Movable automatic discharging device and work method thereof

A technology of an automatic discharging device and a discharging box is applied in the field of mechanical equipment, which can solve the problems of high manufacturing and operating costs, inability to move flexibly, and complicated personnel operations, and achieve low manufacturing and operating costs, low operating costs, and personnel operations. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

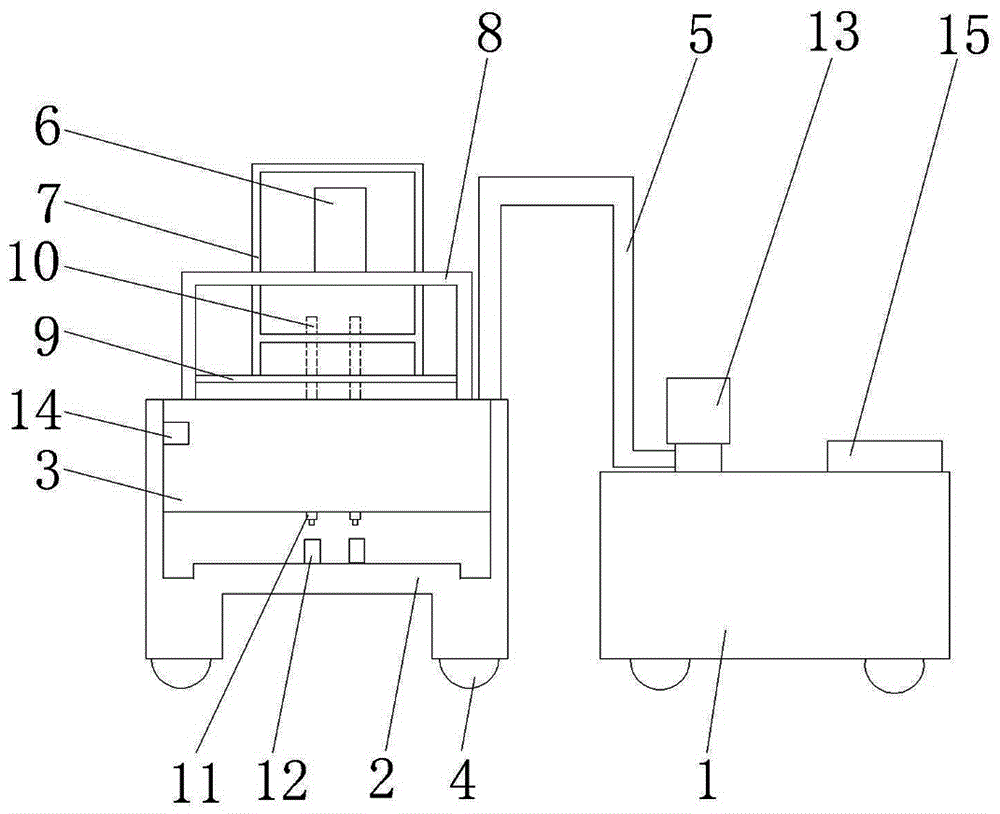

[0033] like figure 1 As shown, a movable automatic discharge device in this embodiment includes: a storage box 1, a frame 2, a discharge box 3, a pulley 4, a feeding pipe 5, a cylinder 6, a connecting frame 7, and a fixing seat 8 , fixed plate 9, pull rod 10, discharge port 11, receiving bottle 12, motor 13, infrared sensor 14 and control mechanism 15.

[0034] The connection relationship of the above-mentioned components is as follows: the motor 13 is arranged on the top of the material storage box 1, and the two ends of the feed pipe 5 are respectively connected with the discharge box 3 and the storage box 1; the inside of the discharge box 3 is provided with a A group of discharge port 11 and an infrared sensor 14, the receiving bottle 12 is located directly below the discharge port 11; the lower part of the pull rod 10 is slidably connected to the discharge port 11, and the top passes through the fixed seat 8 and is connected with the cylinder 6; The frame 2 is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com