Patents

Literature

50results about How to "Long-term efficient and stable operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

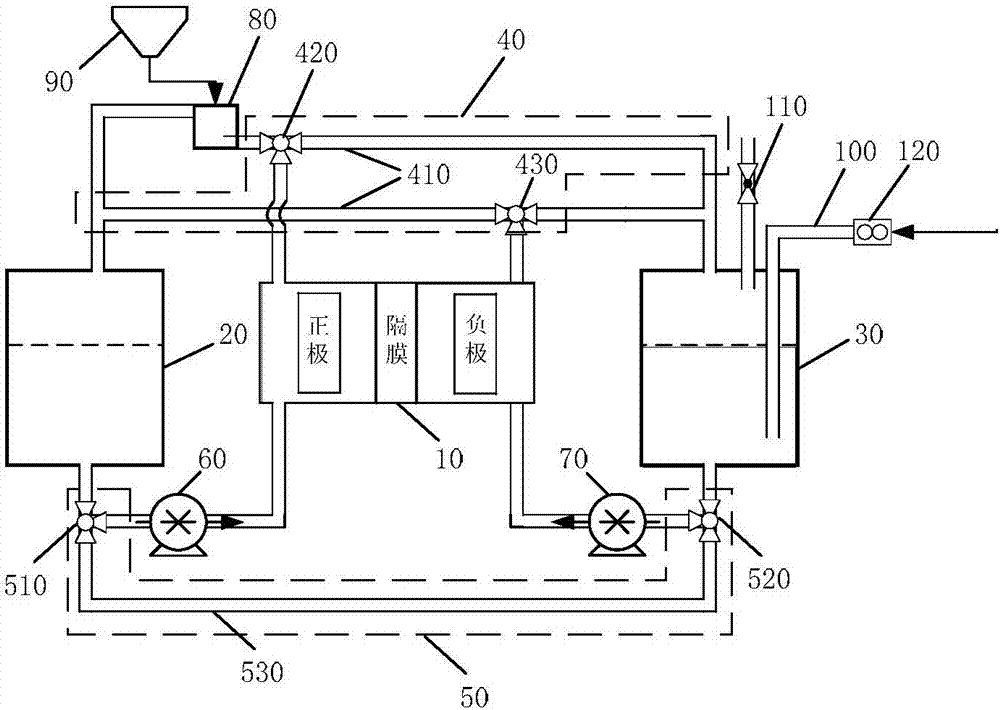

Flow battery system and capacity re-balance method for flow battery

PendingCN107425212ASolve capacity fadingSolve the problem of electrolyte volume imbalanceElectrolyte stream managementRegenerative fuel cellsEngineeringStorage tank

The invention provides a flow battery system and a capacity re-balance method for a flow battery. The flow battery system comprises a flow battery unit, a positive electrode electrolyte storage tank and a negative electrode electrolyte storage tank; the flow battery system also comprises a co-mixing equipartition module; the co-mixing equipartition module comprises an electrolyte co-mixing unit and an electrolyte equipartition unit, wherein the electrolyte co-mixing unit is connected with a positive electrode outlet, a negative electrode outlet, the inlet of the positive electrode electrolyte storage tank and the inlet of the negative electrode electrolyte storage tank separately for co-mixing the electrolyte in the positive electrode electrolyte storage tank and the negative electrode electrolyte storage tank; and the electrolyte equipartition unit is connected with the outlet of the positive electrode electrolyte storage tank, the outlet of the negative electrode electrolyte storage tank, a positive electrode inlet and a negative electrode inlet for performing equipartition on the electrolyte in the positive electrode electrolyte storage tank and the negative electrode electrolyte storage tank. By performing co-mixing and equipartition treatment on the positive and negative electrode electrolyte, the problem of capacity fading caused by imbalance of vanadium ion total quantity in the positive and negative electrode electrolyte and the problem of electrolyte volume imbalance caused by water migration are solved.

Owner:中国东方电气集团有限公司

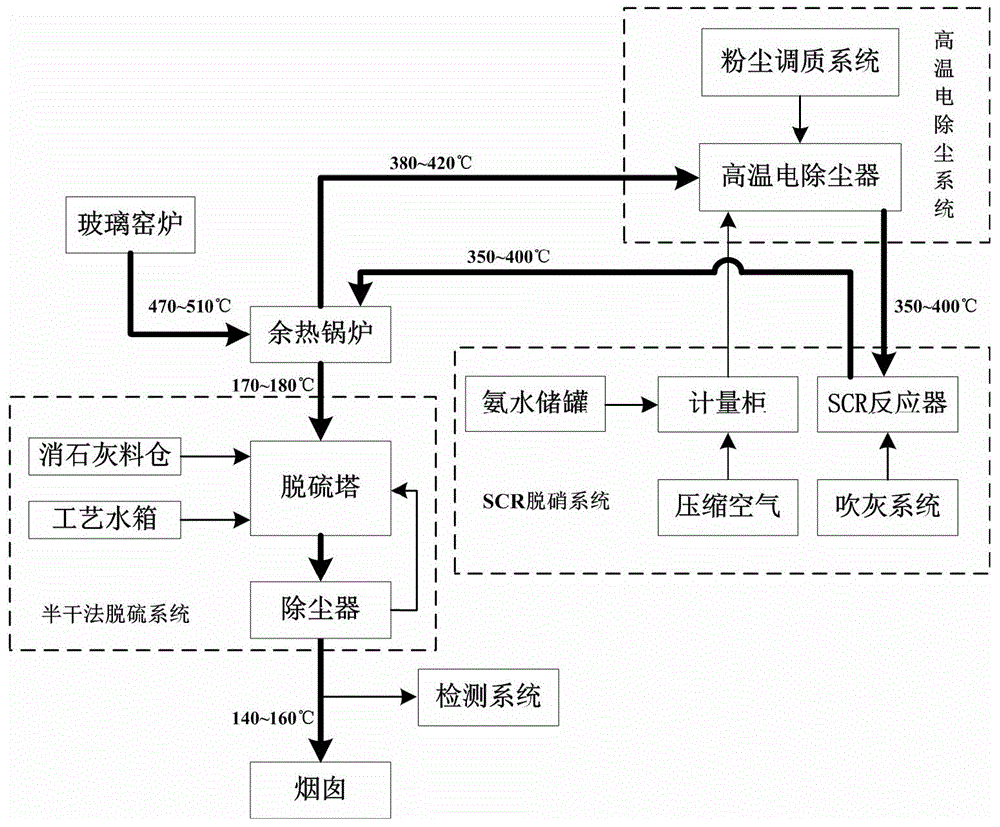

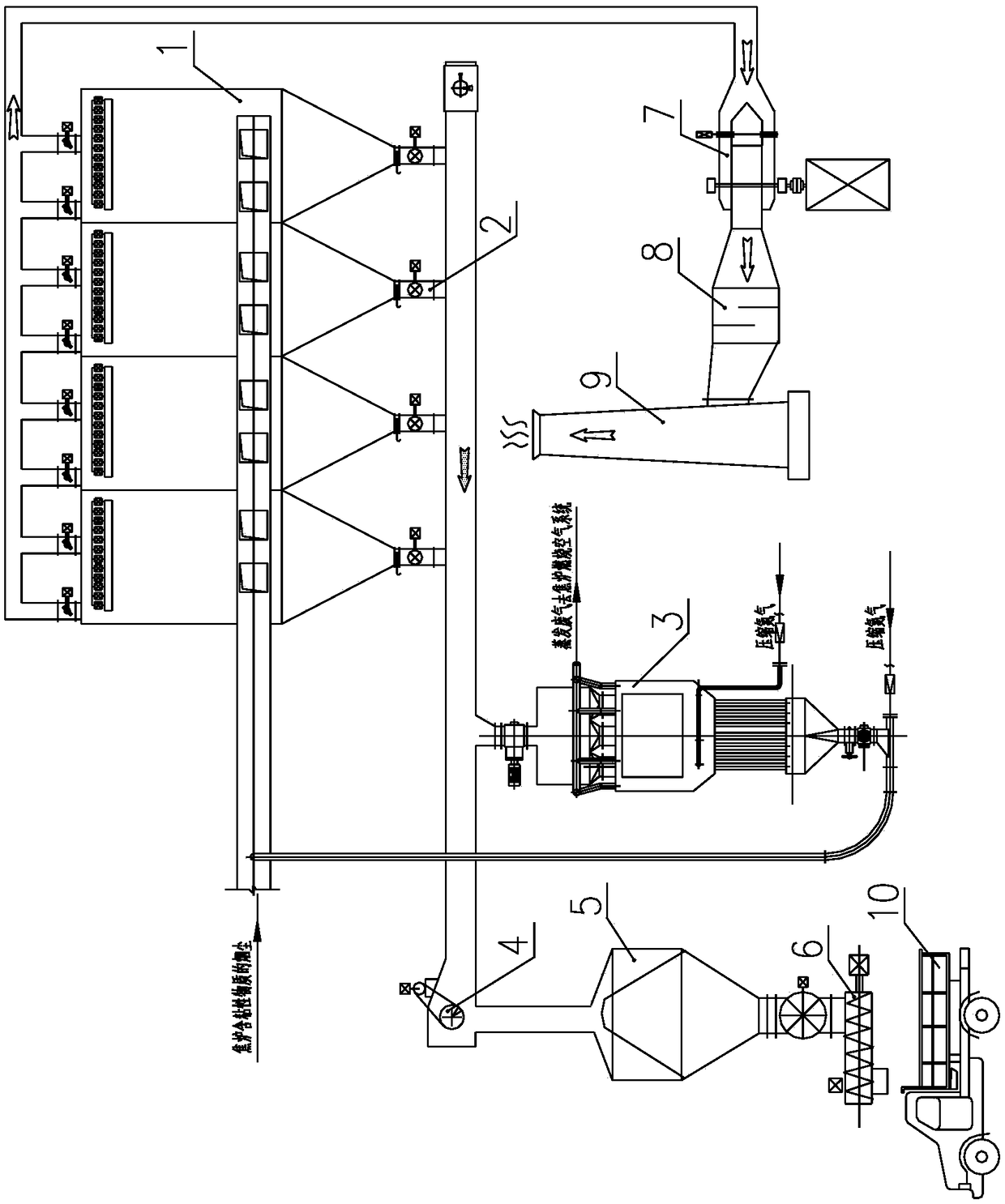

Comprehensive purification process of glass kiln smoke

InactiveCN104984640AImprove dust removal efficiencyHigh temperature resistantDispersed particle separationIncreasing energy efficiencyAtmospheric airEngineering

The invention discloses a comprehensive purification process of glass kiln smoke. The comprehensive purification process comprises the process flows of performing waste heat recovery on high-temperature smoke generated by a glass kiln through a waste heat boiler, leading the smoke into a high-temperature electric precipitator system for high-temperature smoke dust removal treatment in the section of the waste heat boiler at 380 to 420 DEG C, cooling the standard smoke after dust removal to 350 to 400 DEG C, so as to satisfy the requirement of the best active temperature of an SCR denitration catalyst, then leading the smoke after dust removal into an SCR denitration system for removing NOx, leading the smoke after denitration back to the waste heat boiler for waste heat recovery, and leading the smoke into a desulfurization system with a semidry method after the smoke in the waste heat boiler is cooled to 170 to 180 DEG C, so that the standard smoke after desulfurization is cooled to 140 to 160 DEG C and then is discharged into the atmospheric environment through a chimney. The glass kiln smoke after process treatment by adopting the comprehensive purification process reaches the regulations of related national environmental protection discharge standards of a glass industry, the dust discharge concentration is lower than 50 mg / m<3>, the NOx discharge concentration is lower than 700 mg / m<3>, and the SO2 discharge concentration is lower than 400 mg / m<3>.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

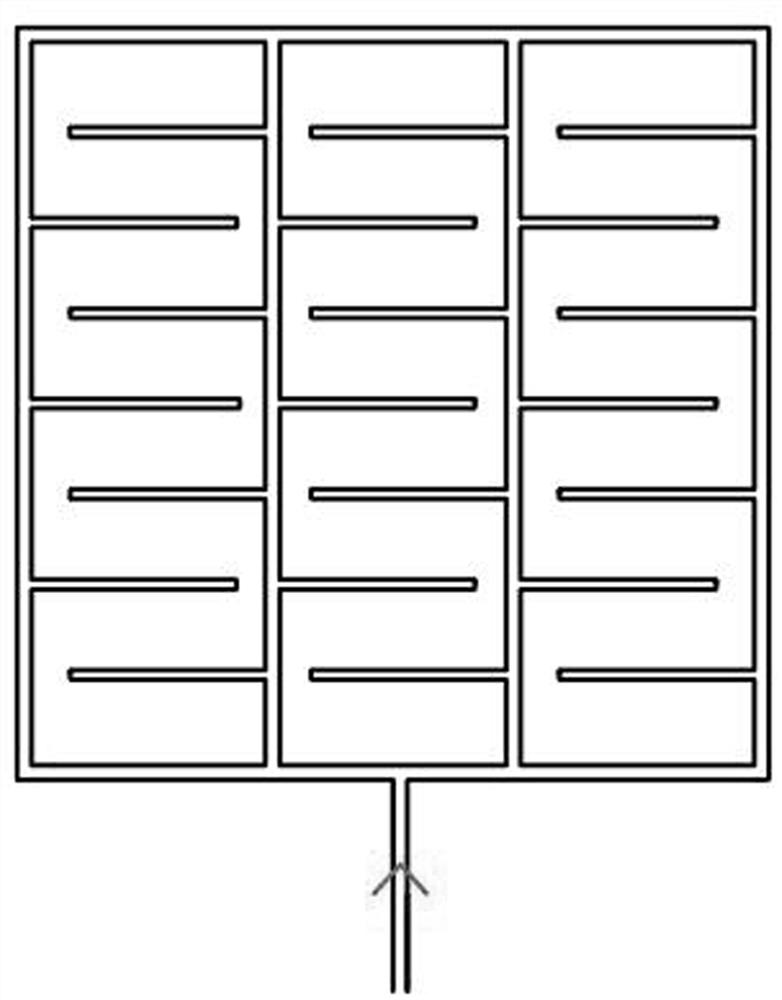

Power distribution line intelligent tour inspection system

InactiveCN105096048ARealize electronicRealize informatizationSensing record carriersResourcesInformatizationElectric power equipment

The invention discloses a power distribution line intelligent tour inspection system comprising an intelligent tour inspection terminal, a main station server and a front-end machine. The intelligent tour inspection terminal is provided with a tour inspection task management device which is provided with a tour inspection task consulting module, a tour inspection content filling module and a tour inspection task uploading module. Tour inspection personnel download power and business data to the intelligent tour inspection terminal via the front-end machine before going out for tour inspection. The tour inspection task consulting module rapidly positions power equipment and automatically prompts tour inspection item content of the power equipment after the tour inspection personnel arrive the scene. The tour inspection personnel are guided to input tour inspection results by the tour inspection content filling module after completion of tour inspection. The tour inspection results are uploaded to the front-end machine by the tour inspection task uploading module after end of tour inspection. Electronic, informatization and intelligent power distribution line tour inspection management can be realized so that leak inspection and false inspection can be reduced to the largest extent, and the long-term and high-efficiency stable operation of the electric power line can be ensured.

Owner:LISHUI POWER SUPPLY COMPANY OF STATE GRID ZHEJIANG ELECTRIC POWER +2

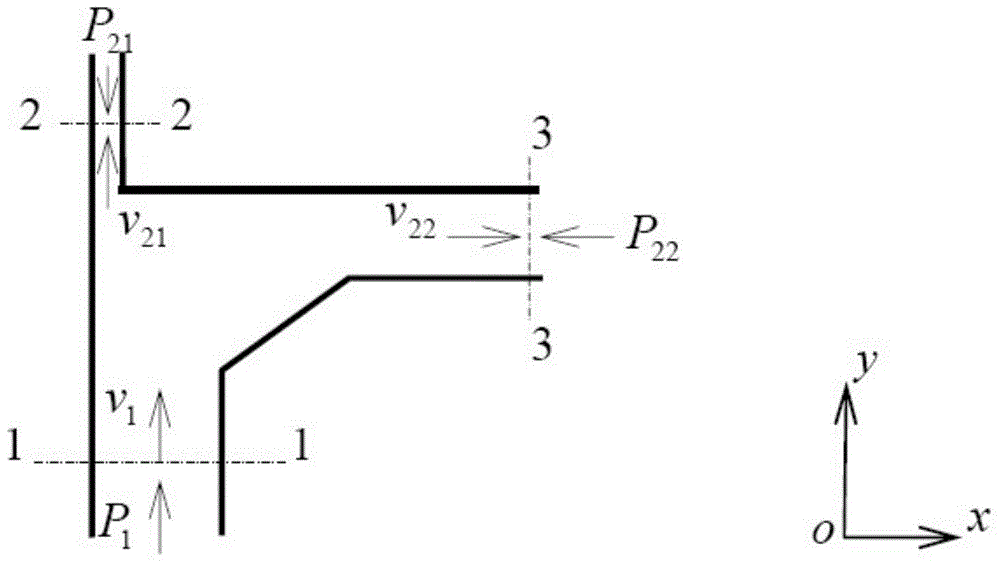

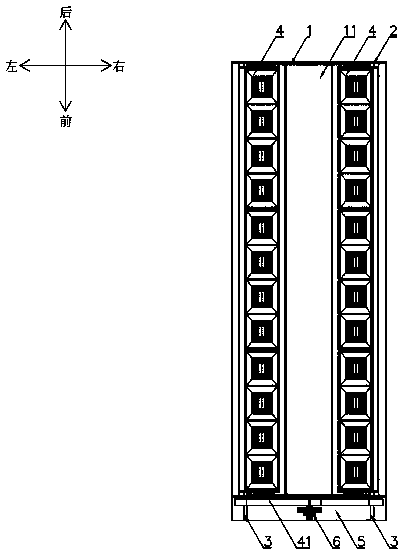

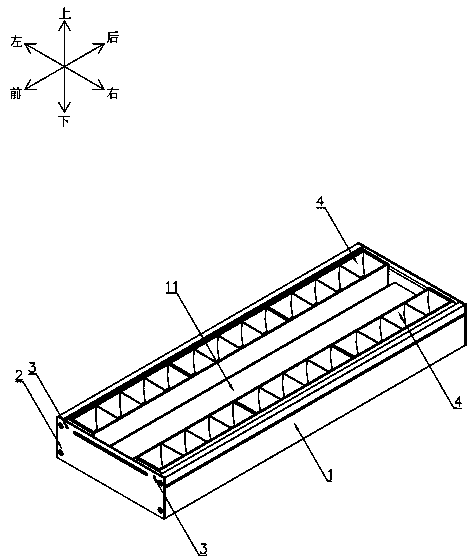

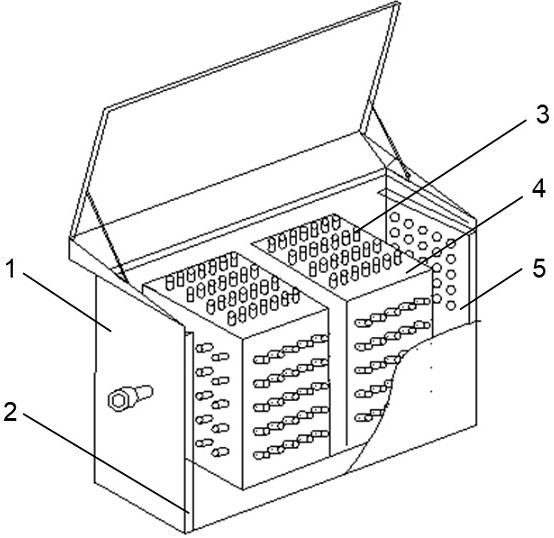

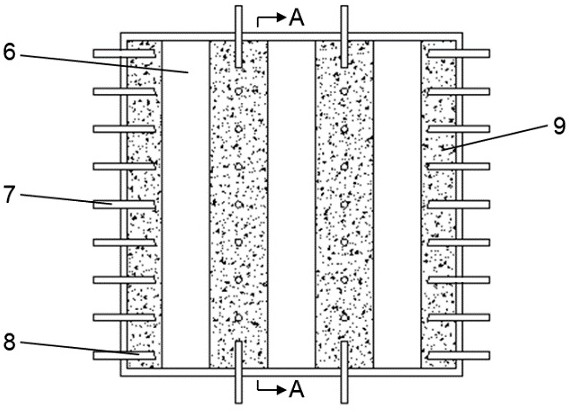

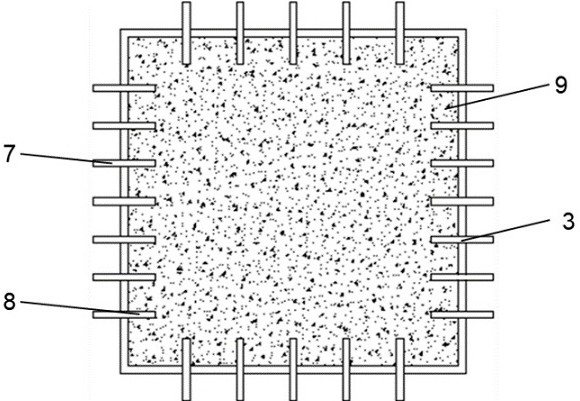

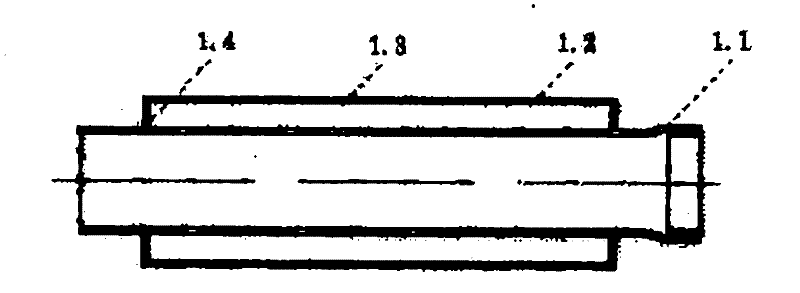

Immersed self-flow-interfering shell-and-tube-type heat exchanger

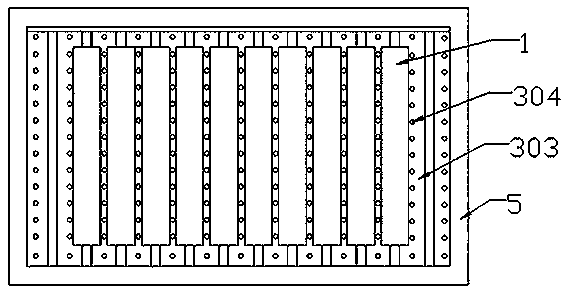

ActiveCN110631301AEnhanced perturbation strengthImprove heat transfer effectIndirect heat exchangersModifications using liquid coolingTemperature controlPlate heat exchanger

The invention provides an immersed self-flow-interfering shell-and-tube-type heat exchanger. The heat exchanger comprises a shell, a liquid distribution device, a self-flow-interfering device and a liquid collection device; a cooling liquid inlet and a cooling liquid outlet are formed in the shell; the cooling liquid inlet communicates with the liquid distribution device; the liquid distribution device communicates with the self-flow-interfering device; the liquid collection device is located on the upper part of the shell and below the liquid surface of cooling liquid; the liquid collection device communicates with the cooling liquid outlet; the cooling liquid enters the shell sequentially through the cooling liquid inlet, the liquid distribution device and the self-flow-interfering device, and flows out of the cooling liquid outlet through the liquid collection device; a heat source is immersed in the cooling liquid in the shell; and the liquid distribution device comprises a liquiddistribution mother tube which communicates with the cooling liquid inlet. The immersed self-flow-interfering shell-and-tube-type heat exchanger is controlled through liquid outlet temperature, so that the effects of automatic controlling and energy saving are realized; the interfering strength of a cooling liquid flowing field in the shell is enhanced; and the heat exchanging efficiency is improved.

