A Low-Temperature Solid Oxide Fuel Cell Based on ZnO-SnO Composite

A technology of solid oxides and composite materials, applied in fuel cells, battery electrodes, circuits, etc., can solve problems such as short circuits, achieve high oxygen ion conductivity, reduce electrode polarization loss, and achieve good output power effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention can be better understood from the following examples. However, those skilled in the art can easily understand that the content described in the embodiments is only for illustrating the present invention, and should not and will not limit the present invention described in the claims.

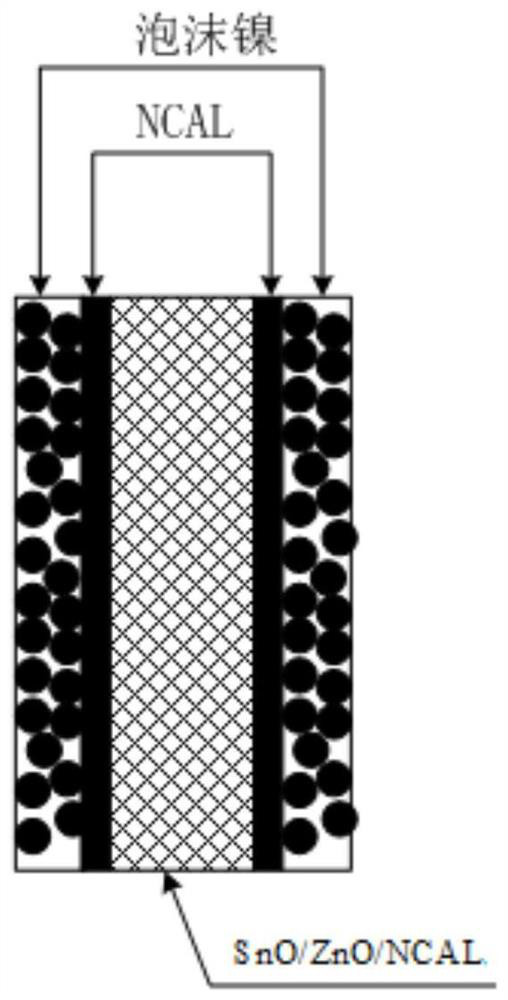

[0029] Such as figure 1 As shown, the nickel foam that the surface is coated with NCAL constitutes a symmetrical electrode, the fuel cell cathode and anode of the present invention all adopt the nickel foam that the surface is coated with NCAL, and the core electrolyte layer is a composite material of SnO / ZnO and NCAL, so the structure of the fuel cell For: nickel foam / / NCAL / / SnO / ZnO / NCAL / / NCAL / / nickel foam; where NCAL is Ni 0.8 co 0.15 Al 0.05 LiO 2-δ Materials, SnO / ZnO is a composite material prepared by wet synthesis; nickel foam is a foamed nickel material purchased commercially, and NCAL powder is nickel-cobalt-aluminum-lithium powder purchased commercially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com