Safety protection type automatic clamping mechanical hand

A technology of safety protection and manipulators, applied in the field of manipulators, can solve problems such as the inability to guarantee efficient and stable operation of the clamping work, the axial impact force easily damages the workpiece, and the high cost of manufacturing and operation, etc., to achieve good heat insulation protection effect and improve The effect of safety, low manufacturing and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

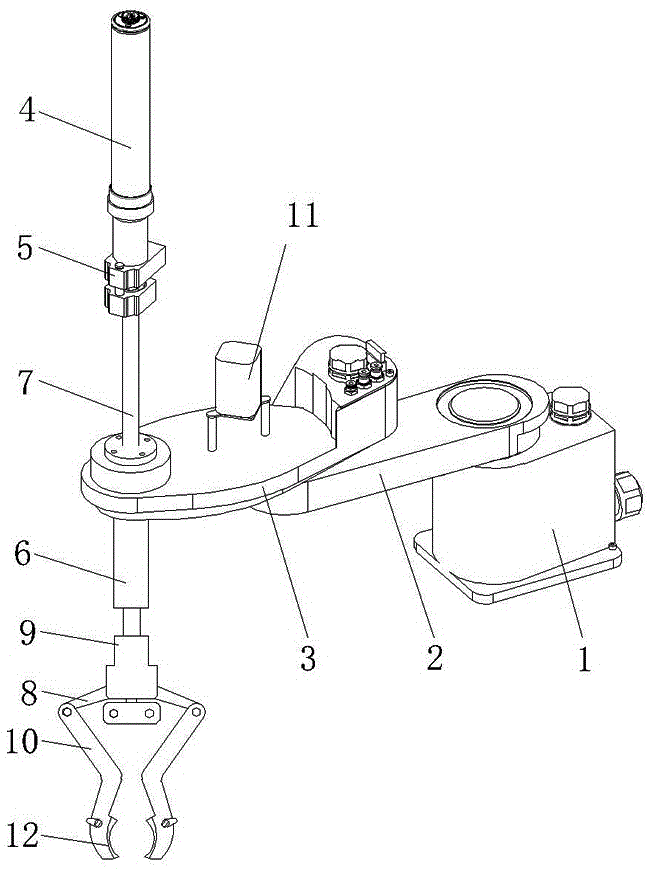

[0025] Such as figure 1 As shown, a safety protection type automatic gripping manipulator in this embodiment includes: a body 1, a first joint shaft 2, a second joint shaft 3, a cylinder 4, a buffer mechanism 5, a sealing sleeve 6, a piston rod 7, Connecting rod 8, shaft coupling 9, clamping finger 10, detection device 11 and magnetic block 12.

[0026] The connection relationship of the above-mentioned components is as follows: the two ends of the first joint shaft 2 are respectively connected with the fuselage 1 and the second joint shaft 3, and the first joint shaft 2, the second joint shaft 3 and the gripping finger 10 are all Driven by a servo motor provided inside the fuselage 1; the upper end of the piston rod 7 is connected with the cylinder 4 through the buffer mechanism 5, and the lower part of the piston rod 7 passes through the second joint arm 3 and is embedded in the sealing sleeve 6, and The bottom is fixedly connected with the shaft coupling 9; the clamping fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com