Owner:SHANDONG UNIV

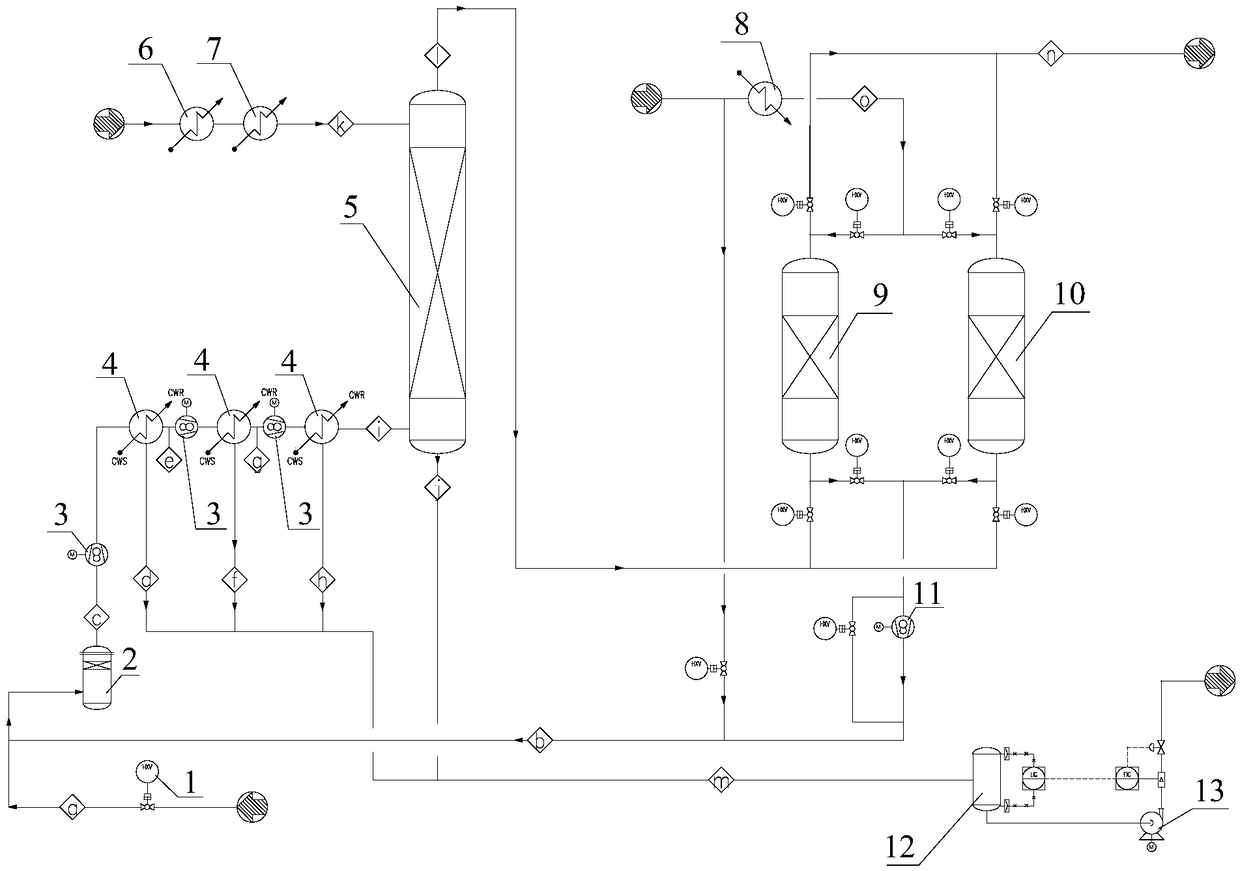

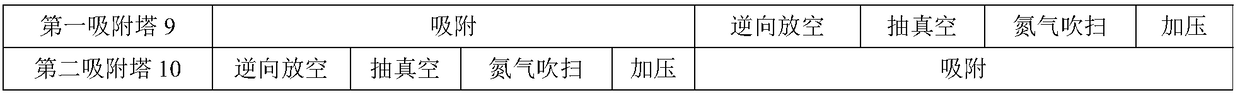

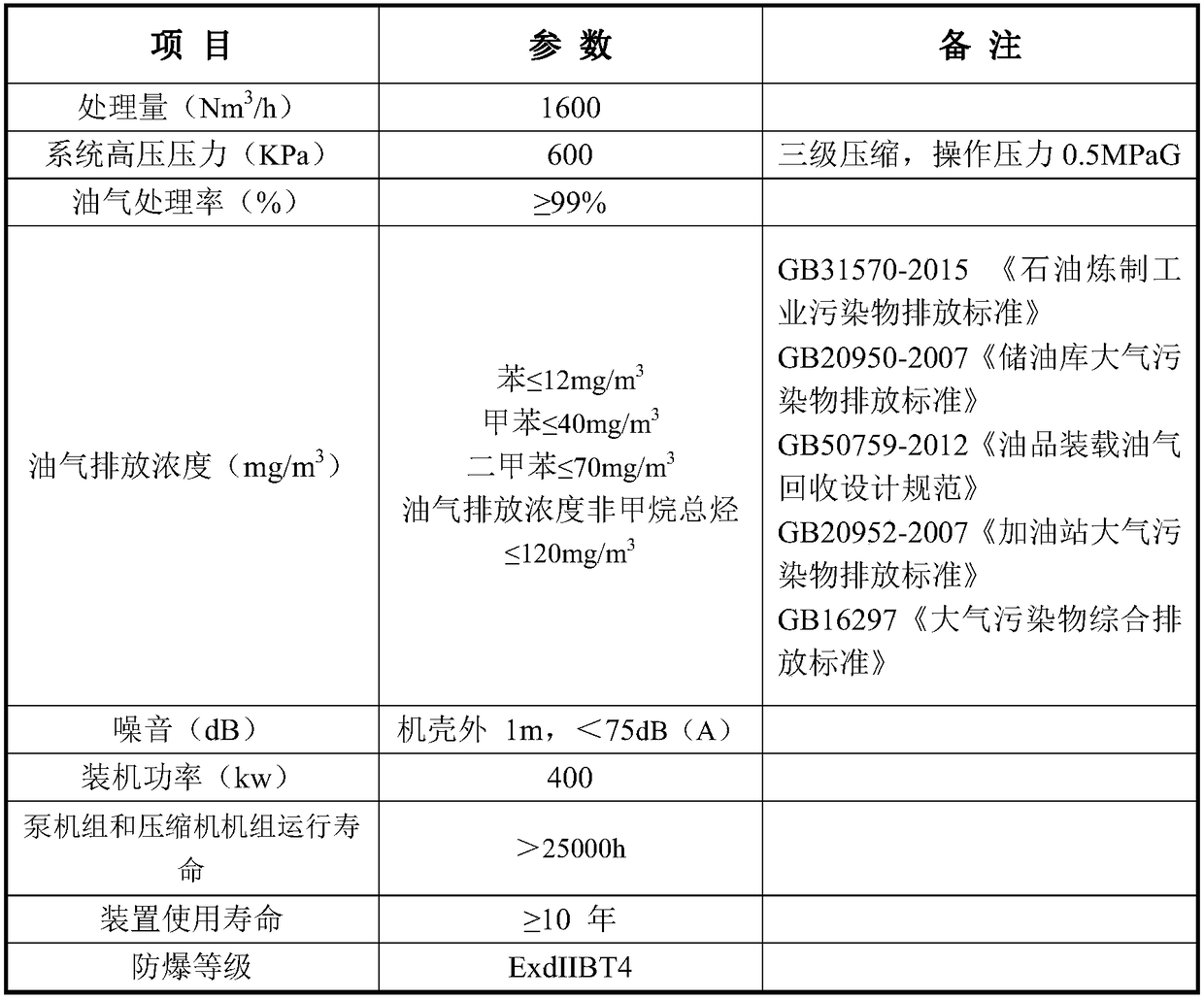

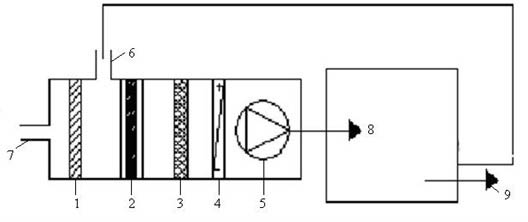

Integrated oil and gas recovery system and recovery process

InactiveCN109045739ALow quality scoreEliminate multi-stage preprocessingGas treatmentDispersed particle separationRecovery methodAtmospheric air

The invention belongs to the technical field of oil and gas recovery, and discloses an integrated oil and gas recovery system and a recovery process. The integrated oil and gas recovery system comprises a pressure buffer tank, a tail gas compression and preliminary condensation device, a lean oil cooling and absorbing device, an absorption device and a recovery device, wherein the original oil andgas are conveyed into the pressure buffer tank, and then sent to the tail gas compression and preliminary condensation device; after being subjected to compression and condensation, the oil and gas enter an absorption tower of the lean oil cooling and absorbing device; gasoline No.93 enters the absorption tower after being precooled by means of an absorbent oil precooler and subjected to deep cooling of an absorbent oil deep freezer; after being subjected to low-temperature spraying of the absorption tower, the oil and gas is conveyed to an oil collecting tank, and the remaining tail gas enters the absorption device for absorbing; the absorbed tail gas is discharged to the atmosphere, and the absorbed hydrocarbon components are recovered to the pressure buffer tank by means of vacuum thermal analysis. The system and the process integrate compression, condensing absorption and absorbing, can enable emissions to reach the standards, have multiple safeguards, can remarkably improve the oil and gas recovery effect, and greatly reduce equipment size and equipment investment.

Owner:伟林环保科技(大连)有限公司

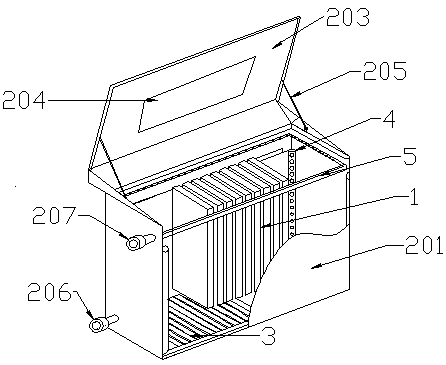

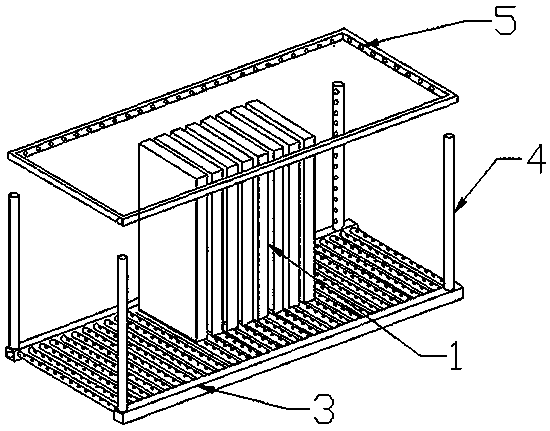

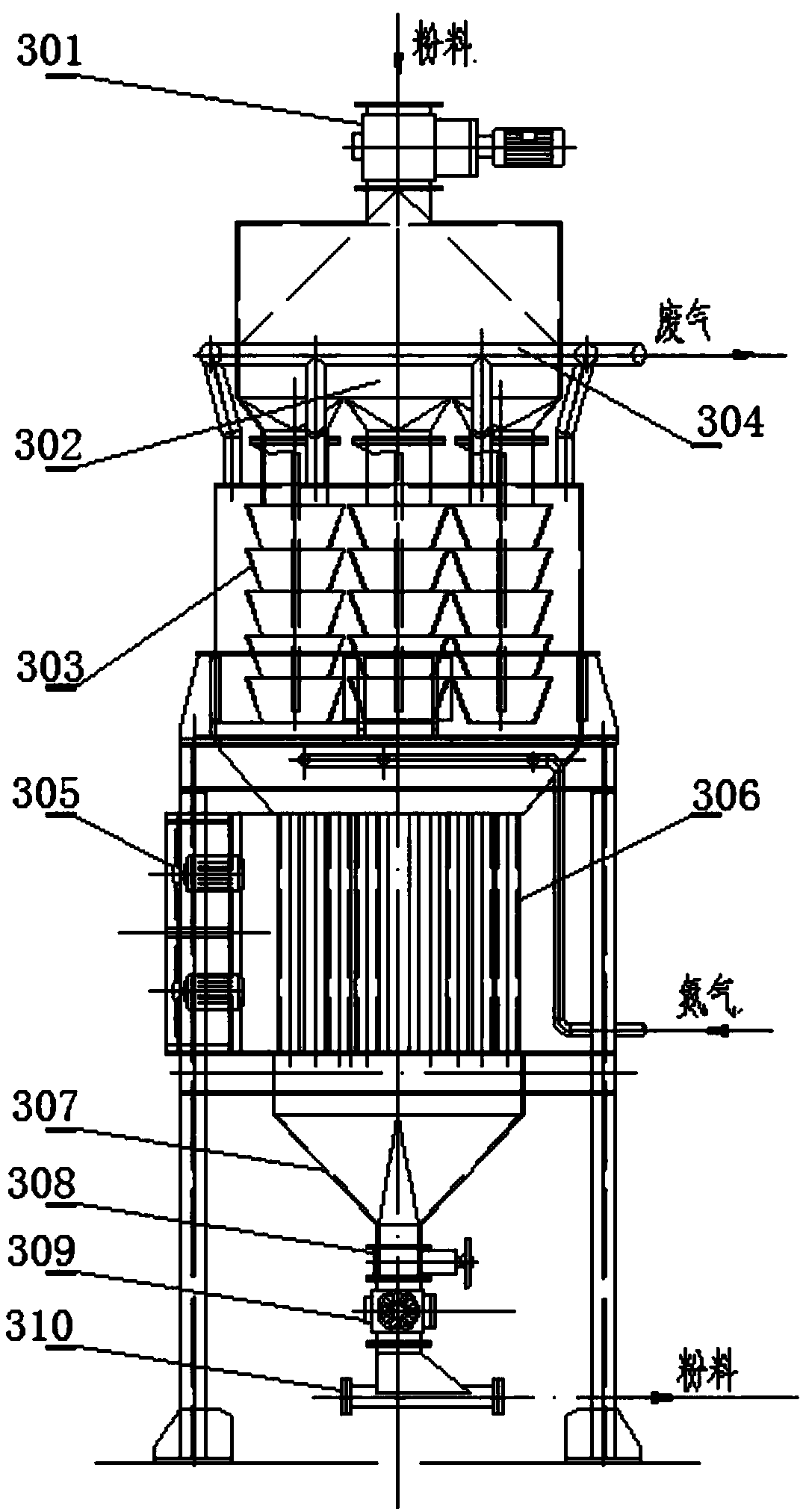

Sticky smoke dust removal system and method for actively regenerating pre-sprayed powder for coke oven

ActiveCN108261853ACompact structureRegeneration of pyrolytic activityDispersed particle filtrationOven incrustations prevention/removalSpray coatingCoke oven

The invention relates to a sticky smoke dust removal system and method for actively regenerating pre-sprayed powder for a coke oven. The tops of bag type dust removers are provided with purified gas outlets; the purified gas outlets are connected with a dust removal fan, a muffler and a chimney in sequence; the lower parts of dust removal chambers of the bag type dust removers are provided with smoke dust inlets; the smoke dust inlets are connected with dust remover inlet pipelines; the dust remover inlet pipelines in front of the smoke dust inlets are provided with pre-sprayed powder inlets;the pre-sprayed powder inlets are connected with a powder exhaust nozzle of a powder active regeneration and jetting integrated device through powder conveying pipelines; the bottoms of ash bins of the bag type dust removers are provided with ash outlets; the ash outlets are connected with a mill dust inlet and a mill dust bin of the powder active regeneration and jetting integrated device respectively through a scraper. The sticky smoke dust removal system is used, through configuring the powder active regeneration and jetting integrated device, for realizing the automatic addition, the excess material outward delivery, the active pyrolysis and regeneration, the automatic spray coating, the output amount regulation and the recycling of the pre-sprayed powder in the dust removal system; the pre-sprayed powder does not need to be externally supplemented, and thus, the reliable and stable running of the dust removal system is ensured.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

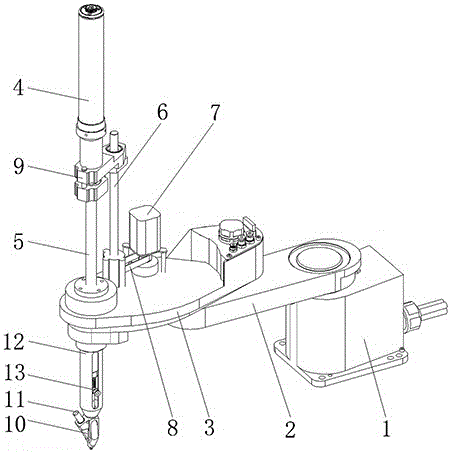

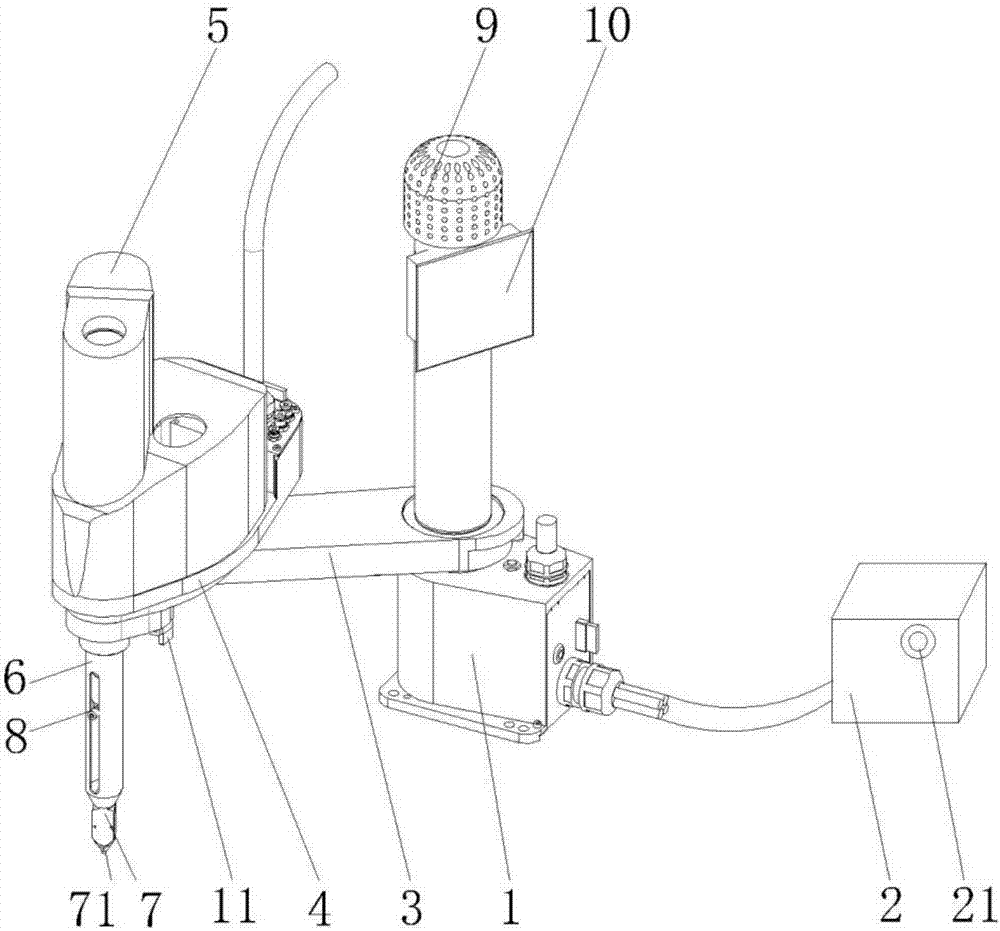

Working method for joint robot for assembly

InactiveCN106003086AAvoid offsetImprove calibration accuracyMetal working apparatusManipulatorArthrobotrysRivet

The invention discloses a working method for a joint robot for assembly, and mainly relates to the technical field of the joint robot. The working method comprises the following steps: a first joint shaft and a second joint shaft on a machine base are driven by a servo motor to start rotary regulation in the horizontal direction; under action of a sucker assembly, a bolt or a rivet enters a gripper head through a vacuum suction nozzle; a synchronous belt is driven by a motor to sequentially drive a lead screw and a buffer mechanism, and to drive a spline shaft with a screwdriver head or a riveting head at the bottom end to pass through a connecting sleeve for jacking the bolt or rivet; after the bolt or the rivet is calibrated by the screwdriver head or the riveting head, the spline shaft is driven by an electric motor to drive the screwdriver head or the riveting head to rotate and press together until assembly is completed; and finally, the spline shaft is driven by the motor to drive the screwdriver head or the riveting head to move upwards to wait for a next-time working order. The working method is precise in station calibration, is high in assembly speed, is low in load requirement, is not liable to damage a workpiece during working, and is low in operation cost.

