A rotary drilling tool

A technology of rotary punching drilling and assembly, applied in the field of rotary punching drilling tools, can solve the problems that the service life cannot meet the requirements of on-site use, and the internal structure, materials and process technology of the drilling tools cannot be seen, so as to prevent the accident of falling well. , The effect of compact structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

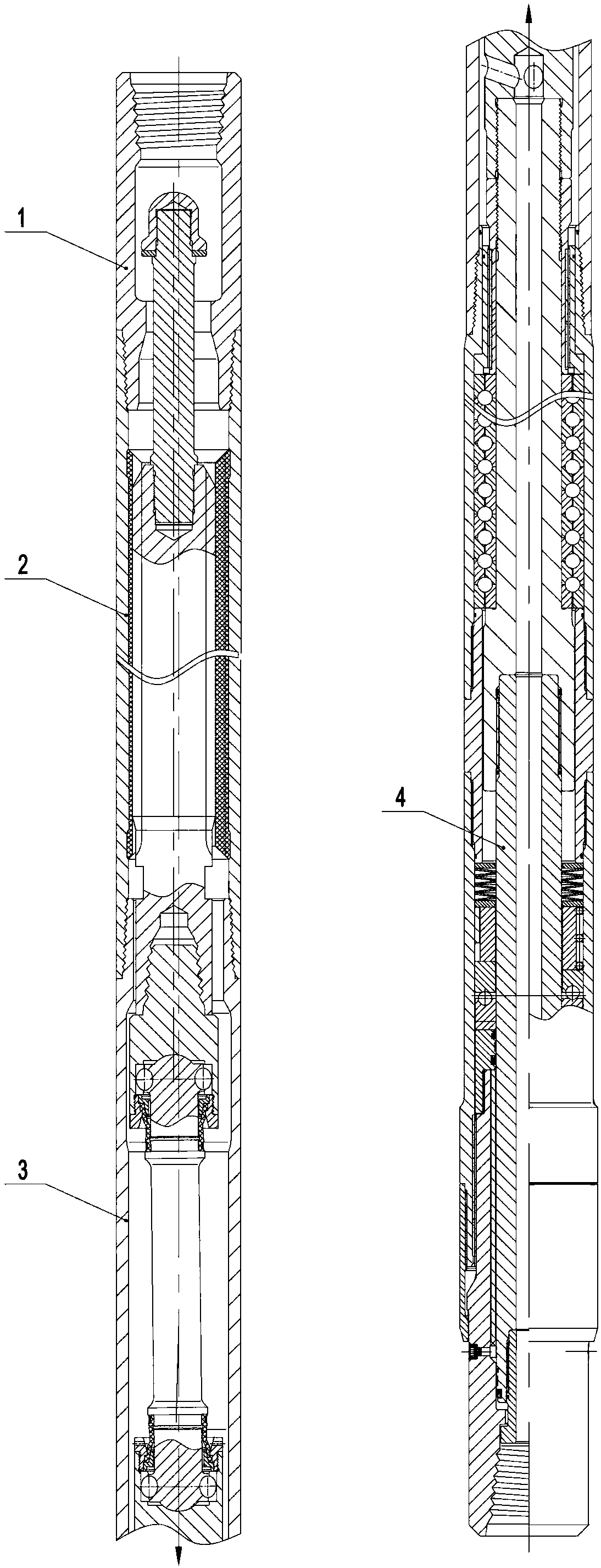

[0039] Such as figure 1 As shown, a rotary percussion drilling tool includes an anti-drop conversion assembly 1, a motor assembly 2, a cardan shaft assembly 3 and a transmission impact assembly 4;

