Riveting robot with real-time monitoring function

A real-time monitoring and robotic technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problem that the riveting work cannot be guaranteed to run efficiently and stably for a long time, the working status of the locking claw head cannot be monitored in real time, and the rivet locking is prone to interference. and other problems, to achieve the effect of convenient and fast feeding, significant alarm prompt effect, and improved safety and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

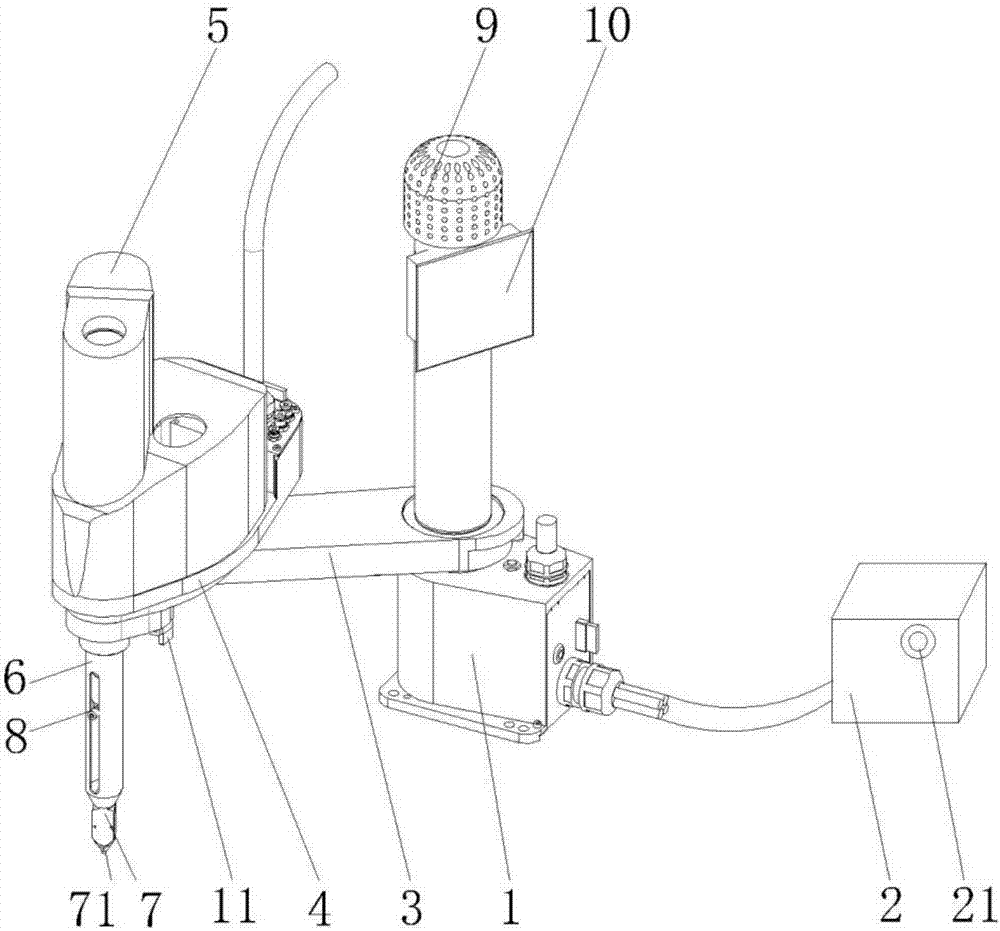

[0027] Such as figure 1 As shown, a riveting robot with real-time monitoring function in this embodiment includes a base 1, a controller 2, a first articulated arm 3, a second articulated arm 4, an air motor 5, a connecting sleeve 6, and a locking claw head 7. Vacuum suction nozzle 71, suction head assembly 8, sonar sensor 9, display screen 10, CCD camera 11 and automatic alarm device 21.

[0028] The connection relationship of the above-mentioned components is as follows: the first articulated arm 3 is installed on the base 1, the second articulated arm 4 is installed on the first articulated arm 3, the first articulated arm 3 and the second articulated arm 4 Both are driven by an AC torque motor; the air motor 5 and the connecting sleeve 6 are installed on the second articulated arm 4, and the connecting sleeve 6 is provided with a suction head assembly 8 and a screw, and the screw rod is connected with the air motor 5 up and down respectively. , the locking claw head 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com