Owner:苏州塞默机械有限公司

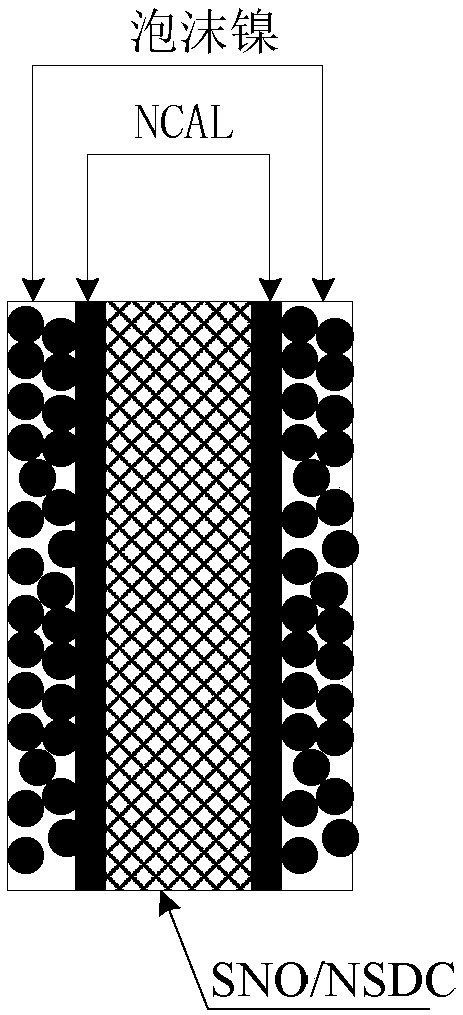

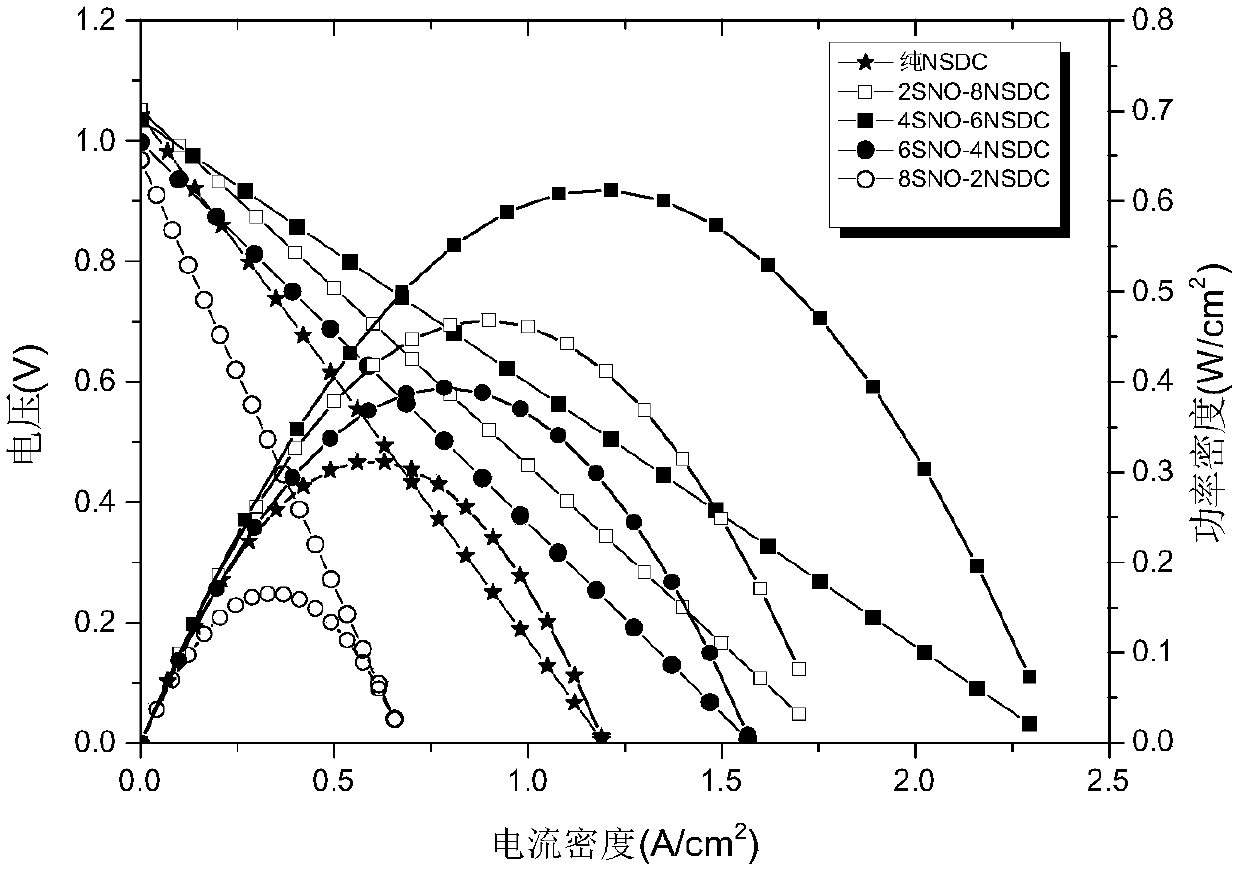

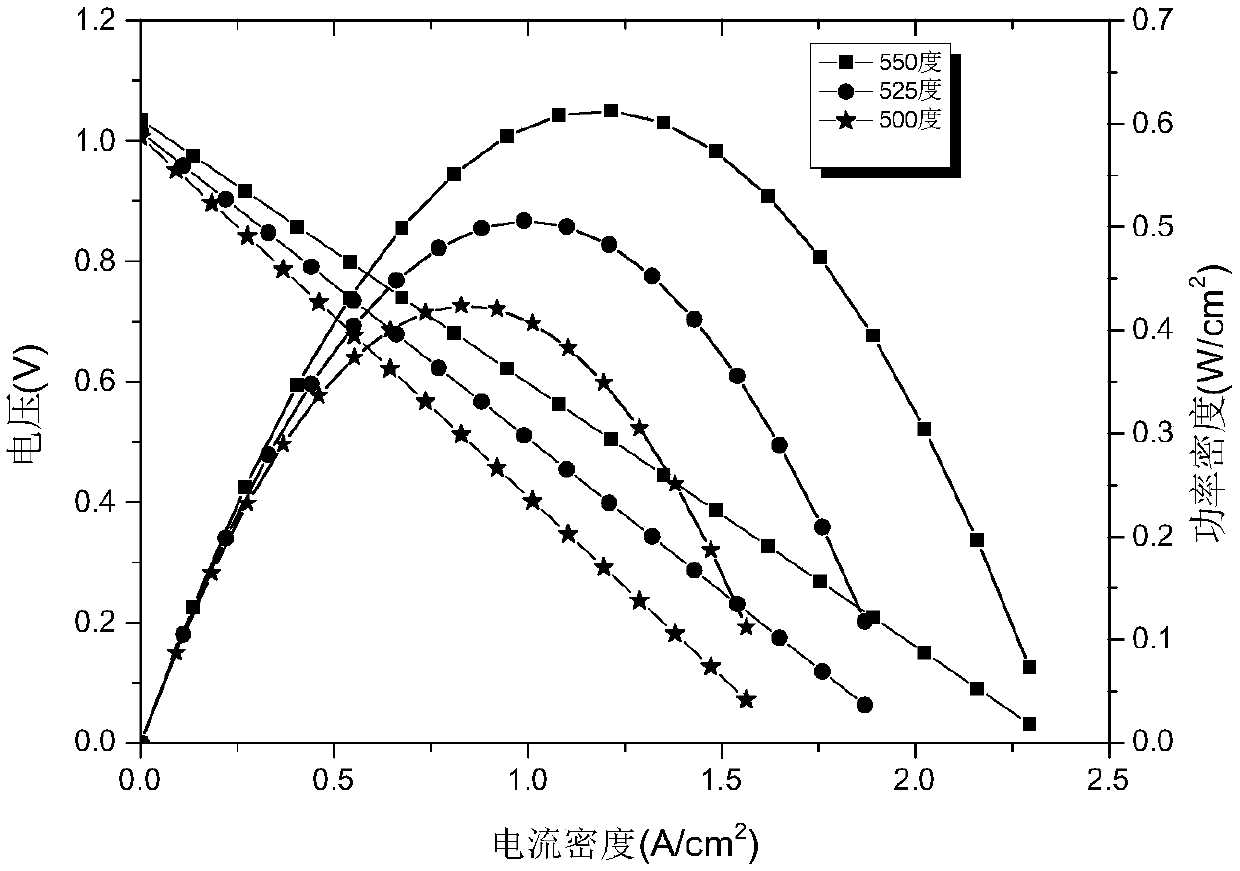

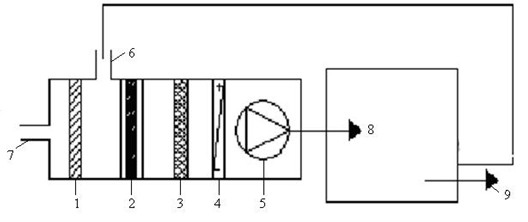

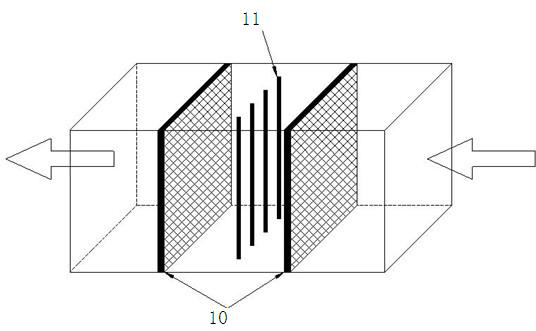

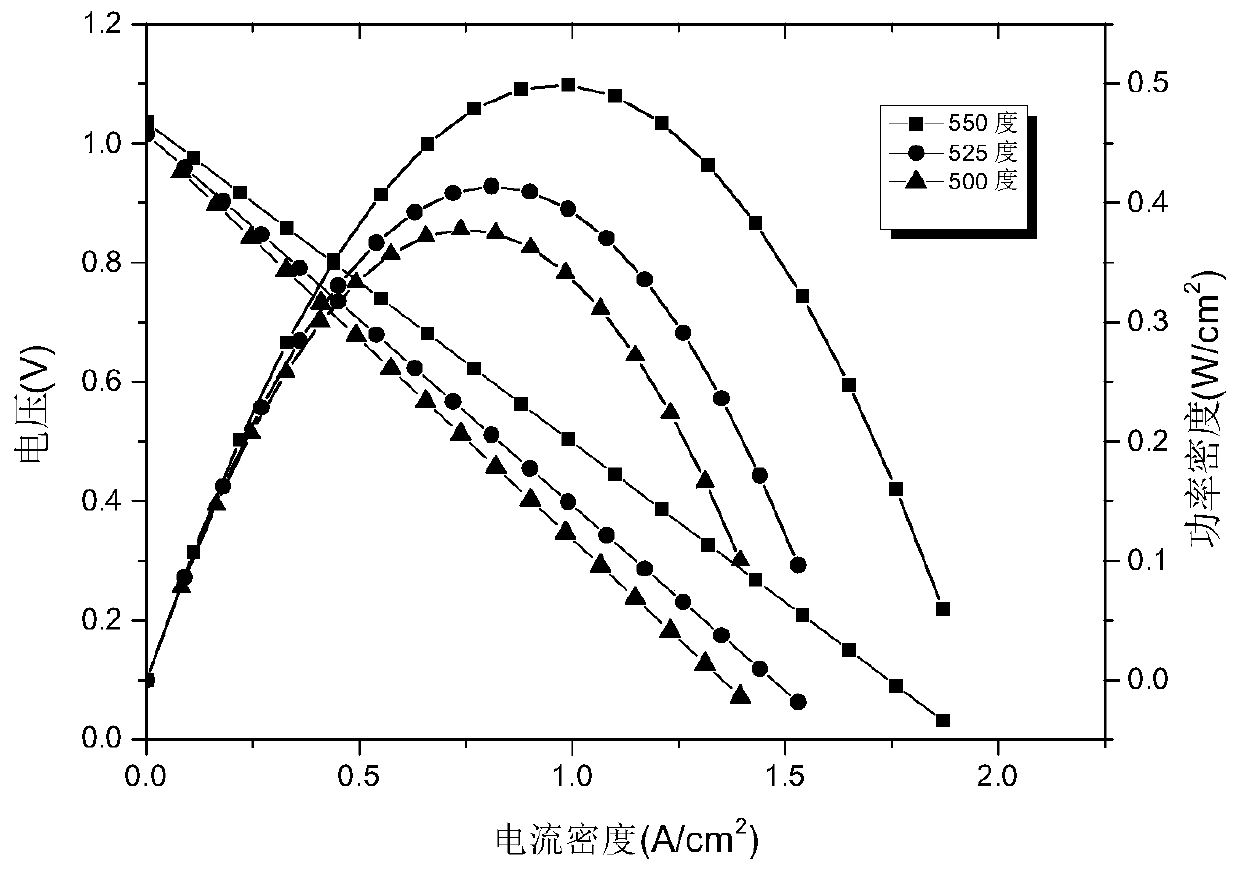

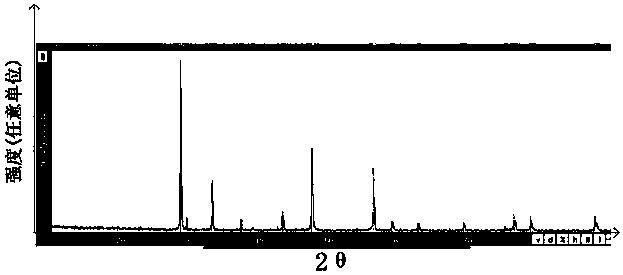

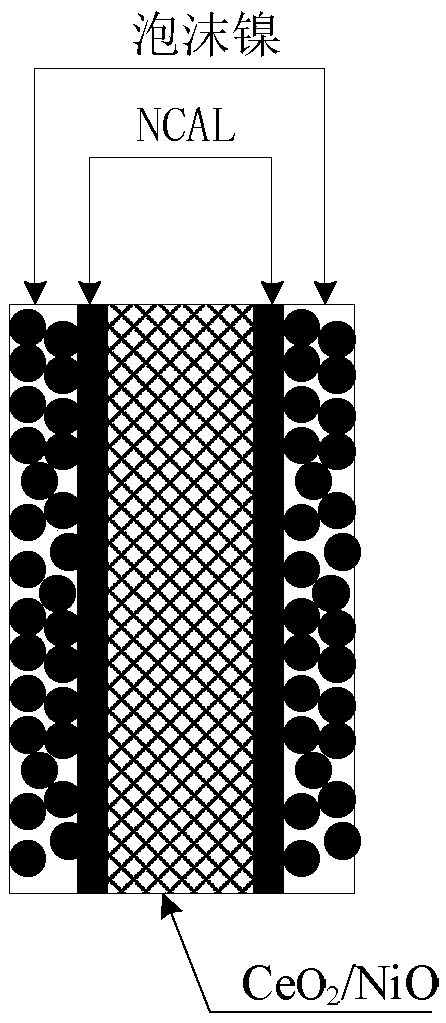

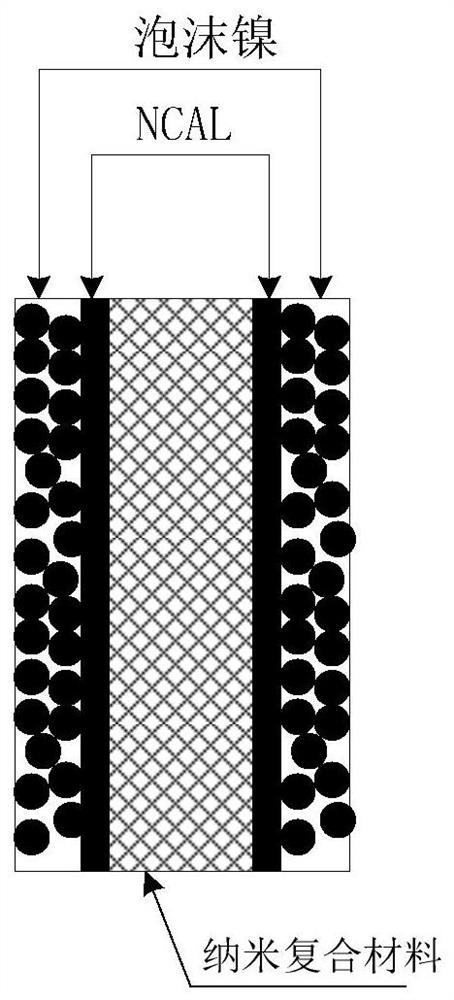

Oxide fuel cell based on lanthanum nickelate and lanthanum-doped yttrium oxide composite material

InactiveCN109687005AImprove transmission performanceIncrease output powerElectrolytesFuel cellsElectrical conductorOxide composite

The invention discloses an oxide fuel cell based on a lanthanum nickelate and lanthanum-doped yttrium oxide composite material. A cathode and an anode of the fuel cell are made from foam nickel coatedwith NCAL on the surface, and an electrolyte layer of the fuel cell is a SNO / NSDC composite material, that is, the structure of the fuel cell is made from foam nickel / / NCAL / / SNO / NSDC / / NCAL / / foam nickel. The low-temperature solid oxide fuel cell uses the lanthanum-doped yttrium oxide (NSDC) composite material, prepared by utilizing a sodium carbonate precipitation process, of an ionic conductor asan electrolyte layer, and greatly reduces the electrode polarization loss during the electrochemical reaction of the fuel cell; in addition, the electrolyte material has good output power in the lowtemperature section, so that the solid oxide fuel cell using the electrolyte material can be efficiently and stably operate in a low temperature range (300-600 DEG C) for a long period of time. Stableoperation.

