Safety rope socket and fuse calculation method for same

A technology for fuses and rope caps, applied in the field of safety rope caps and fuse calculations, can solve the problems of inability to accurately control the fracture value, increase the difficulty of accident handling operations, and steel wires falling into wells, so as to avoid accidents of broken steel wires falling into wells, with simple structure and easy operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

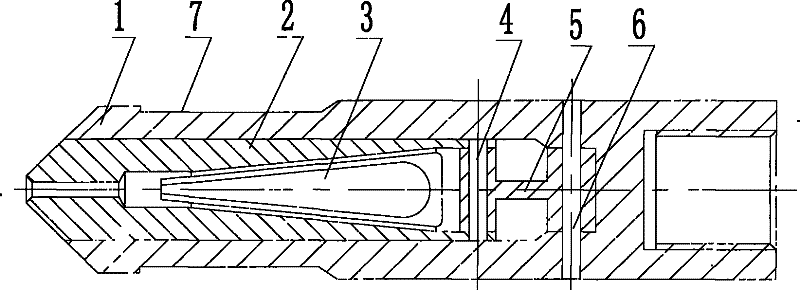

[0048] Example, 2.8mmAPI9A steel wire, breaking force T g =959kg, steel wire theoretical weight W g =46.6kg / km, downhole steel wire length L=4km, total weight of downhole tools W j =85kg, safety factor f j Take it as 5, and the insurance factor f takes a value of 0.85, calculated as follows:

[0049] The minimum breaking force of fuse 5 is:

[0050] T bmin =f j W j =5×85=425kg

[0051] Calculate the breaking force of fuse 5 as:

[0052] T b =fT g -W g ·L=0.85×959-46.6×4=628.75kg

[0053] According to the formula three T b ≥ T > T bminIn this embodiment, the fuse 5 can be selected to have a breaking force T value of 550-600 kg.

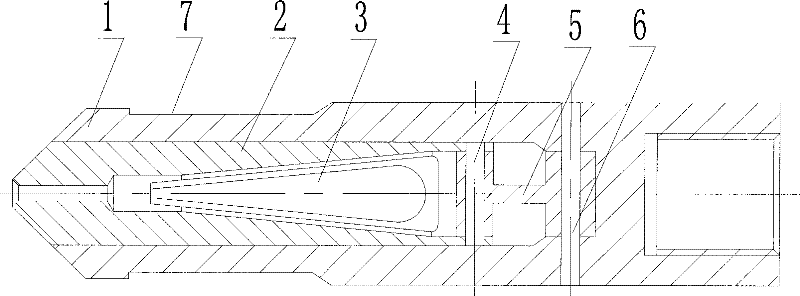

[0054] The safety rope cap of the present invention adds a fuse device to the structure of the existing taper sleeve and taper rod type quick-connect rope cap. The fuse is made of average metal materials. On the basis of the breaking force test and according to the experimental data, the minimum cross-sectional size of the fuse is design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com