Flame-retardant and waterproof power line

A technology for power cords and metal conduction, applied to circuits, insulated cables, power cables, etc., can solve the problems of poor flame retardancy, weak, easily damaged internal structures, etc., and achieve good torsional performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

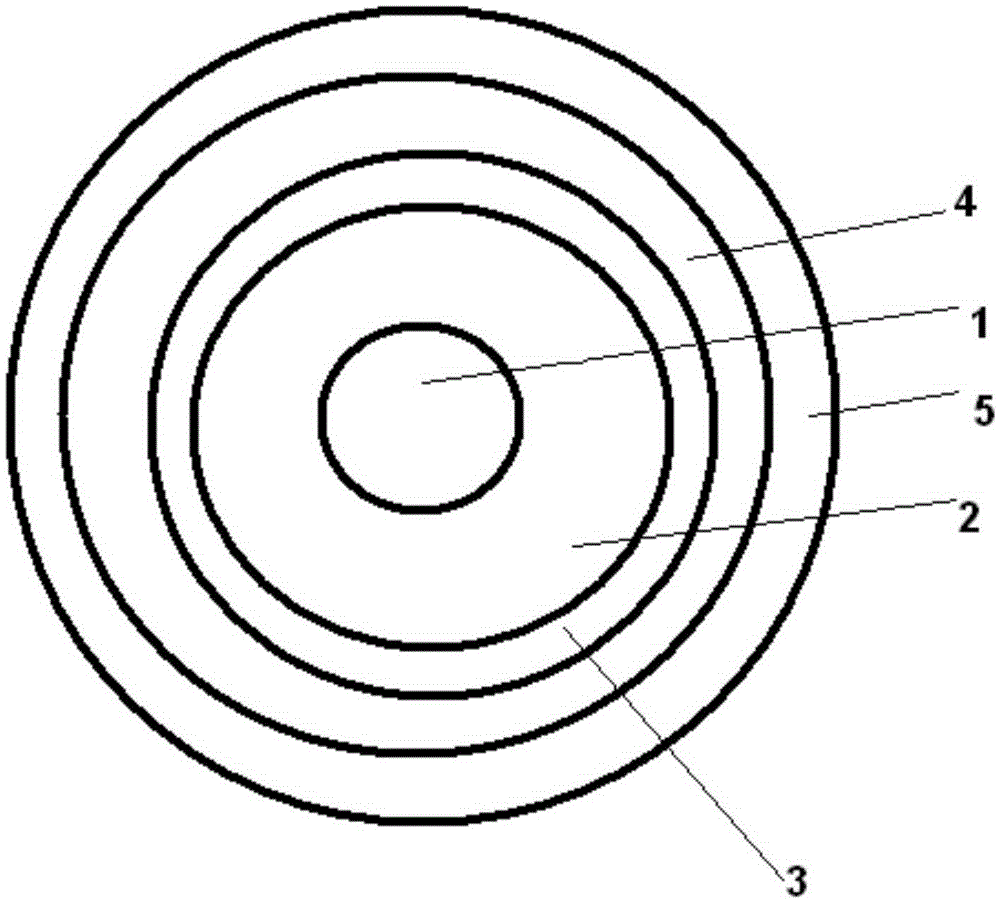

[0011] For better understanding of the present invention, further describe below by accompanying drawing:

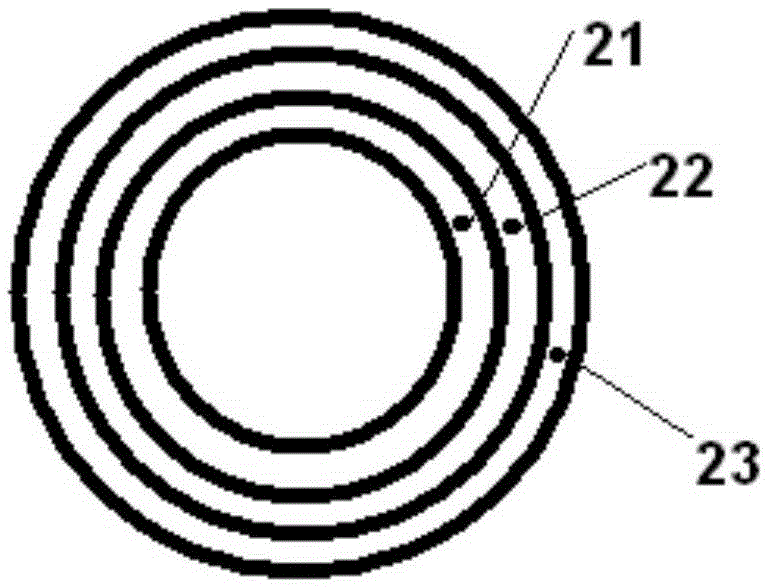

[0012] like Figure 1-2 As shown, a flame-retardant and waterproof power cord, the power cord includes the innermost metal conductor 1, surrounded by a layer of insulating and durable protective layer 2 outside the metal conductor 1, and the insulating and durable protective layer 2 Surrounded by a layer of polyvinyl chloride layer 3, the insulating and durable protective layer 2 includes the following three layers from the inside to the outside: TPU and EVA composite environmental protection wear-resistant layer 21, and the TPU and EVA composite environmental protection wear-resistant layer is next to the Reinforcement layer 22, next to the reinforcement layer is a waterproof layer 23; the reinforcement layer is a glass fiber layer, and the tensile strength of the glass fiber is 5000-5100Mpa; A braided layer 4, a layer of halogen-free flame-retardant TPEE material laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com