Outflow optimization device of pontoon type water-lifting aerator

A water pumping aeration and flow optimization technology, applied in water aeration, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of increasing the amount of organic matter in water bodies, accelerating the process of eutrophication in water bodies, and increasing the number of water plants Deal with cost and other issues to achieve the effect of improving the water flow state, ensuring long-term efficient and stable operation, and avoiding fatigue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

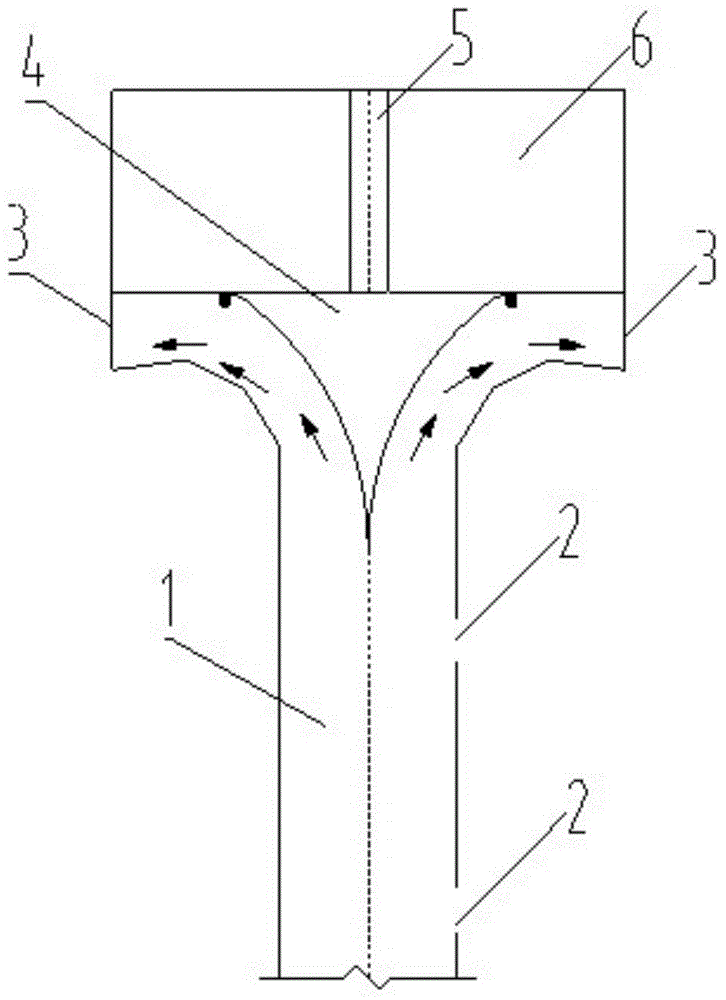

[0019] see figure 1 , a buoy-type pumping aerator outflow optimization device of the present invention, comprising a top rising cylinder 1, a middle outflow cylinder 5, a diversion cone 4 and a floating body 6; the floating body 6 is arranged on the top of the top rising cylinder 1, and the middle outflow The flow tube 5 is arranged in the center of the floating body 6, and the lower end of the middle outflow tube 5 is provided with a diversion cone 4, and the top ascending tube 1, the floating body 6 and the diversion cone 4 are formed on the top circumference of the top rising tube 1 There are several bell mouths 3 of the ascending cylinder, and several discharge holes 2 are opened on the circumference of the side wall of the ascending cylinder 1 on the top. Further, two discharge orifices 2 are provided on the circumferential dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com