Owner:NANJING XIAOZHUANG UNIV

Improvement method of air-conditioner purifier

InactiveCN102434924AEasy to disassemble and replaceIncrease the areaLighting and heating apparatusAir conditioning systemsAdhesiveFiltration

Owner:SHENYANG JIANZHU UNIVERSITY

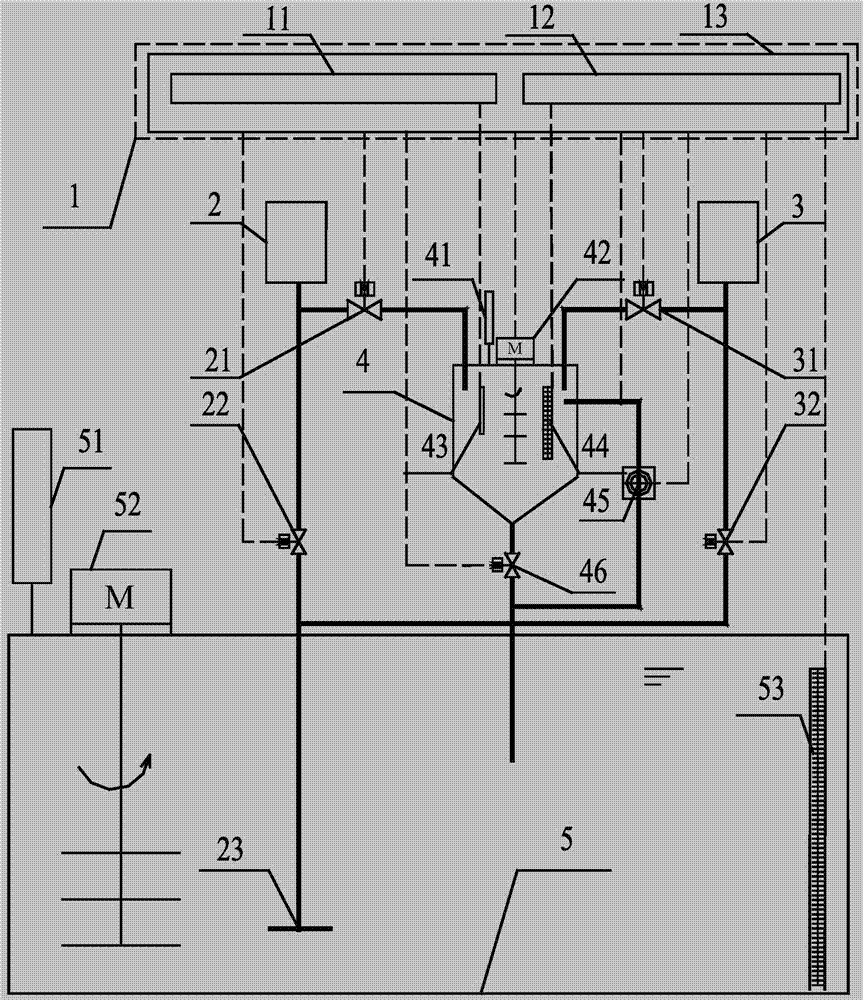

Bioreactor for online automatic pH control and control method thereof

ActiveCN107416969AAvoid local shocksAvoid interferenceWater treatment parameter controlTreatment using aerobic processesPeristaltic pumpEngineering

The invention discloses a bioreactor for online automatic pH control. The bioreactor comprises a data acquisition controller, an alkali storage tank, an acid storage tank, a regulation tank and a biological reaction tank, wherein the data acquisition controller comprises a pH acquisition unit, a liquid level acquisition unit and an electromagnetic valve which are connected with a peristaltic pump control unit; the alkali storage tank and the acid storage tank are connected with the regulation tank and the biological reaction tank through a pipeline with an electromagnetic valve; a liquid inlet of the regulation tank is connected with the biological reaction tank through a pipeline with a peristaltic pump, and a liquid outlet is connected with the biological reaction tank through the pipeline with an electromagnetic valve; the regulation tank is provided with a pH meter and a liquid level meter; the biological reaction tank is provided with a gas outlet, a stirrer and a liquid level meter; the pH meter is connected with the pH acquisition unit; the liquid level meter is connected with the liquid level acquisition unit; the electromagnetic valve and the peristaltic pump are connected with the electromagnetic valve and the peristaltic pump control unit. The bioreactor disclosed by the invention can effectively realize online control on the pH in the reactor in real time so as to avoid local impact of high-concentration acid-base reagent on microbial activity and promote long-term efficient and stable operation of the reactor.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

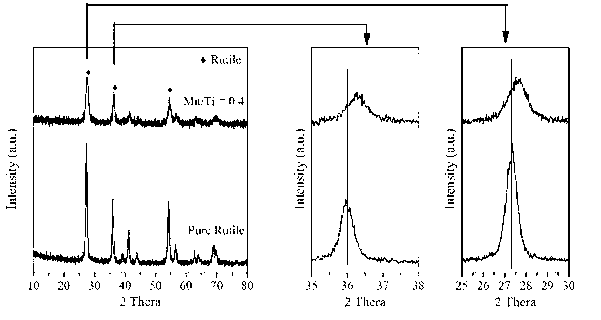

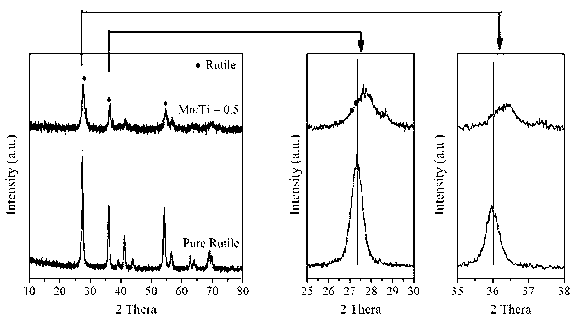

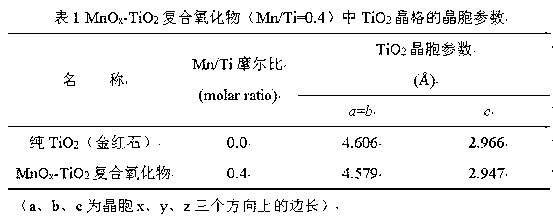

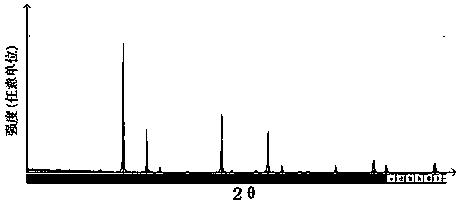

MnOx-TiO2 composite oxide with rutile TiO2 serving as matrix

ActiveCN102935361AGood dispersionInhibition of sintering growthNitrous oxide captureDispersed particle separationDispersityIce water

The invention relates to MnOx-TiO2 composite oxide with rutile TiO2 serving as a matrix and application of the MnOx-TiO2 composite oxide with rutile TiO2 serving as the matrix in fume low-temperature Selective Catalytic Reduction (SCR) denitration. In the fume low-temperature SCR denitration, the MnOx-TiO2 composite oxide serves as a catalyst. The method comprises steps of adding titanium tetrachloride to an acidic aqueous solution under ice-water bath slowly and dropwisely; subjecting TiCl4 and water to the reaction to produce transparent and colorless hydrated TiO6; hydrolyzing the hydrated TiO6 at the room temperature and on the acidic condition; generating rutile TiO2 precursor micelles; adding soluble manganese salt to the precursor micelles and conducting dispersion with stirring; conducting heat processing; and obtaining the nano MnOx-TiO2 composite oxide with rutile TiO2 serving as the matrix and with MnOx serving as an active component. MnOx has high dispersity on the rutile TiO2 matrix. Therefore, the MnOx-TiO2 composite oxide can serve as the low-temperature SCR denitration catalyst and has high catalytic activity. The removing rate of NO can reach 100 mol% under the condition that the NO concentration is 800ppm, the reaction temperature is 160 DEG C and the space speed is 50,000 hours-1.

Owner:GUODIAN ENVIRONMENTAL PROTECTION RES INST CO LTD

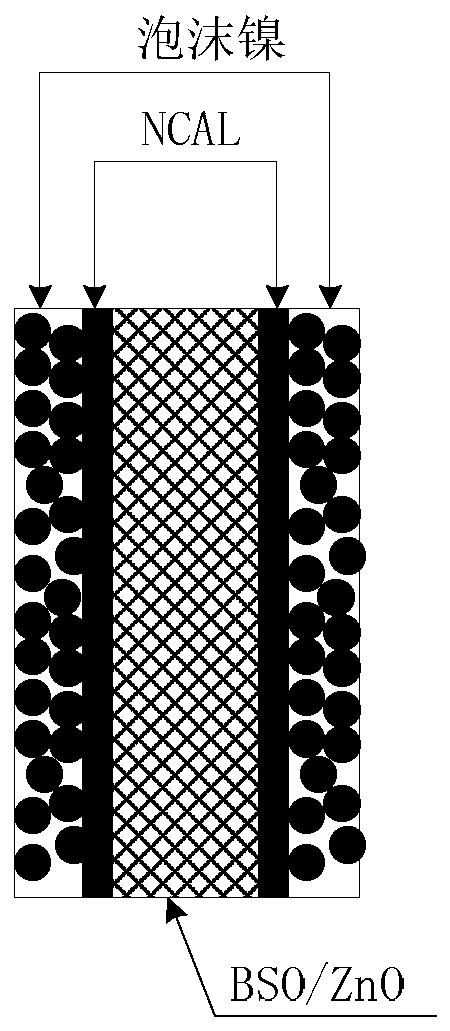

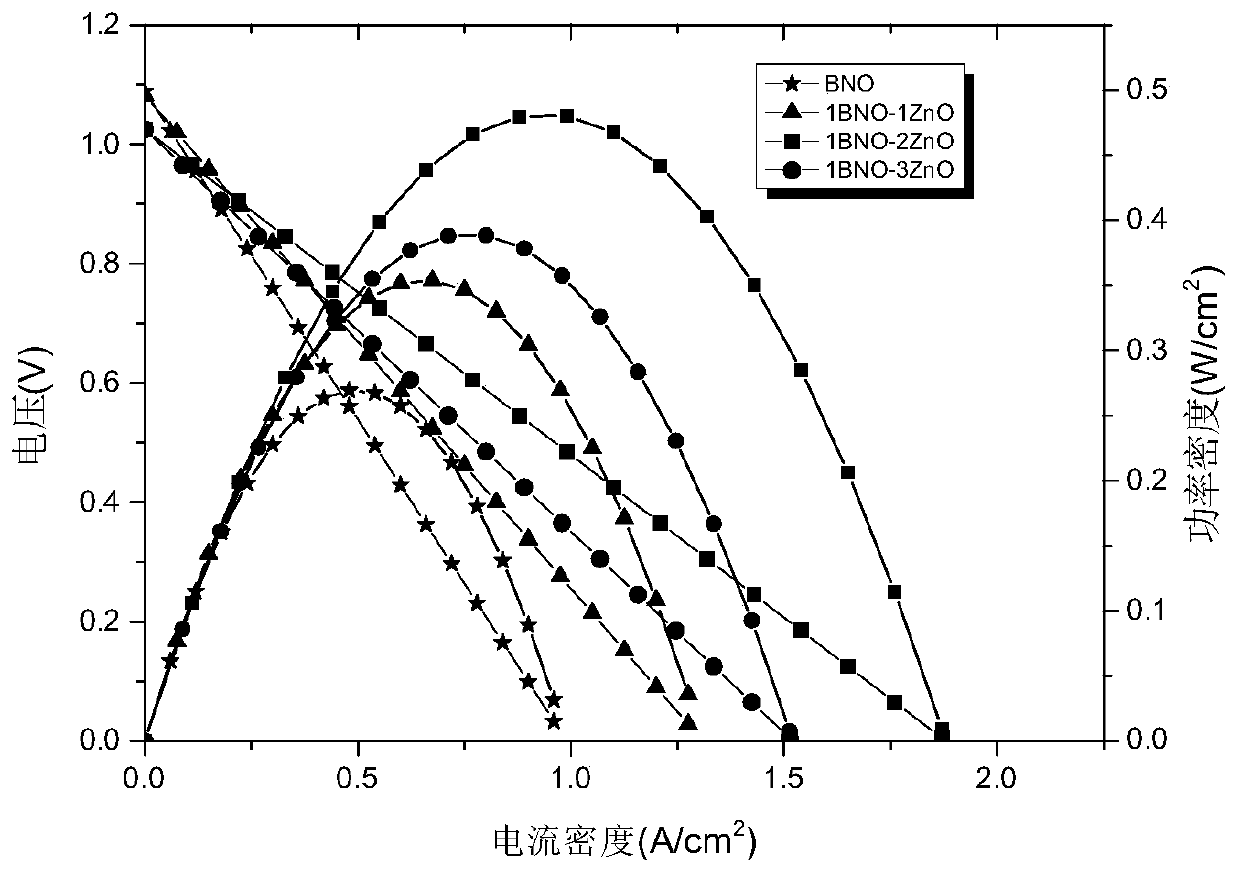

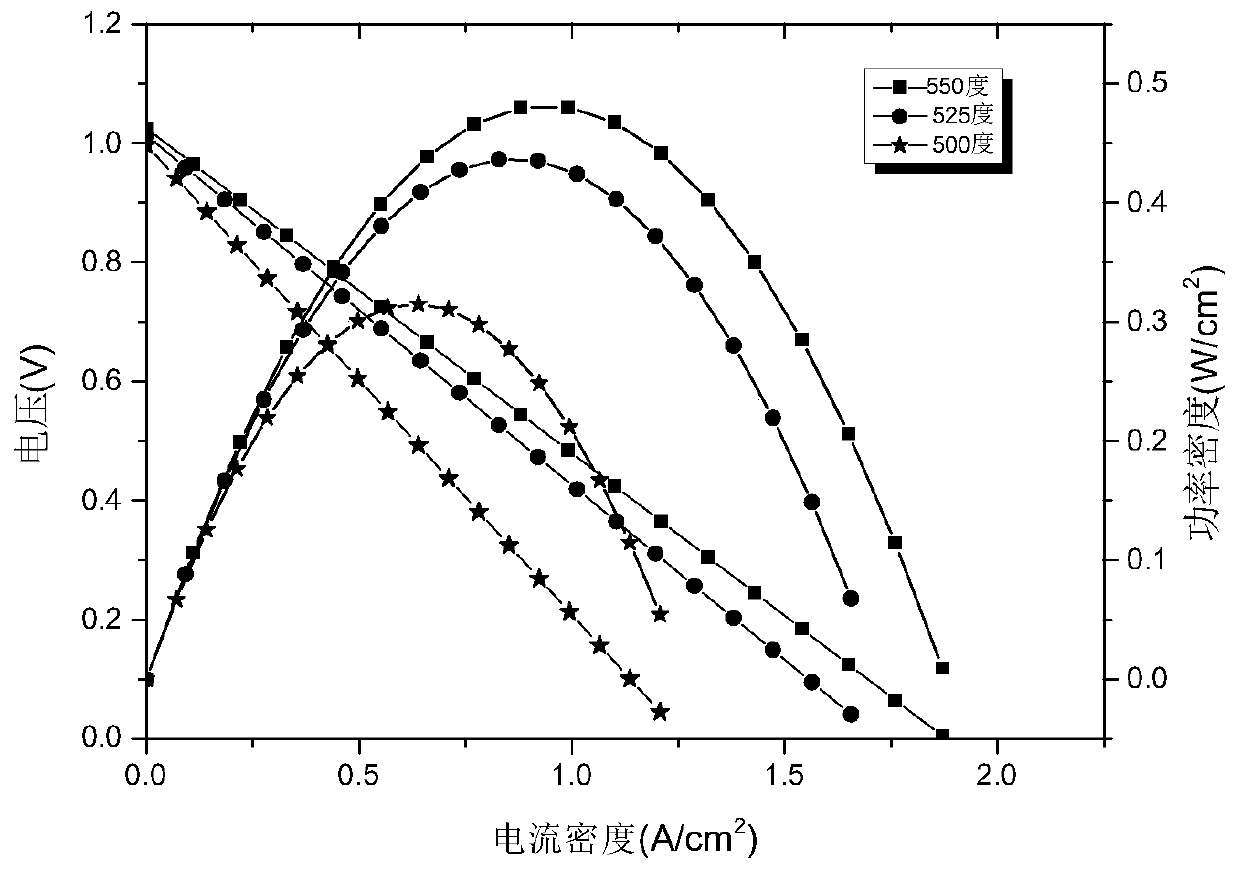

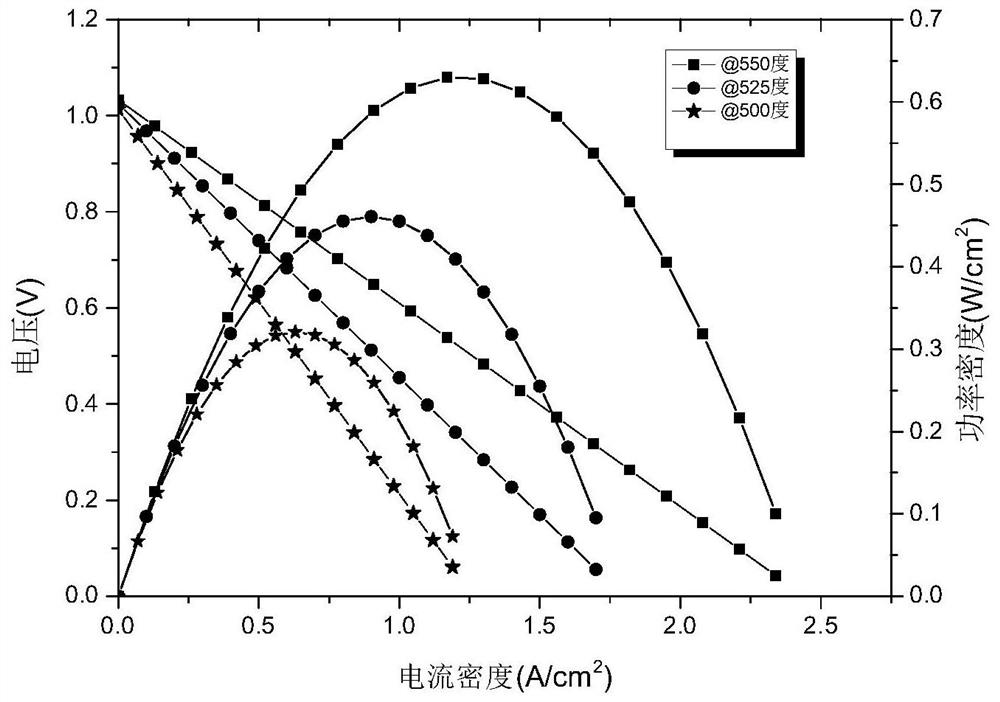

Low-temperature solid oxide fuel cell based on barium stannate/zinc oxide composite material

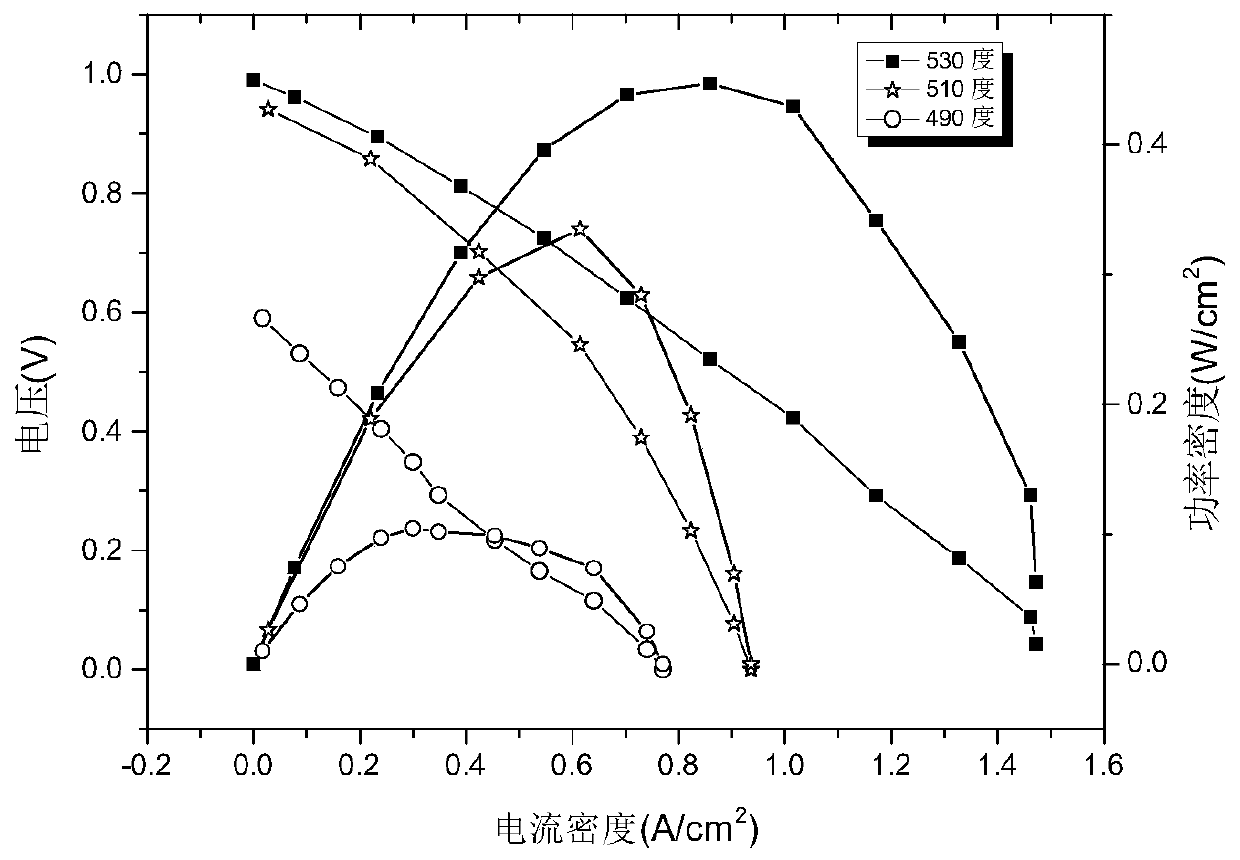

ActiveCN109742430AReduce electrode polarization lossLong-term efficient and stable operationFuel cellsChemical reactionBarium titanate

The invention discloses a low-temperature solid oxide fuel cell based on a barium stannate / zinc oxide composite material. A cathode and an anode of the fuel cell are made of foamed nickel with the surface being coated with NCAL, and an electrolyte layer of the fuel cell is made of a BSO / ZnO composite material. The fuel cell structurally comprises foamed nickel / / NCAL / / BSO / ZnO / / NCAL / / foamed nickel.The low-temperature solid oxide fuel cell adopts the composite material of barium stannate which is of a perovskite structure and nano-zinc oxide as the electrolyte layer of the fuel cell, and the electrode polarization loss in the electrochemical reaction process of the fuel cell is greatly reduced; and in addition, the electrolyte material has good output power in the low-temperature stage, so that the solid oxide fuel cell adopting the electrolyte material can operate efficiently and steadily for a long term in the low-temperature stage (300-600 DEG C).

