MnOx-TiO2 composite oxide with rutile TiO2 serving as matrix

A composite oxide, rutile-type technology, used in metal/metal oxide/metal hydroxide catalysts, nitrous oxide capture, chemical/physical processes, etc. The problems of reduced exposure and large specific surface area of the catalyst can achieve the effects of high production efficiency, inhibition of sintering growth, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

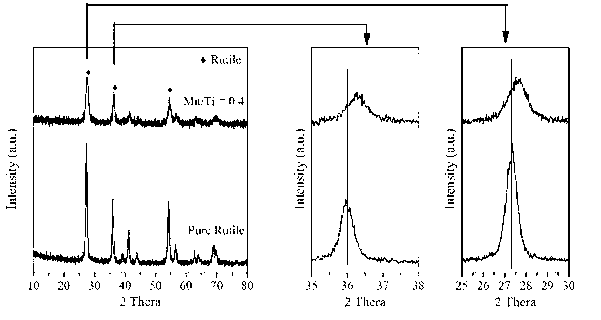

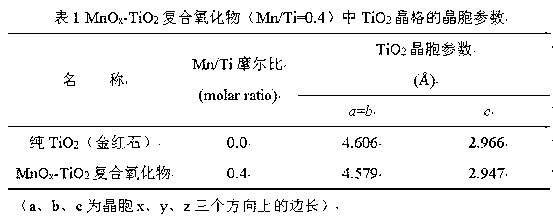

[0022] one. Rutile TiO 2 MnO as the matrix x -TiO 2 Preparation of composite oxides

[0023] Add 10 ml of concentrated hydrochloric acid to 200 ml of deionized water, slowly add 10 ml of titanium tetrachloride solution dropwise under ice-water bath and stirring conditions, and keep stirring until the solution is clear. Then, the solution was continuously stirred for 24 h under the condition of 30 °C water bath, and the solution changed from clear and transparent to milky white turbid liquid. Settle the above solution, discard the supernatant, wash the filter cake with 300 ml of nitric acid solution with a concentration of 0.6 mol / L, then disperse the filter cake into 200 ml of deionized water, stir well and add 0.8 g / ml manganese nitrate solution8 ml, keep stirring for a certain period of time. The above solution was evaporated to dryness with stirring, dried at 100 °C, ground, and calcined at 500 °C for 4 h to obtain MnO x -TiO 2Composite oxide, wherein the molar ratio...

Embodiment 2

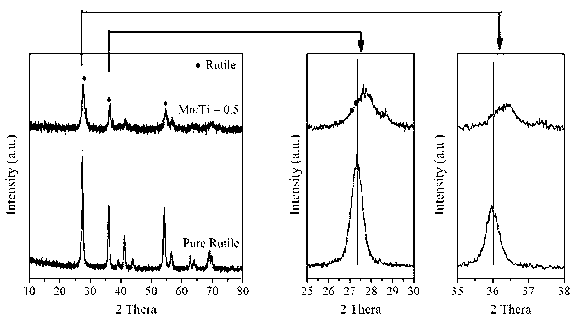

[0033] Add 10 ml of concentrated hydrochloric acid to 200 ml of deionized water, slowly add 10 ml of titanium tetrachloride solution dropwise in an ice-water bath with stirring, and keep stirring until the solution is clear. Then, the solution was continuously stirred for 24 h under the condition of 30 °C water bath, and the solution changed from clear and transparent to milky white turbid liquid. Let the above solution settle, filter, discard the supernatant, wash the filter cake with 300 ml of nitric acid solution with a concentration of 0.6 mol / L, remove the supernatant, stir and add 10 ml of 0.8 g / ml manganese nitrate solution, and continue stirring for a certain period of time . The above solution was stirred and evaporated to dryness, dried at 100 °C, ground, and calcined at 500 °C for 4 h. MnO x -TiO 2 The molar ratio of manganese and titanium in the composite oxide was 0.5.

[0034] The resulting MnO x -TiO 2 The spectrum obtained by X-ray diffraction (XRD) of th...

Embodiment 3

[0038] Add 15 ml of concentrated hydrochloric acid to 200 ml of deionized water, slowly add 10 ml of titanium tetrachloride solution dropwise in an ice-water bath with stirring, and keep stirring until the solution is clear. Then, the solution was continuously stirred for 24 h under the condition of 30 °C water bath, and the solution changed from clear and transparent to milky white turbid liquid. Settle the above solution, discard the supernatant, wash the filter cake with 300 ml of 0.6 mol / L nitric acid solution, redisperse the filter cake into deionized water, stir well, add 4 ml of 0.8 g / ml manganese nitrate solution and continue Stir for a certain period of time. The above solution was stirred and evaporated to dryness, dried at 100 °C, ground, and calcined at 500 °C for 4 h. MnO x -TiO 2 The molar ratio of manganese and titanium in the composite oxide was 0.2.

[0039] BenMnO x -TiO 2 Composite oxides are used as SCR denitrification catalysts. The NO conversion rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com