A shell-and-tube heat exchanger combining heat pipes and phase change materials

A technology of phase change materials and heat exchangers, applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating transformation, etc., can solve the problems of low heat transfer efficiency, extend service life, and achieve uniform heat transfer , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

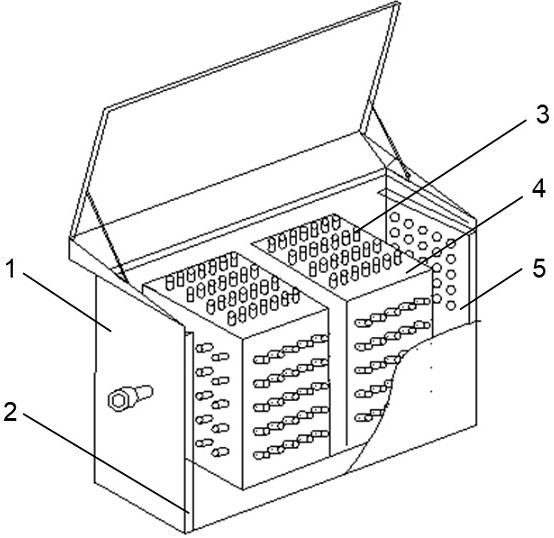

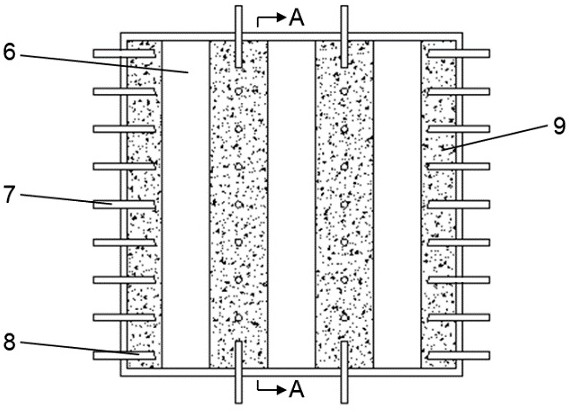

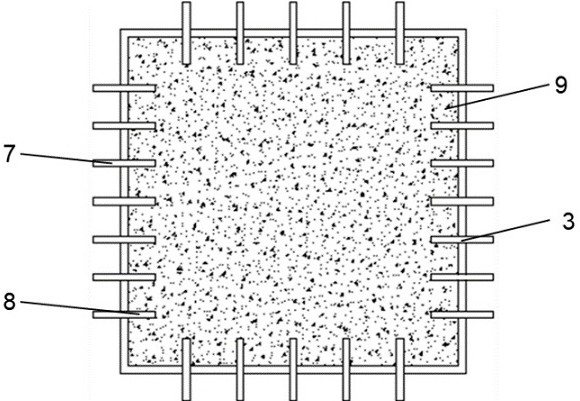

[0031] figure 1 A heat exchange system combining heat pipes, phase change materials and immersion liquid cooling is demonstrated. Such as figure 1 As shown, the system includes a housing 1, a cooling liquid inlet, a cooling liquid outlet, a heat pipe 3, a power pump, a refrigerant source and a heat source housing 4, the housing 1 is filled with cooling liquid, and the heat source housing 4 is set In the casing 1, the heat source casing 4 includes a heat source 6 and a phase change material 9, the heat source 6 is surrounded by the inside of the phase change material 9, and the evaporation end 8 of the heat pipe 3 is arranged on the phase change material 9 Among them, the condensing end 7 of the heat pipe 3 extends through the outside of the heat source housing 4; the housing 1 is respectively provided with a cooling liquid inlet and an outlet for the cooling liquid to enter and exit the housing 1; the cooling liquid inlet and outlet are connected by a pipeline They are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com