Bioreactor for online automatic pH control and control method thereof

A bioreactor and biological reaction technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems of cumbersome pH regulation, difficult pH online regulation, and difficult implementation, and avoid interference. , avoid local impact, control the effect of accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

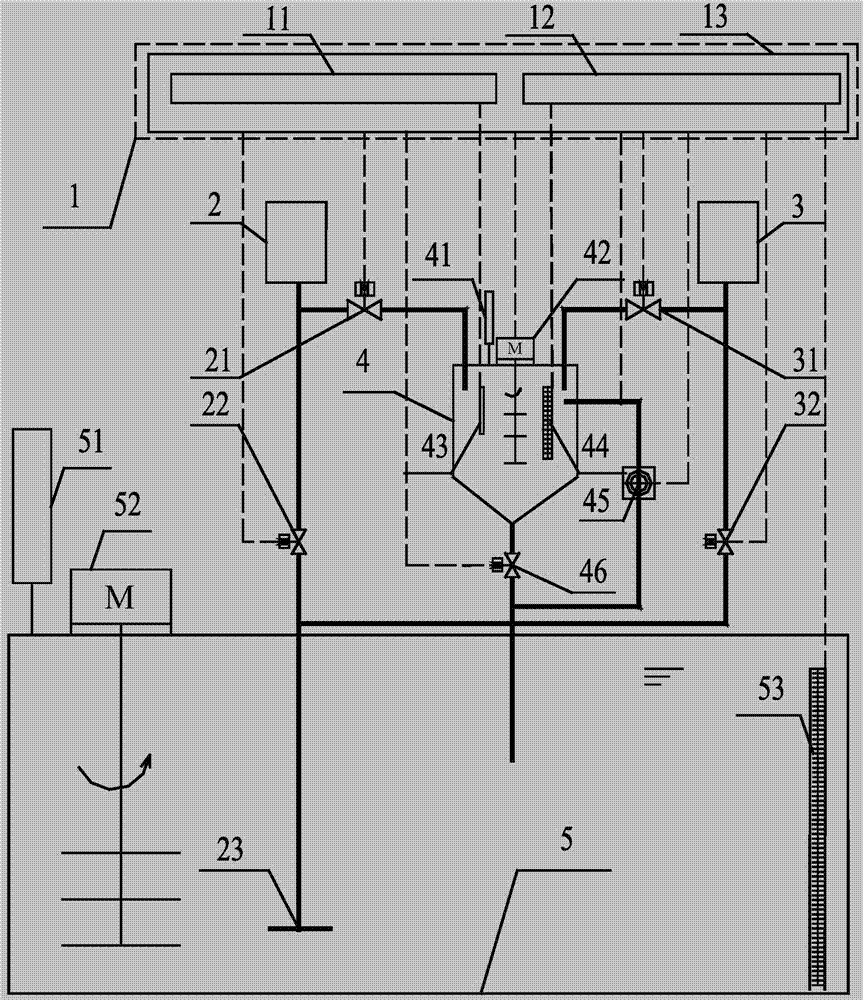

[0024] Such as figure 1 , a bioreactor for online automatic pH adjustment, comprising a data acquisition controller 1, an alkali storage tank 2, an acid storage tank 3, a debugging tank 4 and a bioreactor 5, the volume range of the debugging tank 4 is 0.020-20L, and the bioreactor 5 can be anaerobic bioreactor or aerobic bioreactor. Wherein, the data acquisition controller 1 includes a pH acquisition unit 11, a liquid level acquisition unit 12, a solenoid valve and a peristaltic pump regulation unit 13, and the alkali storage tank 2 is connected to the debugging tank 4 through a pipeline with a solenoid valve 121, and is connected to the debugging tank 4 through a pipeline with an electromagnetic valve 12. The pipeline of valve two 22 is connected with bioreactor 5. The acid storage tank 3 is connected to the debugging tank 4 through a pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com