Working method for joint robot for assembly

A working method and robot technology, applied in manipulators, metal processing, manufacturing tools, etc., can solve the problems of poor work stability, high operating costs, horizontal and vertical offsets, etc., and achieve high workpiece calibration accuracy and low operating costs. , the effect of simple working process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

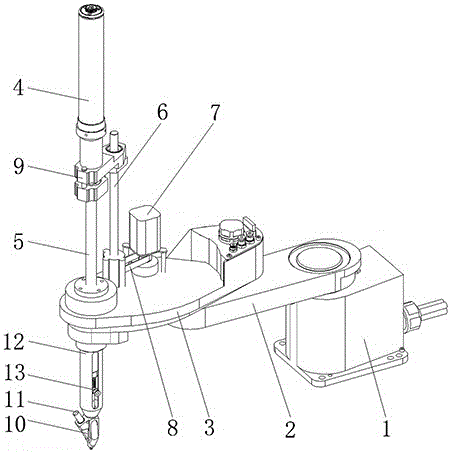

[0024] Such as figure 1 As shown, the working method of a joint robot for assembly in this embodiment, the specific working steps are as follows:

[0025] (1) First, turn on the power switch, and after the staff set the working parameters, the first joint axis 2 and the second joint axis 3 on the machine base 1 start to rotate and adjust in the horizontal direction under the drive of the servo motor;

[0026] (2) Screws or rivets enter the claw head 10 through the vacuum nozzle 11 under the action of the suction head assembly 13;

[0027] (3), the synchronous belt 8 drives the screw rod 6 and the buffer mechanism 9 sequentially under the drive of the motor 7, and drives the spline shaft 5 connected with the screwdriver head at the bottom end to pass through the connecting sleeve 12 and push toward the screw;

[0028] (4) After the screwdriver head calibrates the screw, the spline shaft 5 is driven by the motor 4 to drive the screwdriver head to rotate and press down until the...

Embodiment 2

[0032] Such as figure 1 As shown, the working method of a joint robot for assembly in this embodiment, the specific working steps are as follows:

[0033] (1) First, turn on the power switch, and after the staff set the working parameters, the first joint axis 2 and the second joint axis 3 on the machine base 1 start to rotate and adjust in the horizontal direction under the drive of the servo motor;

[0034] (2) The rivet enters the claw head 10 through the vacuum nozzle 11 under the action of the suction head assembly 13;

[0035] (3), the synchronous belt 8 drives the screw rod 6 and the buffer mechanism 9 in turn under the drive of the motor 7, and drives the spline shaft 5 connected with the riveted joint at the bottom end to pass through the connecting sleeve 12 and push toward the rivet;

[0036] (4) After the rivet joint calibrates the rivet, the spline shaft 5 is driven by the motor 4 to drive the rivet joint to rotate and press down until the assembly is completed; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com