Refined wire with high low-temperature high-speed torsional property and production method and application thereof

A technology of torsion performance and wire rod, applied in the field of metallurgy, can solve the problems of work hardening, unreasonable deformation pass setting, etc., to achieve the effect of excellent plasticity and increase production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

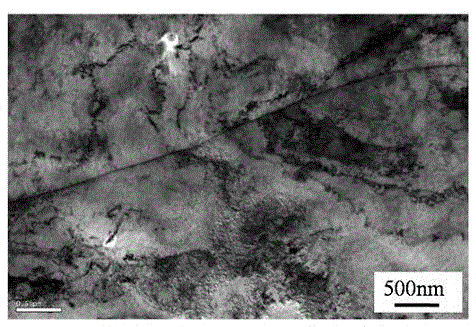

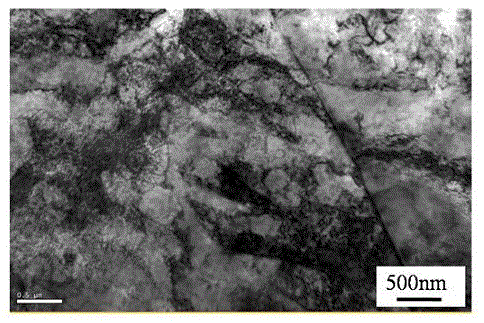

Image

Examples

Embodiment 1

[0027] The wire rod adopted in the embodiment, its composition is according to weight percentage: C: 0.05%, Si: 0.06%, Mn: 0.30%, P: 0.020%, S: 0.020%, the balance is Fe and other unavoidable impurities , The diameter of the wire rod is Φ14mm.

[0028] The wire rod is pickled, phosphated and saponified, followed by rough drawing. In the rough drawing stage, the drawing is from Φ14mm to Φ11.4mm, and the total area reduction rate of rough drawing is 33.69%. The deformation is completed in two passes, the first pass is drawn from Φ14mm to Φ12.1mm, the second pass is drawn from Φ12.1mm to Φ11.4mm, and the deformation of the first pass accounts for 75% of the total rough drawing deformation. The intermediate heat treatment temperature is 670°C, the holding time is 4h, and the furnace temperature is 400°C. The annealed material was drawn from Φ11.4mm to Φ11.1mm after pickling, phosphating and saponification, and the area reduction rate was 5.19%.

[0029] Refined wire rods are ma...

Embodiment 2

[0031] The wire rod adopted in the embodiment, its composition is according to weight percentage: C: 0.06%, Si: 0.07%, Mn: 0.40%, P: 0.020%, S: 0.020%, the balance is Fe and other unavoidable impurities , The diameter of the wire rod is Φ11mm.

[0032] The wire rod is pickled, phosphated and saponified, followed by rough drawing. In the rough drawing stage, the drawing is from Φ11mm to Φ8.99mm, and the total area reduction rate of rough drawing is 33.2%. The deformation is completed in two passes, the first pass is drawn from Φ11mm to Φ9.7mm, the second pass is drawn from Φ9.7mm to Φ8.99mm, and the deformation of the first pass accounts for 67% of the total rough drawing deformation. The intermediate heat treatment temperature is 690°C, the holding time is 4.5h, and the furnace temperature is 350°C. The annealed material was drawn from Φ8.99mm to Φ8.8mm after pickling, phosphating and saponification, and the area reduction rate was 4.18%.

[0033] Refined wire rods are made...

Embodiment 3

[0035] The wire rod adopted in the embodiment, its composition according to weight percentage is: C: 0.03%, Si: 0.06%, Mn: 0.39%, P: 0.010%, S: 0.030%, the balance is Fe and other unavoidable impurities . The diameter of the wire rod is Φ10mm.

[0036]The wire rod is pickled, phosphated and saponified, followed by rough drawing. In the rough drawing stage, the drawing is from Φ10mm to Φ8.08mm, and the total area reduction rate of rough drawing is 34.71%. The deformation is completed by two passes, the first pass is drawn from Φ10mm to Φ8.74mm, the second pass is drawn from Φ8.74mm to Φ8.08mm, and the deformation of the first pass accounts for 68% of the total rough drawing deformation. The intermediate heat treatment temperature is 685°C, the holding time is 5h, and the furnace temperature is 450°C. The annealed material was drawn from Φ8.08mm to Φ7.85mm after pickling, phosphating and saponification, and the area reduction rate was 5.62%.

[0037] Refined wire rods are ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com