Owner:NANJING XIAOZHUANG UNIV

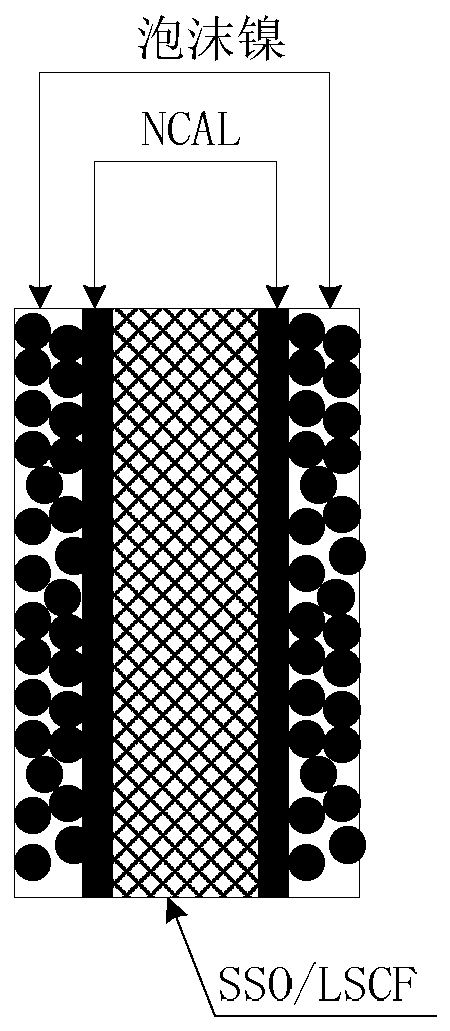

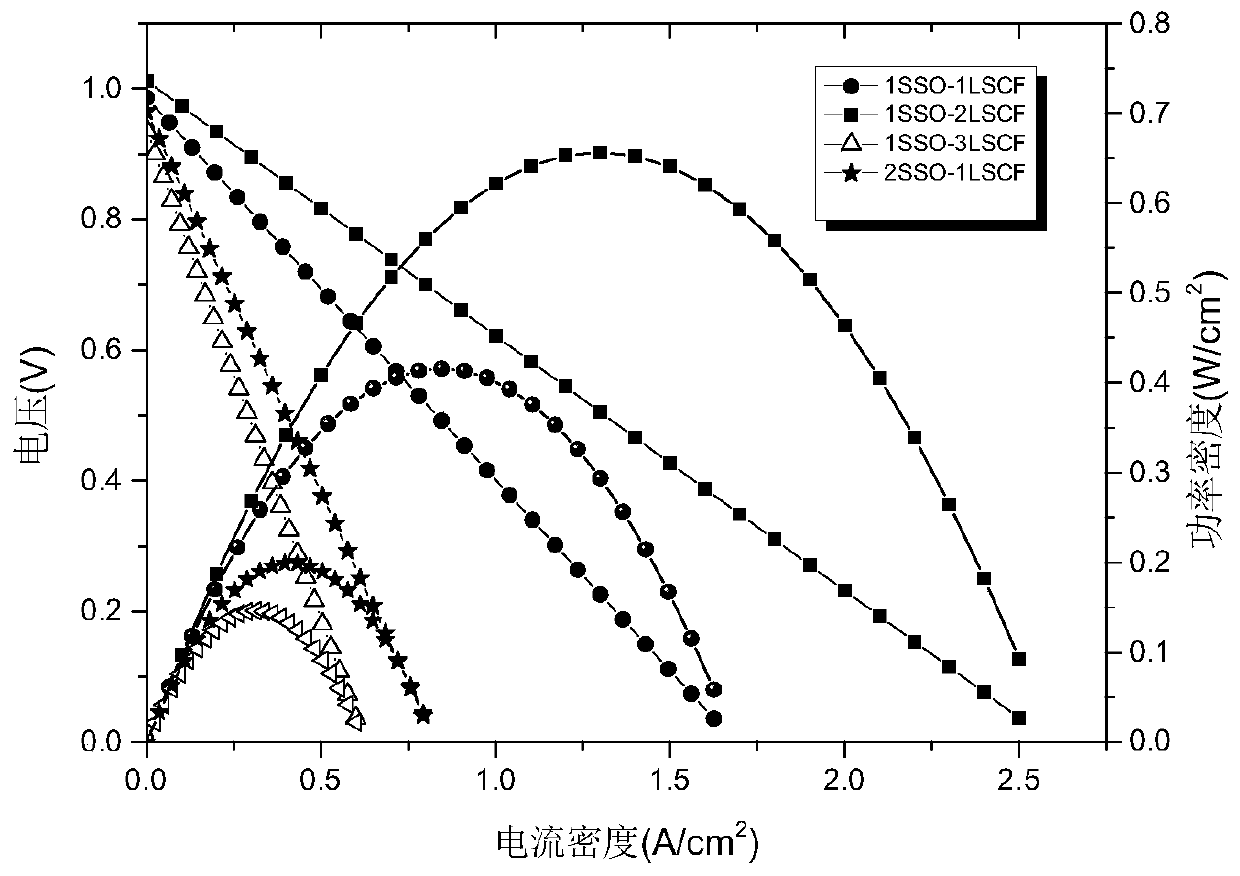

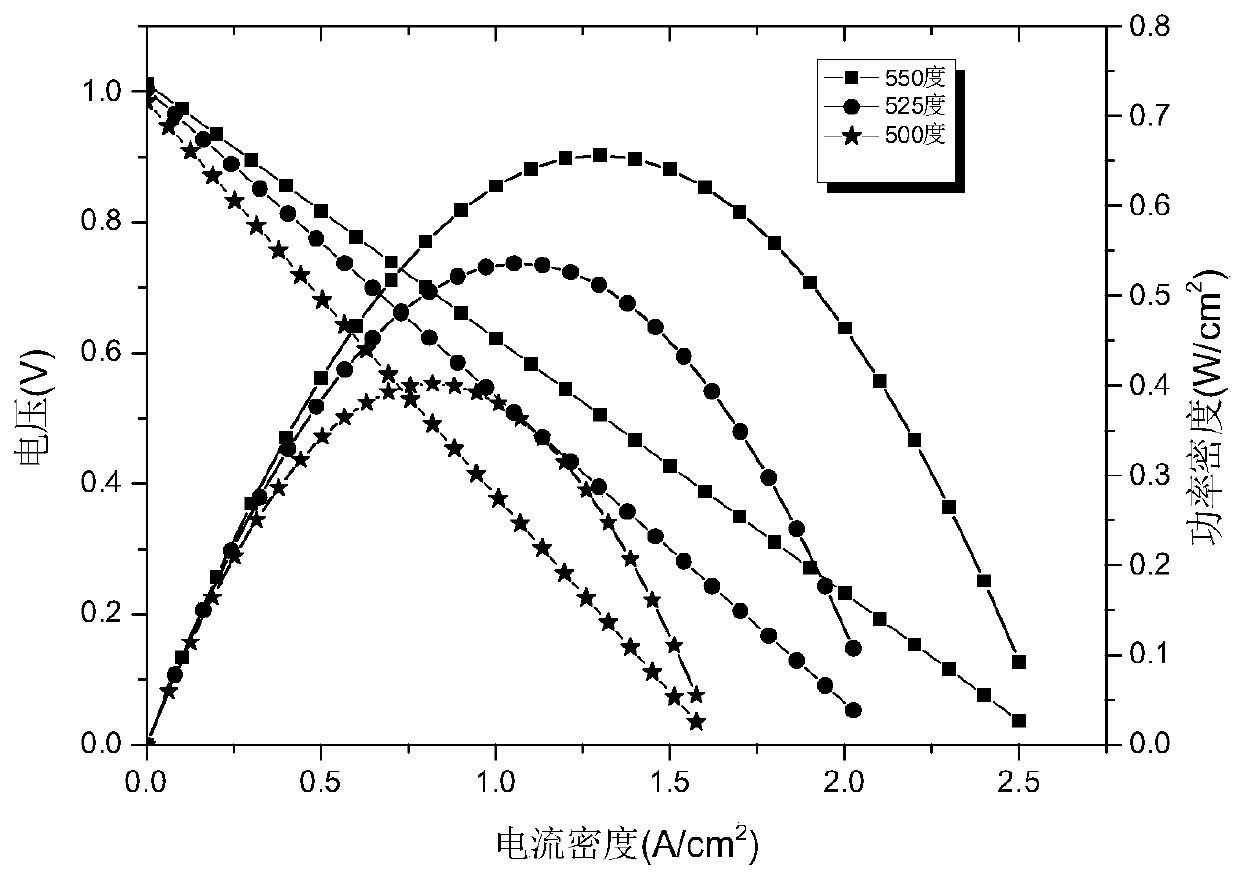

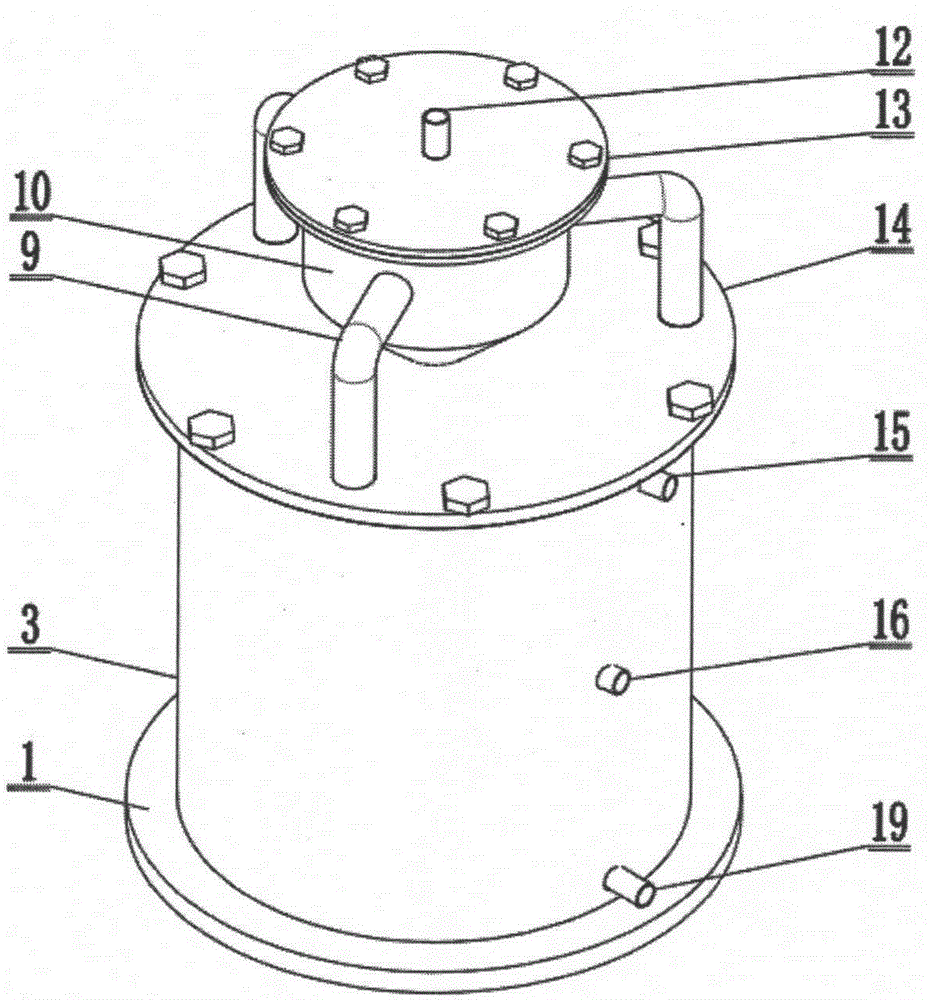

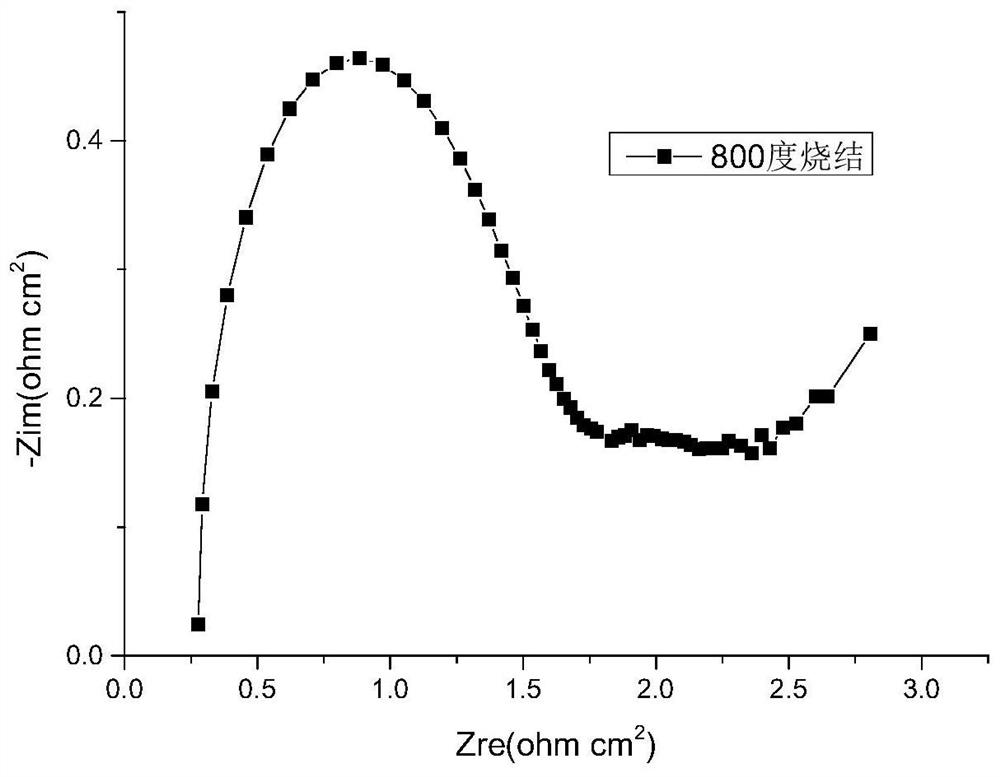

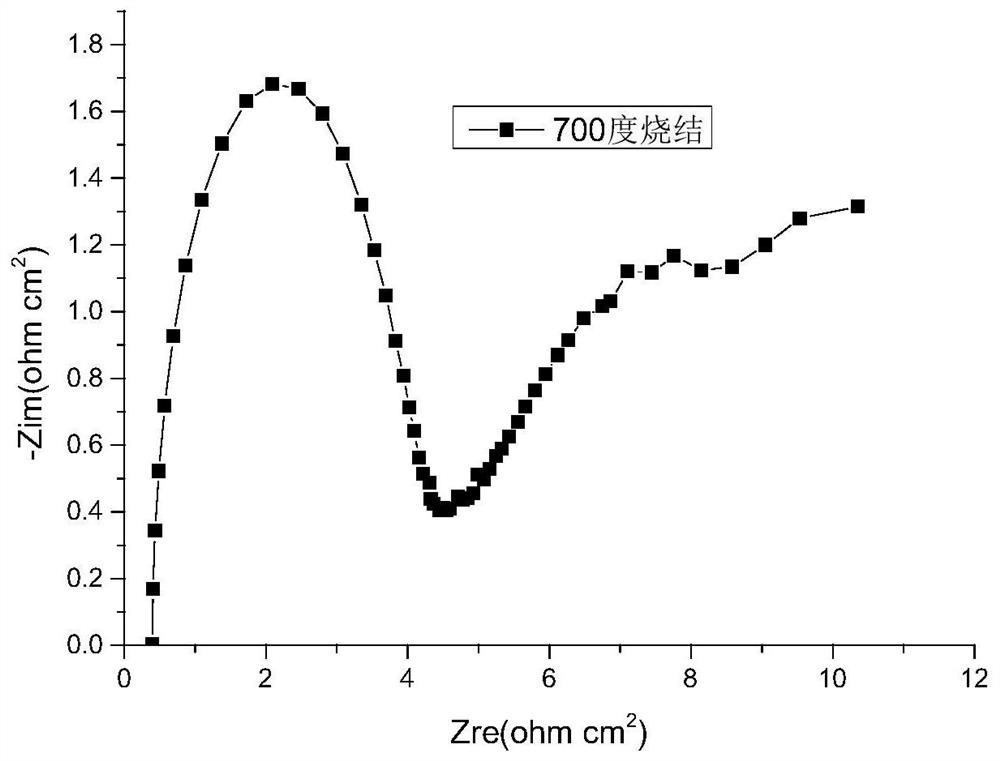

Strontium stannate/lanthanum strontium cobalt iron composite material-based low-temperature solid oxide fuel cell

ActiveCN109786795AReduce electrode polarization lossLong-term efficient and stable operationCell electrodesSolid electrolyte fuel cellsElectrochemistryLanthanum

The invention discloses a strontium stannate / lanthanum strontium cobalt iron composite material-based low-temperature solid oxide fuel cell. A negative electrode and a positive electrode of the fuel cell are foamed nickel of which a surface is coated with NCAL, and an electrolyte layer of the fuel cell is an SSO / LSCF composite material. The structure of the fuel cell is foamed nickel / / NCAL / / SSO / LSCF / / NCAL / / foamed nickel. In the low-temperature solid oxide fuel cell, a perovskite-structure strontium stannate and lanthanum strontium cobalt iron composite material is used as the electrolyte layerof the low-temperature solid oxide fuel cell, and the electrode polarization loss during the electrochemical reaction process of the fuel cell is greatly reduced; and the electrolyte material has favorable output power at a low-temperature segment, so that the solid oxide fuel cell employing the electrolyte material can efficiently and stably run for a long term at the low-temperature segment (300-600 DEG C).

Owner:NANJING XIAOZHUANG UNIV

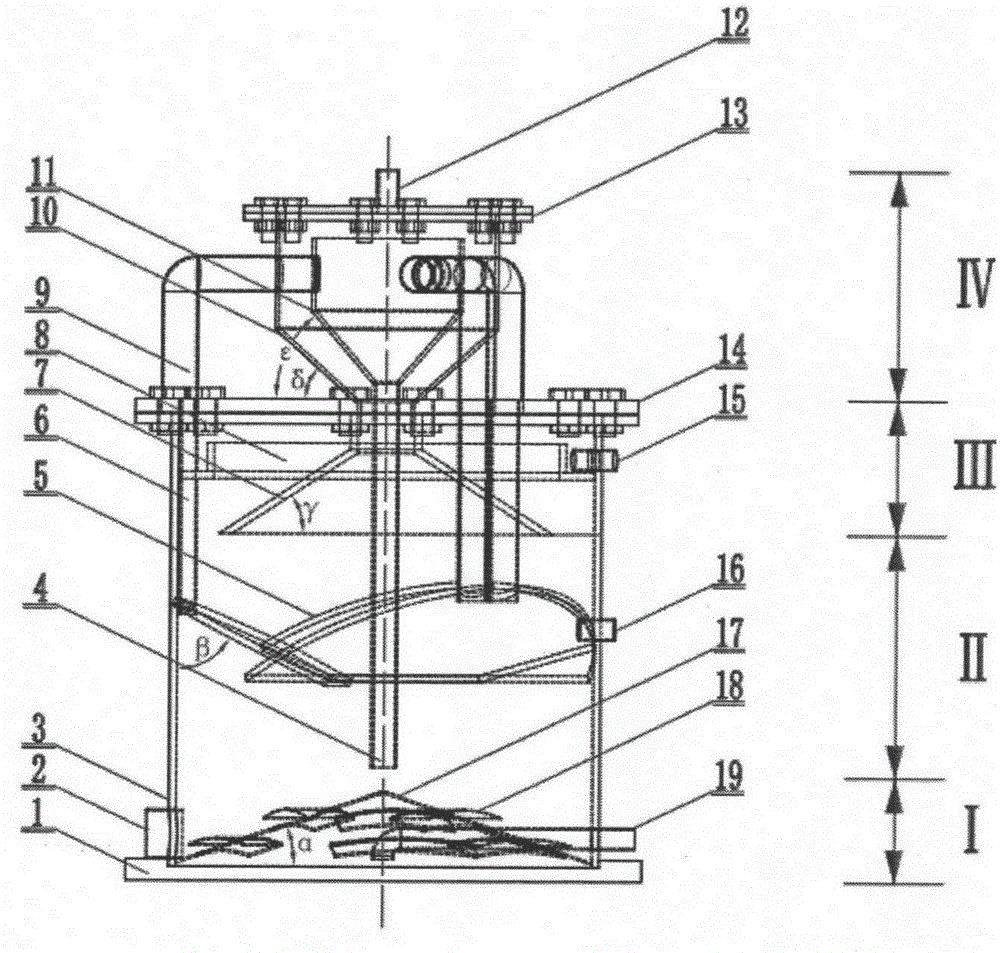

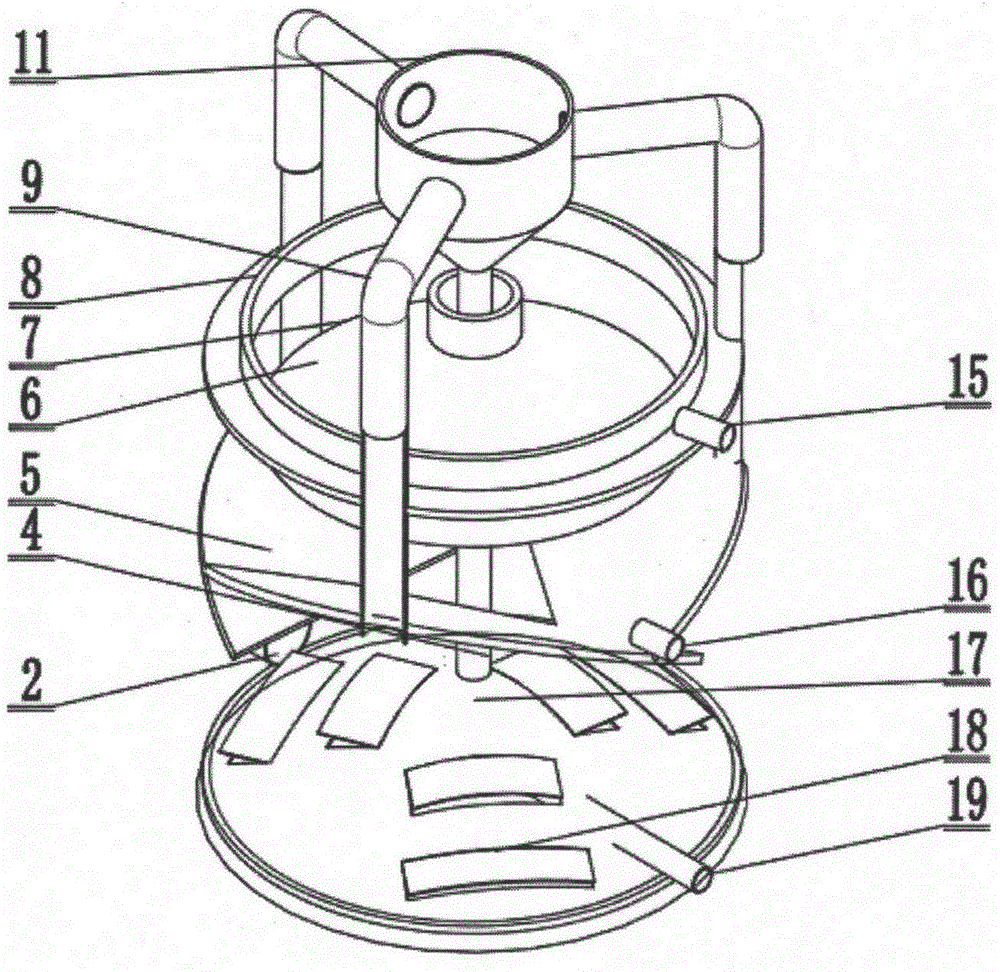

Internal recycle strengthened perfect mixing flow anaerobic reactor

ActiveCN105152321AReduce aspect ratioCompact structureTreatment with anaerobic digestion processesHigh concentrationPhase mixing

The invention provides an internal recycle strengthened perfect mixing flow anaerobic reactor. The reactor is provided with a water distribution area, a perfect mixing area, a first separating area and a second separating area from bottom to top; the water distribution area is provided with a bottom plate, an emptying port, a water inlet pipe, a hollow cone water distributor and an arc baffle plate; the perfect mixing area is provided with a return pipe, rotational flow baffle plates, a lower end lifting pipe and a mud discharge pipe; the first separating area is provided with a three-phase separator, a downflow weir and a water outlet pipe; the second separating area is provided with an upper end lifting pipe, an outer separating cylinder, an inner separating cylinder and an air outlet pipe. According to the reactor provided by the invention, through the arrangement of three rotational flow baffle plates which are arranged in a 120 degree rotation manner and an inner recycle structure, the tangential flow velocity and axial flow velocity in a rotational flow mixing area are respectively increased, so as to achieve the effects of strengthening inter-phase mixing in the rotational flow mixing area and reducing waterpower dead zones, thereby effectively diluting high concentration feeding water, improving volume efficiency of the reactor and guaranteeing the stable running of the reactor.