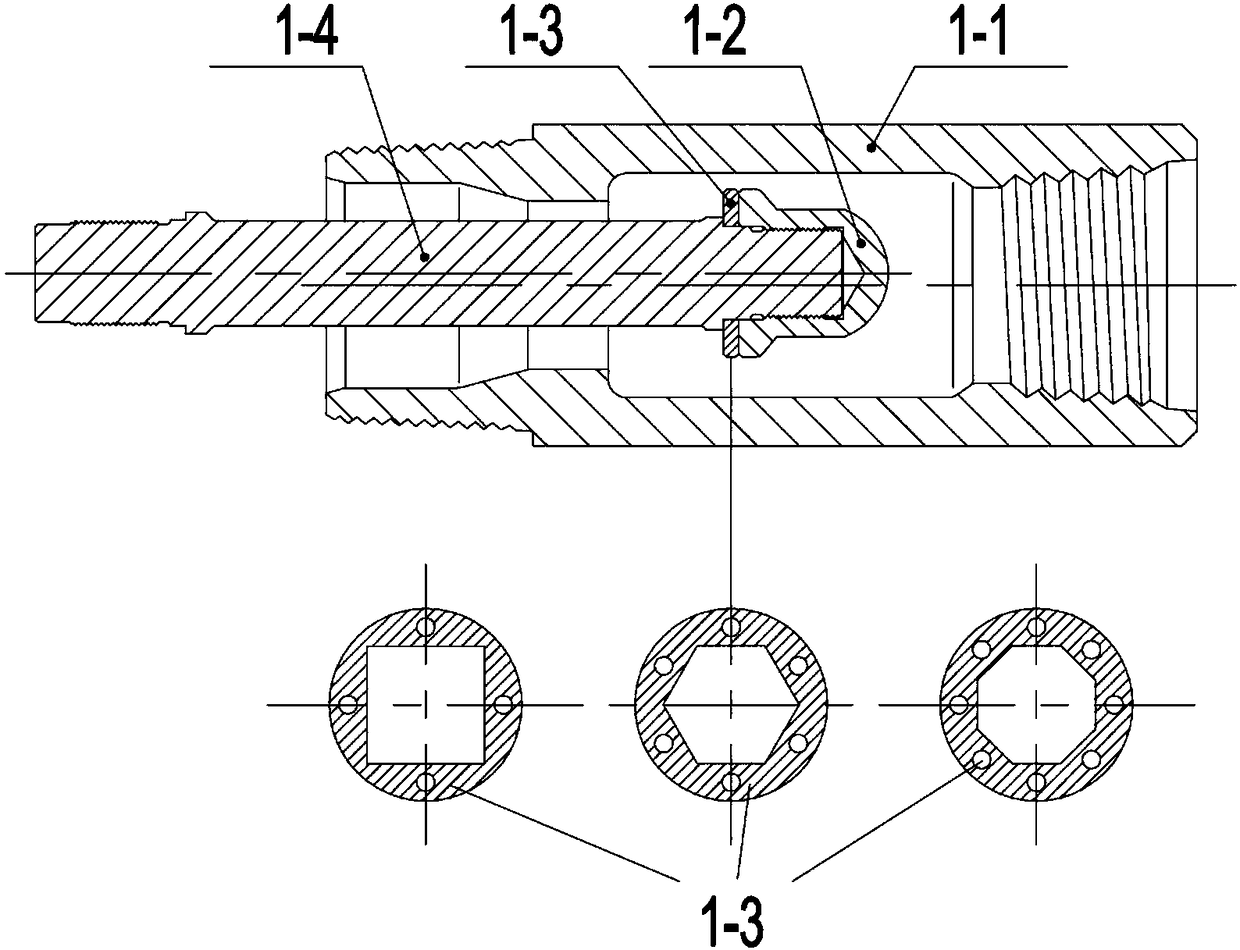

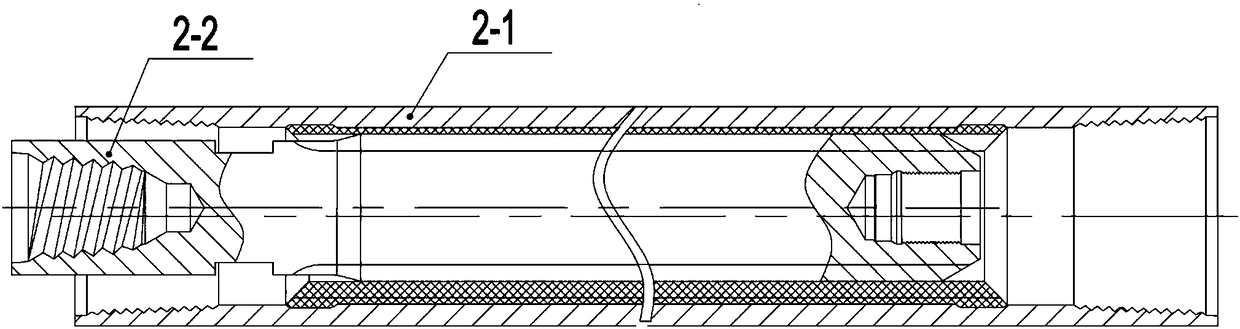

[0040] Such as figure 2 As shown, the anti-drop conversion assembly 1 includes an anti-drop conversion joint 1-1, an anti-drop disc 1-3 and an anti-drop connecting rod 1-4, and an anti-drop conversion joint 1-1 is provided with an anti-drop disc 1- 3. The upper end of the anti-drop connecting rod 1-4 is inserted into the anti-drop disc 1-3, and fixed by the backup nut 1-2, and the other end of the anti-drop connecting rod 1-4 is connected to the rotor 2-2 of the motor assembly 2 upper end;

[0041] The upper end of the anti-drop conversion joint 1-1 is connected to the drill string, and the lower end of the anti-drop connecting rod 1-4 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com