Sticky smoke dust removal system and method for actively regenerating pre-sprayed powder for coke oven

A viscous smoke and dust removal system technology, applied in coking ovens, separation methods, chemical instruments and methods, etc., can solve the problem of safety and reliability of dust removal ground stations, long-term stable operation hidden dangers, and the demand for imported powder that cannot be used in time, The problem of limited storage capacity of the pre-spraying powder silo ensures long-term efficient and stable operation, eliminates fire risks, and reduces labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

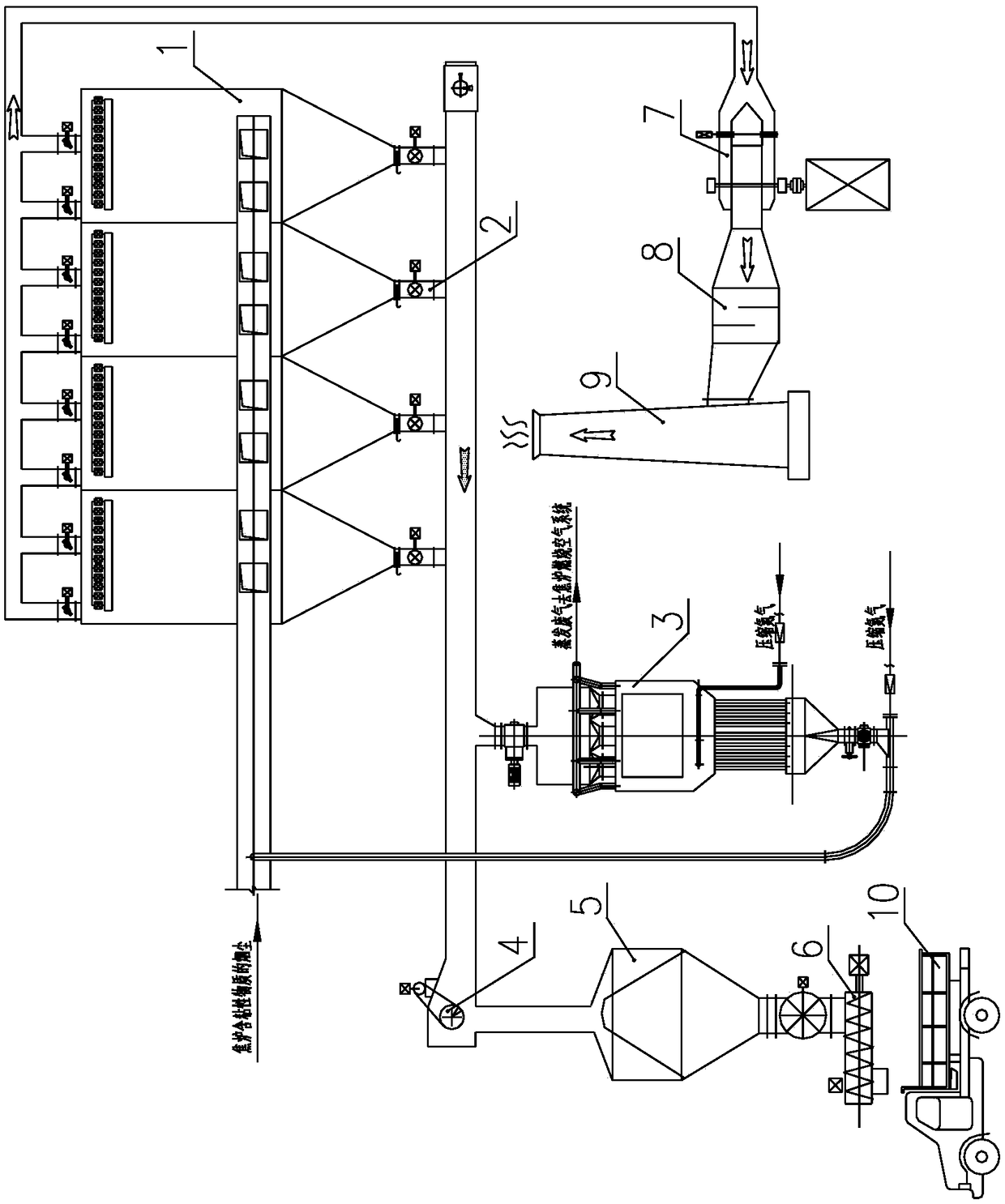

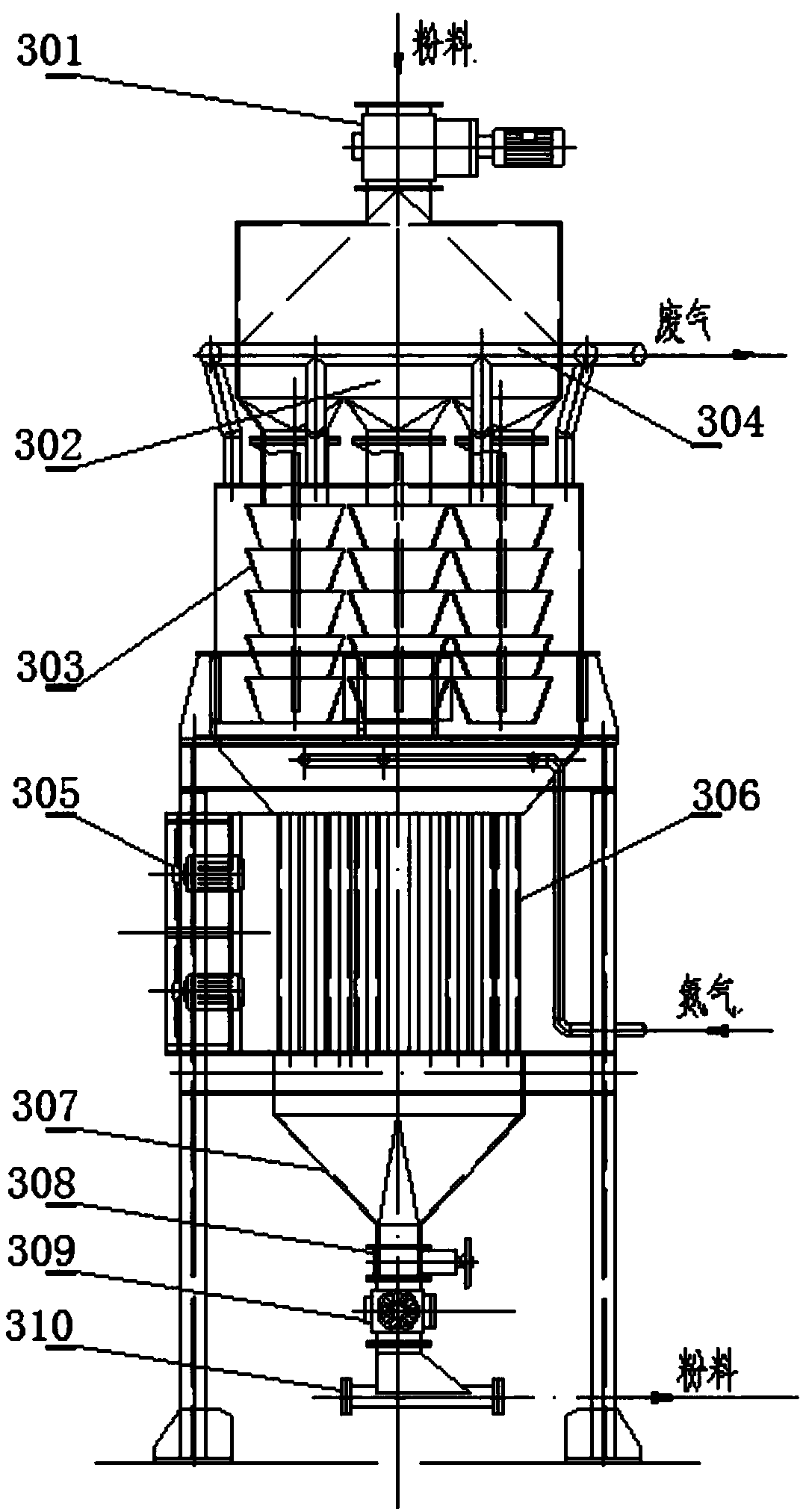

[0038] Such as figure 1 As shown, the coke oven viscous dust removal system for active regeneration of pre-spray powder according to the present invention includes a bag filter 1, a scraper machine 4, a dust bin 5, an integrated device for active regeneration and injection of powder 3, and a dust removal Fan 7, muffler 8 and chimney 9; the top of the bag filter 1 is provided with a clean gas outlet, which is connected to the dust removal fan 7, muffler 8 and chimney 9 in turn through the clean gas pipeline; The dust inlet is connected to the inlet pipe of the dust collector, and the inlet pipe of the dust collector is connected to the dust conveying pipe of the coke oven. The inlet pipe of the dust collector in front of the dust inlet is provided with a pre-spraying powder inlet, and the powder inlet of the pre-spraying powder is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com