Owner:浙江沃乐科技有限公司

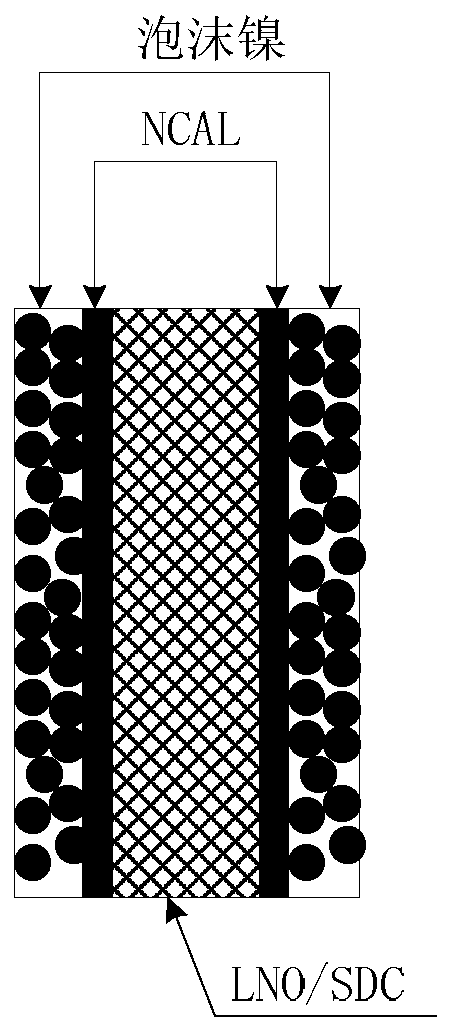

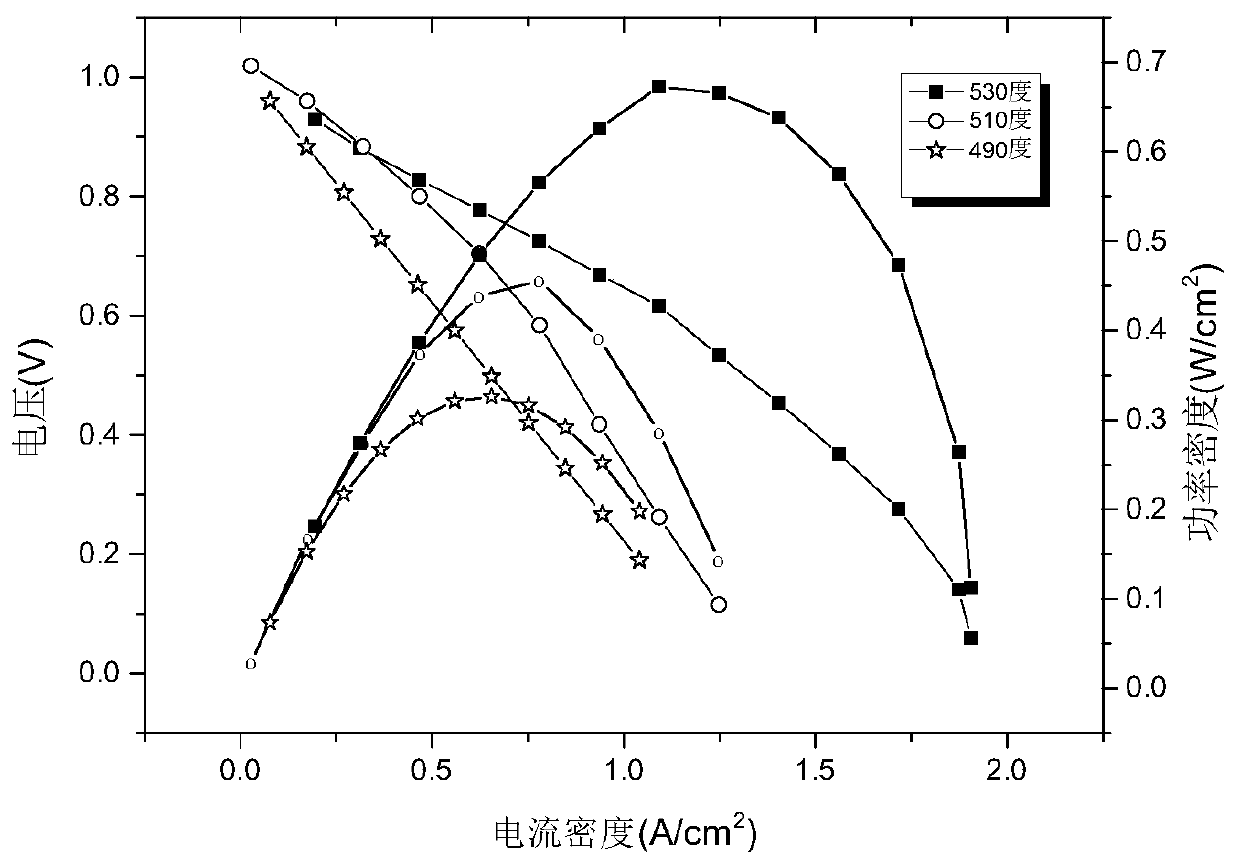

Low-temperature solid oxide fuel cell

InactiveCN109802161AImprove transmission capacityIncrease output powerCell electrodesFuel cellsIonNickel

The invention discloses a low-temperature solid oxide fuel cell. The cathode and anode of the fuel cell are made of nickel foam coated with NCAL; and the electrolyte layer of the fuel cell is made ofan LNO / SDC composite material. The structure of the fuel cell of the present invention is foam nickel / / NCAL / / LNO / SDC / / NCAL / / foam nickel. According to the low-temperature solid oxide fuel cell of the invention, a composite material composed of LNO of a perovskite structure and ionic conductor samarium-doped cerium oxide is adopted as the electrolyte layer of the low-temperature solid oxide fuel cell, and therefore, electrode polarization loss during the electrochemical reaction of the fuel cell can be greatly reduced; and the electrolyte material has good output power in a low temperature section, so that the solid oxide fuel cell using the electrolyte material can operate efficiently and stably for a long period of time in the low temperature section (300 to 600 degrees Celsius).

Owner:NANJING XIAOZHUANG UNIV

Riveting robot with real-time monitoring function

InactiveCN107081743ALong-term efficient and stable operationImprove securityProgramme-controlled manipulatorGripping headsCcd cameraProtection layer

The invention discloses a riveting robot with a real-time monitoring function, and relates to the technical field of intelligent manufacturing. A pneumatic motor and a connecting sleeve are both installed on a second joint arm, a suction head assembly and a screw are arranged inside the connecting sleeve, the upper portion and the lower portion of the screw are connected with the pneumatic motor and a locking claw head in a matched manner, and the screw is driven by a hollow shaft motor connected with the screw; the suction head assembly is connected with the locking claw head and a vacuum suction nozzle, and a riveting head is connected to the bottom of the vacuum suction nozzle; a base is connected with an external controller, and an automatic alarm device is arranged on one side of the controller; a CCD camera connected with a display screen is arranged at the bottom of a second joint arm; and the surfaces of the base, the first joint arm and the second joint arm are provided with protection layers, and the surface of the connecting sleeve is coated with a self-light-emitting layer. The robot is good in safety and stability, a worker can monitor the working state in real time, the service life is long, cost is low, and it is guaranteed that the riveting work is done efficiently and stably for a long time.

Owner:TAICANG WEIGUAN ELECTROMECHANICAL

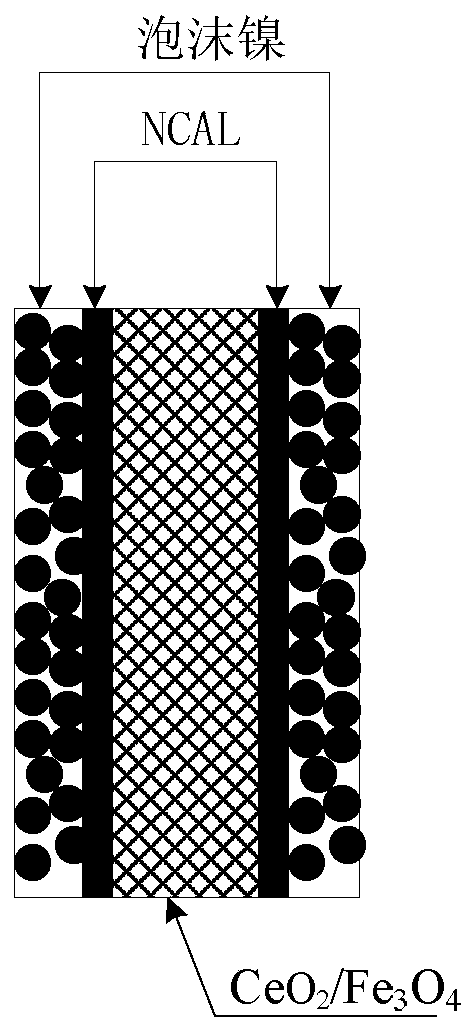

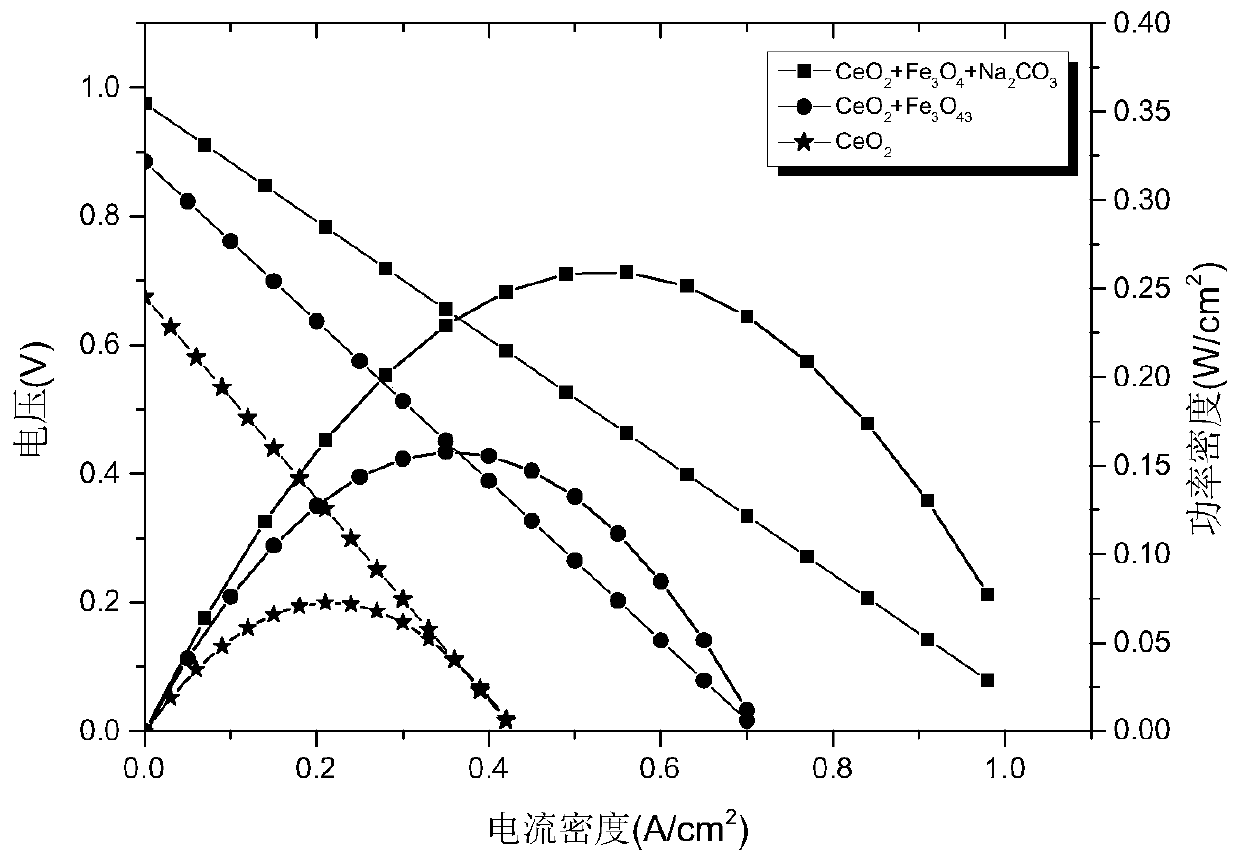

Low-temperature solid oxide fuel cell based on cerium oxide/ferroferric oxide composite material

ActiveCN109818021AReduce electrode polarization lossLong-term efficient and stable operationFuel cellsChemical reactionFuel cells

The invention discloses a low-temperature solid oxide fuel cell based on a cerium oxide / ferroferric oxide composite material. A cathode and an anode of the fuel cell are foamed nickel with NCAL coatedon the surfaces, and an electrolyte layer of the fuel cell is a CeO2 / Fe3O4 composite material. The structure of the fuel cell is foamed nickel / / NCAL / CeO2 / Fe3O4 / NCAL / foamed nickel. According to the low-temperature solid oxide fuel cell, the CeO2 / Fe3O4 nano composite material is adopted as the electrolyte layer of the low-temperature solid oxide fuel cell, so that the electrode polarization loss inthe electrochemical reaction process of the fuel cell is greatly reduced; the electrolyte material has high oxygen ion conductivity in a low-temperature section, so that the solid oxide fuel cell adopting the electrolyte material can efficiently and stably operate for a long time in the low-temperature section (300-600 DEG C).

Owner:NANJING XIAOZHUANG UNIV

An electric power tower real-time detection system based on a tower image

InactiveCN109598696AReal-time detection of operating conditionsLong-term efficient and stable operationImage analysisElectric power systemEngineering

The invention discloses an electric power tower real-time detection system based on a tower image, and aims to provide the electric power tower real-time detection system based on the tower image, which can detect the operation condition of an electric power tower in real time, improve the inspection quality of the electric power tower, reduce missed detection and wrong detection to the maximum extent, and ensure that the electric power tower operates efficiently and stably for a long time. The system comprises an intelligent inspection data processor and an electric power tower detection terminal. The electric power tower detection terminal and a main station server perform bidirectional data transmission through a mobile network. The intelligent inspection data processor is provided withan inspection task processing device, and an inspection task comparison module and an image processing module are arranged in the inspection task processing device; The electric power tower detectionterminal is provided with an image acquisition module, and the image acquisition module is used for acquiring image information of a tower in real time and transmitting the image information to the inspection task management module for comparison and processing.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD QUZHOU POWER SUPPLY CO +1

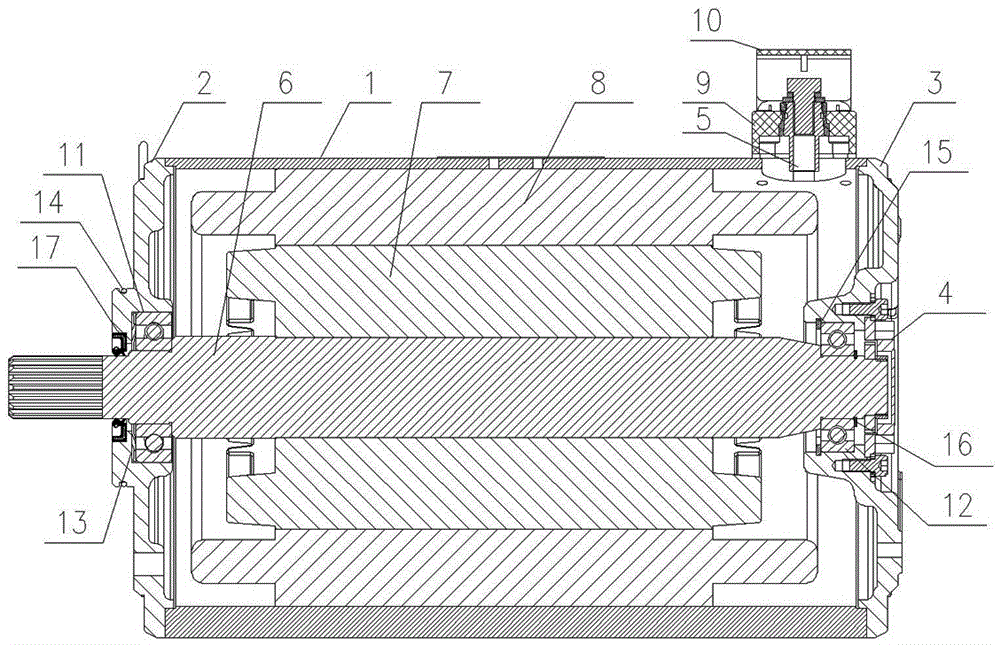

Protection-type AC variable frequency motor for electric fork-lift truck

ActiveCN106026534AAvoid accidentsLong-term efficient and stable operationStructural associationSupports/enclosures/casingsCouplingWave shape

The invention discloses a protection-type AC variable frequency motor for an electric fork-lift truck, and mainly relates to the technical field of AC variable frequency motors. A main shaft passes through an external housing which is formed by the connection of a front end cover, an engine base and a rear end cover. One end of the engine base is fixedly connected with a wiring board, wherein the interior of the wiring board is provided with a temperature sensor, and the exterior of the wiring board is provided with a wiring board cover. A rotor assembly is cooperatively connected with the main shaft and a stator assembly in the engine base. Two ends of the main shaft are respectively in cup joint with a first bearing and a second bearing. A coder is connected with the main shaft through a shaft coupler. A waveform spring piece is disposed between the front end cover and the first bearing, and an oil seal is disposed between the front end cover and the main shaft. Two ends of the second bearing are respectively provided with a circlip for a hole, and a circlip for a shaft. The motor is simple in overall structure, and greatly reduces the assembly difficulty. Moreover, the excellent performances of the motor can meet the actual demands, and the motor is good in sealing performance, is high in protection level, is wide in application range, and is safe and reliable.

