Preparation technology of non-tempered steel long rod-like axial forgings

A technology of non-quenched and tempered steel and preparation process, applied in mechanical equipment, temperature control, metal rolling, etc., can solve the problems of limited range of torsional performance improvement, mismatch between torsional performance and strength of non-quenched and tempered steel, and achieve fatigue Excellent performance, good torsional performance, excellent performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] A non-quenched and tempered steel long rod-shaped shaft part, the chemical composition of which is calculated by weight percentage includes: C0.30~0.50, Mn 1.20~1.60, Si 0.68~0.90, Cr 0.10~0.30, Ni≤0.25, V 0.05~ 0.15, Nb 0.01~0.05, Ti 0.01~0.05, Cu 0.21~0.35, Al 0.05~0.10, N 0.008~0.02, S≤0.02, P≤0.01, and the rest are Fe and unavoidable impurities.

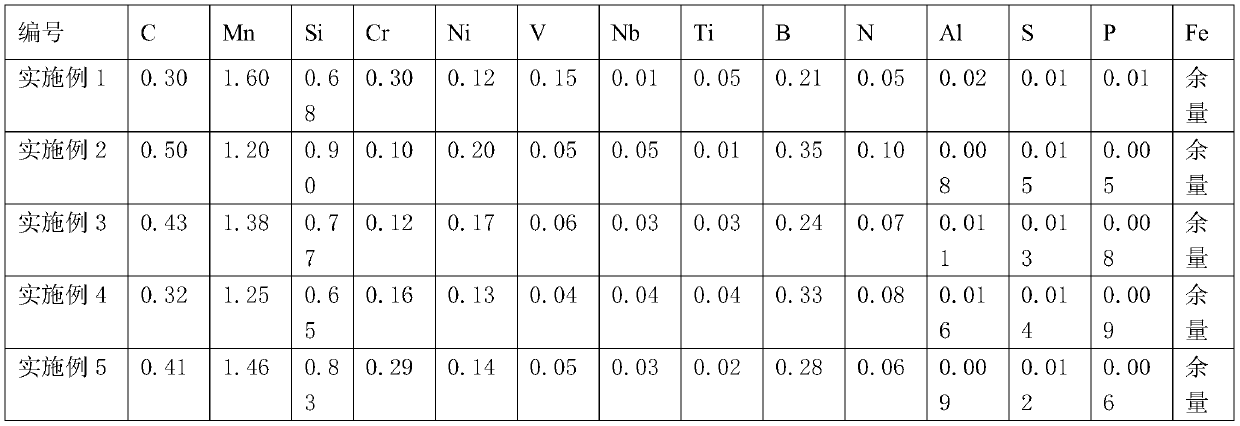

[0011] According to the production process of the present invention, the components of each embodiment are as shown in Table 1.

[0012] The chemical composition (wt%) of the embodiment of table 1

[0013]

[0014] The above-mentioned non-quenched and tempered steel long rod-shaped shaft forgings preparation process, the preparation process is: batching → electric furnace smelting → LF refining → VD vacuum treatment → continuous casting and rolling → blanking → radial forging → controlled cooling → bar , the specific operation process is as follows.

[0015] In the electric furnace smelting process: strictly control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com