Mechanical arm torsion cable

A mechanical arm and cable technology, applied in the field of mechanical arm torsion cables, can solve the problems of not ensuring long-term efficient operation of equipment and short working life of cables, and achieve the effect of strong fatigue resistance and good torsion performance

Inactive Publication Date: 2017-02-15

HWATEK WIRES & CABLE

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

As an important part of the automation field, the twisting cable of the mechanical arm has the vitality of the machine, and is suitable for connecting lines such as robotic equipment, mechanical arms, and CNC machine tools. The torsion of the conventional cable makes the working life of the conventional cable short and cannot guarantee the long-term efficient operation of the entire device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

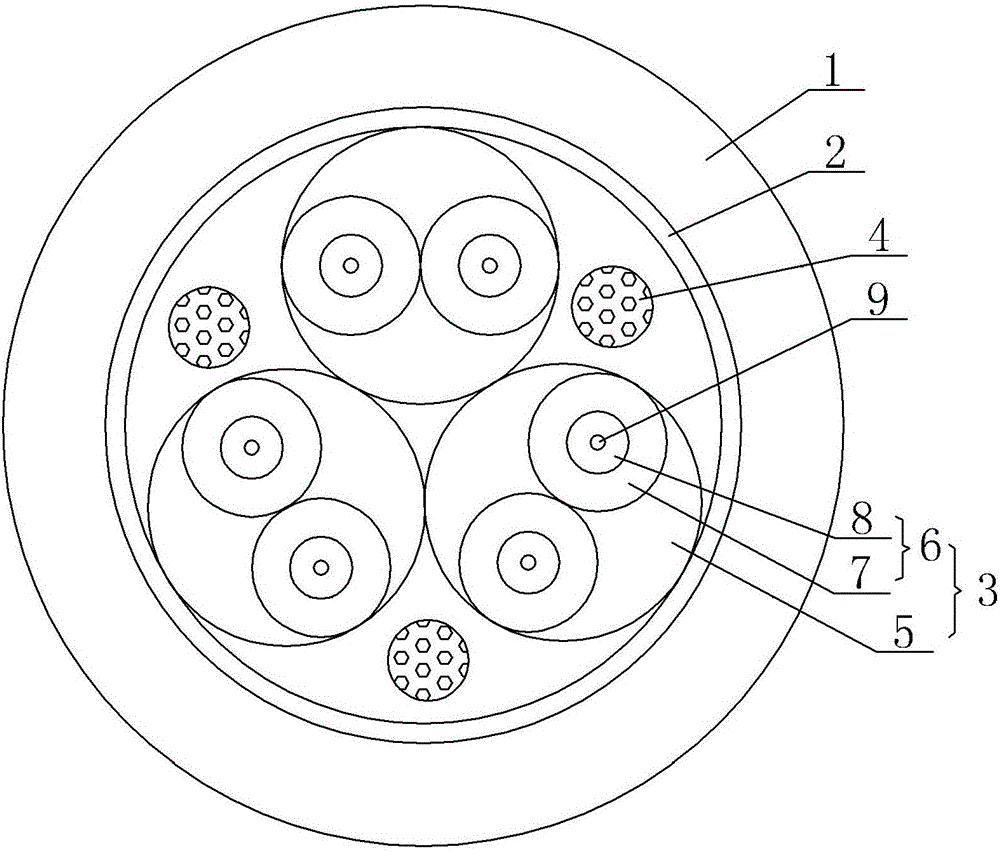

[0022] Specific embodiment: three groups of signal wires 3 are arranged around the central axis of the tape layer 2 to form an overall structure to ensure the torsional characteristics of the three groups of signal wires 3 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a mechanical arm torsion cable. The mechanical arm torsion cable has good torsion performance and high anti-fatigue capability, and has the characteristic that a core wire cannot be broken after the mechanical arm torsion cable is bended for several million times; and thus, long-term high-efficiency steady operation of a mechanical arm can be ensured. The mechanical arm torsion cable comprises an outer jacket layer and a covering layer, which are sequentially arranged from outside to inside, and have circular cross sections; a plurality of sets of signal wires and a plurality of cotton thread structures are arranged in the cavity of the covering layer; the signal wires are combined and annularly arranged in the centre of the cavity of the covering layer; the adjacent signal wires are appressed to each other; the outer walls of the signal wires are appressed to the inner wall of the covering layer; and the cotton thread structures are arranged in the cavity among the signal wires and the covering layer.

Description

technical field [0001] The invention relates to the technical field of cable structures, in particular to a mechanical arm twisting cable. Background technique [0002] In recent years, my country's mechanical arm torsion cable industry has developed rapidly, and its market position has gradually improved. As an important part of the automation field, the twisting cable of the mechanical arm has the vitality of the machine, and is suitable for connecting lines such as robotic equipment, mechanical arms, and CNC machine tools. The torsion of the cable makes the working life of the conventional cable short, and cannot guarantee the long-term efficient operation of the entire device. Contents of the invention [0003] In view of the above problems, the present invention provides a mechanical arm torsion cable, which has the characteristics of good torsion performance, strong fatigue resistance, and can undergo millions of times of bending without breaking the core wire, so a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01B7/18H01B11/02H01B7/17H01B7/04

CPCH01B7/1825H01B7/041H01B7/17H01B11/02

Inventor 史家有郭民

Owner HWATEK WIRES & CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com