Owner:苏州新能健电气有限公司

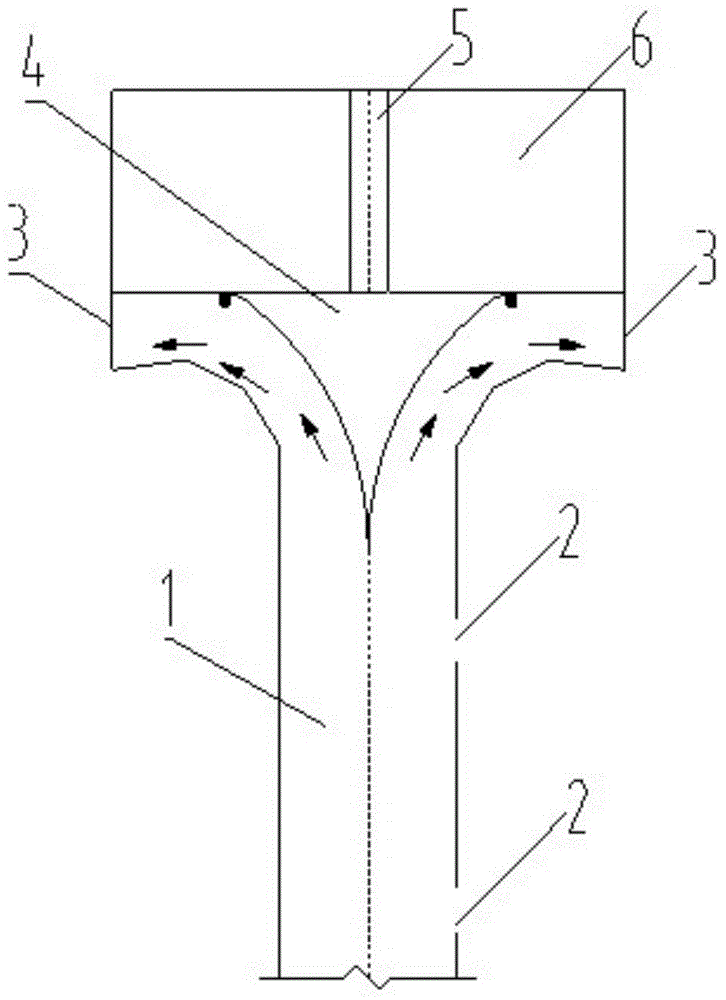

Outflow optimization device of pontoon type water-lifting aerator

InactiveCN104445657AImprove water flowAvoid fatigue damageWater aerationSustainable biological treatmentBell mouthEnergy loss

The invention discloses an outflow optimization device of a pontoon type water-lifting aerator. The outflow optimization device comprises a top ascending cylinder, a middle outflow cylinder, a diversion conical frustum and a floating body, wherein the floating body is arranged at top of the top ascending cylinder, the middle outflow cylinder is arranged at the center of the floating body, the diversion conical frustum is arranged at lower end of the middle diversion cylinder, and a plurality of bell mouths of the ascending cylinder are upwards formed in the circumferential direction of the top of the top ascending cylinder among the top ascending cylinder, the floating body and the diversion conical frustum; and a plurality of drainage holes are formed in the circumferential direction of the side wall of the top ascending cylinder. When a water flow in the ascending cylinder of the water-lifting aerator is close to an outflow device, part of the water flow firstly flows out of the side wall of the ascending cylinder, the other part of the water flow flows out in a radial manner via a channel between the diversion conical frustum and the bell mouths at the top of the ascending cylinder, and the impact force of the ascending water flow to the water-lifting aerator is reduced by about one half in comparison with an original corresponding value, so that fatigue damages to various connection parts and the floating body at the top of the water-lifting aerator are effectively avoided, energy loss when the water flow passes through the outflow device is reduced, and long-term efficient and stable operation of the water-lifting aerator is ensured.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Lighting lamp with variable light-emitting angle

PendingCN111520628AAdjustable angleAvoid free turningLighting support devicesElectric circuit arrangementsEngineeringSilica gel

The invention discloses a lighting lamp with a variable light-emitting angle, which comprises a lamp holder. The middle of the lamp holder protrudes towards the inner side to form a power source groove in the outer side, a driving power source is installed in the power source groove, and two lamp grooves are symmetrically formed in the positions, on the two sides of the power source groove, of theinner side of the lamp holder; end plates are detachably connected to the two ends of the lamp holder, a rotating shaft is rotatably connected to the position, between the two end plates, of each lamp groove;the rotating shafts are fixedly connected with lamp bodies;cables are arranged between the lamp bodies and the driving power source; the lamp bodies are provided with silica gel pads connected with the end plates in an abutting mode. A transmission box is arranged on the outer side of the end plate, and a linkage assembly for promoting the two rotating shafts to rotate synchronously and aseparation assembly for promoting the linkage assembly to be separated to enable the two rotating shafts to rotate independently are arranged in the transmission box. According to the lighting lamp with the variable light emitting angle, large-area cross light emitting can be achieved, and the lighting effect is enriched.

Owner:广东特优仕照明科技有限公司

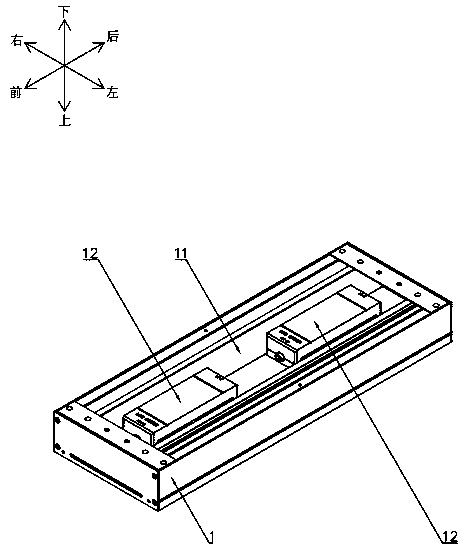

A shell-and-tube heat exchanger combining heat pipes and phase change materials

ActiveCN110631302BSolve heat transfer problemsFast heat exchange response speedChemical industryIndirect heat exchangersData connectionTemperature control

The invention provides a heat tube and phase change material combined shell-and-tube heat exchanger. The system comprises a shell, a cooling liquid inlet, a cooling liquid outlet, a heat tube, a powerpump, a cold medium source and a heat source shell. The shell is filled with cooling liquid. The heat source shell is arranged in the shell. The heat source shell internally comprises a heat source and a phase change material. The heat source surrounds the interior of the phase change material. The evaporating end of the heat tube is arranged in the phase change material. A second temperature sensor is arranged on the surface of the heat source shell and is in data connection with a controller. The controller automatically controls the opening degree of a valve according to the detected temperature data. By controlling the temperature of the surface of the heat source shell, the temperature of the heat source is prevented from being too high or too low, and the effect of automatically controlling and saving energy is realized. Heat generated during conveying of the heat tube is used, the phase change heat transferring is realized through the liquid, and the heat exchange problem of high heat flux density can be quite well solved.

Owner:SHANDONG UNIV

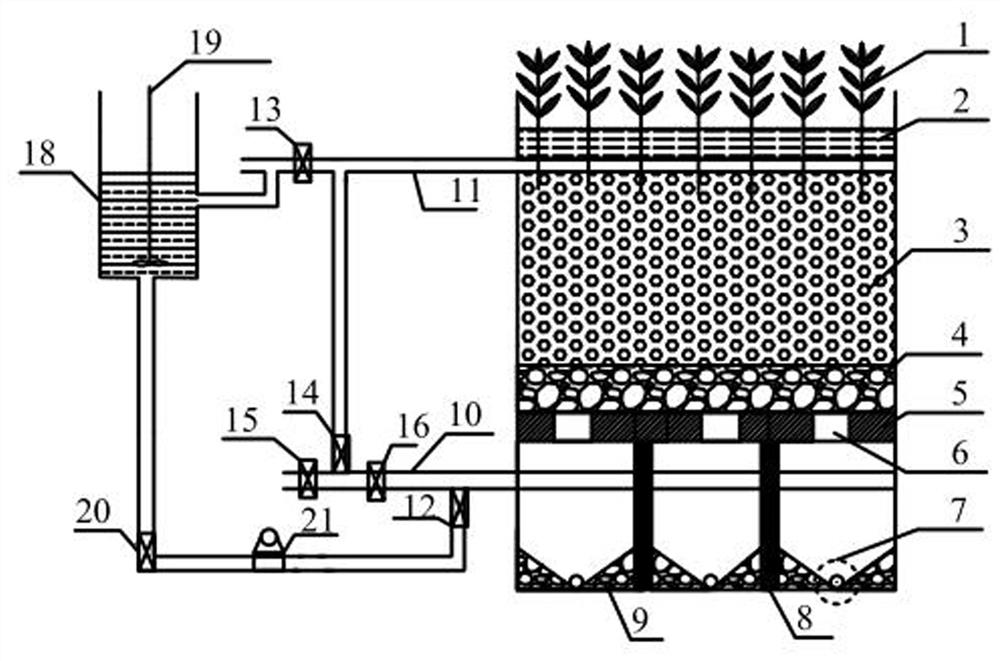

Autotrophic anti-clogging constructed wetland for deep purification of tail water of sewage treatment plant

PendingCN112159034AReduce concentrationImprove phosphorus removal effectWater treatment compoundsSpecific water treatment objectivesConstructed wetlandSludge

The invention relates to an autotrophic anti-clogging constructed wetland for deep purification of tail water of a sewage treatment plant. The wetland comprises a water purification plant, a water collection area, a core functional filler matrix area, a cobblestone layer and a water distribution and sludge discharge area which are sequentially arranged from top to bottom, and the water distribution and sludge discharge area comprises a perforated support plate, a multi-bucket V-shaped sludge collection tank, support columns and wetland bottom fixed support columns; the perforated support plateis supported; the lower part of the multi-bucket V-shaped sludge collecting tank is filled with large cobblestones; the core functional filler matrix area is arranged at the upper part of the perforated support plate, the bottom of the perforated support plate is provided with a cobblestone layer to ensure uniform water inflow, purification plants are planted at the upper part of the core functional filler matrix area, and a drainage pipe is arranged in the water collection area to collect treated tail water and discharge the tail water out of the wetland. The constructed wetland can solve the problems that the concentration of NO3-N in tail water of an existing sewage treatment plant is high, the phosphorus concentration needs to be further reduced, a matrix of an autotrophic wetland isseriously hardened in long-term operation of actual engineering, a system is blocked and the like.

Owner:ZHENGZHOU UNIV +1

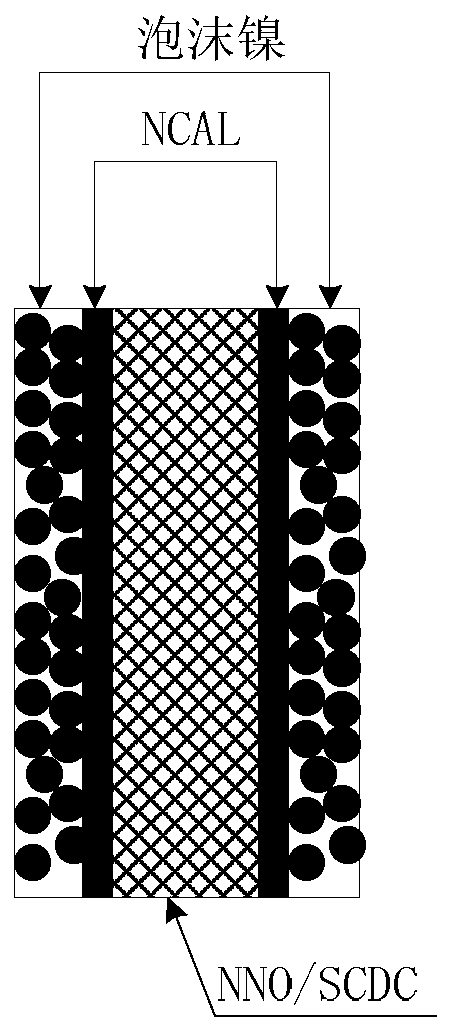

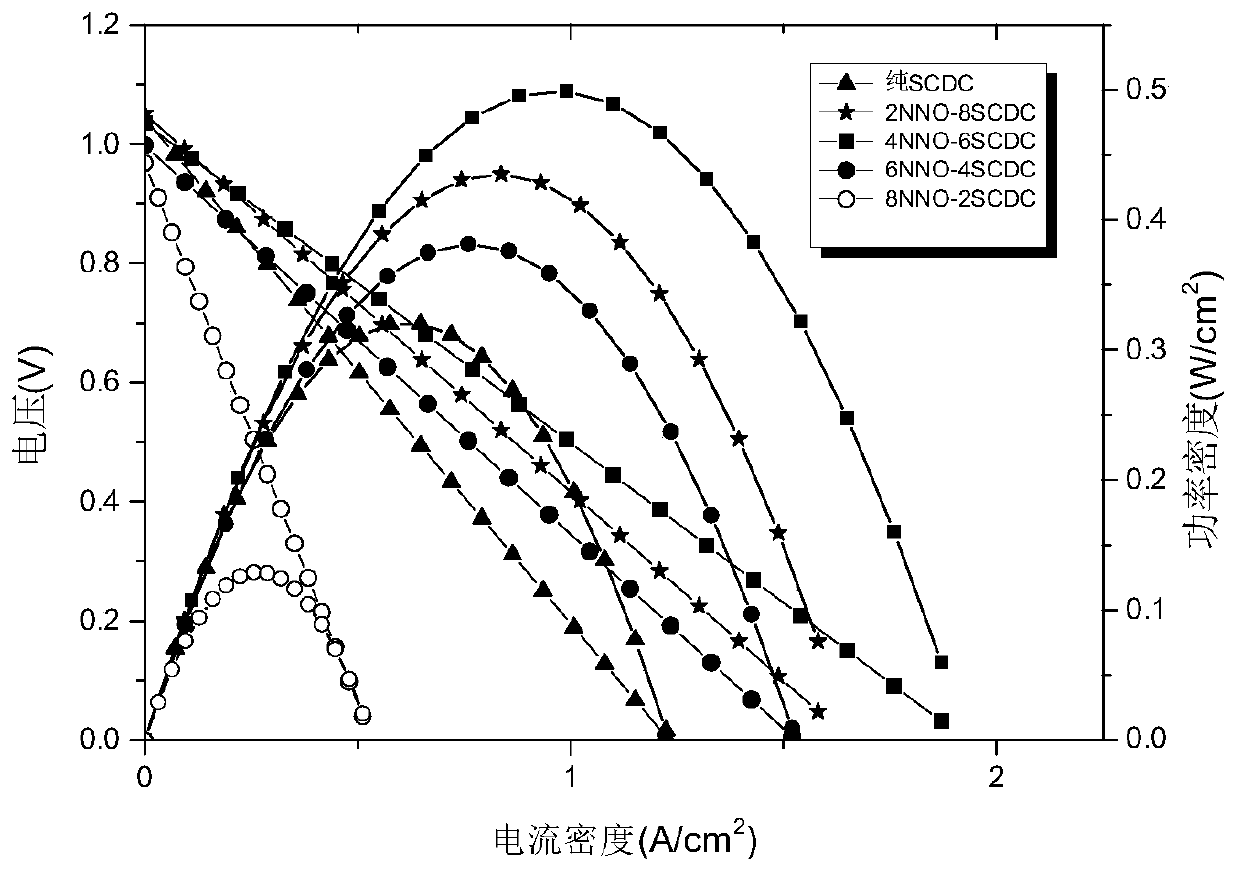

Oxide fuel cell based on neodymium nickelate and samarium-calcium co-doped cerium oxide composite material

InactiveCN109818027AImprove transmission performanceIncrease output powerFuel cellsElectrical conductorElectrochemistry

The invention discloses an oxide fuel cell based on a neodymium nickelate and samarium-calcium co-doped cerium oxide composite material. A cathode and an anode of the fuel cell are foamed nickel withNCAL coated on the surfaces, and an electrolyte layer of the fuel cell is an NNO / SCDC composite material. The structure of the fuel cell is foamed nickel / / NCAL / NNO / SCDC / / NCAL / foamed nickel. Neodymiumnickelate which is of a perovskite structure and a samarium-calcium co-doped cerium oxide composite material are used as the electrolyte layer, so that the electrode polarization loss in the electrochemical reaction process of the fuel cell is greatly reduced; In addition, the electrolyte material has good output power in a low-temperature section, so that the solid oxide fuel cell adopting the electrolyte material can efficiently and stably operate for a long time in the low-temperature section (400-600 DEG C).

Owner:NANJING XIAOZHUANG UNIV

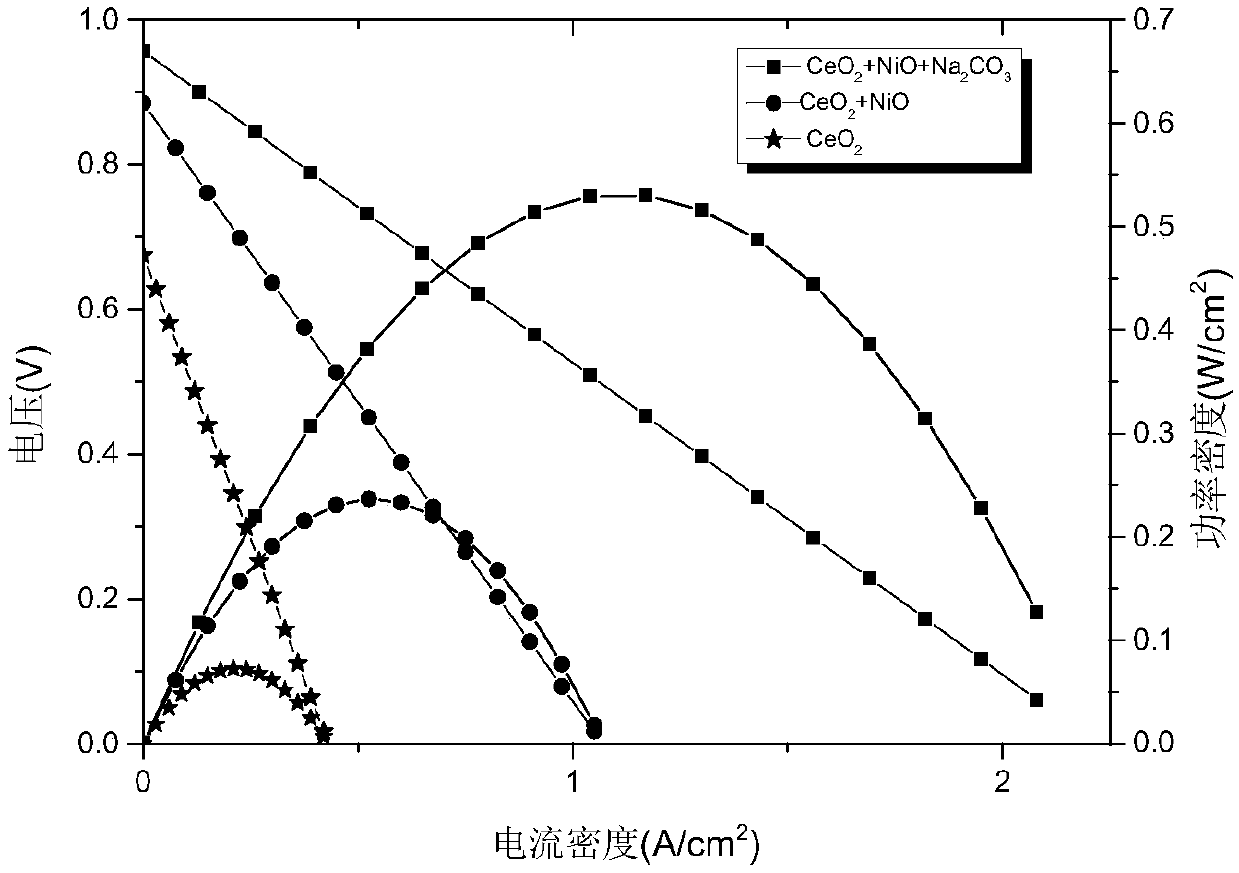

Low-temperature solid oxide fuel cell based on cerium oxide/nickel oxide composite material

ActiveCN109687006ALong-term efficient and stable operationReduce electrode polarization lossFuel cellsChemical reactionFuel cells

The invention discloses a low-temperature solid oxide fuel cell based on a cerium oxide / nickel oxide composite material. A cathode and an anode of the fuel cell are made from foam nickel coated with NCAL on the surface, and an electrolyte layer of the fuel cell is a CeO2 / NiO composite materials, namely, the structure of the fuel cell is foam nickel / / NCAL / / CeO2 / NiO / / NCAL / / foam nickel. The low-temperature solid oxide fuel cell adopts a CeO2 / NiO nanocomposite material as its electrolyte layer, the electrode polarization loss during the electrochemical reaction of the fuel cell is greatly reduced;the electrolyte material has high oxygen ion conducting capability in a low temperature section. Therefore, the solid oxide fuel cell using the electrolyte material can operate stably and stably fora long period of time in a low temperature section (300-600 DEG C).

