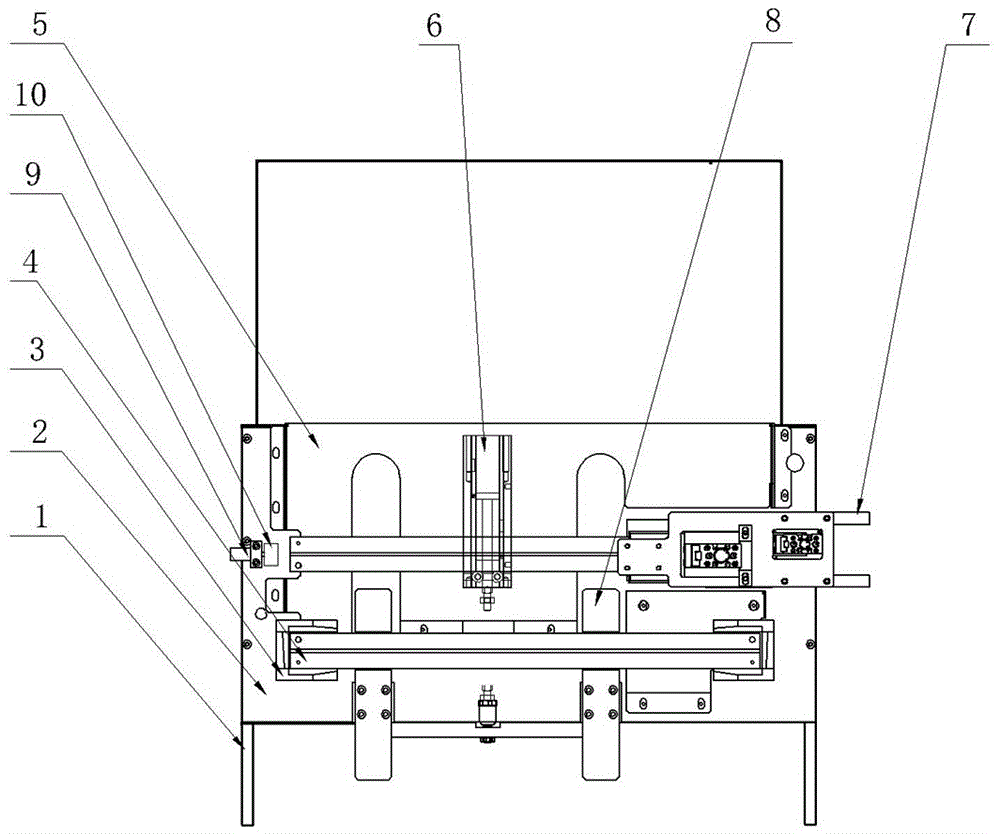

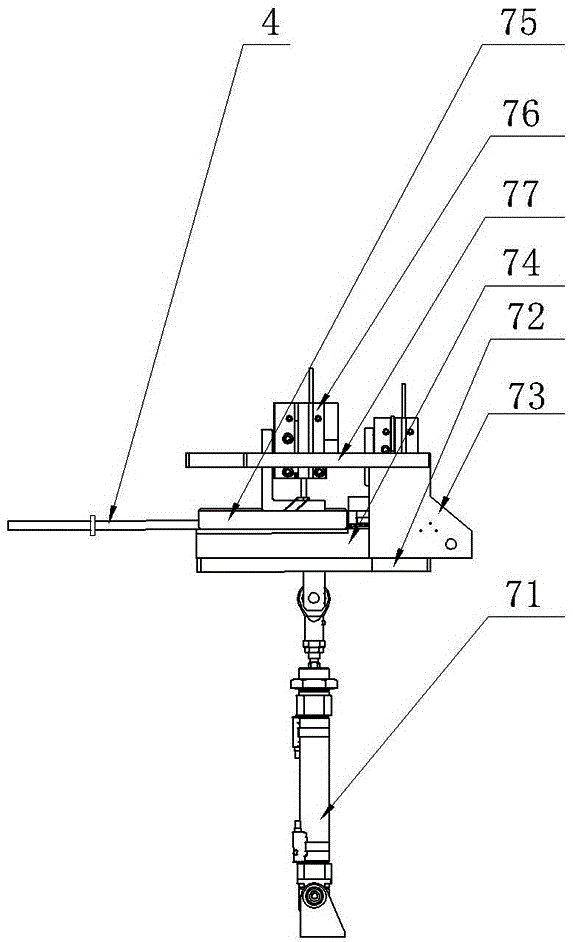

[0029] like Figure 1-Figure 2 As shown, a feeding mechanism for producing flat bridges in this embodiment includes: a feeding vertical plate 1, a feeding panel 2, a magazine 3, a feeding tube 4, a feeding pallet 5, and a push tube cylinder 6 , pipe transfer group 7, material pipe push plate 8, pipe jacking cylinder 9, pipe jacking block 10, riser pipe cylinder 71, riser bottom plate 72, riser riser plate 73, feeding track 74, guide plate 75, pressure pipe cylinder 76 and riser cover plate 77.

[0030] The connection relationship of the above-mentioned components is as follows: the feed vertical plate 1 is fixedly connected to the feed panel 2, the magazine 3, the feed pallet 5, the push tube cylinder 6, the tube transfer group 7 and the tube jack cylinder 9 All are installed on the feeding panel 2; the material pipe 4 is arranged in the magazine 3 and connected with the material pipe push plate 8; the pipe jacking cylinder 9 is connected with the pipe jacking block 10; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com