Owner:NANJING SUOLEYOU ENERGY SAVING TECH CO LTD

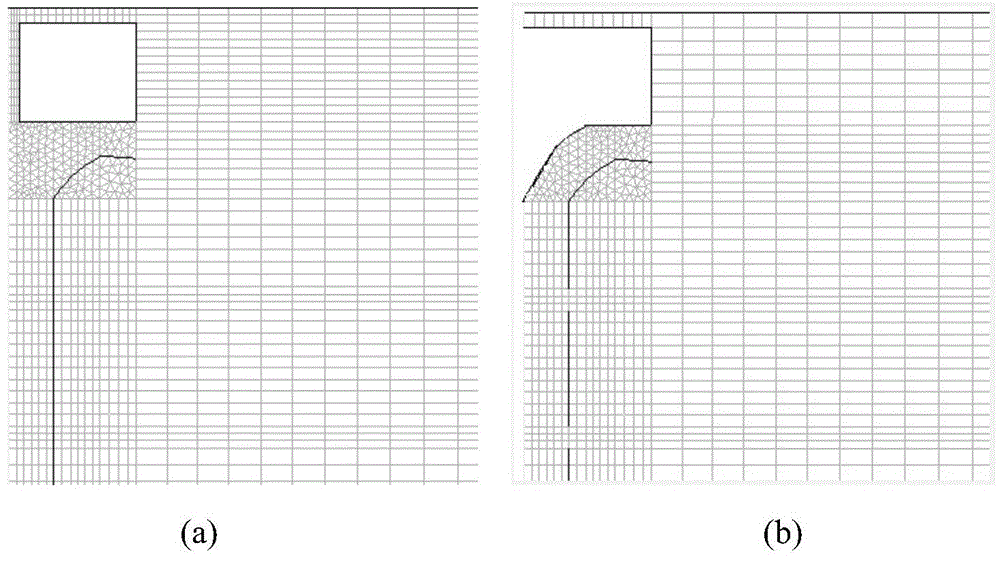

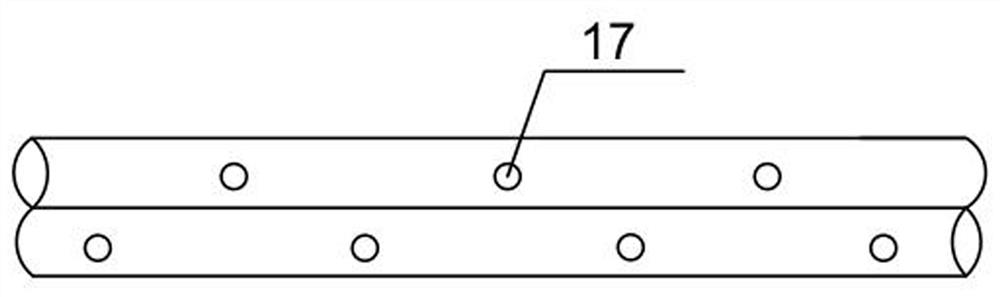

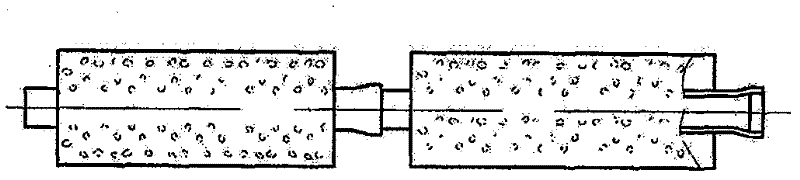

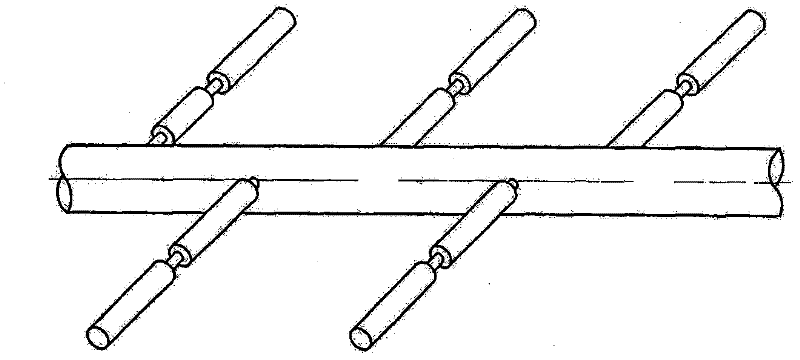

Double-tube water distribution device with biomembrane reaction of subsurface flow type constructed wetland

ActiveCN101704577BLong-term efficient and stable operationIncrease hydraulic loadTreatment with aerobic and anaerobic processesWater/sewage treatment bu osmosis/dialysisConstructed wetlandDouble tube

A subsurface flow type constructed wetland has a double-barreled water distributor with biofilm reaction, which is characterized in that the double-barreled water distributor is formed by sleeving an inner layer pipe and an outer layer pipe, water distribution holes are provided on inner pipe and outer pipe walls, two ends of the inner pipe and the outer pipe are closed by ring end plates, porous fillers are filled between the inner pipe and the outer pipe, thereby forming a signal biofilm reactor. The porous fillers in the water distributor are particle fillers containing a plurality of metal oxides with rough surfaces and grain size of 15-20mm. The inner pipe of a water distribution pipe is provided with a socket. A reactor with independent biofilm is formed by the sewage passing through the porous fillers. By changing the filler proportion, the reactor can have a purification unit with micro-electrolysis function. The sewage passes through the water distribution pipe network, which has a primary purification process and can remove 30% of pollutant. The sewage is infiltrated to an ecological wetland filter bed after uniform water distribution through the water distributor, thus the sewage is ensured not to form short flow impact during the flowing treatment process. The invention ensures the fluent water distribution and not to block, and realizes the long-acting safe operation.

Owner:WUHAN LVMINGLI HUANNENG CO LTD

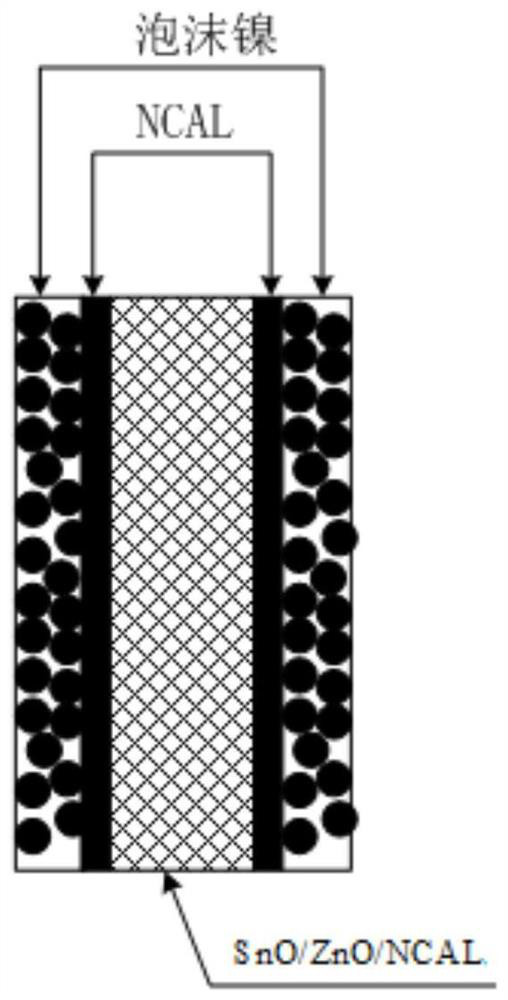

A Low-Temperature Solid Oxide Fuel Cell Based on Composite Materials

ActiveCN109950598BReduce electrode polarization lossLong-term efficient and stable operationCell electrodesFuel cellsSTANNOUS OXIDEComposite electrolyte

The invention discloses a low-temperature solid oxide fuel cell based on a composite material. The electrolyte layer of the fuel cell is a stannous oxide composite material doped with cerium; the cathode and the anode of the fuel cell are coated with NCAL nickel foam. The low-temperature solid oxide fuel cell of the present invention adopts a one-step chemical wet method to prepare a cerium-doped stannous oxide composite electrolyte material, and the obtained cerium-doped stannous oxide composite electrolyte material can prevent electron transmission, At the same time, the transmission speed of oxygen ions is enhanced, so the composite material has good output power in the low temperature section, and the tin oxide composite electrolyte material doped with cerium can also reduce the electrode polarization loss during the electrochemical reaction of the fuel cell; Therefore, the solid oxide fuel cell using the electrolyte material can operate efficiently and stably for a long time at a low temperature range (300-600 degrees).

Owner:NANJING XIAOZHUANG UNIV

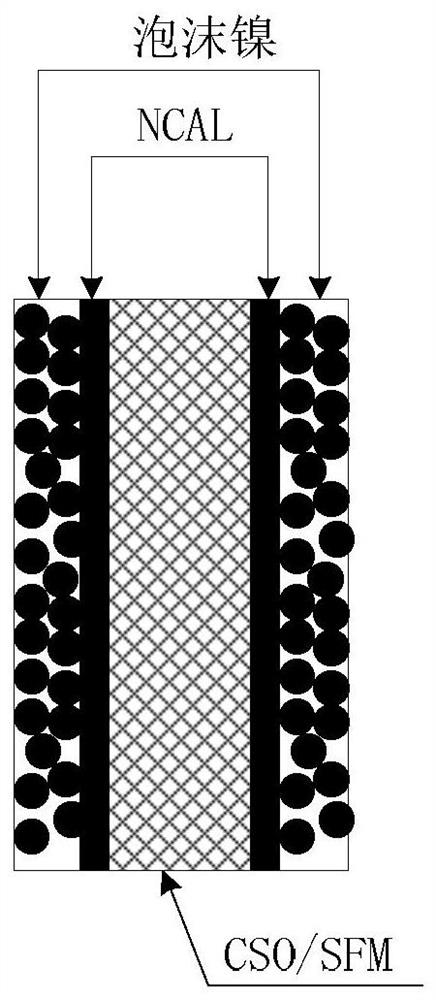

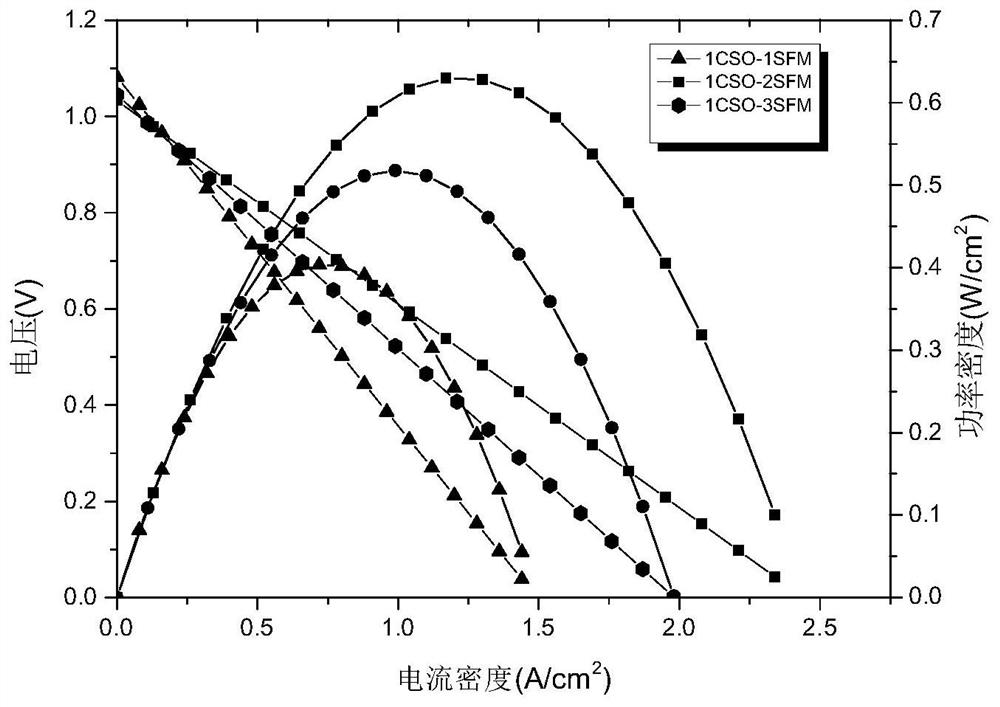

A Low Temperature Solid Oxide Fuel Cell Based on Calcium Stannate/Strontium Iron Molybdenum Composite

ActiveCN109830717BReduce electrode polarization lossLong-term efficient and stable operationSolid electrolyte fuel cellsFuel cellsTitanium molybdenum

The invention discloses a low-temperature solid oxide fuel cell based on calcium stannate / strontium-iron-molybdenum composite material. The cathode and anode of the fuel cell are nickel foam coated with NCAL on the surface, and the electrolyte layer of the fuel cell is CSO / SFM composite material. That is, the structure of the fuel cell of the present invention is: nickel foam / / NCAL / / CSO / SFM / / NCAL / / nickel foam. The low-temperature solid oxide fuel cell of the present invention adopts the composite material of calcium stannate and strontium-iron-molybdenum of perovskite structure as its electrolyte layer, which greatly reduces the electrode polarization loss in the electrochemical reaction process of the fuel cell; The low temperature section has good output power, so that the solid oxide fuel cell using the electrolyte material can operate efficiently and stably for a long time in the low temperature section (300-600 degrees).

Owner:博蔓医疗器械(常州)有限公司

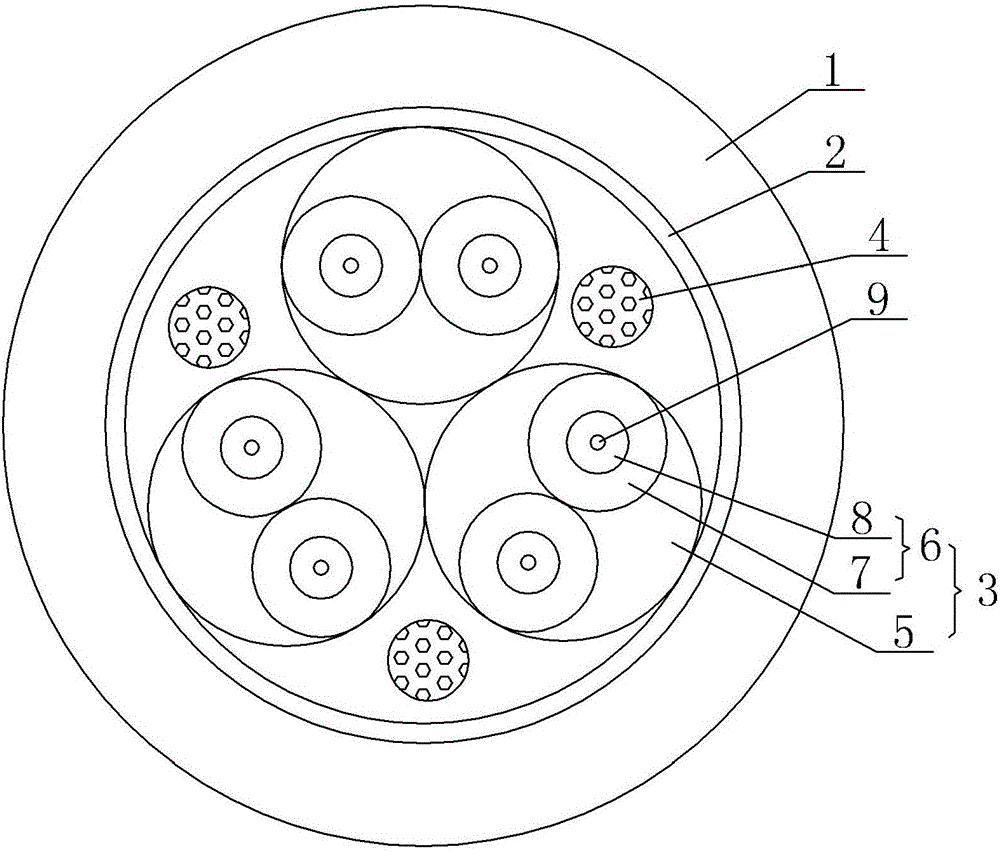

Mechanical arm torsion cable

InactiveCN106409408AGood torsion performanceStrong fatigue resistanceFlexible cablesFlexible conductorsCotton threadInternal cavity

The invention provides a mechanical arm torsion cable. The mechanical arm torsion cable has good torsion performance and high anti-fatigue capability, and has the characteristic that a core wire cannot be broken after the mechanical arm torsion cable is bended for several million times; and thus, long-term high-efficiency steady operation of a mechanical arm can be ensured. The mechanical arm torsion cable comprises an outer jacket layer and a covering layer, which are sequentially arranged from outside to inside, and have circular cross sections; a plurality of sets of signal wires and a plurality of cotton thread structures are arranged in the cavity of the covering layer; the signal wires are combined and annularly arranged in the centre of the cavity of the covering layer; the adjacent signal wires are appressed to each other; the outer walls of the signal wires are appressed to the inner wall of the covering layer; and the cotton thread structures are arranged in the cavity among the signal wires and the covering layer.

Owner:HWATEK WIRES & CABLE

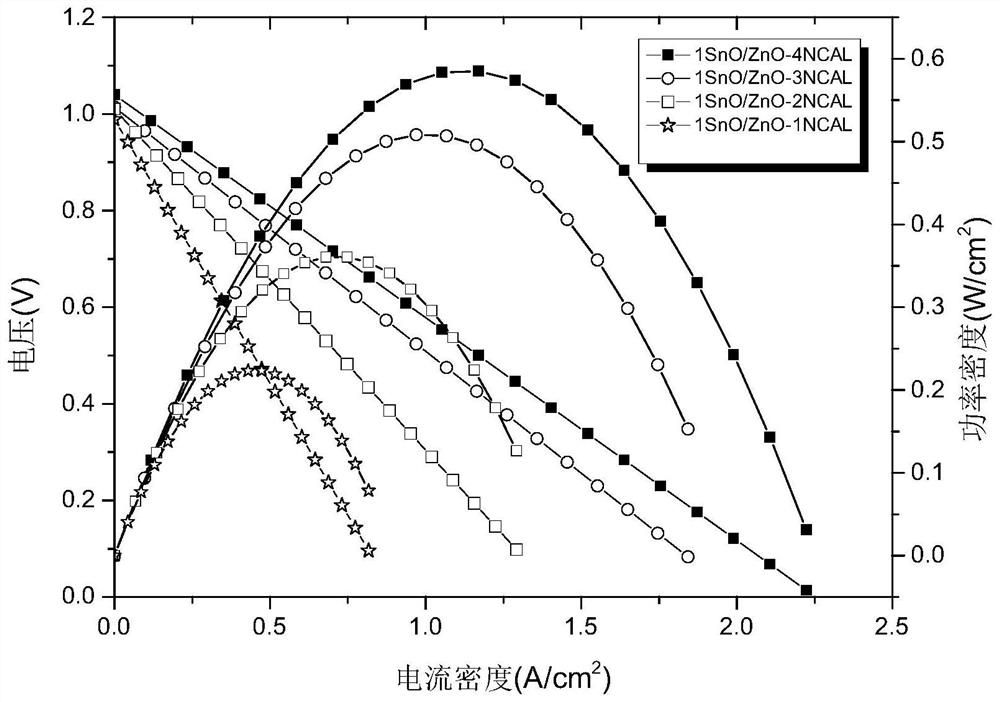

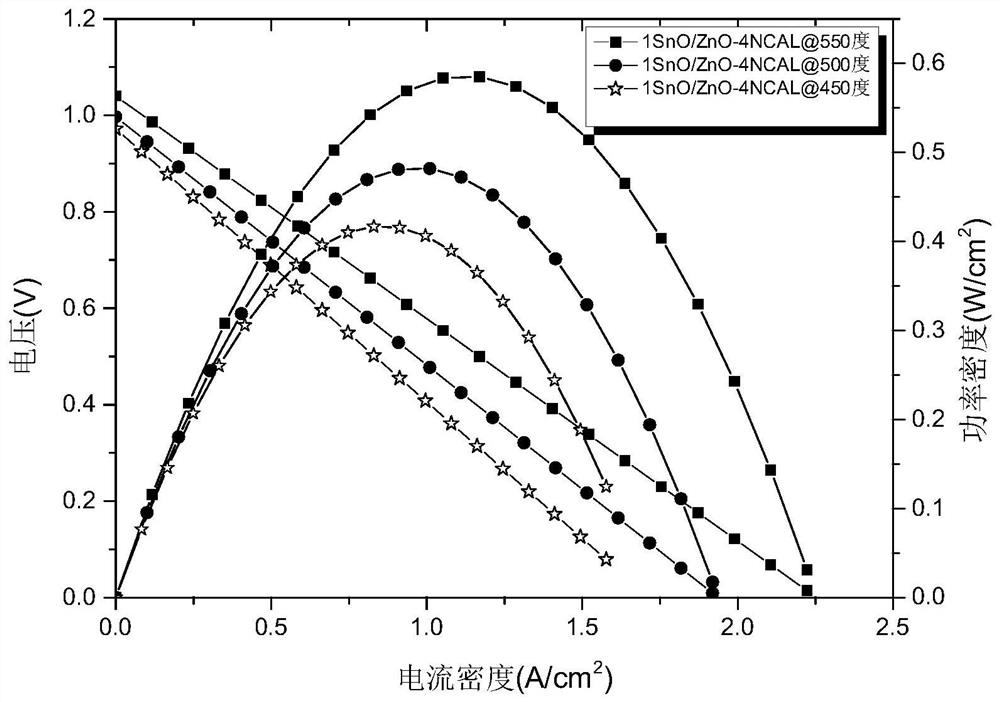

A Low-Temperature Solid Oxide Fuel Cell Based on ZnO-SnO Composite

ActiveCN109802162BReduce electrode polarization lossLong-term efficient and stable operationCell electrodesFuel cellsFuel cellsOxide composite

The invention discloses a low-temperature solid oxide fuel cell based on zinc oxide-sn2 oxide composite material, the cathode and the anode of the fuel cell are nickel foam coated with NCAL on the surface, and the electrolyte layer of the fuel cell is SnO / ZnO / NCAL Composite. That is, the structure of the fuel cell of the present invention is: nickel foam / / NCAL / / SnO / ZnO / NCAL / / NCAL / / nickel foam. The low-temperature solid oxide fuel cell of the present invention uses nickel-cobalt-aluminum-lithium and wet-synthesized SnO / ZnO composite materials as the electrolyte layer of the oxide fuel cell, which greatly reduces the electrode polarization loss during the electrochemical reaction process of the fuel cell; The electrolyte material has good output power in the low temperature section, so that the solid oxide fuel cell using the electrolyte material can operate efficiently and stably for a long time in the low temperature section (300-600 degrees).

Owner:NANJIN SANGLIRUI NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com